Patents

Literature

236 results about "Flaked Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

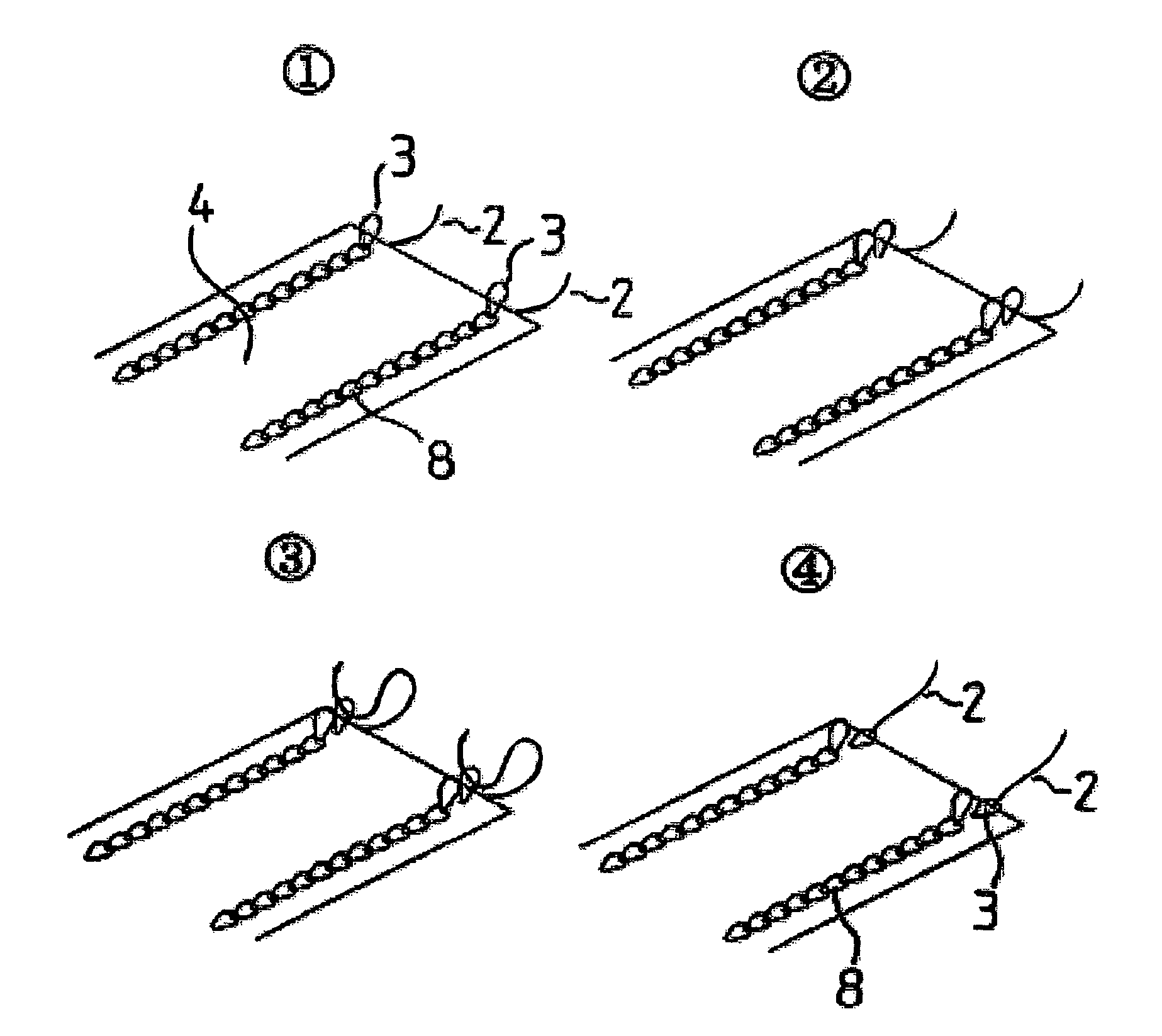

Suture reinforcement material for automatic suturing device

Owner:GUNZE LTD

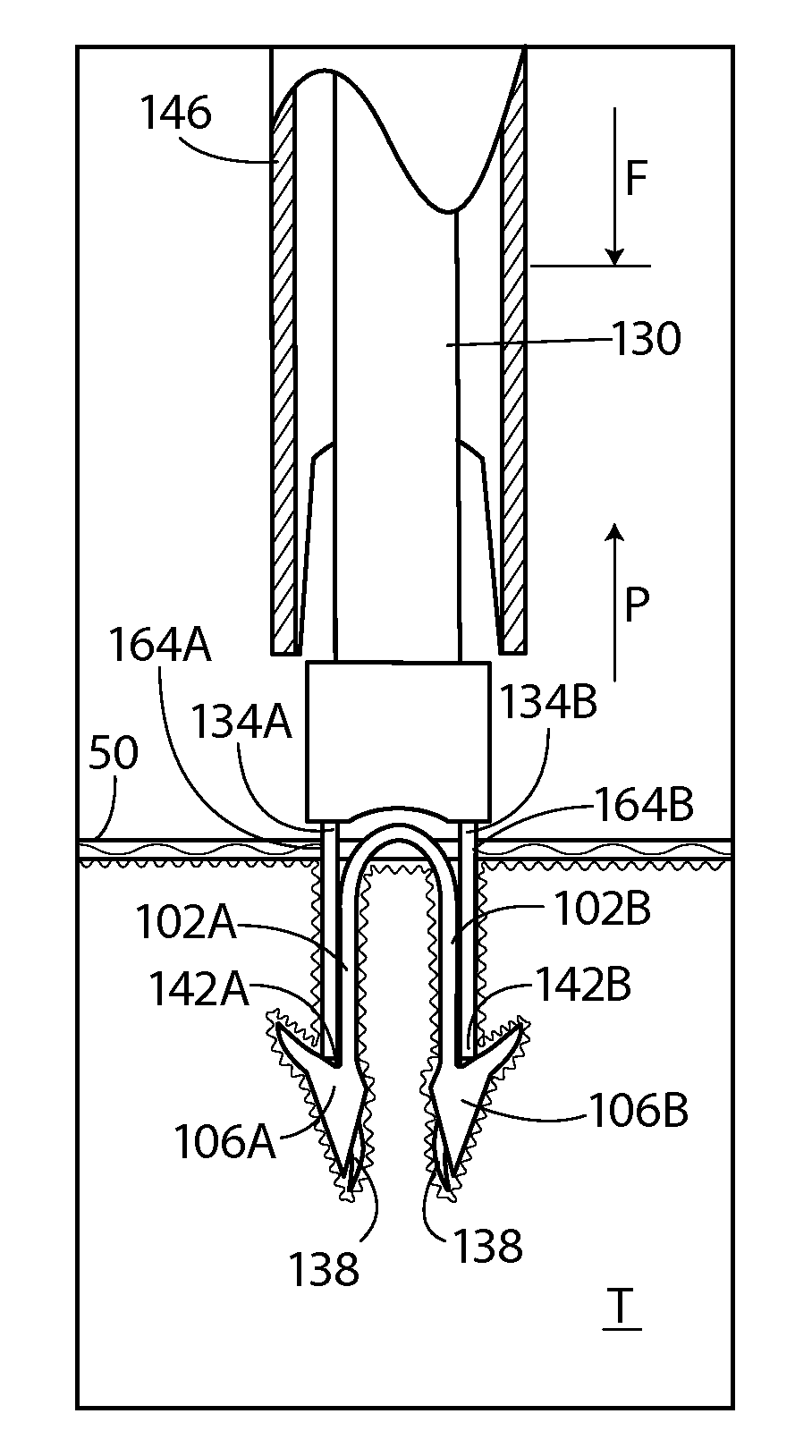

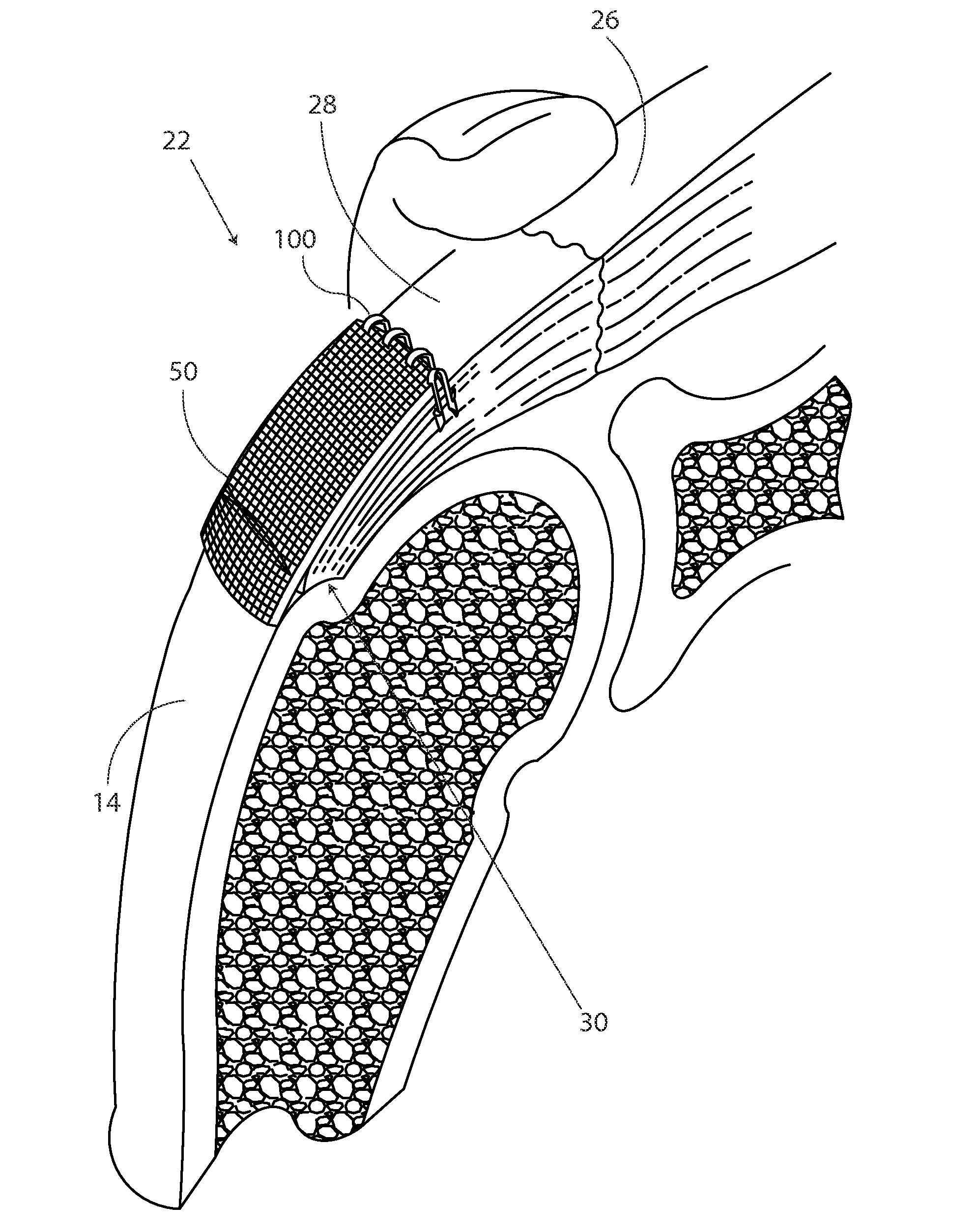

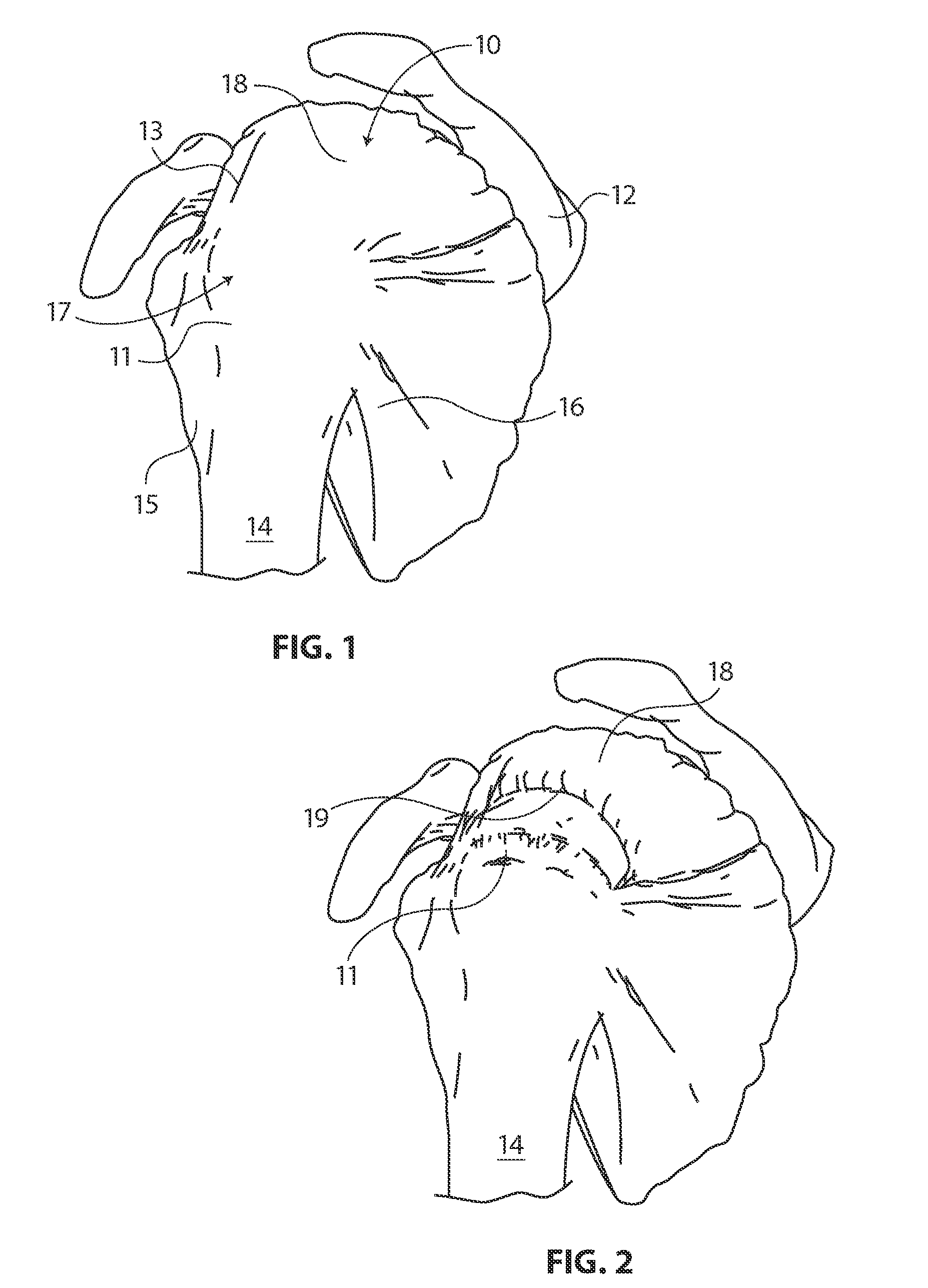

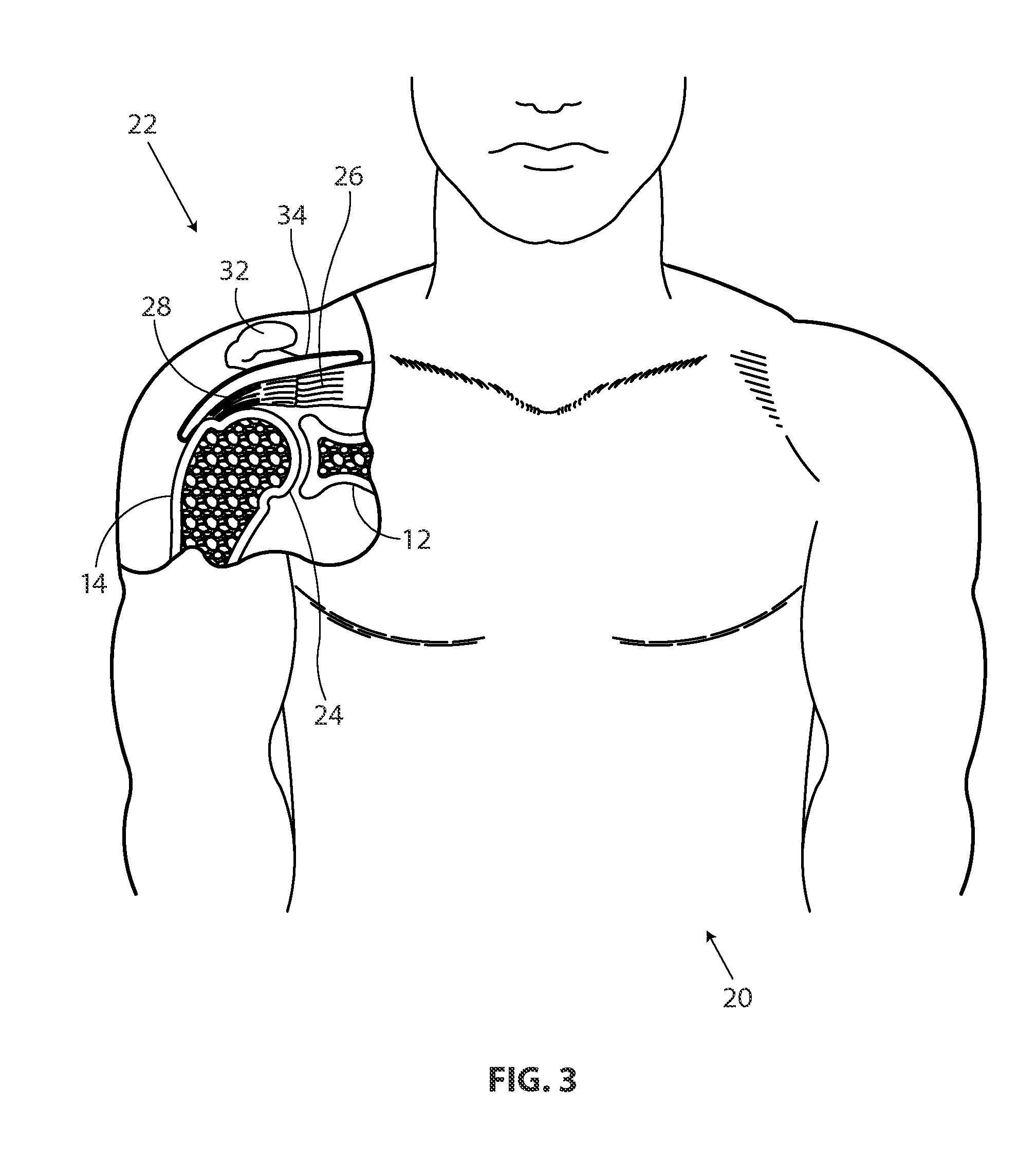

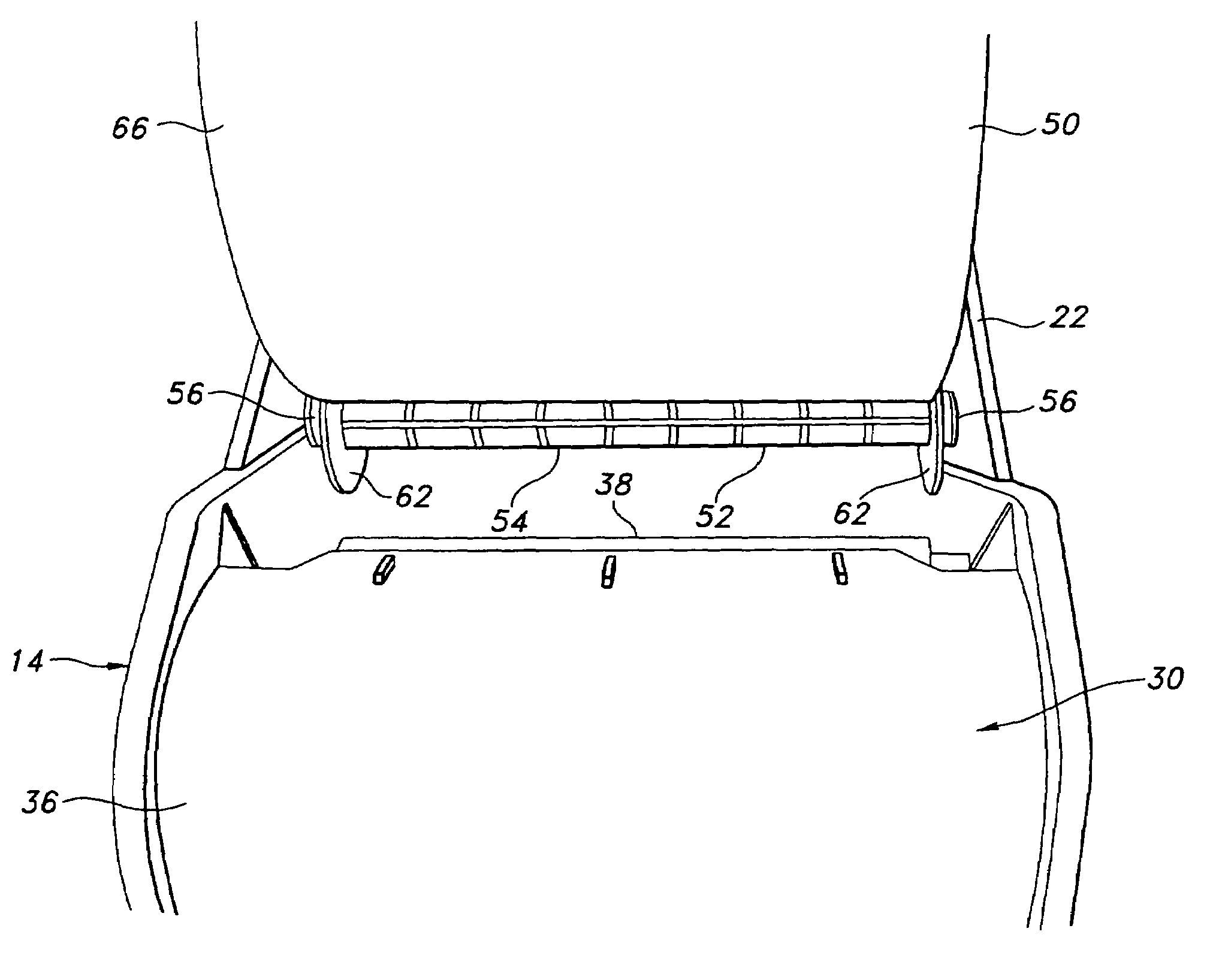

Methods and apparatus for fixing sheet-like materials to a target tissue

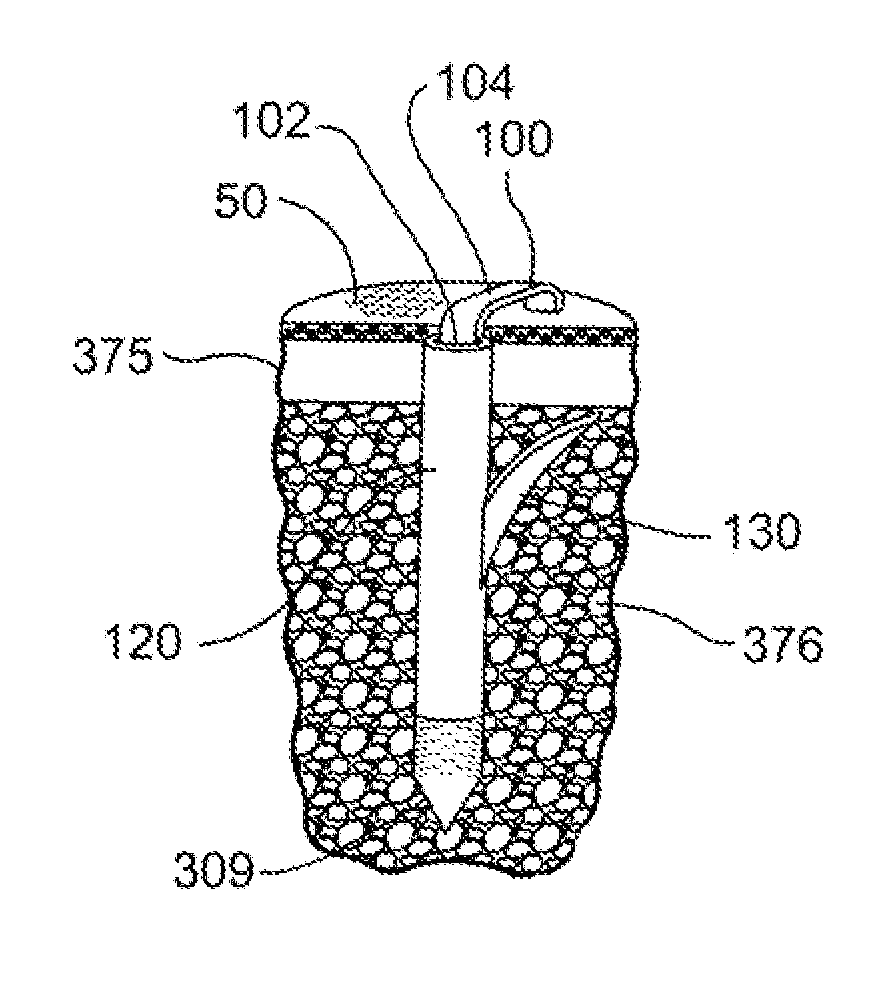

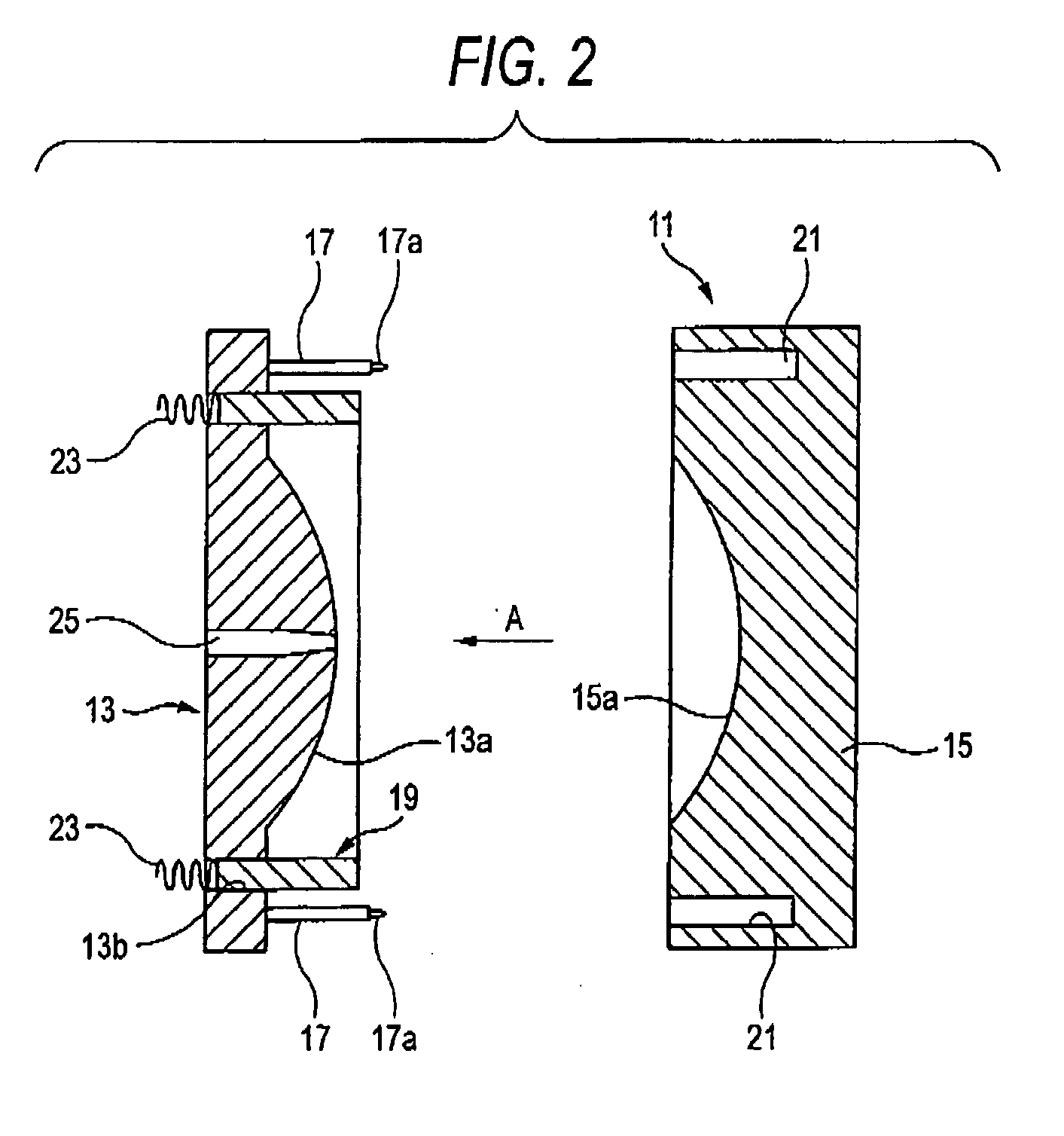

A device for attaching a sheet-like implant to a target tissue. The device includes a fastener push rod including a first portion, a second portion and a force limiting mechanism operably coupled between the first portion and the second portion. A fastener is carried by the second portion of the fastener push rod. The force limiting mechanism transmits longitudinal movement of the first portion to the second portion while the forces applied to the fastener by the fastener push rod are less than a predetermined value such that longitudinal movement of the first portion of the fastener push rod causes substantially equivalent longitudinal movement of the second portion. The force limiting mechanism allows relative longitudinal motion between the first and second portions while the forces applied to the fastener are equal to or greater than the predetermined value such that the application of undue forces to the fastener is prevented.

Owner:ROTATION MEDICAL

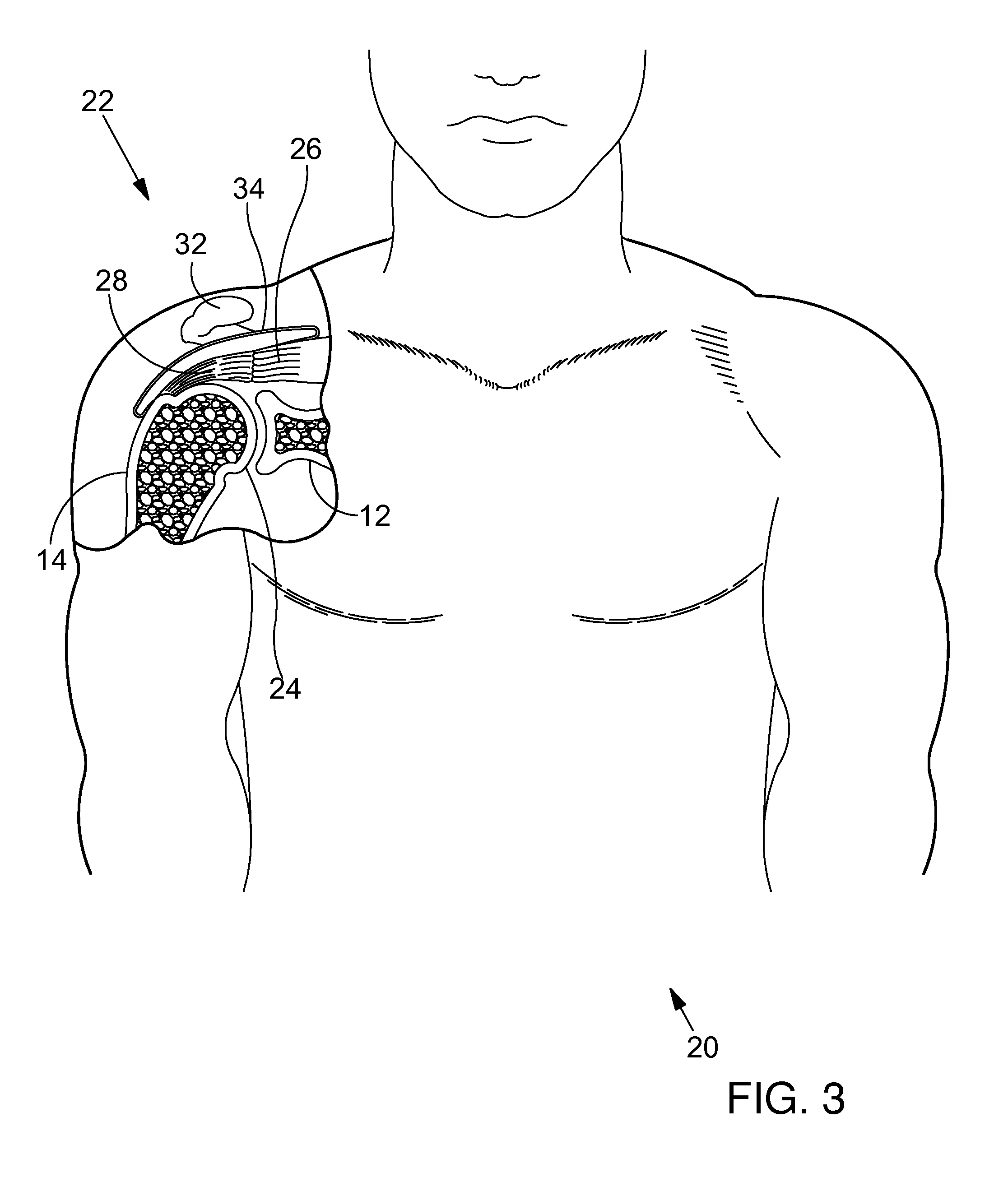

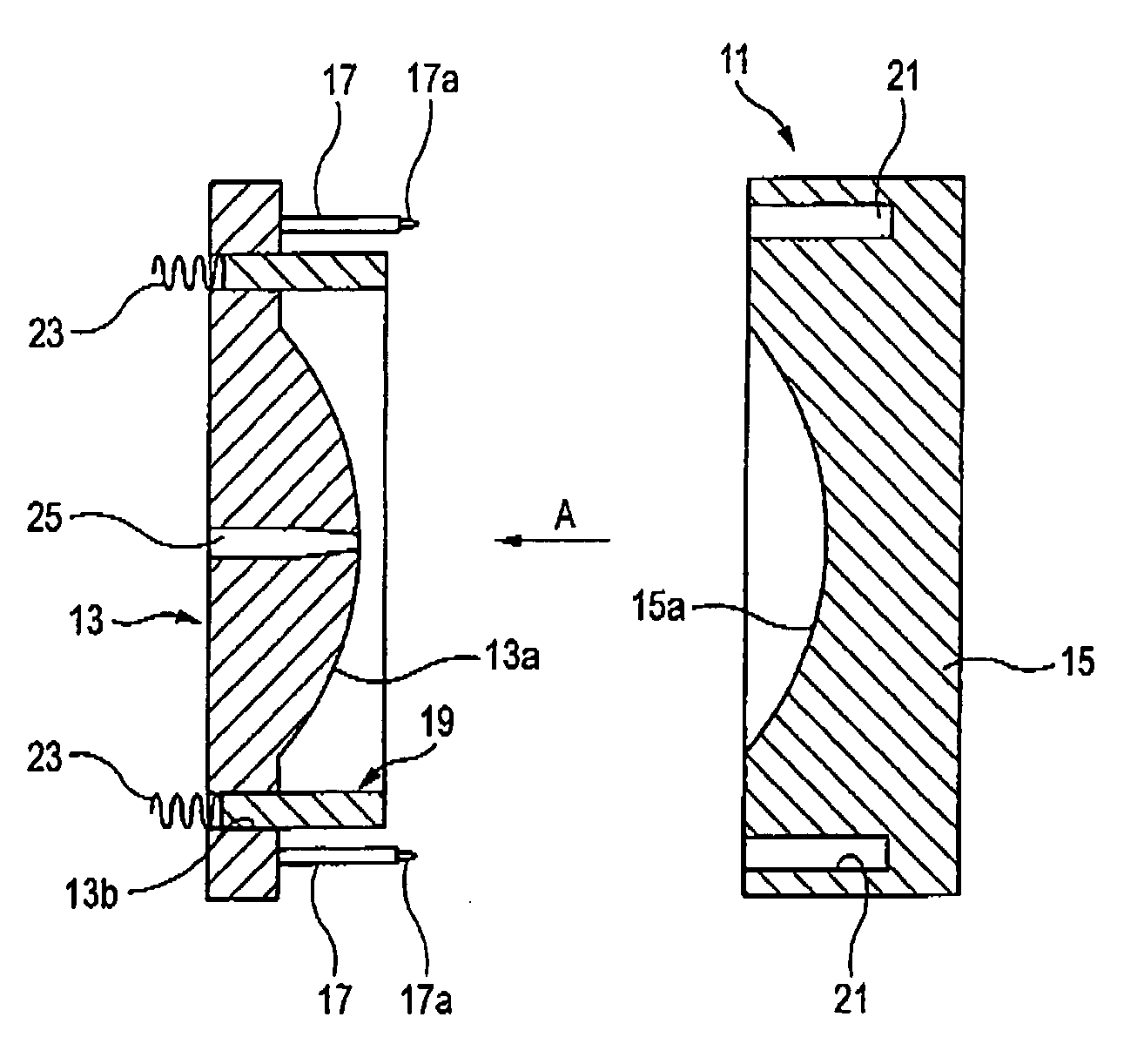

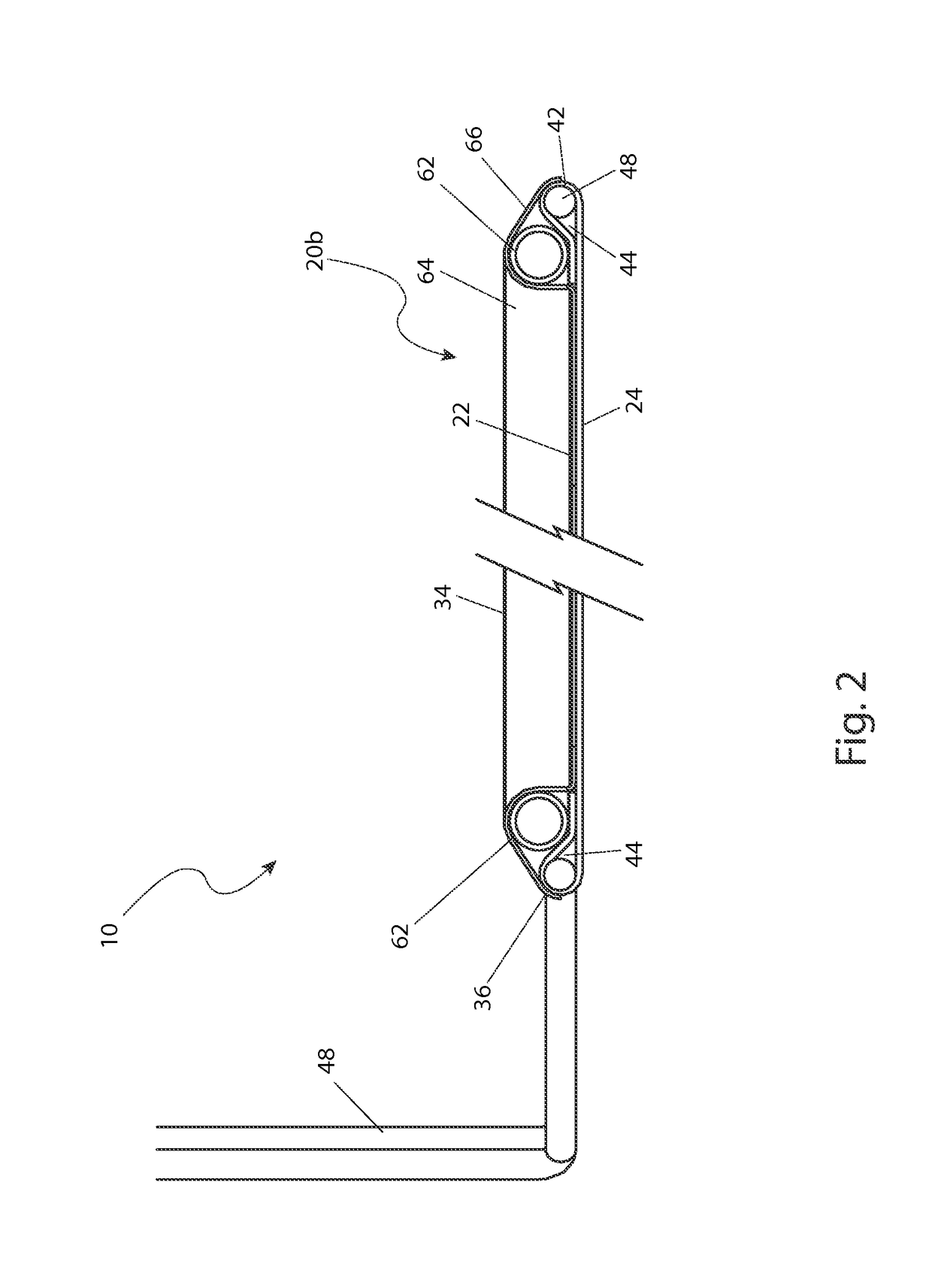

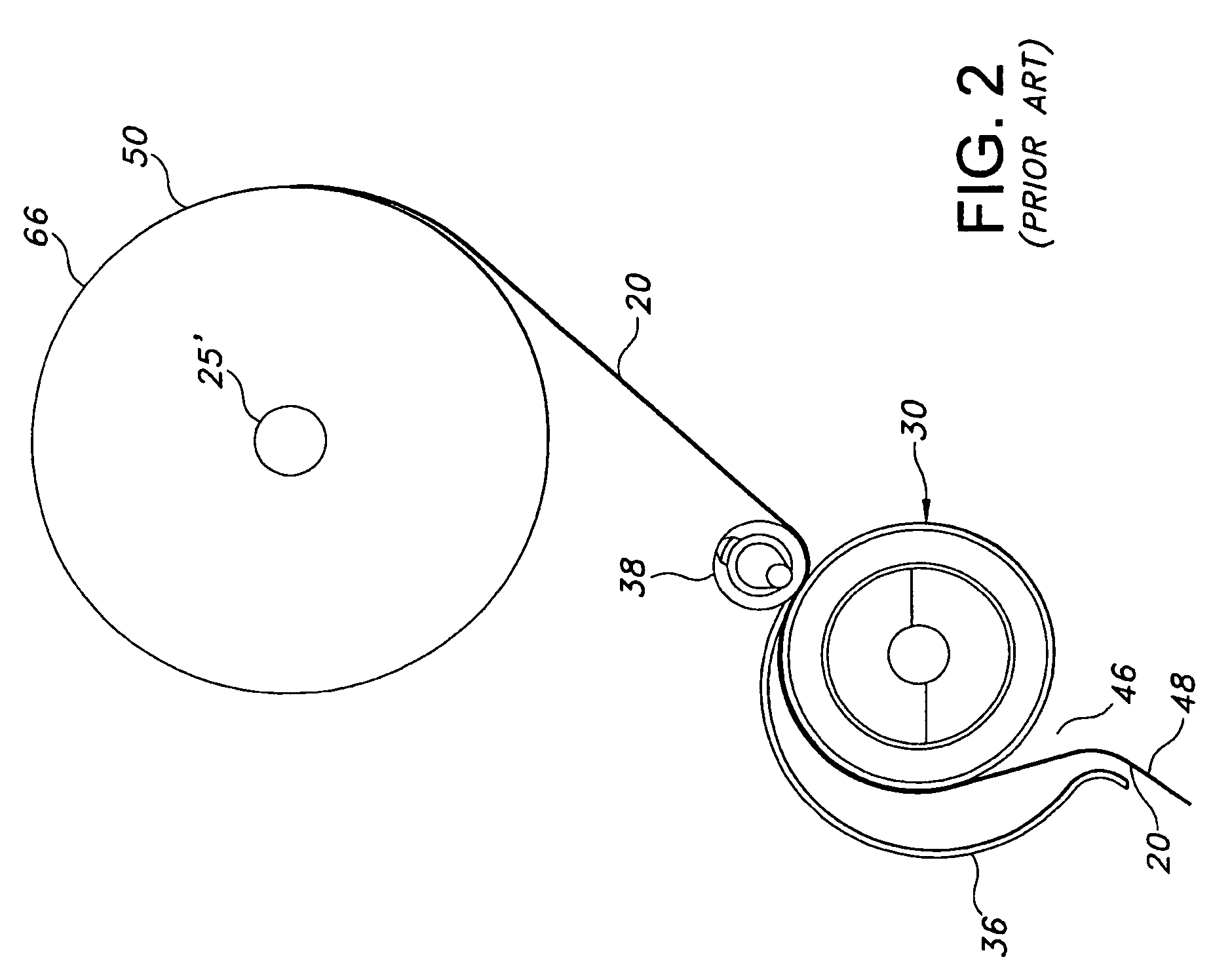

Methods and apparatus for deploying sheet-like materials

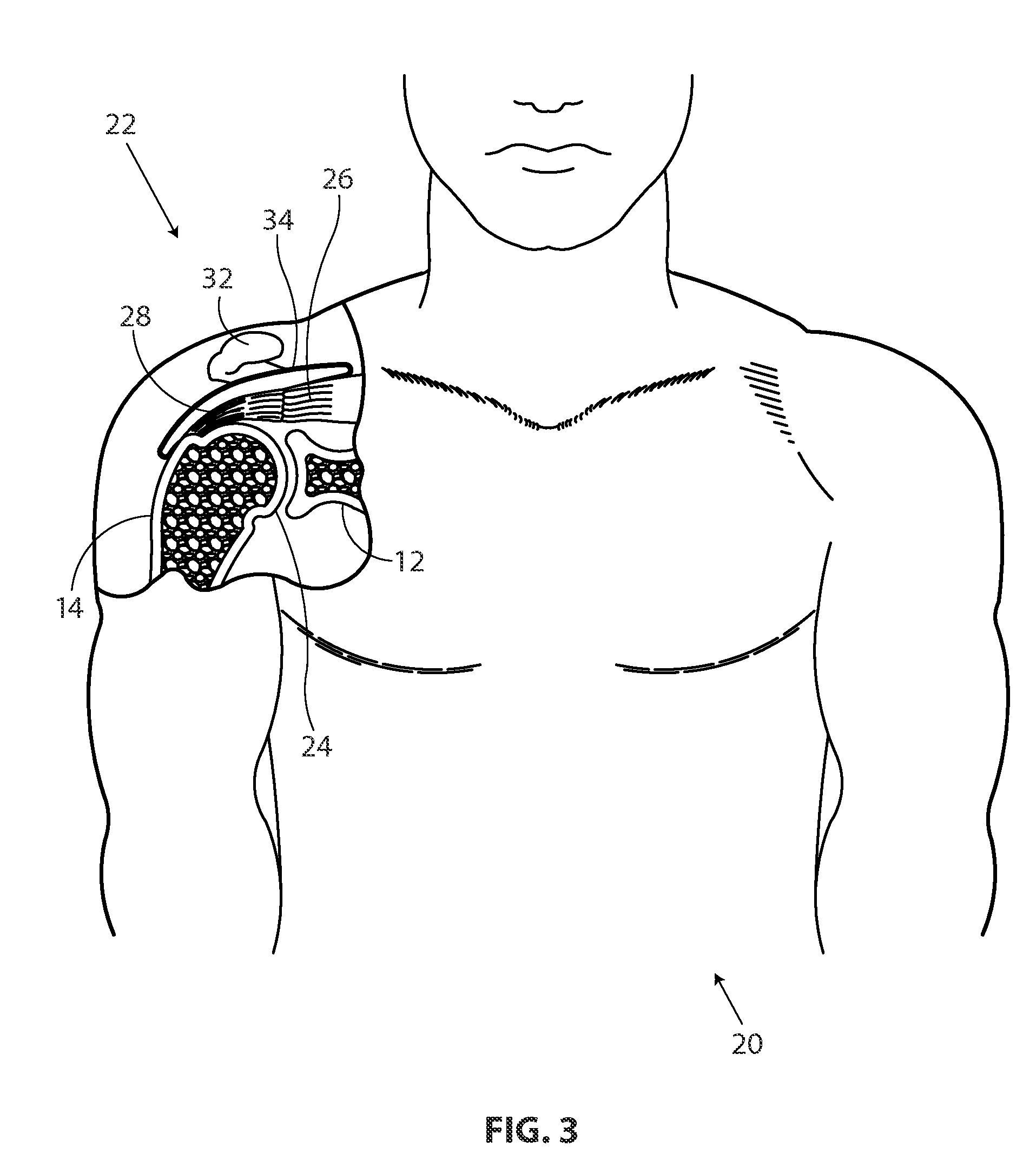

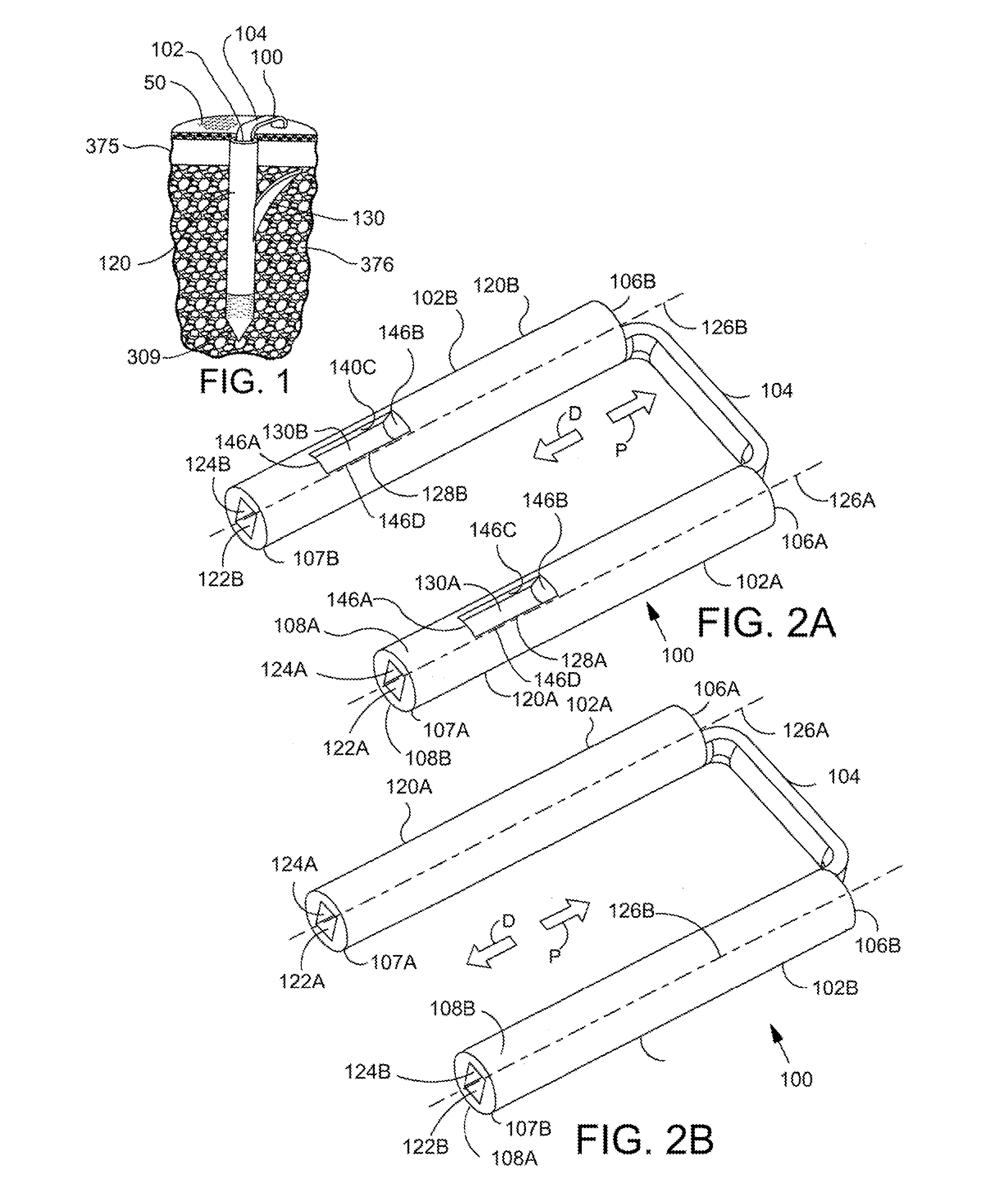

Implant delivery systems for delivering sheet-like implants include a delivery shaft, an implant expander, a sheath, and a sheet-like implant. In some embodiments, the delivery shaft has a proximal end and a distal end. The implant expander is mounted to the distal end of the delivery shaft. The implant expander includes a central portion and a plurality of leg portions radiating from the central portion. The implant expander is evertable between an unstressed configuration in which a distal surface of the implant expander defines a concave surface, and a first compact configuration in which the distal surface of the implant expander defines a convex surface. The implant expander has a first lateral extent when the implant expander is free to assume the unstressed configuration. The sheath defines a lumen having a lumen diameter. At least a portion of the delivery shaft is slidably disposed in the lumen. The lumen diameter is smaller than the first lateral extent of the implant expander so that the sheath holds the implant expander in the first compact configuration when slidably disposed therein. The sheet-like implant overlays at least a portion of the distal surface of the implant expander with portions of the sheet-like implant extending between the leg portions of the implant expander and the sheath. Methods of treating a rotator cuff of a shoulder are also disclosed.

Owner:ROTATION MEDICAL

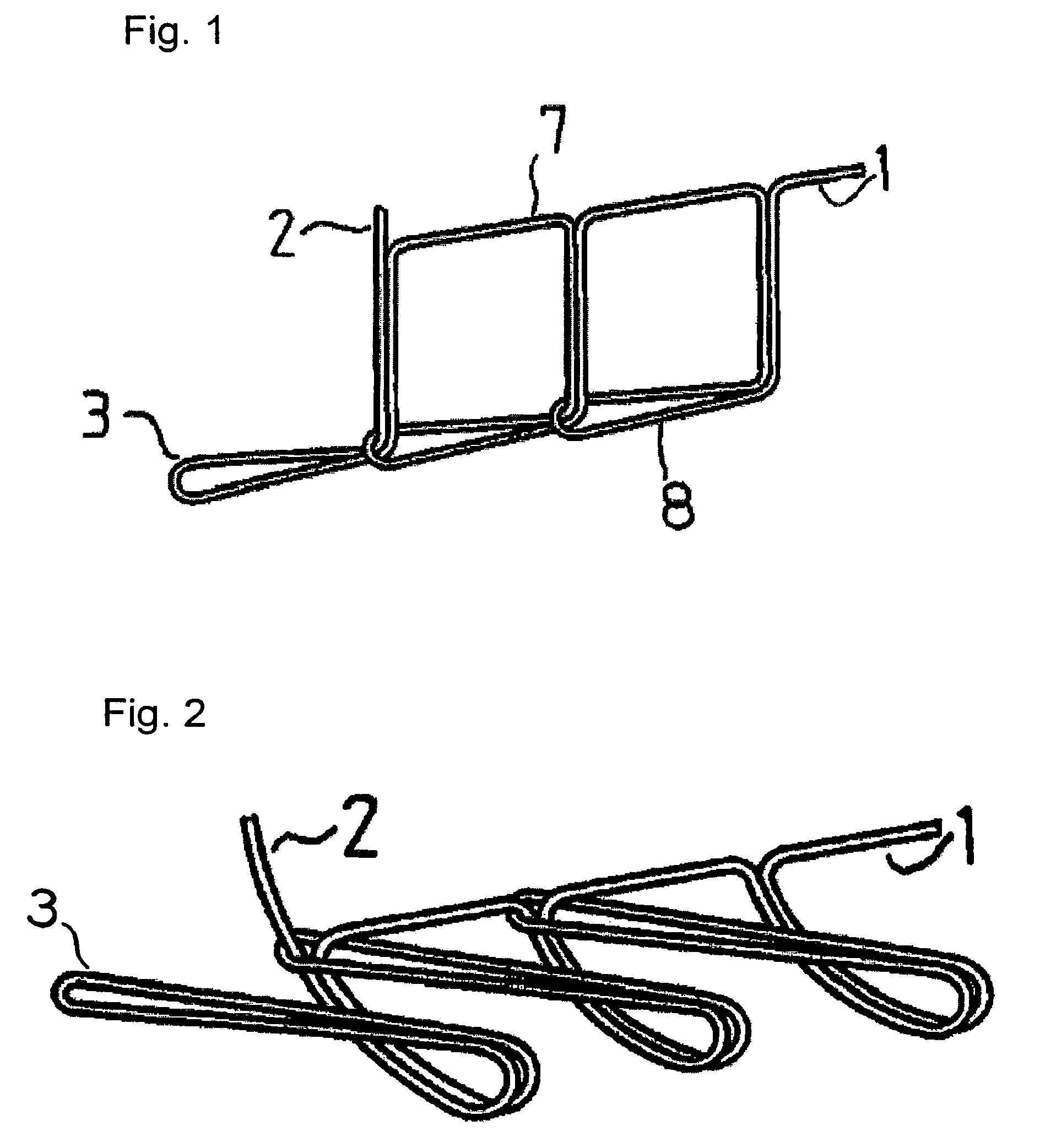

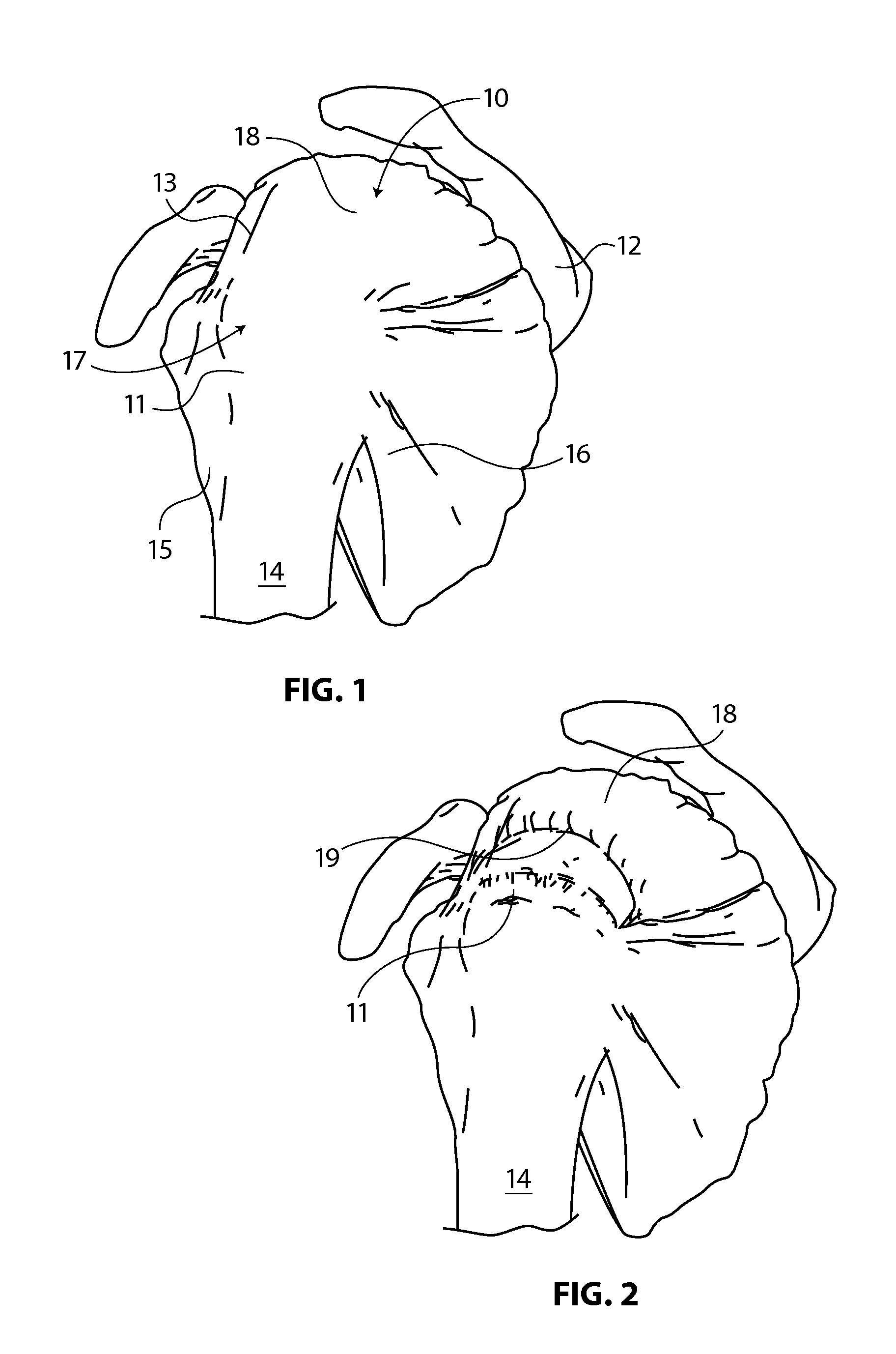

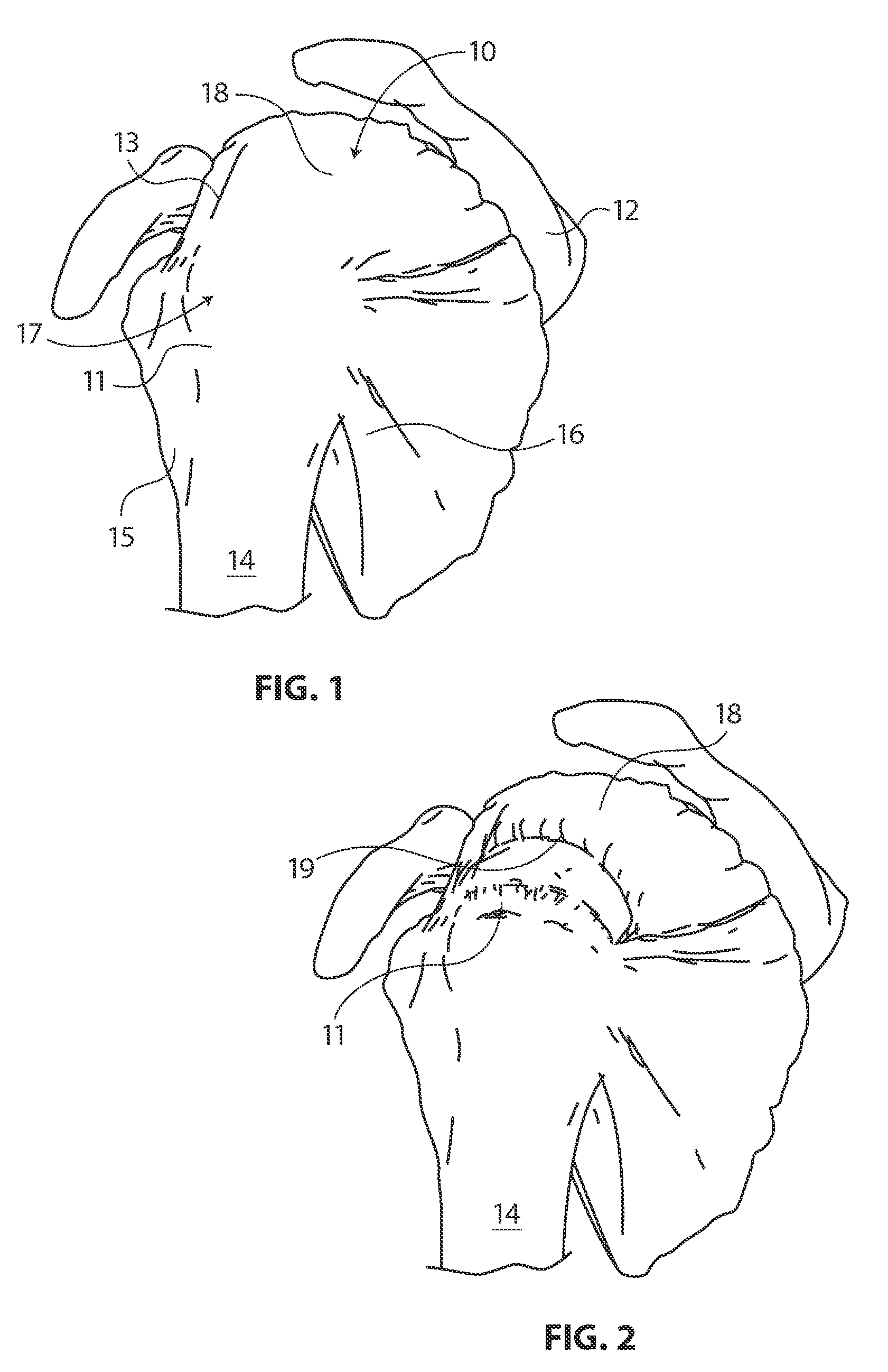

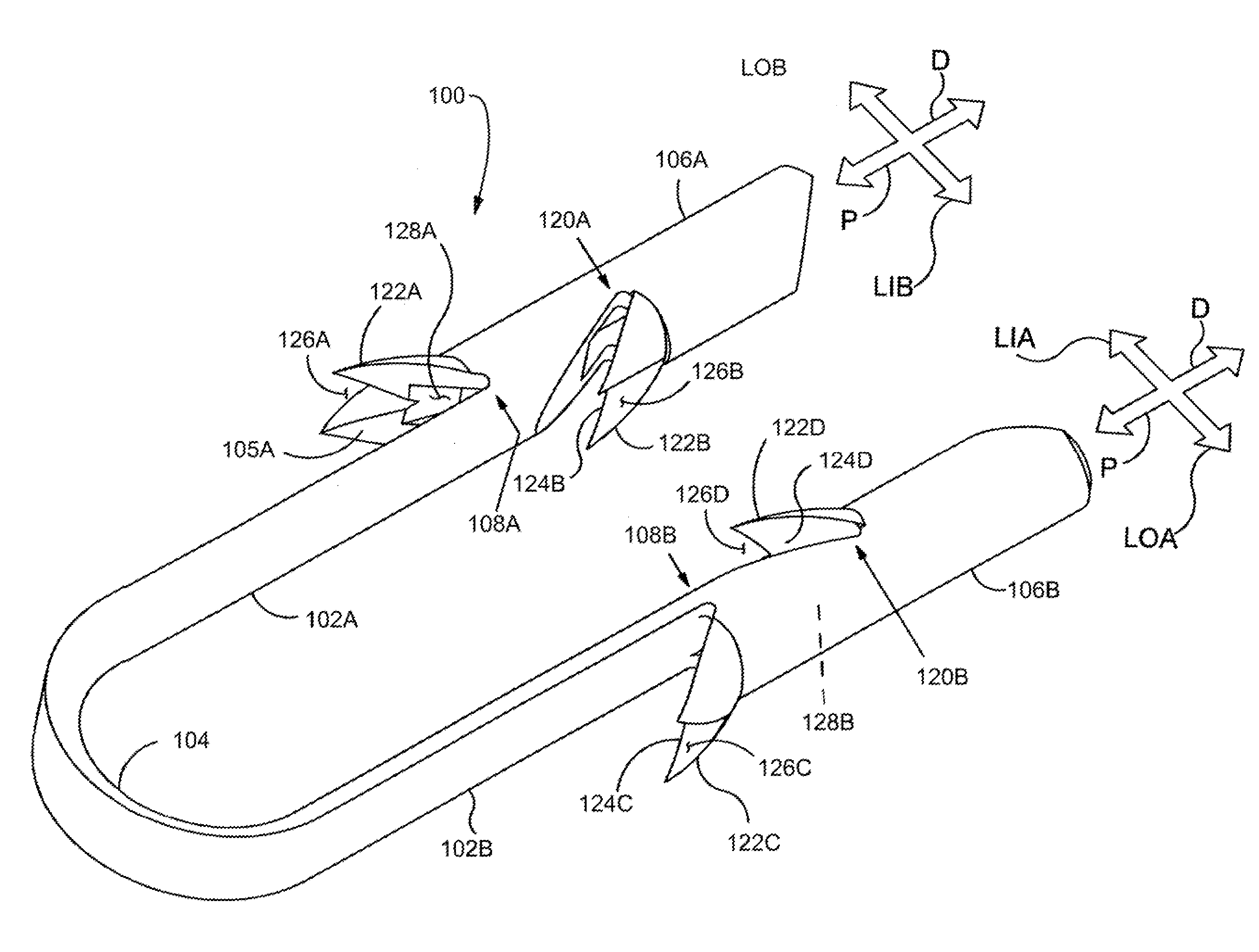

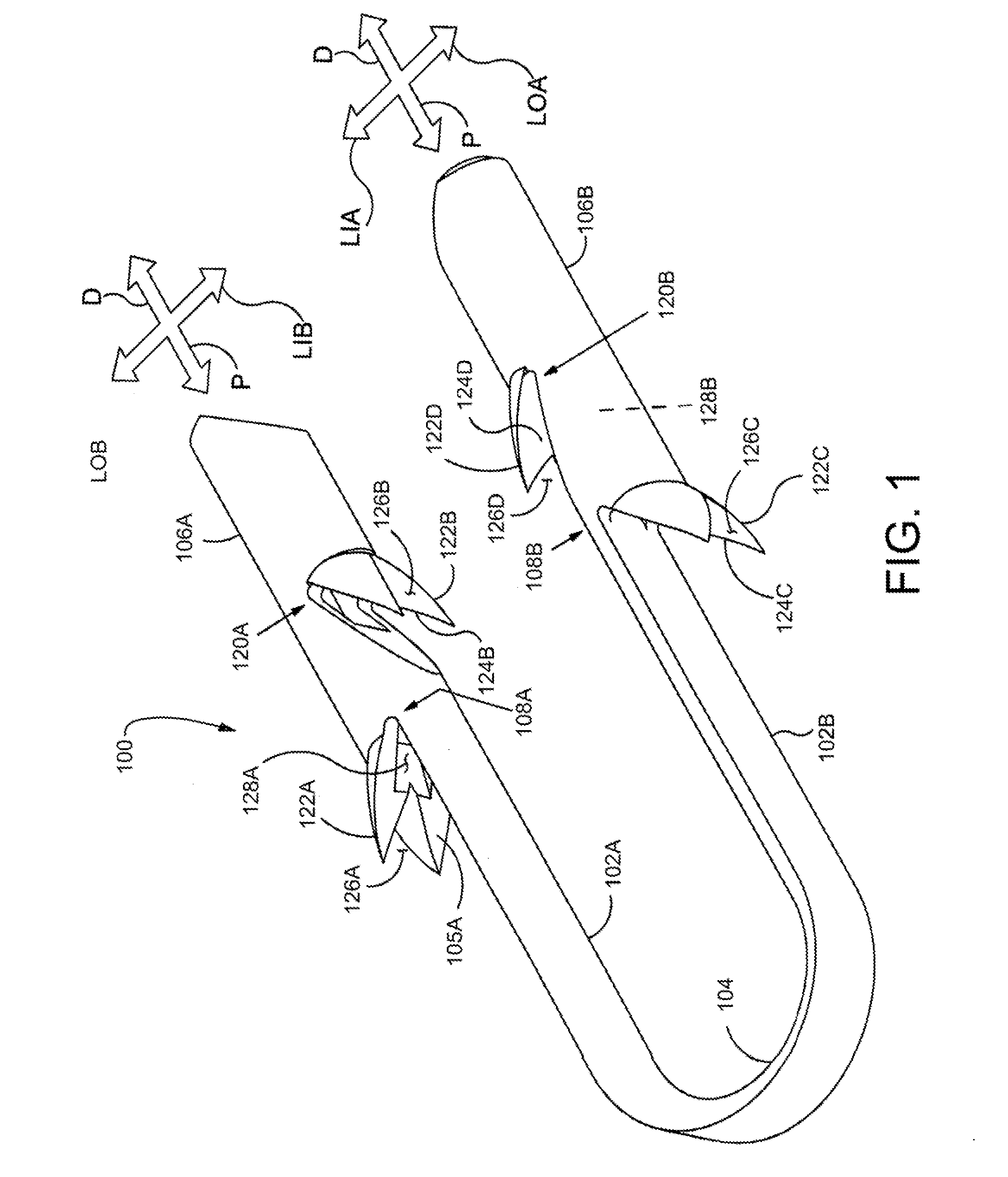

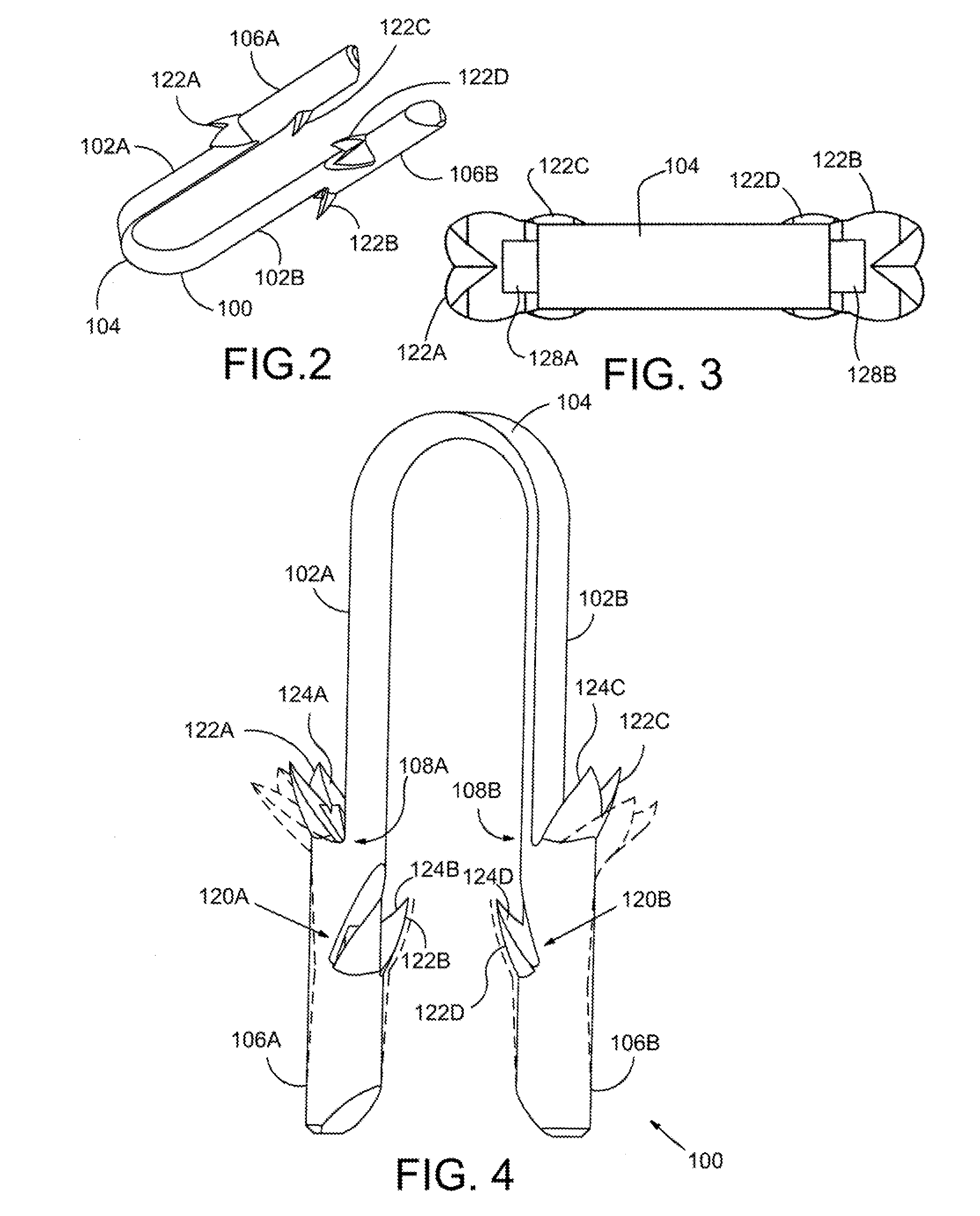

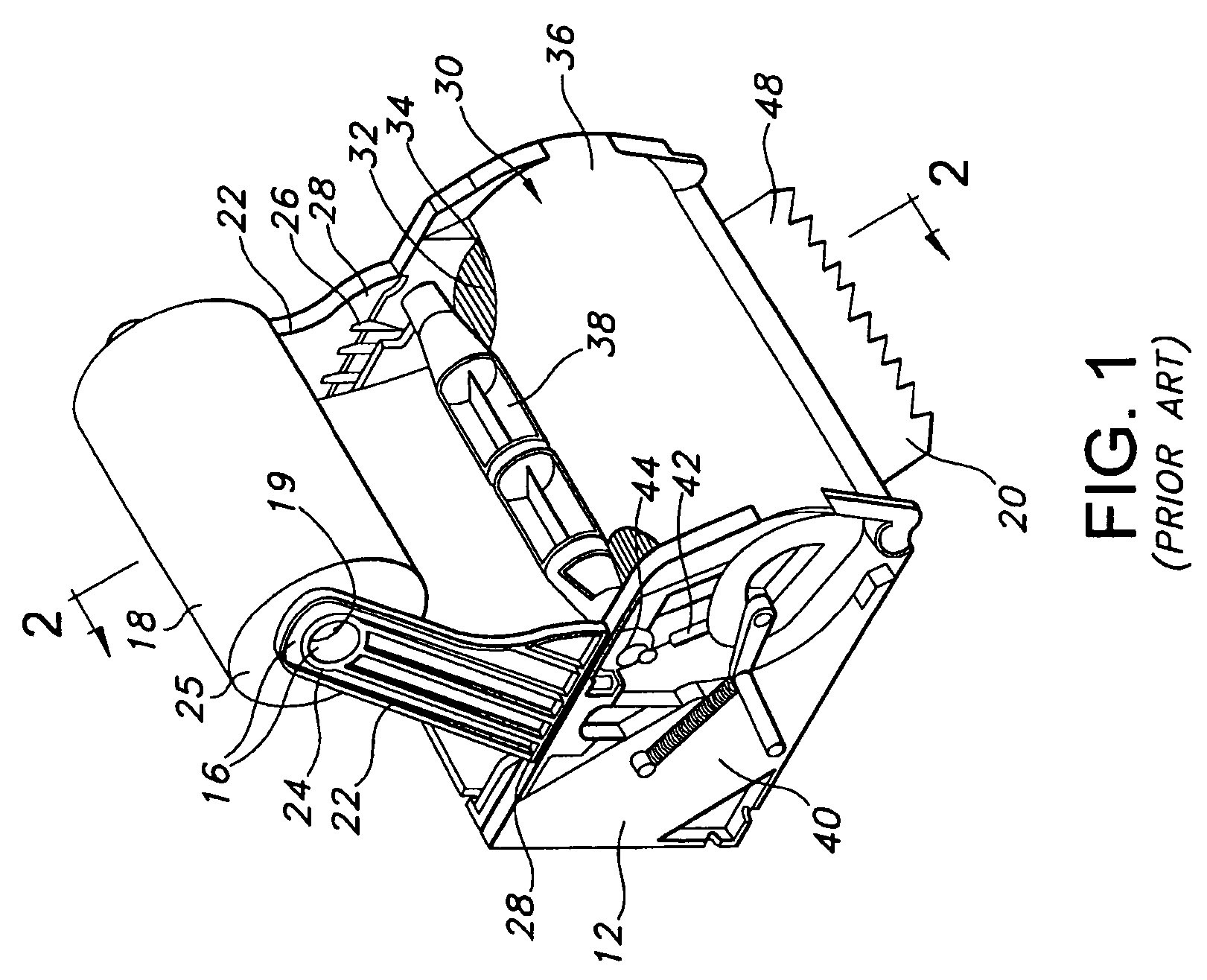

Fasteners and fastener delivery devices for affixing sheet-like materials to bone or tissue

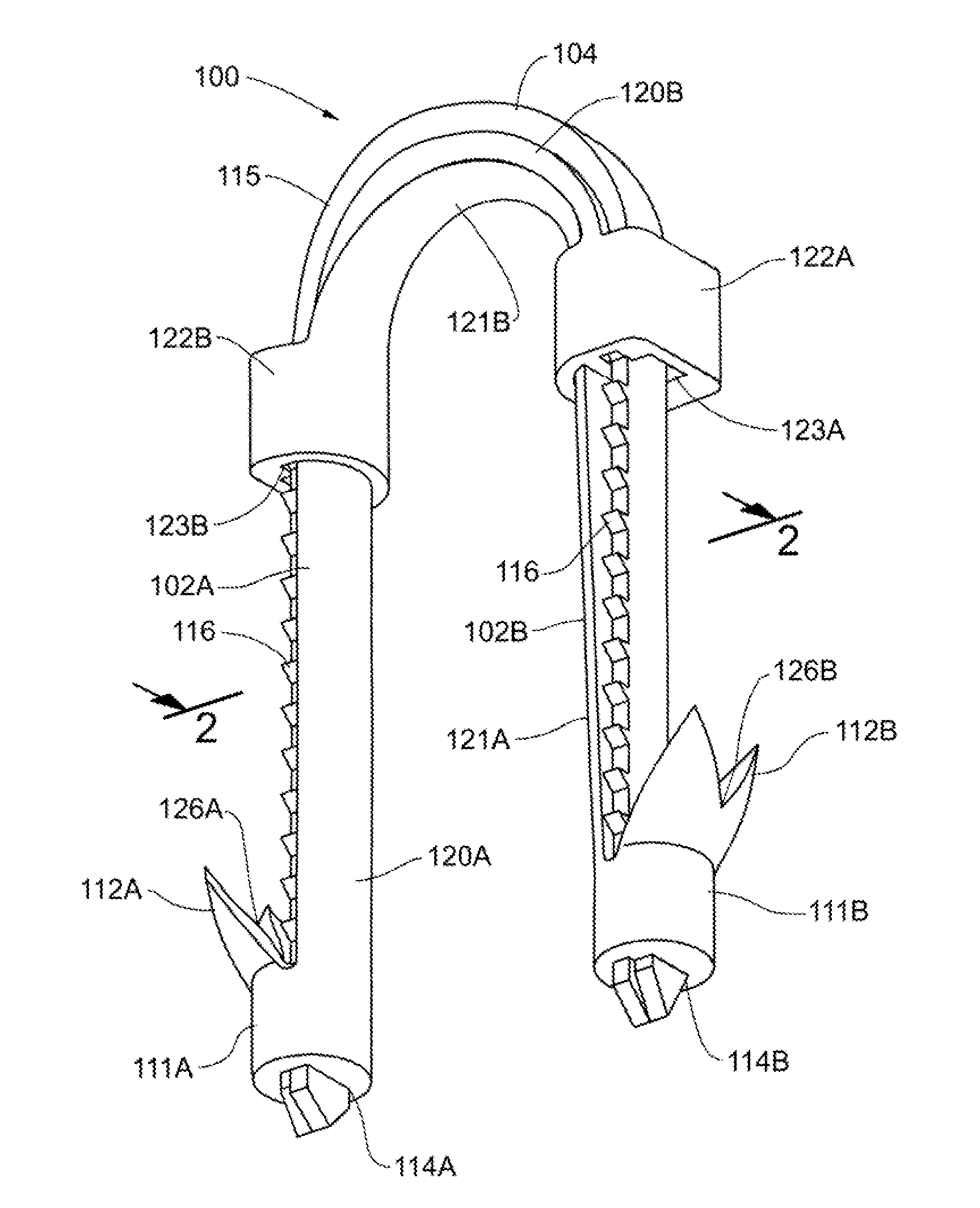

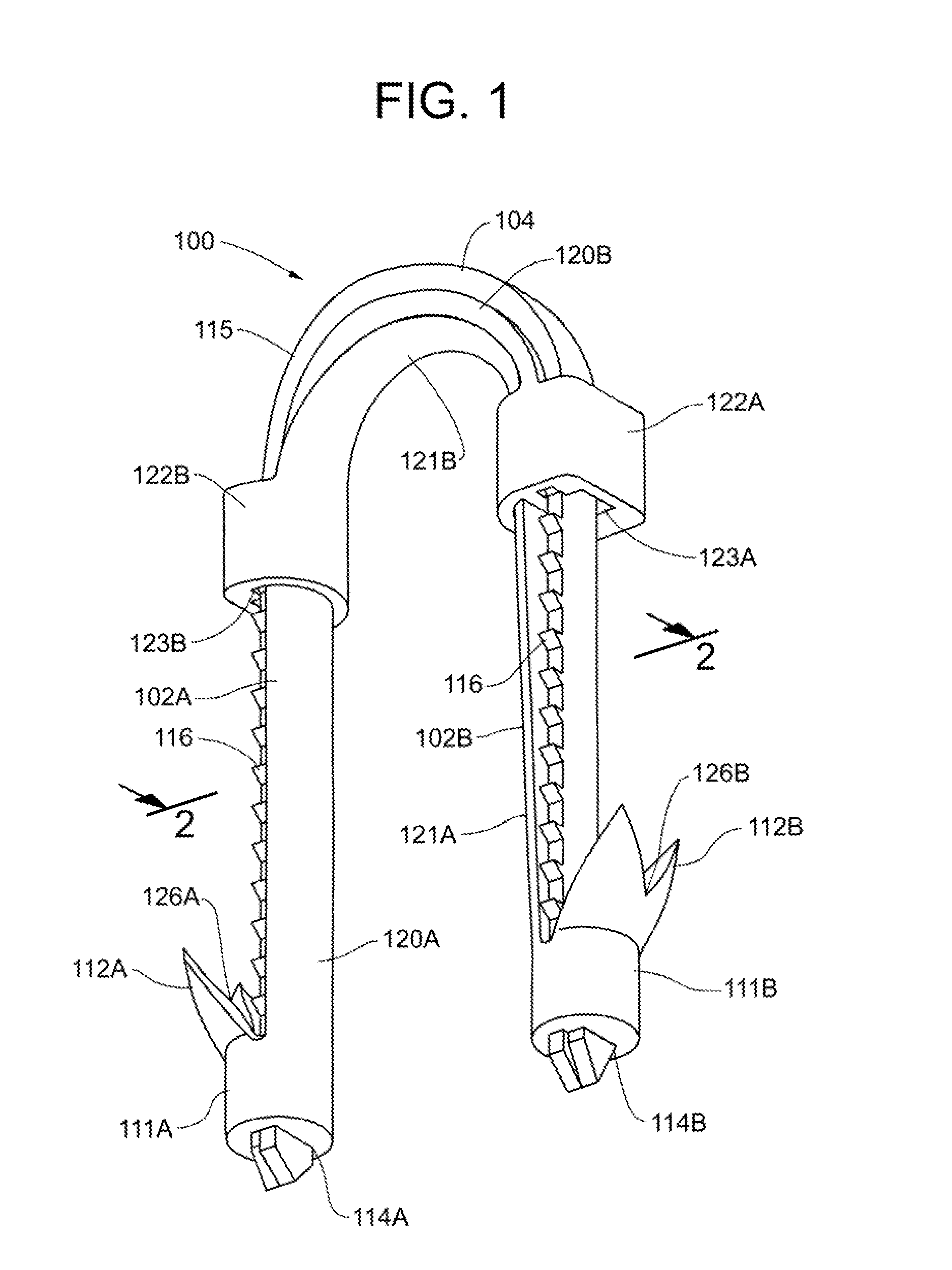

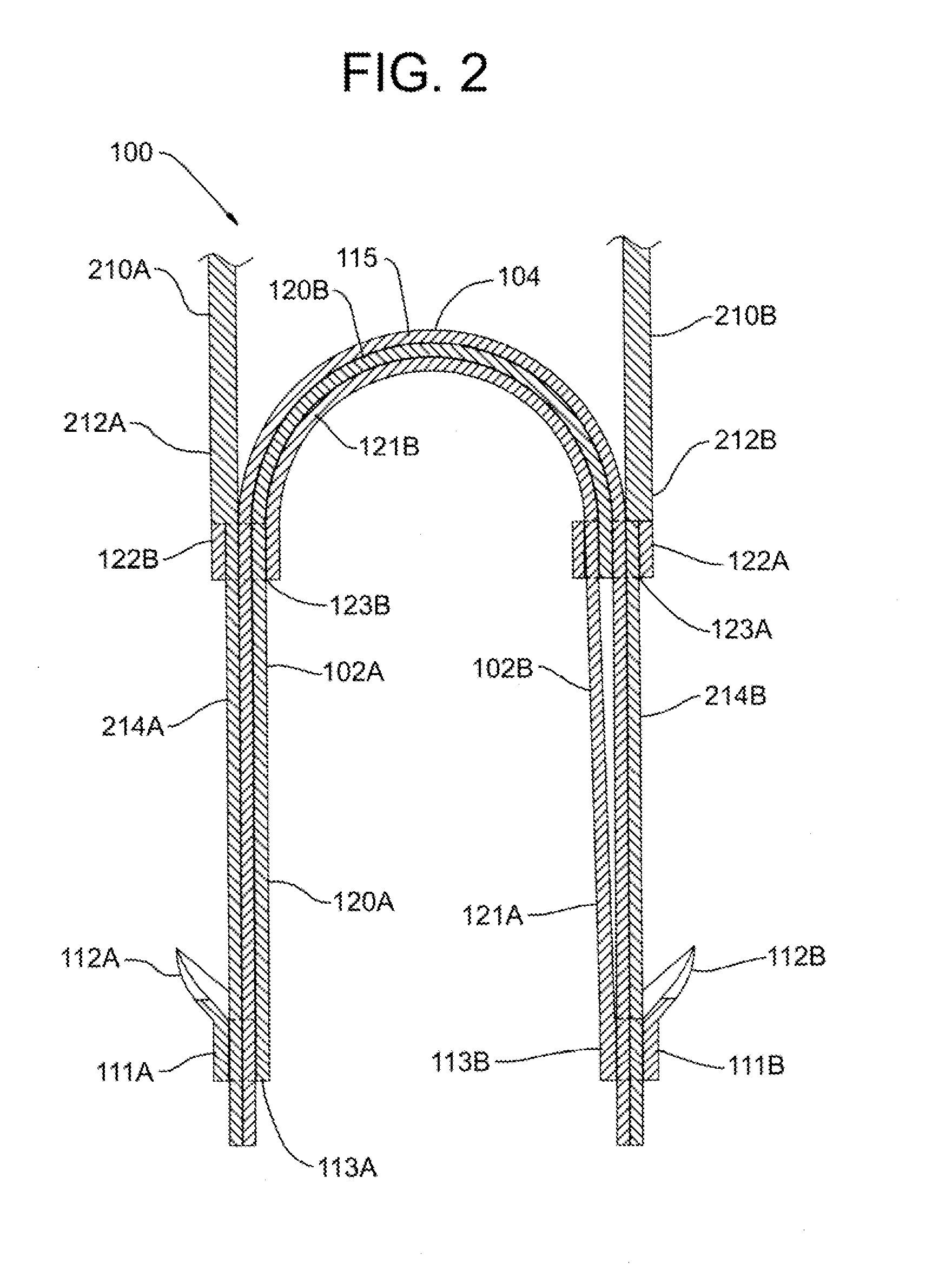

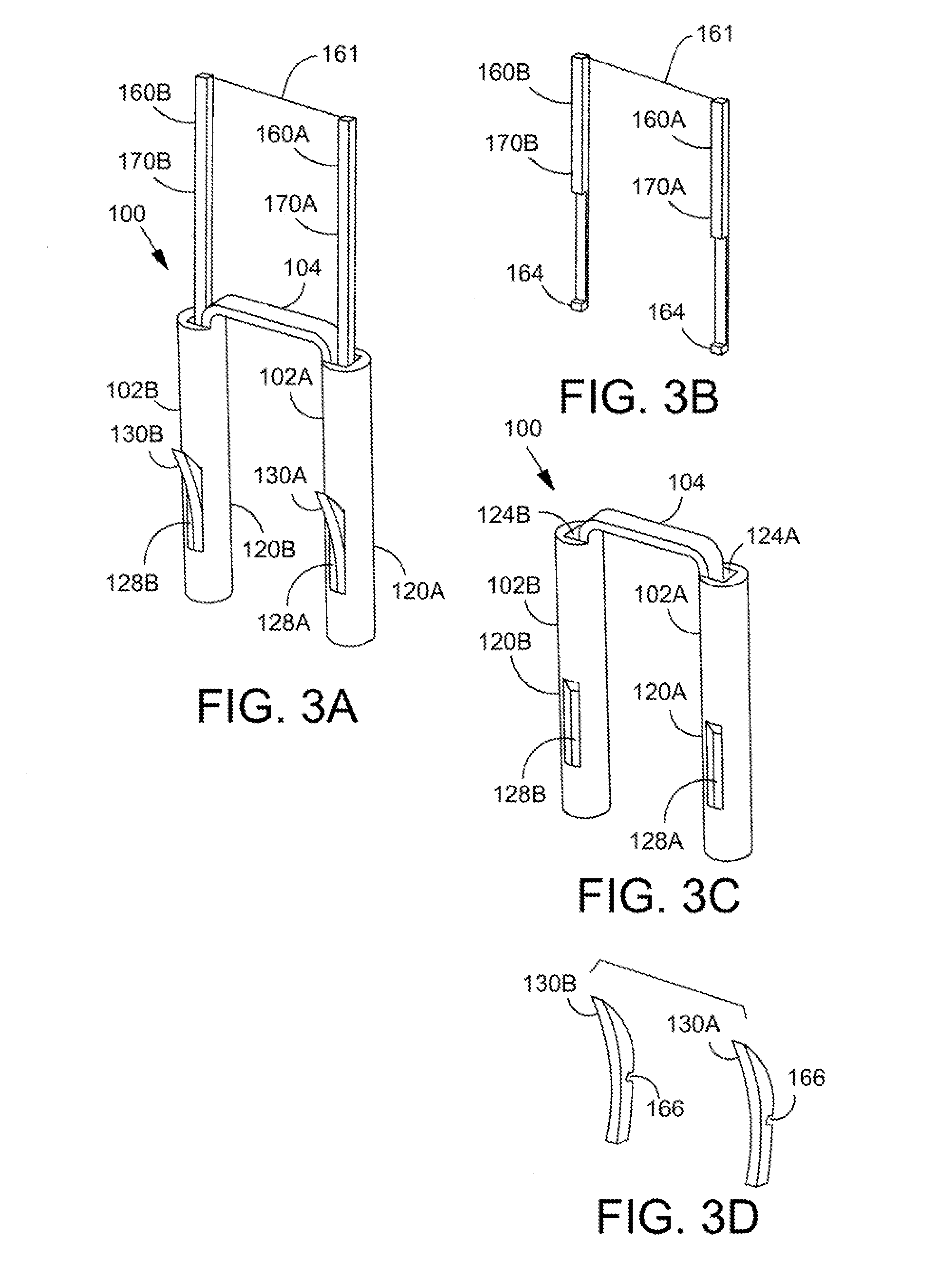

A fastener for attaching a sheet-like implant to tissue or bone may be provided with a first arm having a proximal portion and a distal portion, a second arm having a proximal portion and a distal portion, and a bridge formed at least in part by the proximal portion of the first arm overlapping the proximal portion of the second arm. Each of the first and second arms can include at least a partial loop member having a lumen therethrough slidably receiving the other arm, each arm further including a tissue retention member on a distal portion having a projection extending therefrom for engagement of bone or tissue when inserted therein. The staple can also include a one-way position retention assembly for allowing distal movement of each at least partial loop member relative to the other arm therethrough to tension the fastener and maintain a desired configuration.

Owner:ROTATION MEDICAL

Fasteners and fastener delivery devices for affixing sheet-like materials to bone or tissue

ActiveUS20130153627A1Increased pull-out strengthSuture equipmentsStapling toolsProximateLateral stiffness

A fastener for attaching a sheet-like implant to tissue or bone may be provided with a first arm having a proximal end and a distal end, a second arm having a proximal end and a distal end, and a bridge extending therebetween. Each of the first and second arms include a trunk portion defining at least a portion thereof, the trunk portion having a lateral extent larger than a lateral extent of the bridge or non-trunk portion of the arm adjacent thereto and can be mounted eccentrically to the bridge or non-trunk portion of the arm adjacent thereto such that the staple includes a first change in lateral stiffness disposed proximate the bridge or non-trunk portion of the arm abutment with the trunk. Fastener delivery devices and methods are also disclosed.

Owner:ROTATION MEDICAL

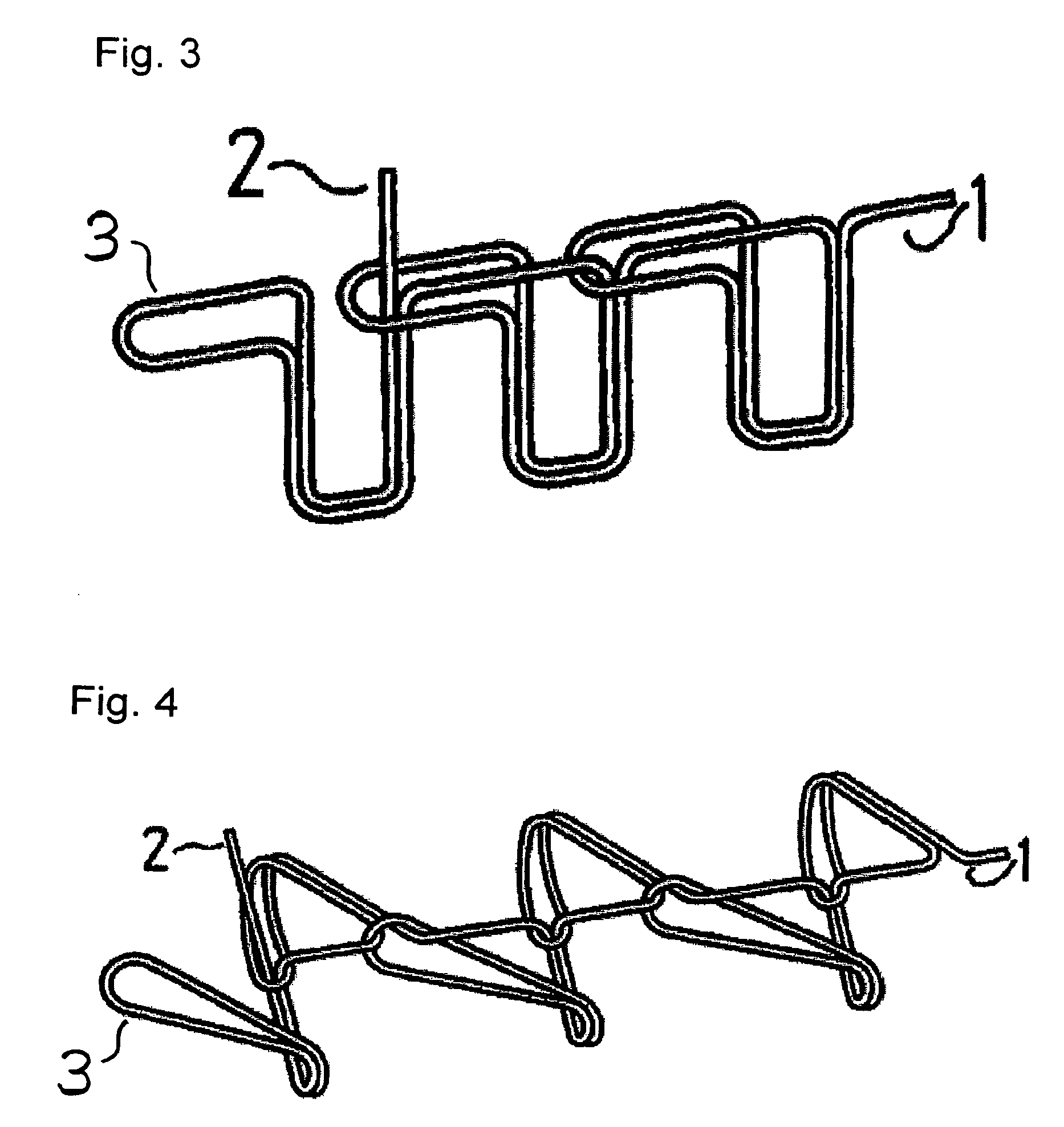

Methods and apparatus for fixing sheet-like materials to a target tissue

A staple for attaching a sheet-like implant to tissue or bone may, include first and second arms, and first and second flukes. In some embodiments, the first arm has a proximal end and a distal end, and the second arm has a proximal end and a distal end. A bridge extends from the proximal end of the first arm to the proximal end of the second arm. The first fluke has a proximal end abutting the distal end of the first arm, and the first fluke extends distally from the first arm. The first fluke has a lateral extent larger than a lateral extent of the first arm and is mounted eccentrically thereto. The first fluke includes a proximal surface projecting at an outward angle in a proximal direction away from the distal end of the first arm to engage the tissue or bone when inserted therein. The second fluke has similar features. This arrangement causes the first and second flukes to rotate in response to a pullout force on the bridge. Methods for attaching a sheet-like implant to a target tissue are also disclosed.

Owner:ROTATION MEDICAL

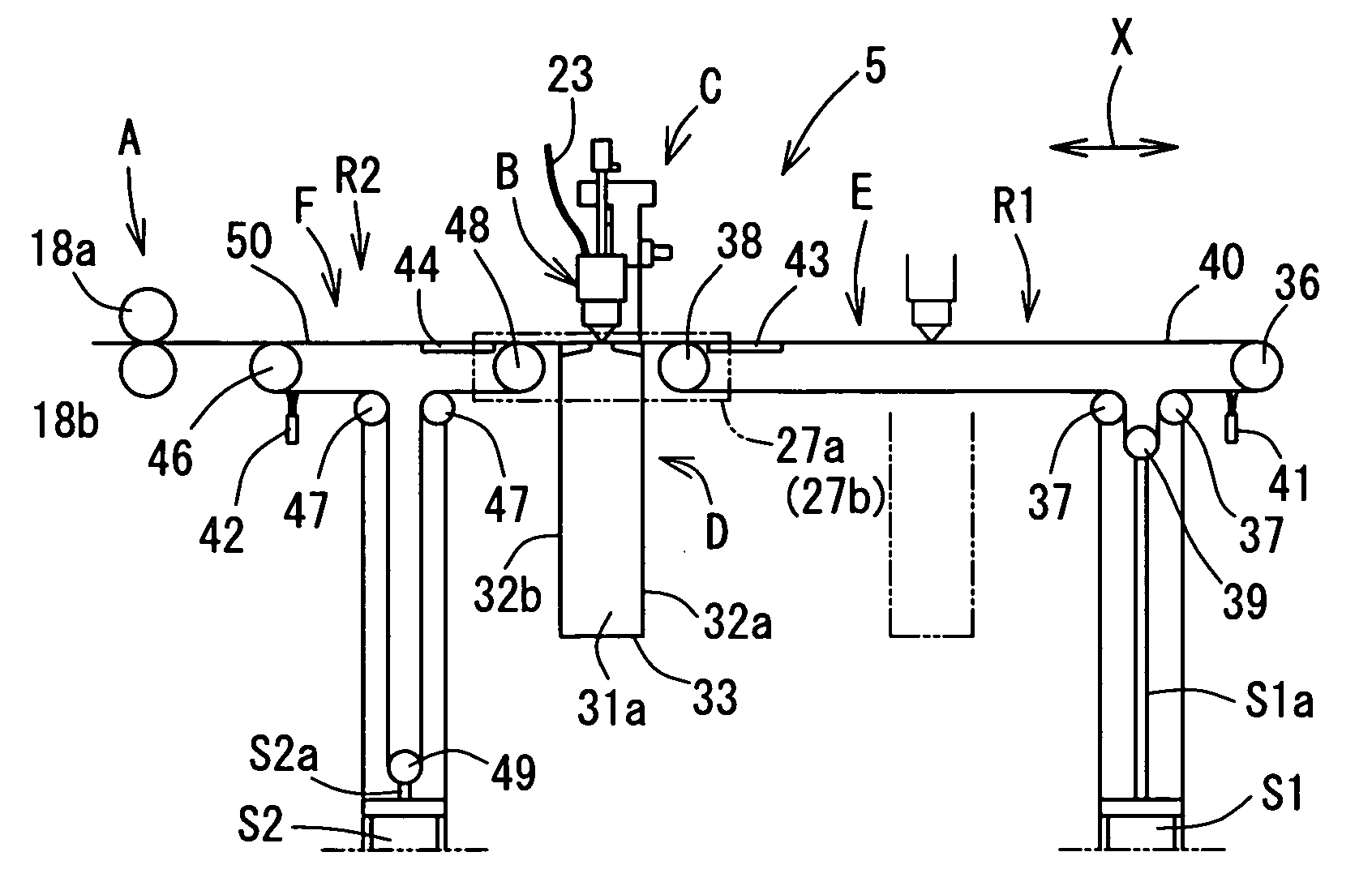

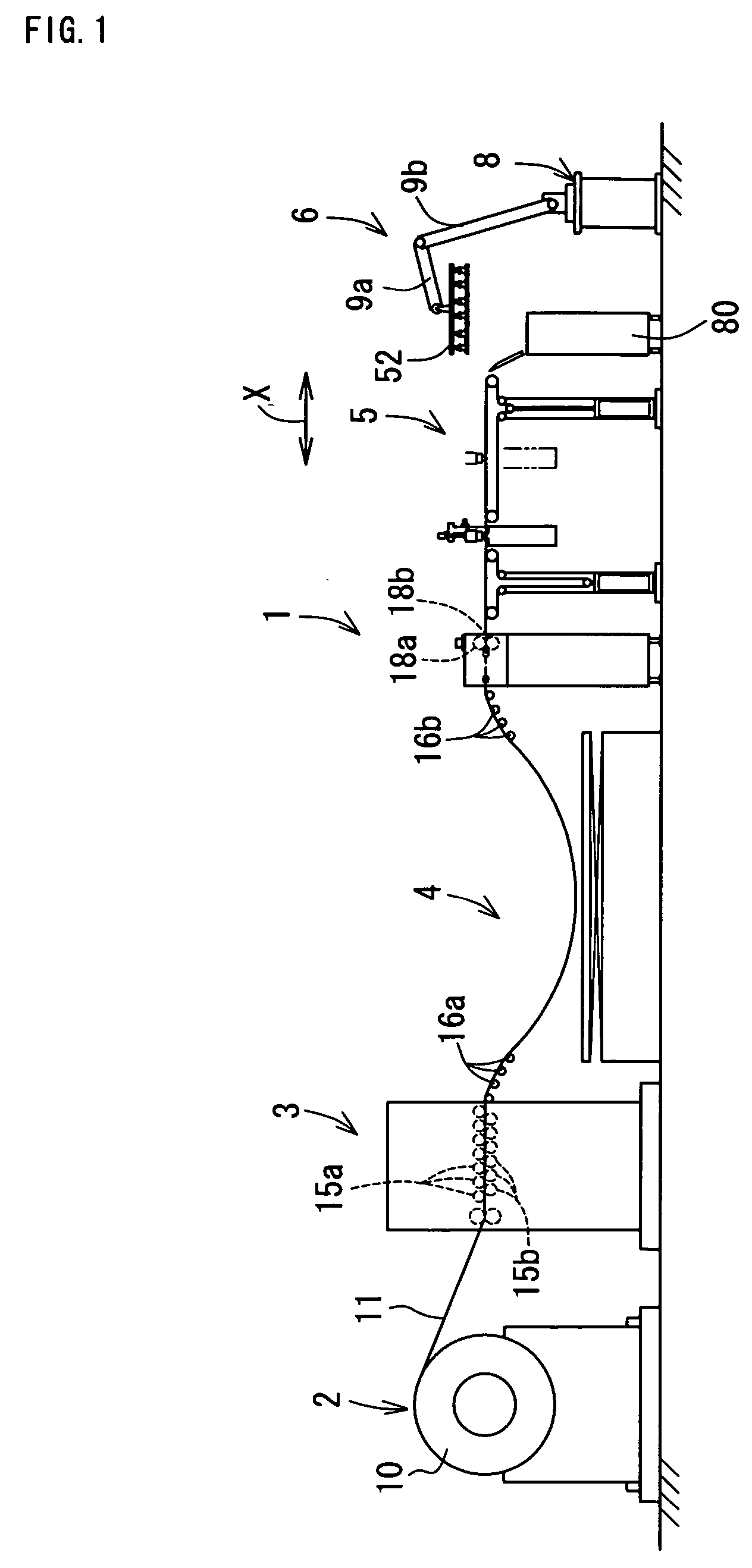

Laser cutting device, laser cutting method, and laser cutting system

InactiveUS20060118529A1Avoid dust adhesionEasy to controlConveyorsWelding/soldering/cutting articlesLaser cuttingLaser light

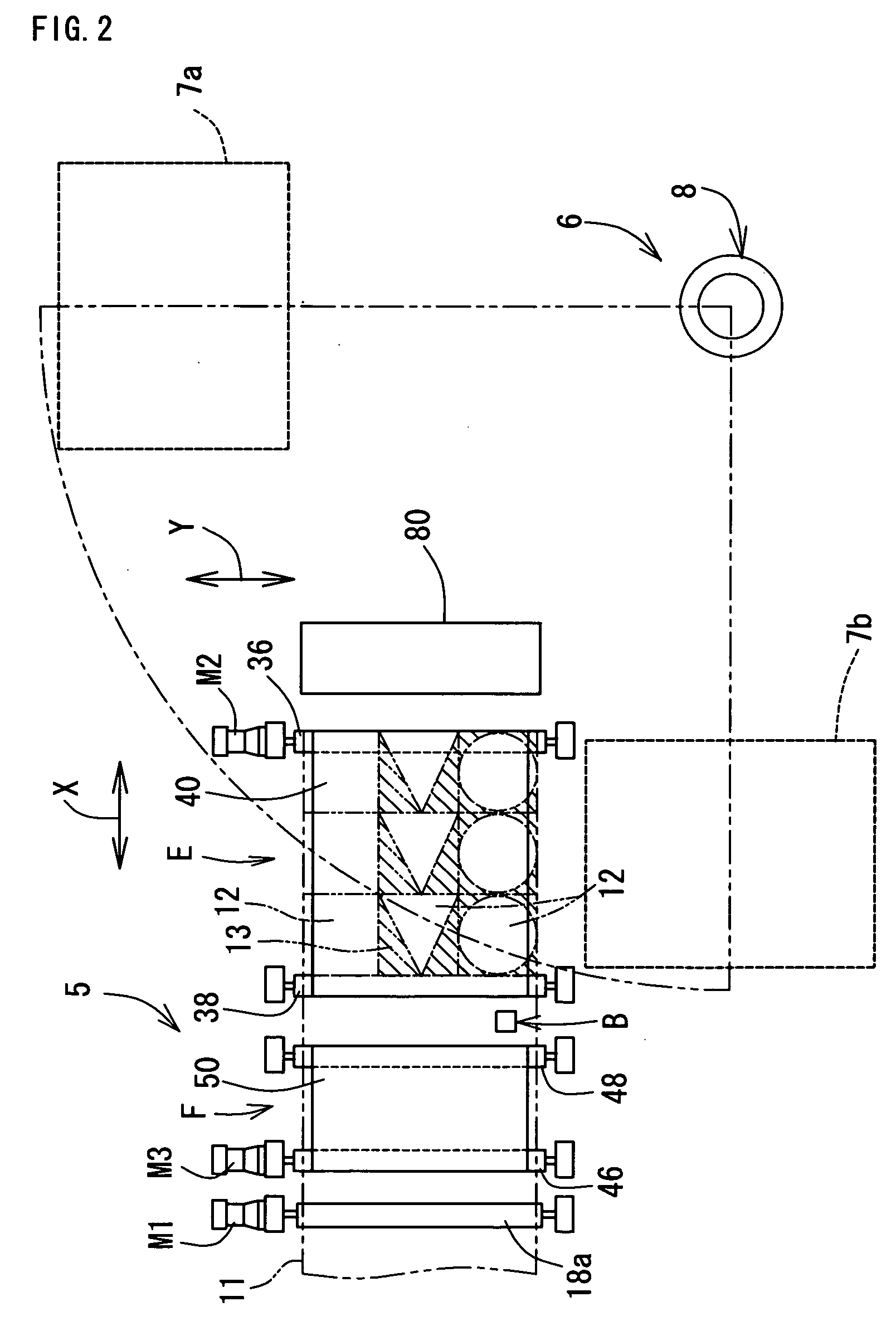

It is an object of the present invention to provide a laser cutting device, a method for laser cutting and a laser cutting system with which it is possible to perform laser cutting of parts of various shapes through easy control, to prevent adhesion of dust or similar and scratches being formed in cut parts, and to send out such parts while reliably supporting the same. The present laser cutting device 5 is comprised with a material transferring means A that transfers a sheet-like material 11 in a feeding direction, a processing head B that is capable of irradiating laser light towards the material, a head moving means C that makes the processing head move in the feeding direction X and a width direction Y of the material, an upstream-sided supporting means (belt conveyer mechanism F) that supports the material on an upstream side of a downward portion of the processing head and that expands and contracts a supporting region R2 for the material accompanying movements of the processing head in the feeding direction, and a downstream-sided supporting means (belt conveyer mechanism E) that supports cut parts on a downstream side of a downward portion of the processing head and that expands and contracts a supporting region R1 for the cut parts accompanying movements of the processing head in the feeding direction.

Owner:TOYOTA STEEL CENT CO LTD

Fasteners and fastener delivery devices for affixing sheet-like materials to bone or tissue

A fastener for attaching a sheet-like implant to tissue or bone. The fastener includes a first arm having a proximal end and a distal end, a second arm having a proximal end and a distal end, and a bridge extending therebetween. Each of the first and second arms include a trunk portion defining at least a portion thereof, the trunk portion having a cavity therein and an aperture through a wall thereof. A claw is disposed in the cavity which is moveable from a first delivery position to a second deployed position. A pull member engages each claw to move the claw from the delivery position to the deployed position.

Owner:ROTATION MEDICAL

Sheet Material Dispenser With Perforation Sensor and Method

InactiveUS20070152010A1Optimize allocationMany limitationDomestic applicationsMetal working apparatusEngineeringMaterial Perforation

A dispenser for dispensing sheet material including a plurality of spaced perforations may include a housing defining an interior for accommodating a source of the sheet material, and an outlet through which the sheet material may be dispensed. The device may also include a perforation sensor configured to sense perforations in the sheet material, disposed in the interior of the housing. The perforation sensor may include at least one light receptor, and at least a portion of the perforation sensor may be positioned in the housing to contact sheet material traveling from the source to the outlet, thereby spreading perforations in the sheet material.

Owner:GPCP IP HLDG LLC

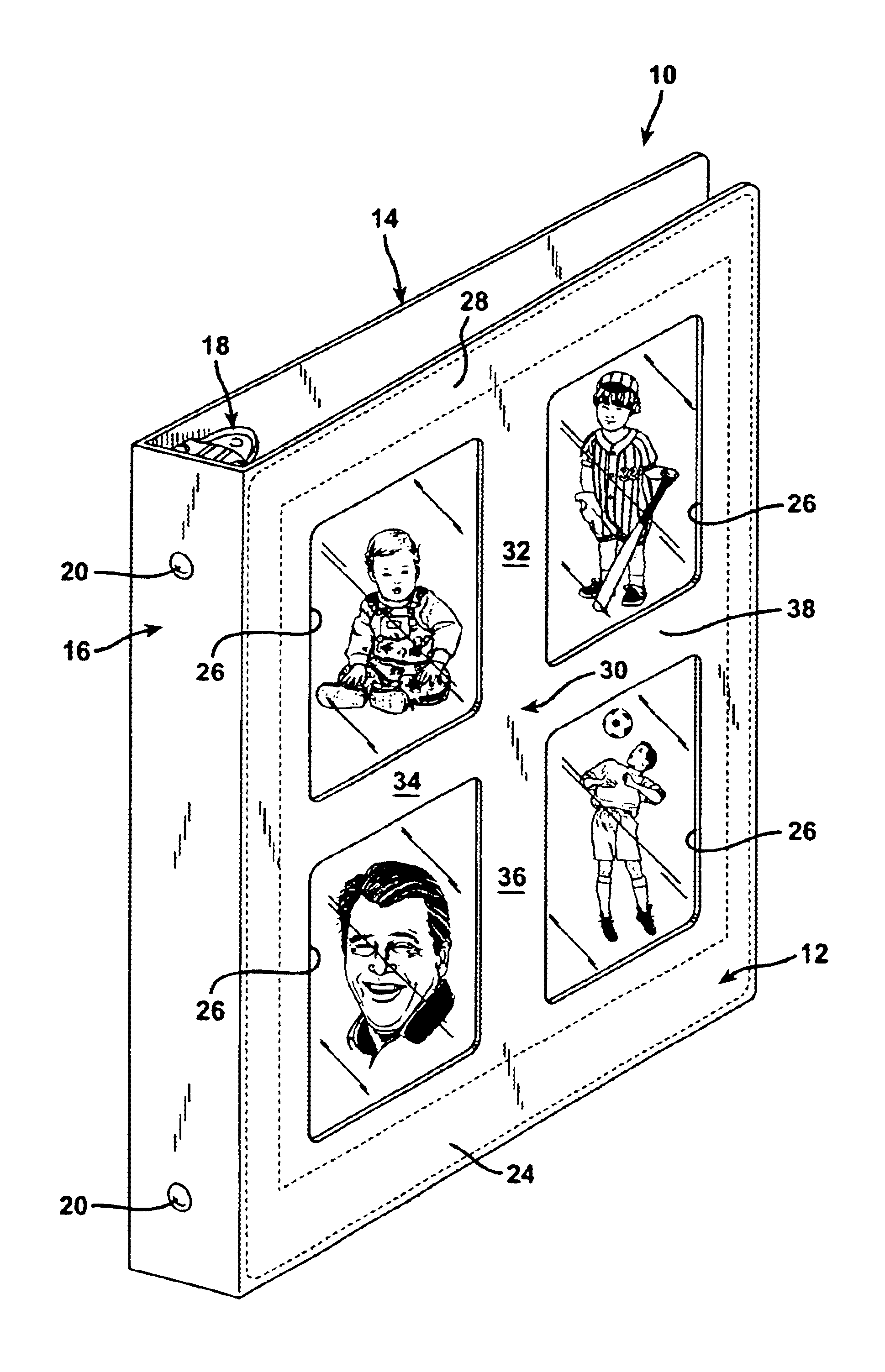

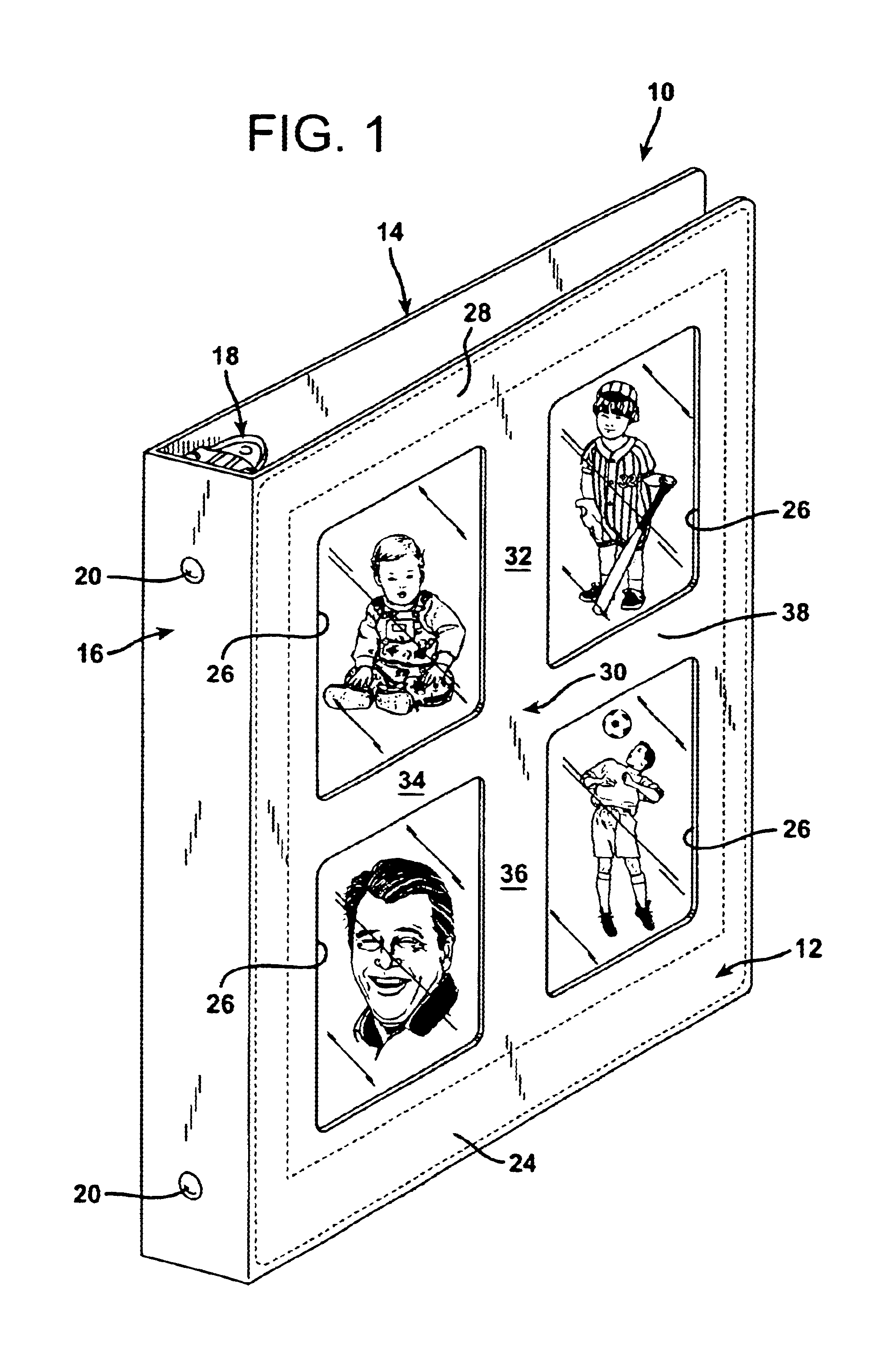

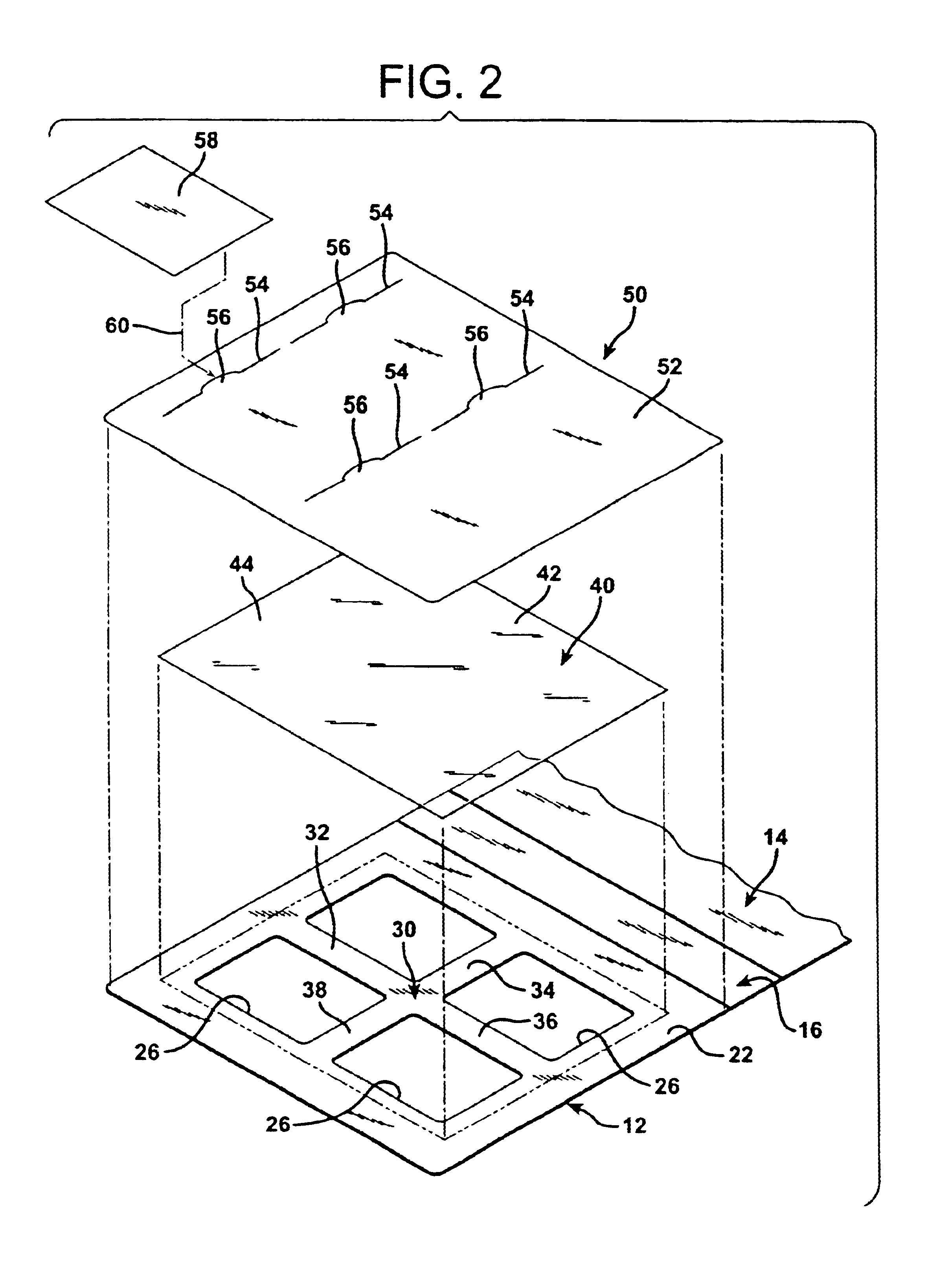

Window view binder cover

InactiveUS6854915B1Suitable for installationOther printing matterPicture framesWindow openingEngineering

A binder for papers, photographs, or other sheet-like materials is provided with a cover having one or more window openings defined therein. A flat, transparent protective sheet is located in contact with the inside surface of the binder cover and a backing sheet overlies the protective sheet. The backing sheet is secured to the peripheral margin of the protective sheet, and elsewhere as required, to delineate at least one, and preferably a plurality of pockets. The pockets are formed between the backing sheet and the protective sheet. An elongated slit in defined through the backing sheet behind each pocket created. The peripheral edges of the backing sheet are permanently secured to the inside surface of the binder cover. Photographs or other flat display materials may be inserted into the pockets formed between the backing sheet and the protective sheet through the elongated slits. The pockets are delineated so that they are aligned with the window opening in the cover. The photographs or other display materials may thereby be viewed through the window openings from the outside through the transparent protective sheet. Selected display materials may be inserted and withdrawn from the pockets through the elongated slits in the backing cover.

Owner:ONG BON S

Alignment of enhancers in cosmetic compositions

InactiveUS6905696B2Easy to organizeLengthen the eyelashes or cover the wrinkles on the lips or skinCosmetic preparationsHair cosmeticsWrinkle skinFiber

The present invention relates to a cosmetic or pharmaceutical composition for topical application to the keratinous surface which comprises a alignment agent for promoting the orderly arrangement of a feature enhancing component for enhancing the lengthening of the eyelashes and / or the covering of wrinkles on the skin surface. The feature enhancing component can be a fibrous component and can include a variety of types of fibers including wicking fibers, evaporating fibers, or a combination of both. The feature enhancing component can also be inert fillers such as platelet materials.

Owner:COLOR ACCESS

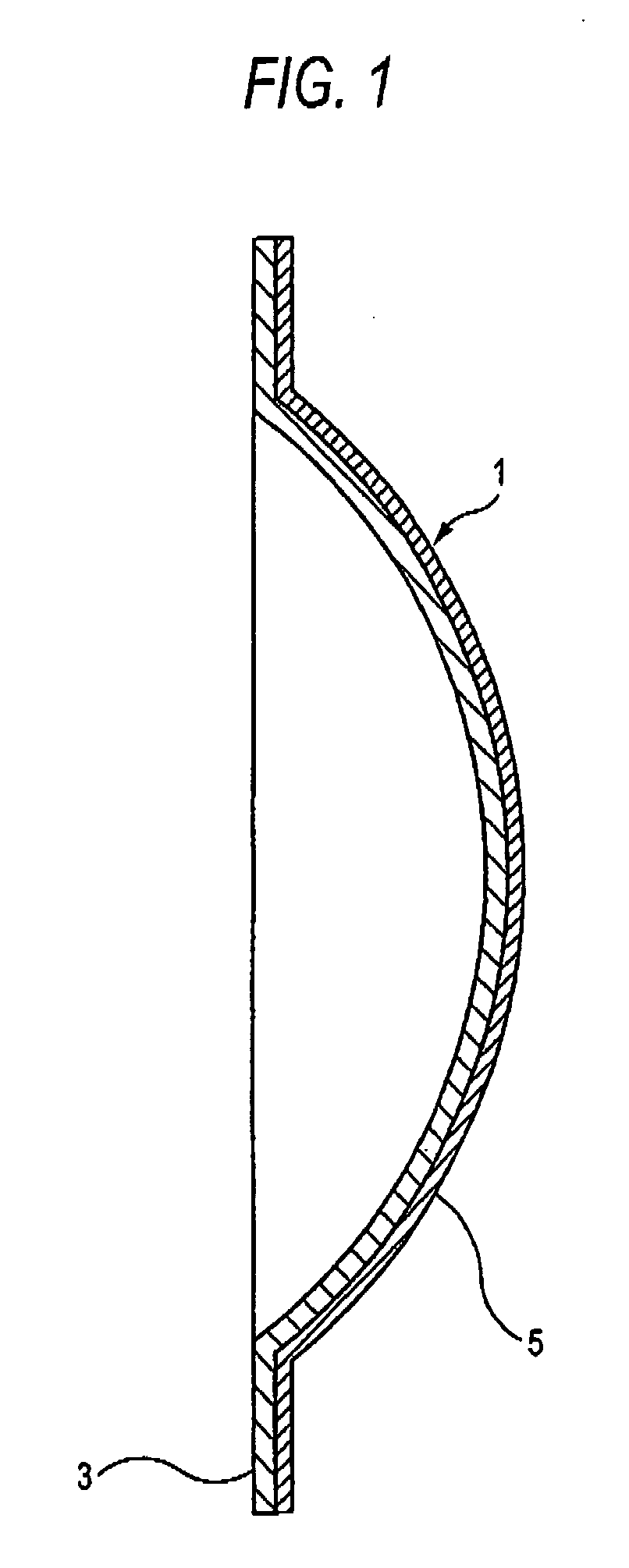

Method for manufacturing speaker-use center cap

InactiveUS20050257998A1Increase production costNumber of manufacturing step is increasedLoudspeaker screensDomestic articlesManufactured materialSynthetic resin

A method is for manufacturing a speaker-use center cap provided with a first cap member layer of synthetic resin and a second cap member layer layered in intimate contact with the first cap member layer and made of a material different from that of the first cap member layer. The method includes: a pre-molding step of attaching a non-molded sheet-like material which is a raw material of the second cap member layer to a mating surface of one of die parts of an injection molding die and thereafter closing the injection molding die to apply a predetermined cap shape to the sheet-like material; and an injection molding step of injecting the synthetic resin material into the injection molding die closed by the pre-molding step to form the first cap member layer to be intimate contact with the second cap member layer.

Owner:PIONEER CORP +1

Preparation method of hemostatic material

ActiveCN104721878AGood hemostatic effectSave rescue timeBiochemical fibre treatmentAbsorbent padsMedicineElectrospinning

The invention discloses a preparation method for a hemostatic material, an absorbable carrier material prepared by an electrospinning technology or a combination of the absorbable carrier material and a blood coagulation factor film-shaped material prepared by the electrospinning technology, wherein blood coagulation factors are fibrinogen and thrombin from human or animal blood. The superfine fibre prepared by the electrospinning technology has the advantages that the specific surface area of the reticulate structure of the hemostatic material is increased, and the mutual fusion action between the reticulate structure and tissues is promoted. The hemostatic material is good in biocompatibility, more remarkable in hemostatic effect and convenient to use, and can be used for hemostasis in trauma treatment and clinical operations.

Owner:GUANGZHOU DIANFANG BIOTECH CO LTD

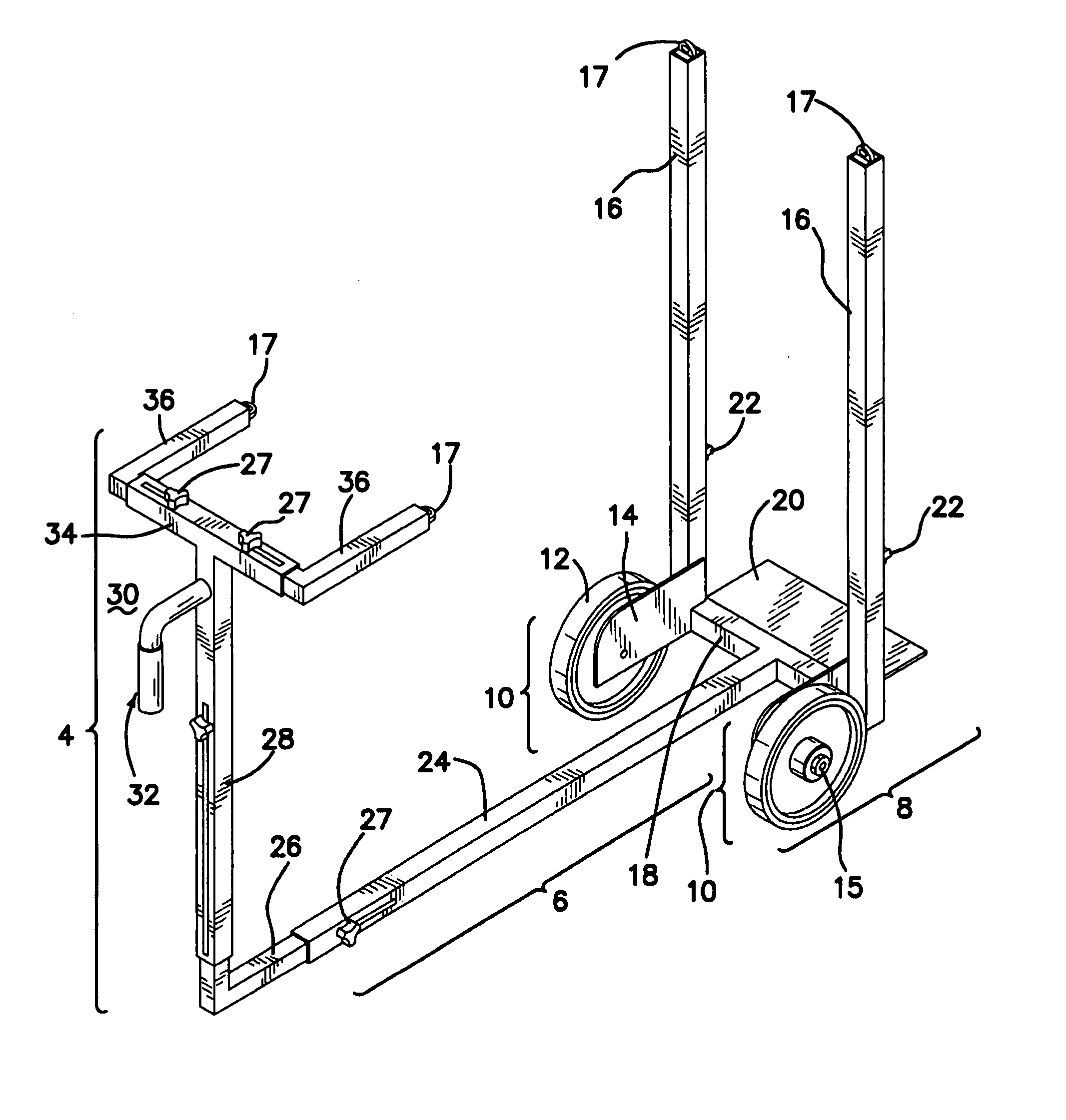

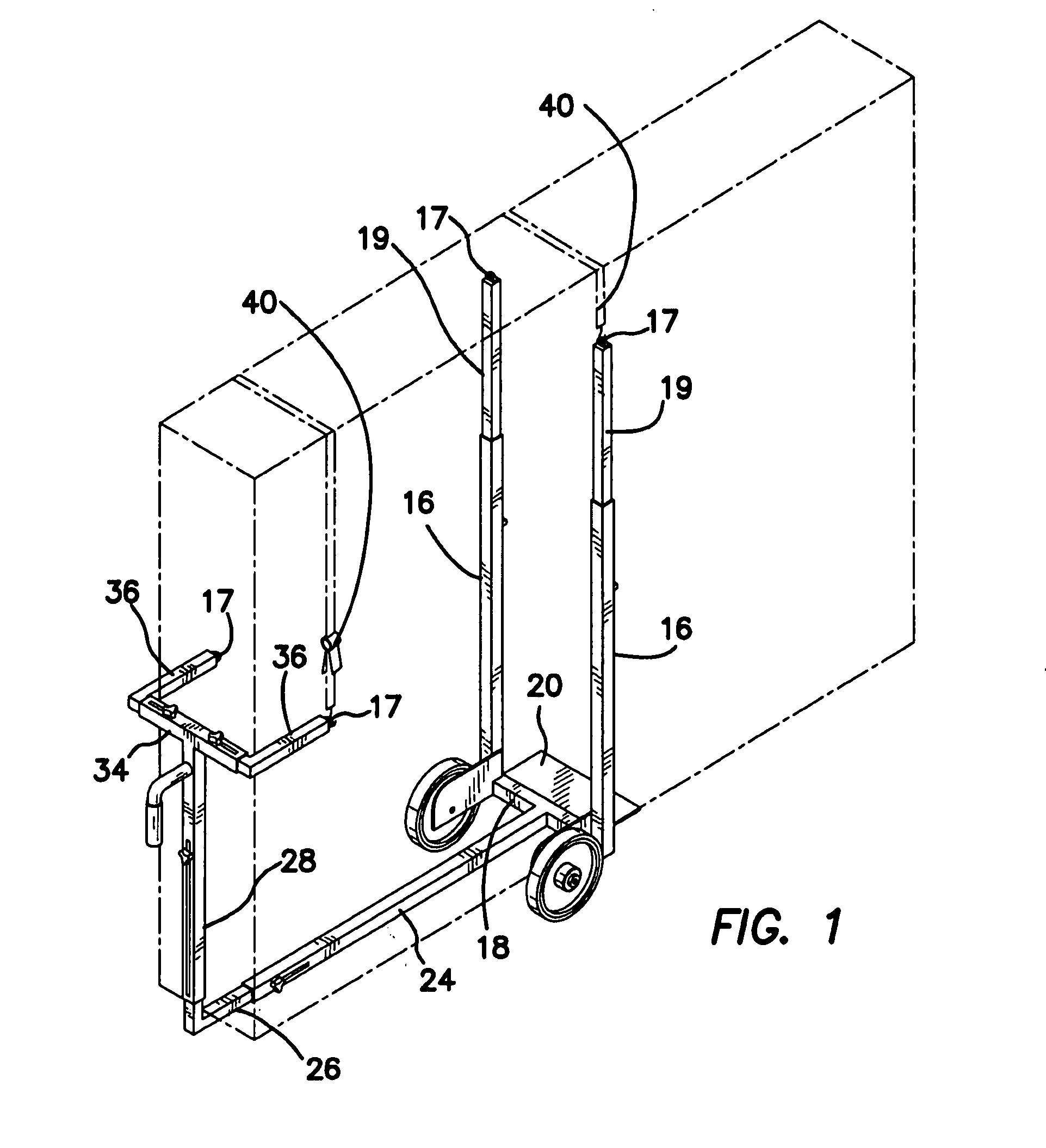

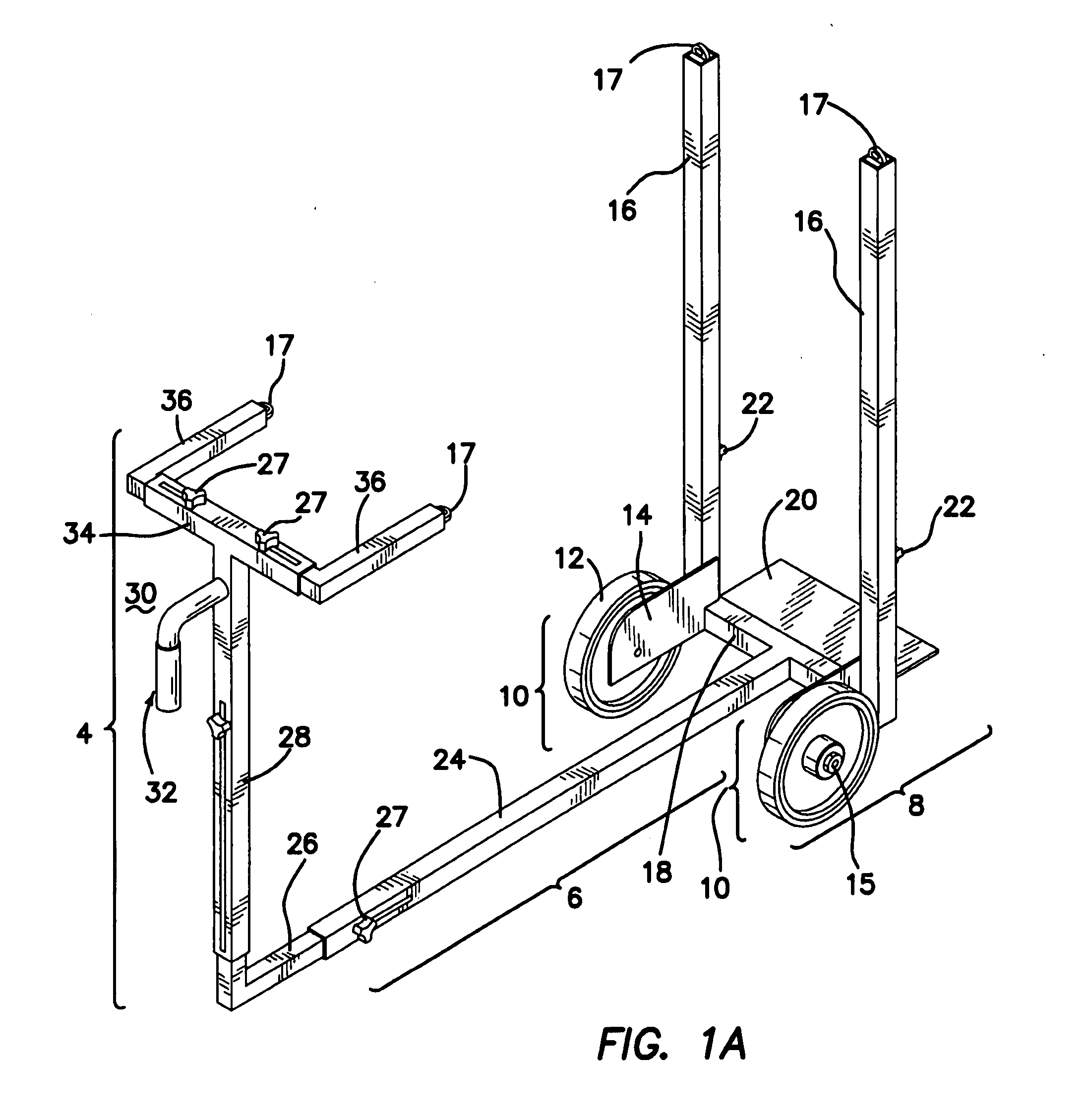

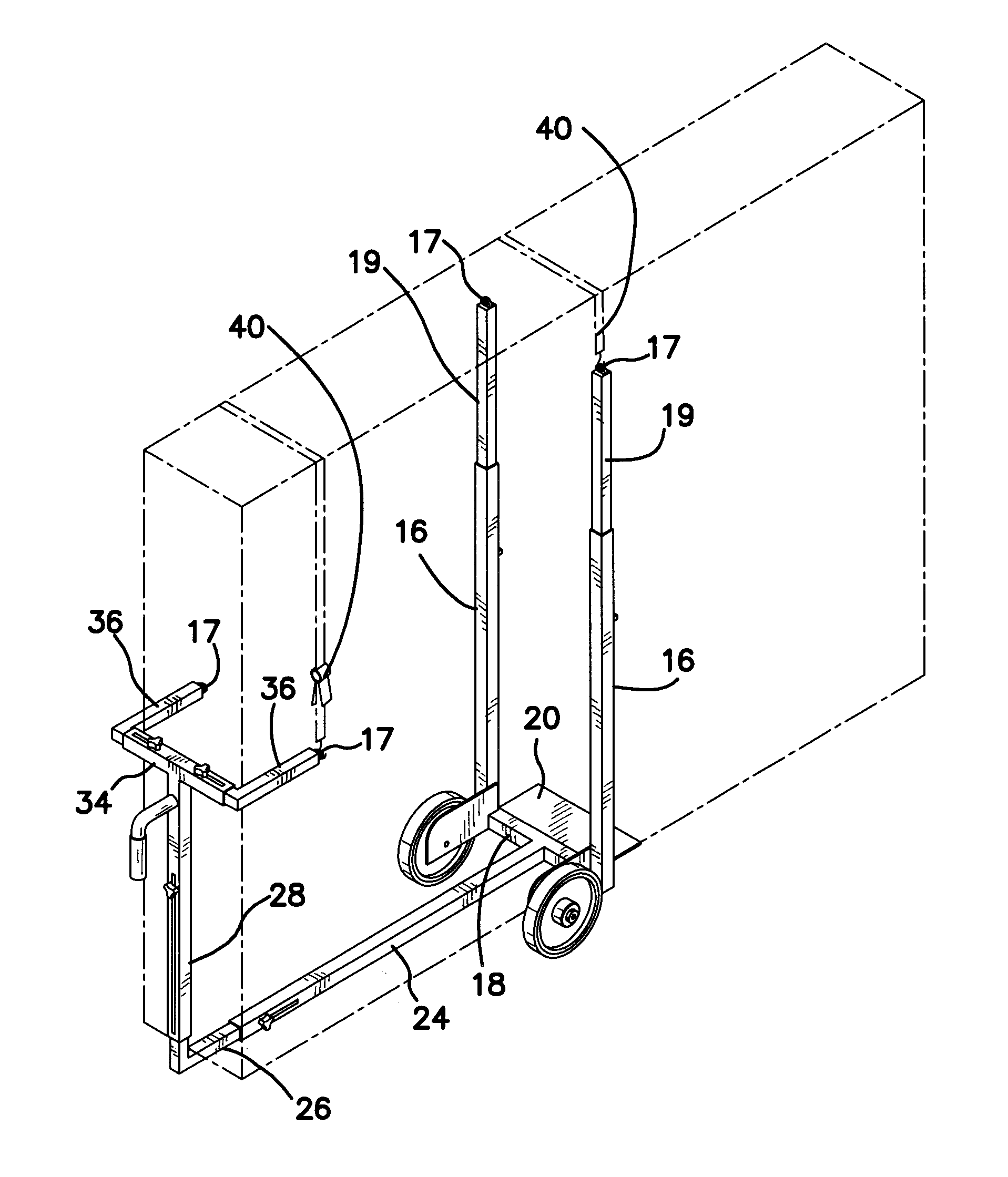

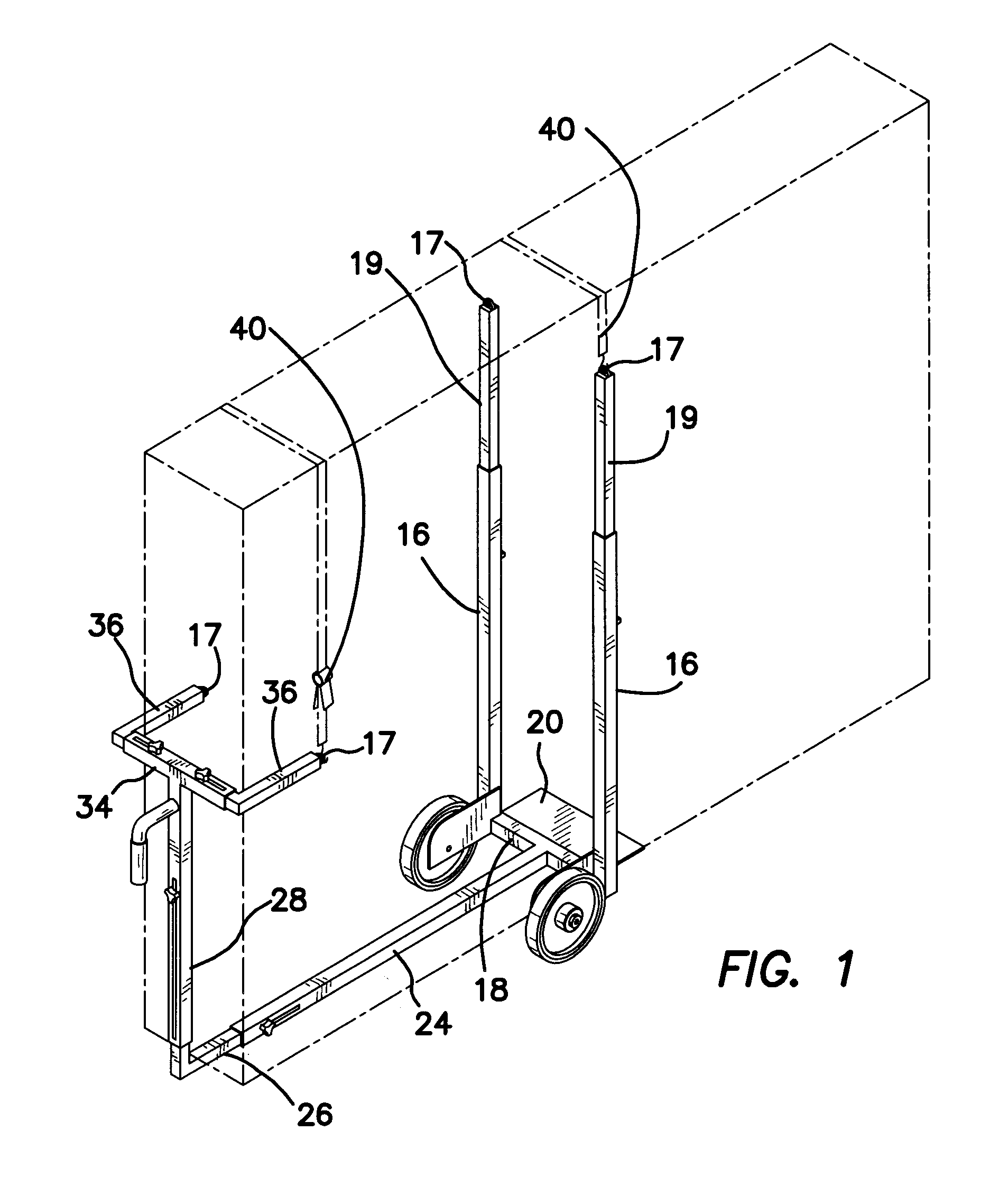

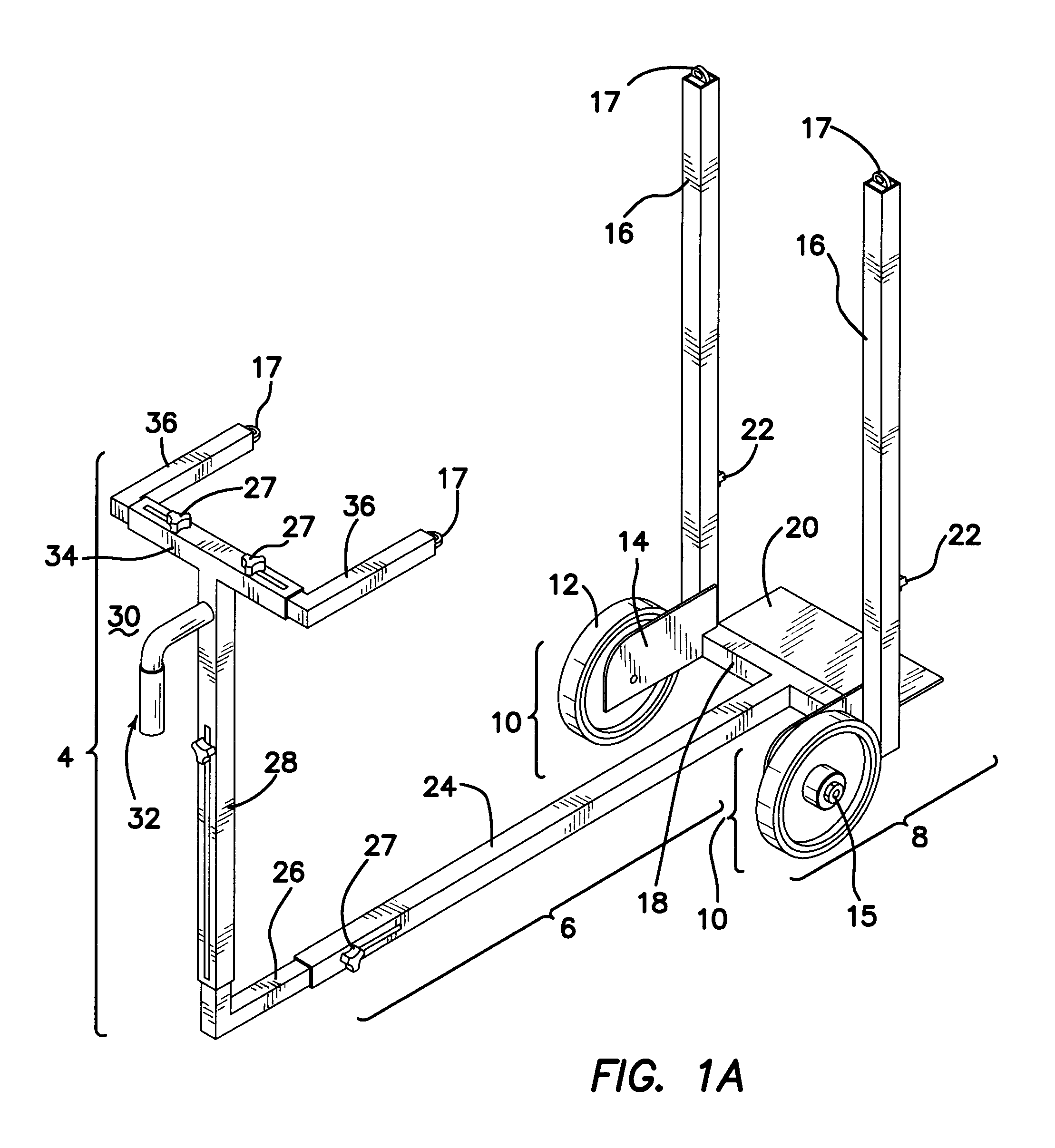

Apparatus for transport of objects

InactiveUS20090026735A1Easy to transportCarriage/perambulator accessoriesSledgesFlat glassMetal sheet

A apparatus and method for transporting oversized objects, particularly substantially flat or planar objects. In certain embodiments the object is a material in sheet form, such as a wood sheet, metal sheet, dry wall, and the like, or a narrow object such as bed mattresses, tabletops, mirrors and plate glass, doors and the like. Preferably the object is capable of being transported by a single person. In certain embodiments the apparatus is structured to be capable of transporting a mattress through an open doorway without unloading the object.

Owner:WATZKE DAVID J

Drill-feeding plugging agent used for oil-based drilling fluid, preparation method and application thereof

The invention discloses a drill-feeding plugging agent used for oil-based drilling fluid, a preparation method and an application thereof. The plugging agent comprises a sheet shape material with fineness less than 200 meshes, a granular material with fineness less than 200 meshes, a fibrous material with fineness less than 100 meshes, and an elastomeric material with fineness less than 100 mesh; wherein the weight ratio of the sheet shape material to the granular material to the fibrous material to the elastomeric material is (2-5): (4-8): (2-5): (0.5-3). The drill-feeding plugging agent can increase the plugging effect of a sand bed and small cracks. The drill-feeding plugging agent is added in the oil-based drilling fluid, in the sand bed with 20-40 meshes, the immersing depth of a filtrate is less than 3 cm, 0.5 mm of cracks are plugged, and the bearing capability is greater than 7 MPa.

Owner:CHINA PETROLEUM & CHEM CORP +1

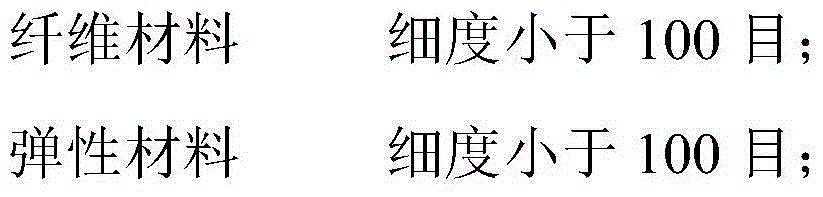

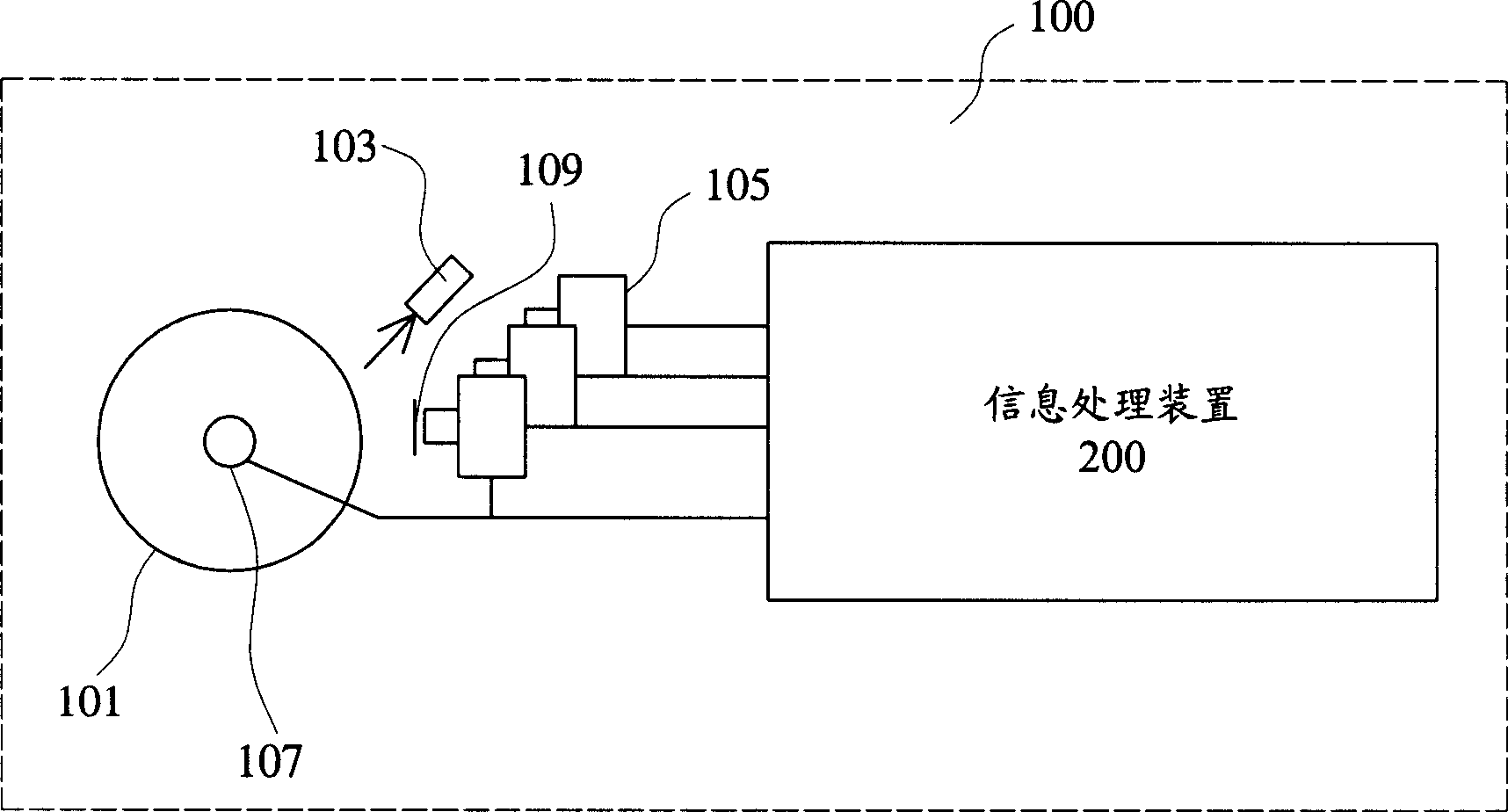

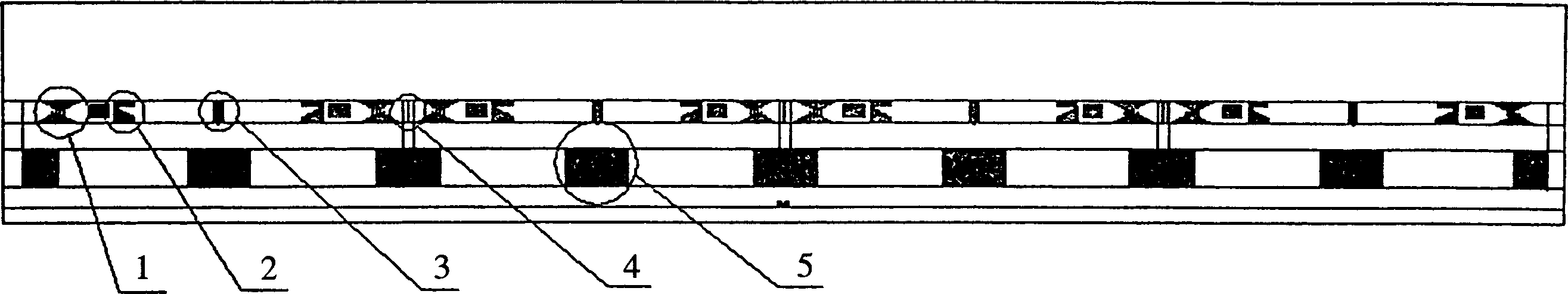

Device and method used for detecting flake material fluorescent image printing quality

InactiveCN1619296AImprove claritySimple structurePaper-money testing devicesOptically investigating flaws/contaminationFluorescenceFlaked Material

The present invention relates to an equipment for detecting printed quality of fluorescence image of sheet material. Said equipment includes transmission device, lighting device, receiving device and information processing device. Said invention also provides the action of the above-mentioned every device and detection method by using said equipment.

Owner:CHINA BANKNOTE PRINTING & MINTING

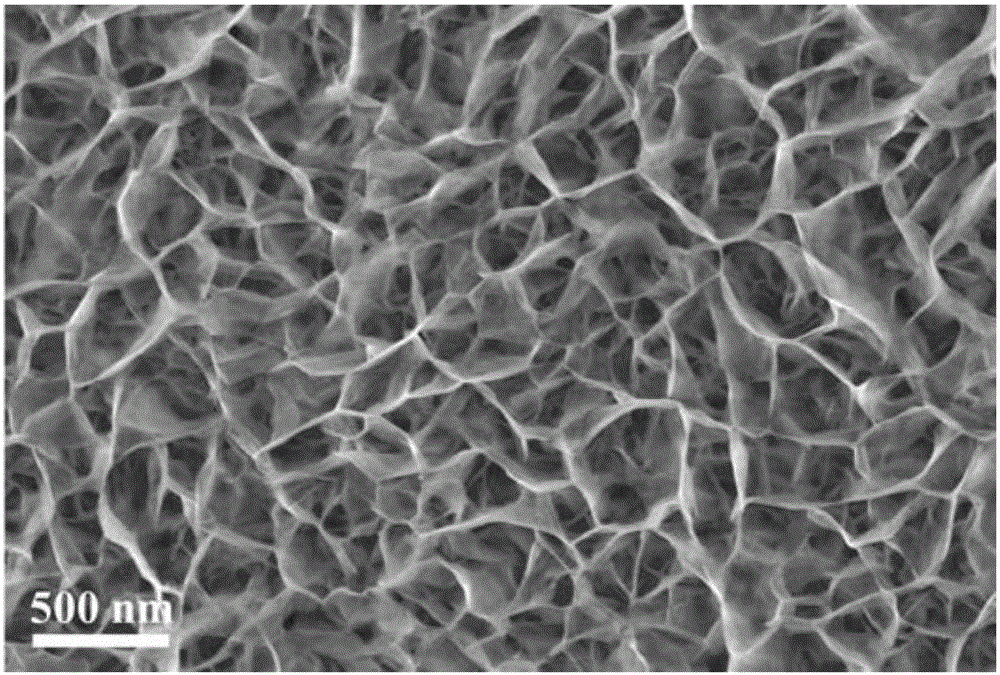

Inorganic sheet composite material with surface having double property and preparation thereof

The invention pertains to the material technology field, and more particularly relates to an inorganic flake composite with the surface having dual natures, and a preparation method thereof. The invention takes an inorganic hollow microsphere, a polymer composite ball with the surface integrated with an inorganic lamella, or polymer composite fiber with the surface integrated with an inorganic lamella as raw materials, the external surfaces of which are modified and crushed to obtain inorganic flake materials; and then exposed fresh surfaces are modified again to obtain the inorganic flake materials with both surfaces having different chemical properties. The inorganic flake composite of the invention with the surface having the dual natures is composed of an inorganic substrate and a single layer, double layers or multiple layers of compounded surface chemicals on the substrate, and both sides of the substrate have different surface chemicals. The method provided by the invention is simple, convenient and easy to be operated, and not only possesses the feasibility of large-scale production, but also can carry out multi-step modification to the surfaces of micro-granules so as to meet different needs.

Owner:INST OF CHEM CHINESE ACAD OF SCI

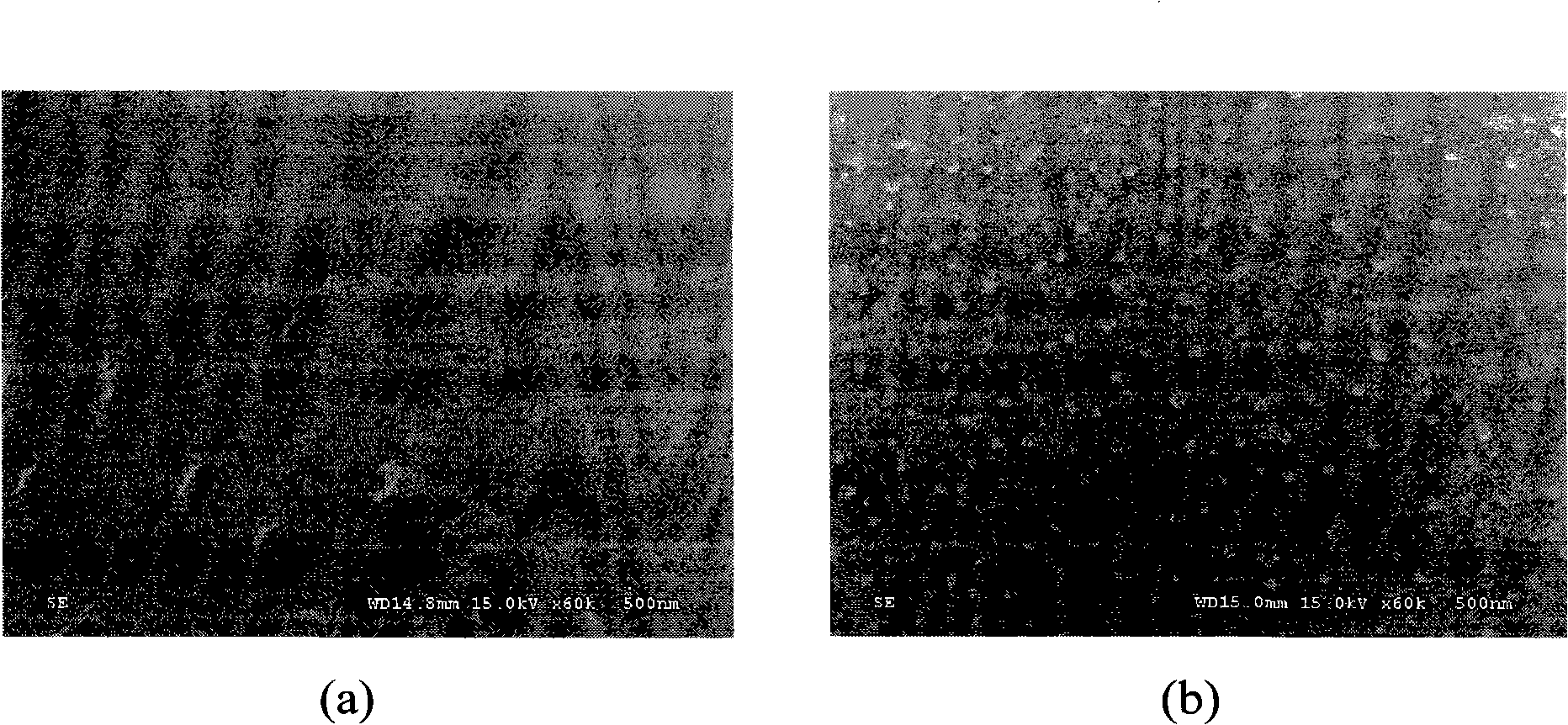

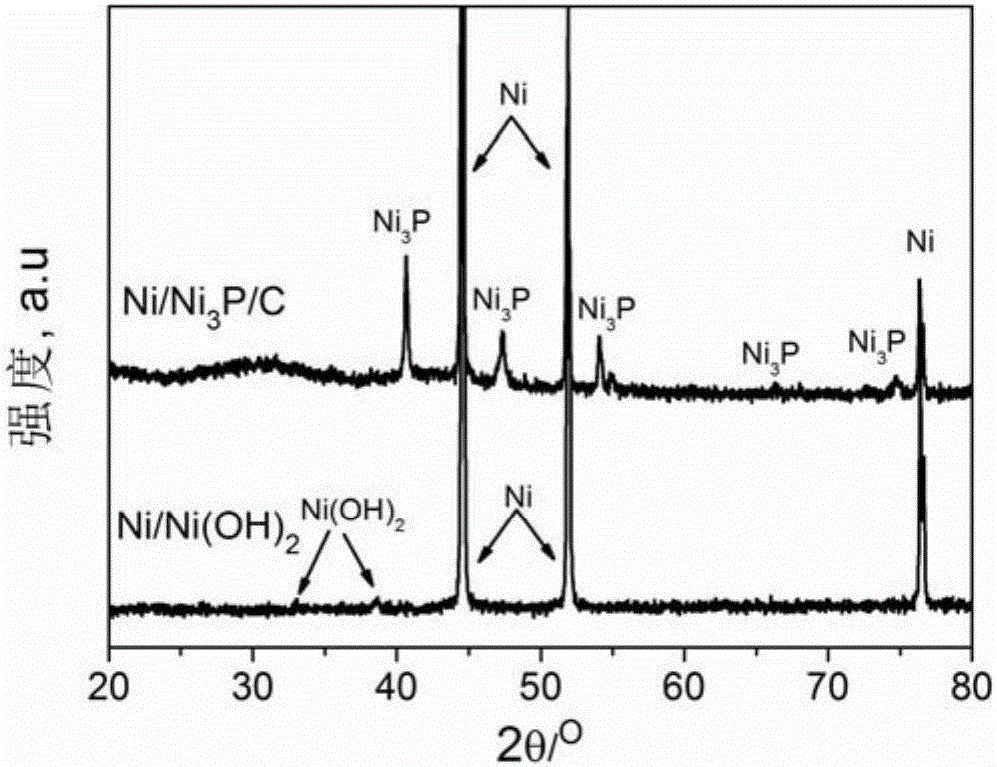

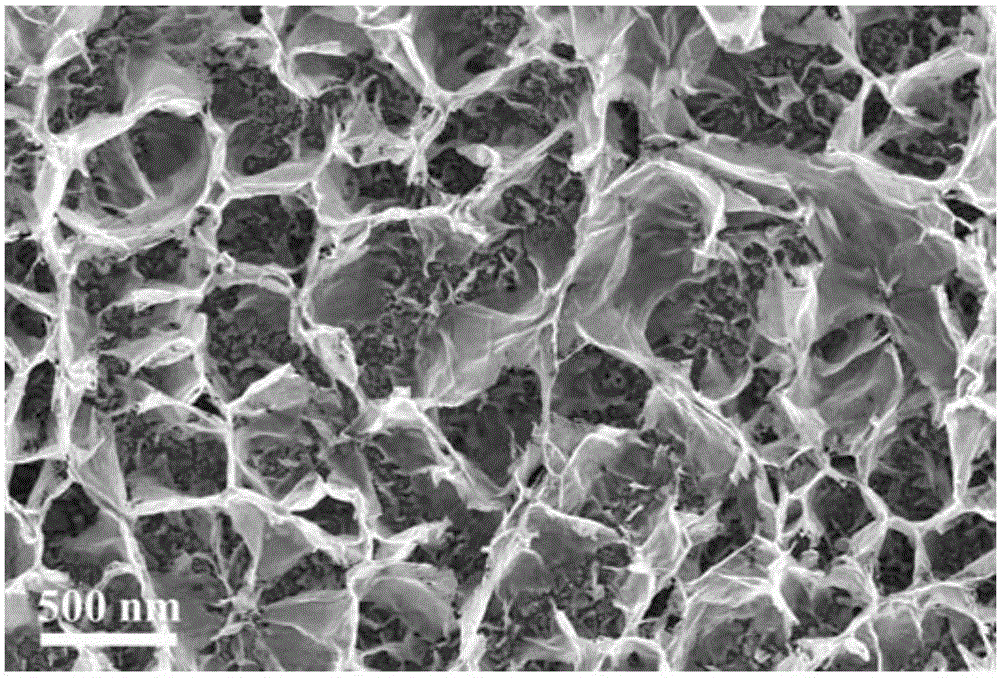

Foamed nickel self-supported flake-shaped Ni3P/C composite material for sodium ion battery negative electrode and preparation method for composite material

ActiveCN105720236AImprove performanceExcellent rate performanceNegative electrodesCarbon coatingThermal insulation

The invention discloses a foamed nickel self-supported flake-shaped Ni3P / C composite material for a sodium ion battery negative electrode and a preparation method for the composite material. According to the composite material, the flake-shaped Ni3P is uniformly growing on the foamed nickel; and the Ni3P is uniformly coated with a C film. The preparation method for the composite material comprises the steps of taking a nickel compound as the raw material, and uniformly growing a flake-shaped nickel hydroxide layer on the surface of the nickel compound through a hydrothermal method; then taking sodium hypophosphite as a phosphorus source, and performing thermal insulation at a temperature of 300 DEG C for 2h to prepare the foamed nickel self-supported flake-shaped Ni3P material; and finally, performing carbon coating on the foamed nickel self-supported flake-shaped Ni3P material to obtain the foamed nickel self-supported flake-shaped Ni3P / C composite material. The sodium ion battery prepared from the Ni3P / C composite material prepared by the invention has excellent specific capacity, rate capability and stable cycling performance; and in addition, the preparation method is simple and feasible, wide in raw material resources and suitable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

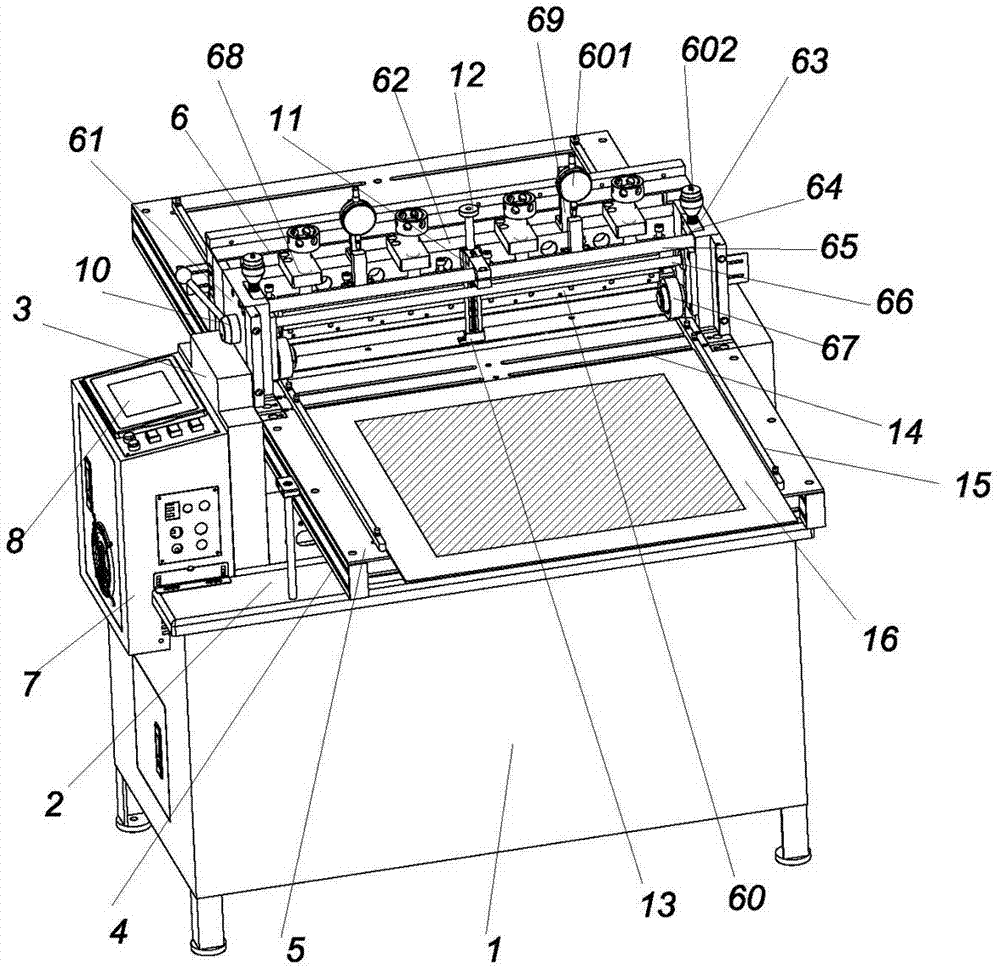

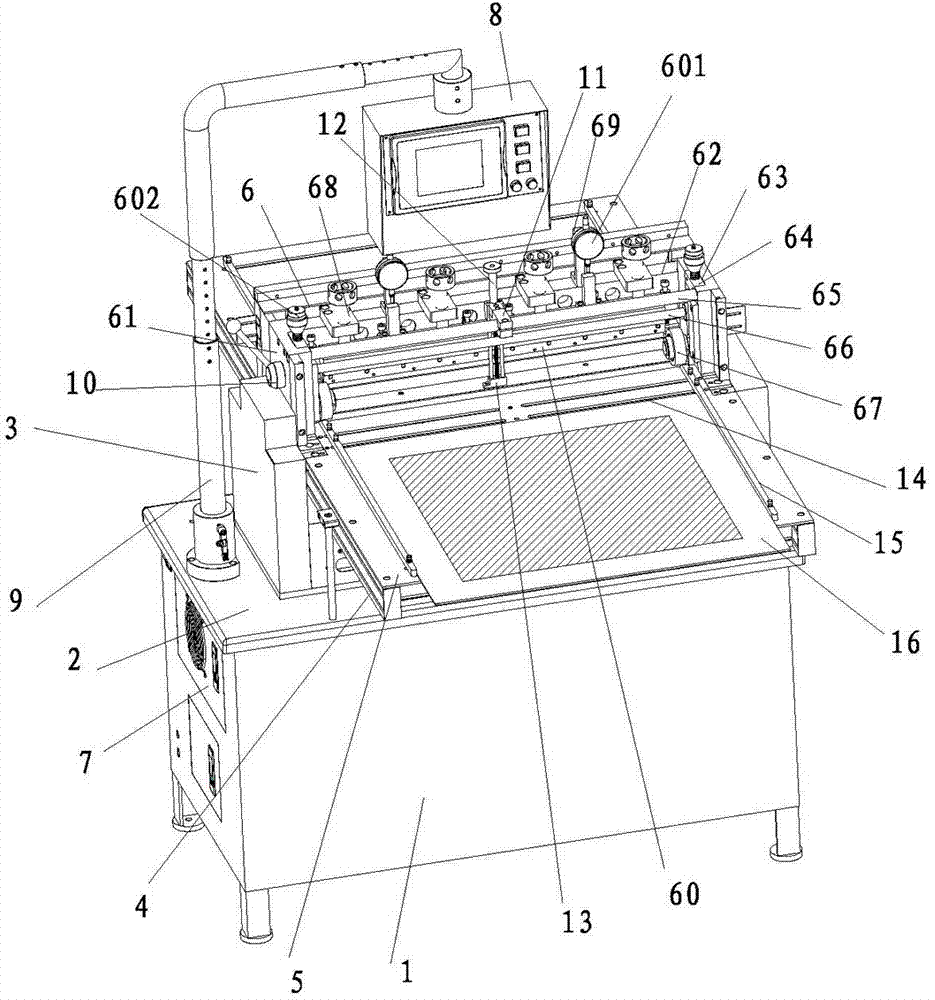

Automatic cutting machine

ActiveCN103934840AEasy to operateLeather clicking/perforating/clickingSevering textilesNumerical controlIdler-wheel

The invention discloses an automatic cutting machine which comprises a work machine table. The upper end of the work machine table is provided with a work table top. The work table top is provided with two supports corresponding to each other. A work-piece conveying table bracket is arranged between the two supports and provided with two corresponding work-piece conveying tables. A cutting device is arranged between the two work-piece conveying tables. One side of the work machine table is provided with an electrical appliance power distribution cabinet. One end of the work table top is provided with a touch type operation panel. Flaky materials are placed on an acrylic plate, a start key is pressed, and feeding idler wheels can advance in a running-down mode; when a photoelectric sensor senses coming of the materials, the edges can be automatically cut and trimmed neatly according to the length set by the photoelectric cardinal number, fixed length cutting is carried out and the cutting number is controlled according to the cut length set by a numerical control device; after the number of cutting is finished, the feeding idler wheels enable the acrylic plate to retreat to the original start position according to the length set by the reversing length.

Owner:东莞市塘厦肇颖机械五金厂

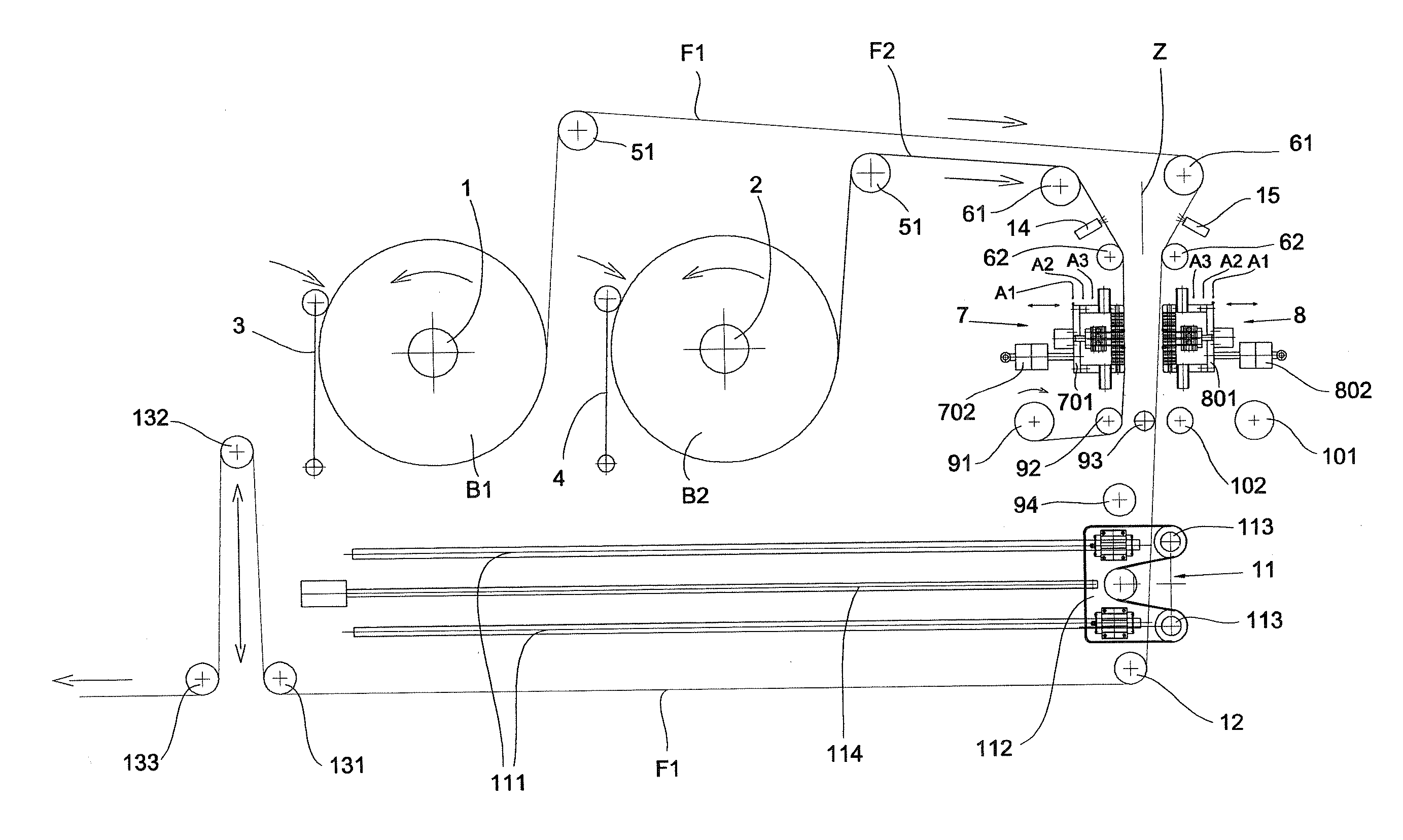

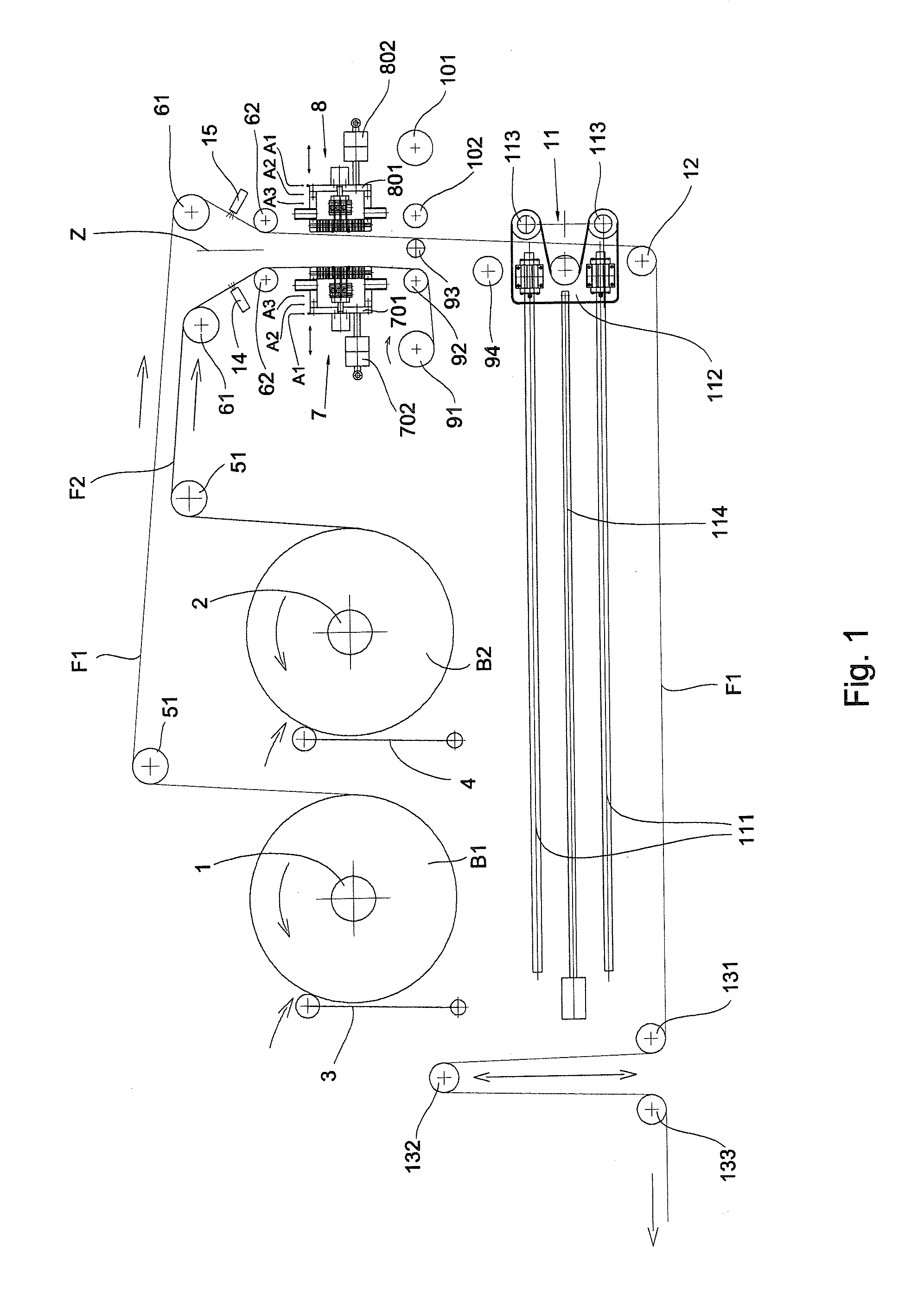

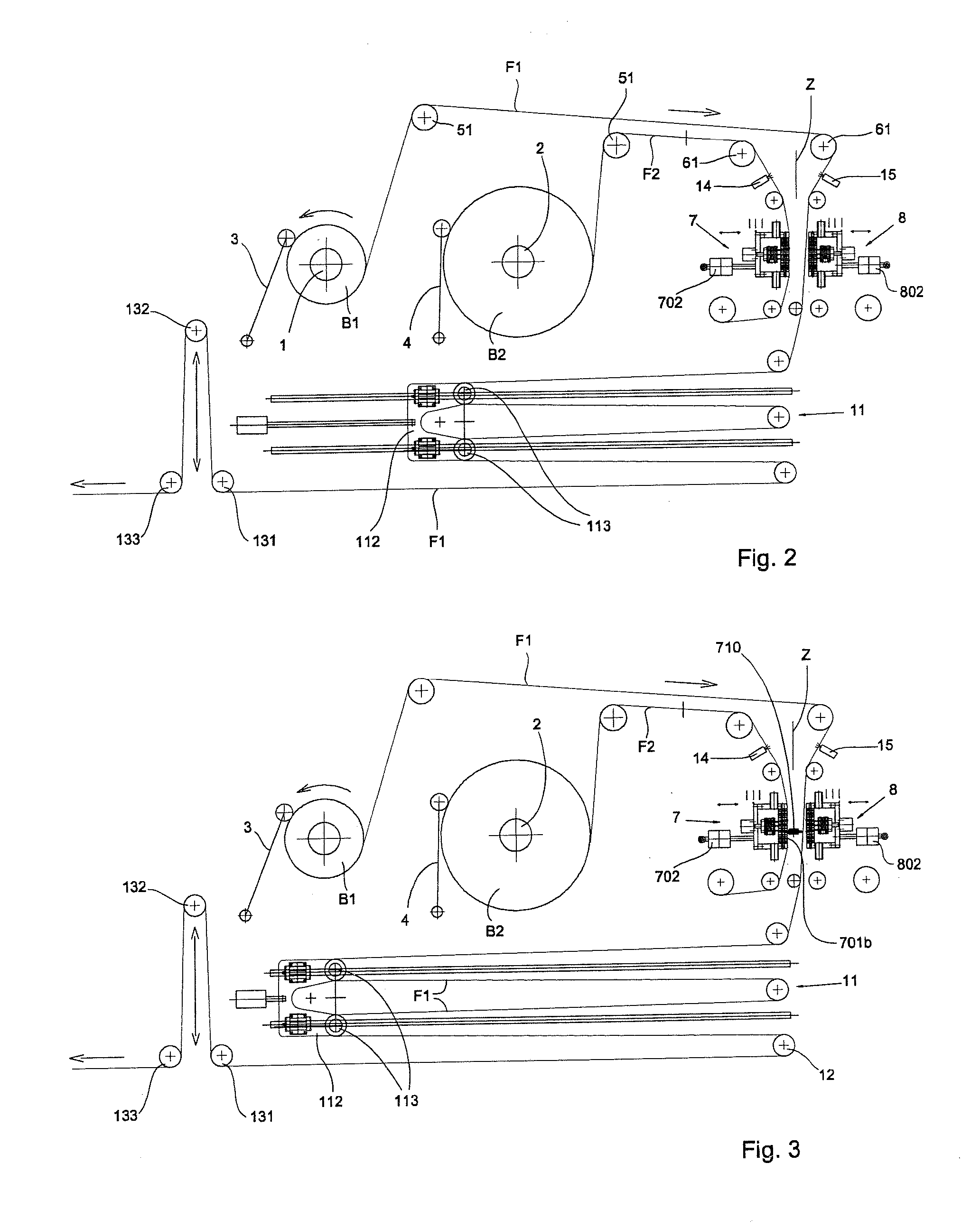

Unit and method for feeding reels of a sheet-like material, in particular but not exclusively a printed plastic film with print-position marks for automatic packaging machines

ActiveUS20120100978A1Simple constructive solutionEasy constructionPaper-makingBox making operationsEngineeringPlastic film

A feeding unit from reels (B1, B2) of sheet-like material (F1, F2), in particular but not exclusively printed plastic film with print-position marks for automatic packaging machines, comprising two unrolling shafts (1, 2) of respective reels (B1, B2) of material (F1, F2), for feeding in turn said material towards means (7, 8) for cutting and welding the tail of material of a running out reel (B1) and the head of a fresh, loaded reel (B2). Such means comprise suction, cutting and welding devices (7, 8) movable so as to approach and move away from each other to press the material (F1, F2) over a welding plane (Z). Each device is formed by a group of mutually stacked suction and cutting modules, at least two of such modules having respective guides for cutting means slidable in a transversal direction with the respect to the feeding direction of the material, whereby it is possible to select and adjust the number of modules according to a desired welding height.

Owner:RENT

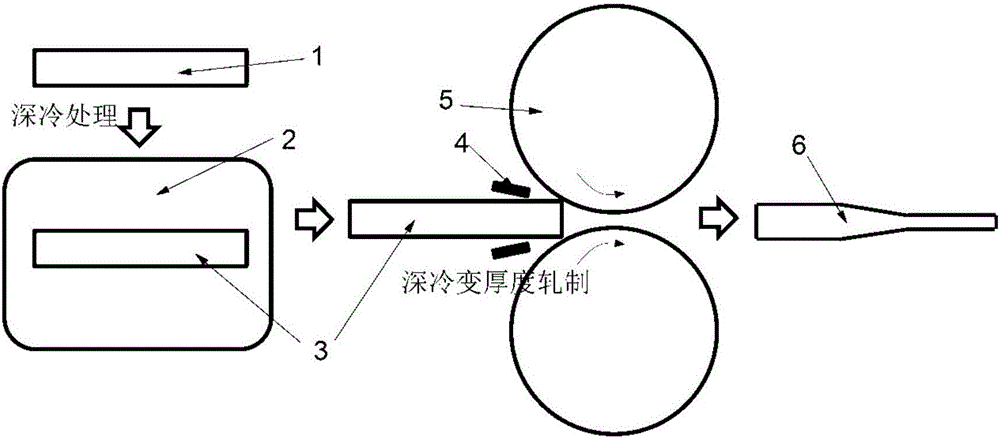

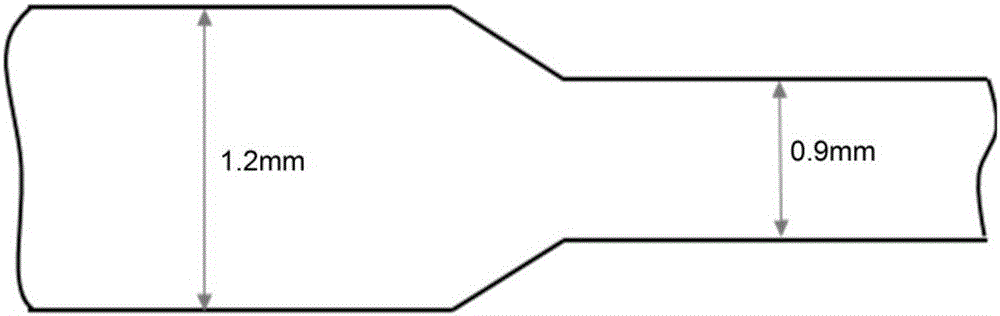

Aluminum alloy deep cooling variable-thickness rolling process

ActiveCN107520270AHigh strengthImprove toughnessWork cooling devicesMetal rolling arrangementsVariable thicknessLiquid nitrogen

The invention discloses an aluminum alloy deep cooling variable-thickness rolling process. An aluminum alloy plate strip serves as a raw material, and is machined into a piece-shaped material with a certain size, the material is placed into liquid nitrogen to be cooled, after cooling, deep cooling variable-thickness rolling is carried out, and high-performance aluminum alloy variable-thickness strip is produced. According to the process, ultra-low temperature plastic deformation is used, the strength and the toughness of the aluminum alloy are synchronously improved, at the same time, variable-thickness rolling is used, and a high-strength toughness aluminum alloy thickness difference plate capable of being directly used for car parts can be prepared.

Owner:CENT SOUTH UNIV

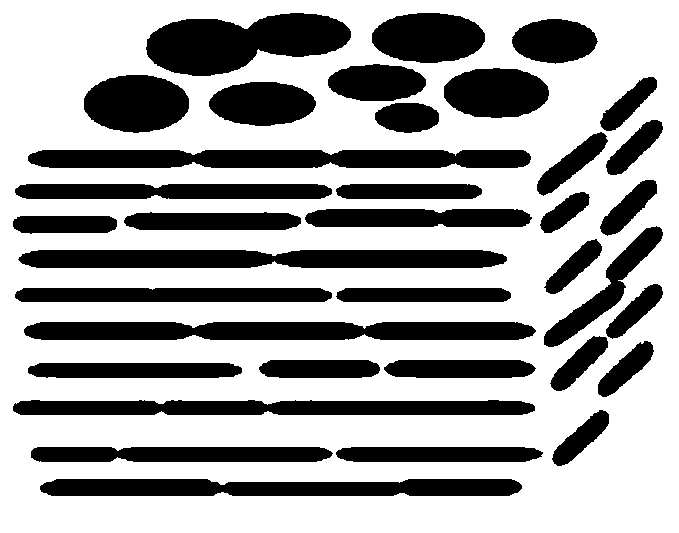

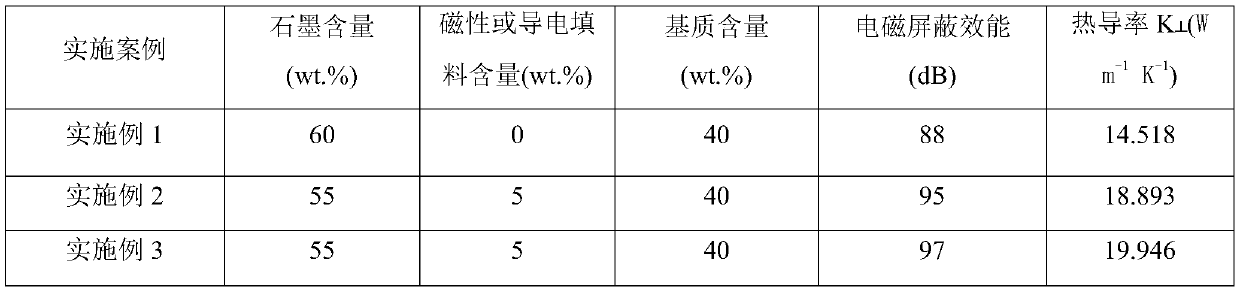

Heat-conducting electromagnetic shielding material with orientation structure and preparation method thereof

ActiveCN111267434AReduce contact resistanceEnhanced interactionMagnetic/electric field screeningSynthetic resin layered productsMagnetic shieldElectromagnetic wave interference

The invention relates to a heat-conducting electromagnetic shielding material with an orientation structure and a preparation method thereof, and particularly discloses a heat-conducting electromagnetic shielding material with a vertical orientation structure. The vertical orientation structure is a laminated sheet material, the sheet material takes a thermoplastic polymer as a matrix, and the matrix contains a filler; the filler is a combination of a heat-conducting filler and a conductive filler, a combination of the heat-conducting filler and a magnetic filler, or a combination of the heat-conducting filler, the conductive filler and the magnetic filler. Electromagnetic wave interference can be effectively reduced, the electromagnetic shielding performance of the material is remarkablyimproved, high anisotropic heat conductivity is achieved, and the purposes of high electric conductivity, high electromagnetic shielding efficiency and high heat conductivity of the composite materialare achieved.

Owner:SHENZHEN INST OF ADVANCED TECH +1

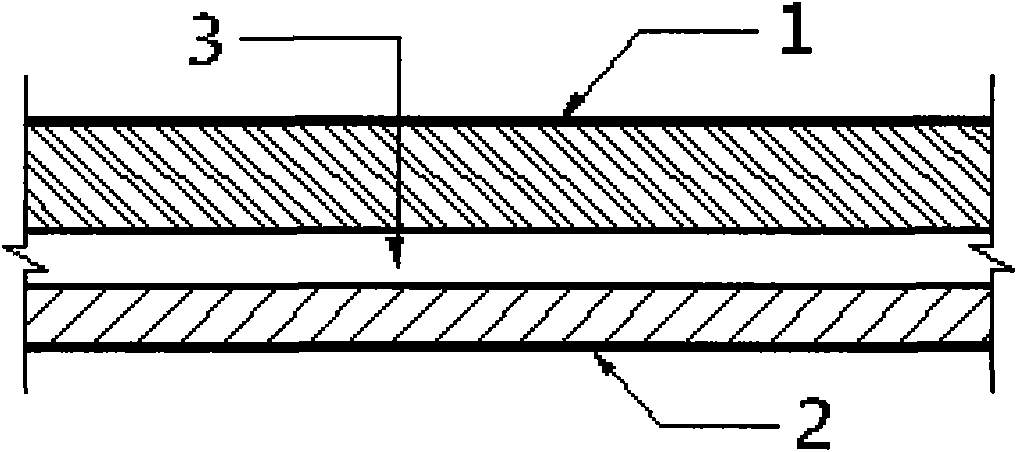

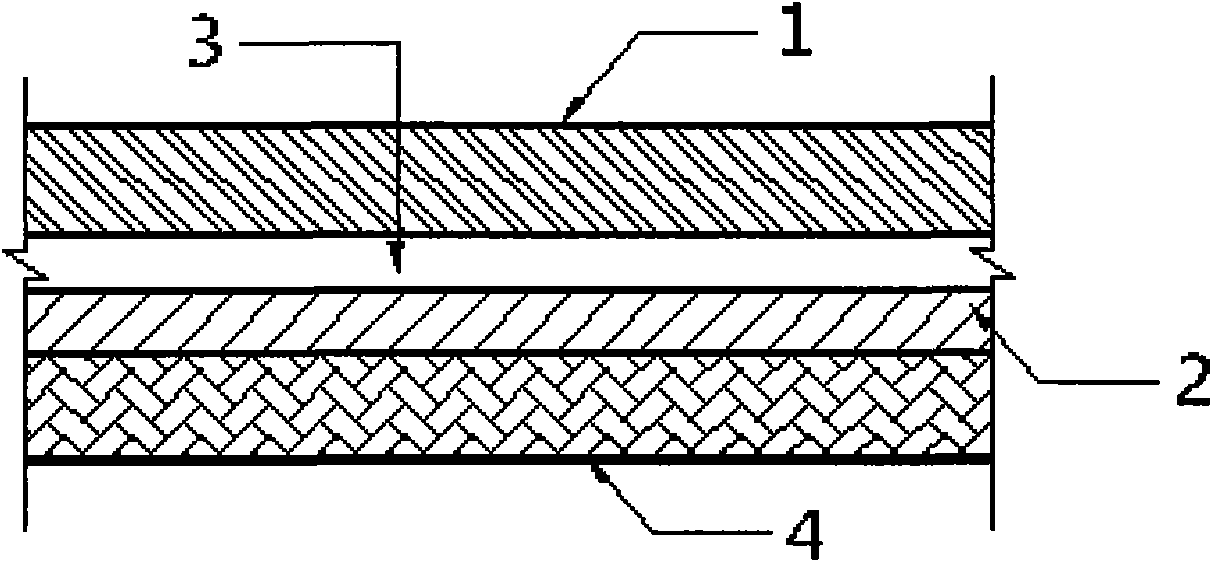

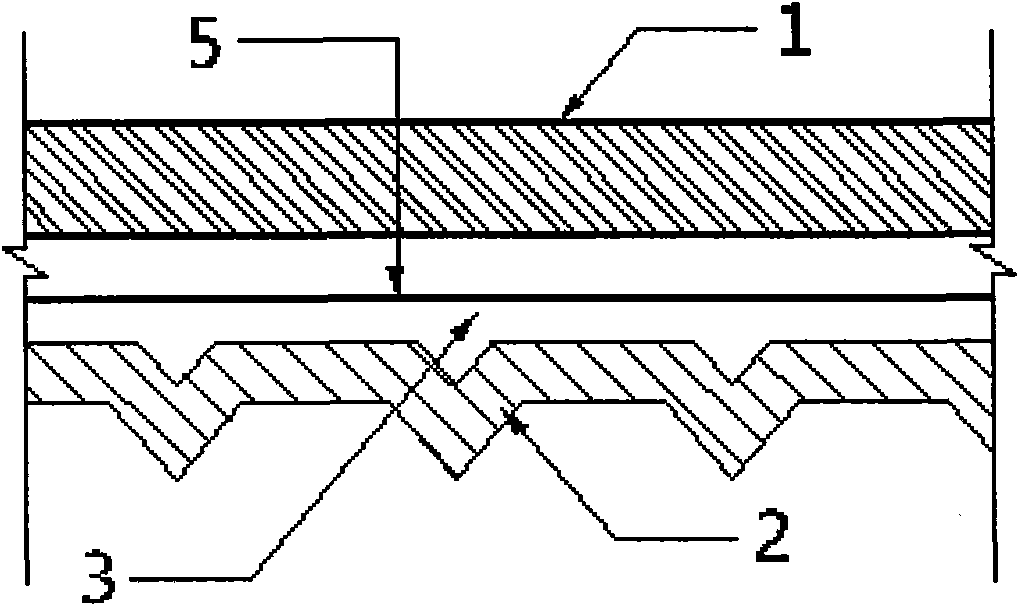

Metal-reinforced composite decorative glass plate

InactiveCN102166859ADeformation constraints are goodHigh tensile strengthSpecial ornamental structuresGlass/slag layered productsThin slabMetallic materials

The invention relates to a metal-reinforced composite decorative glass plate, wherein a glassy sheet is used as a surface layer. The decorative glass plate is convenient for cutting and punching, can be slightly cold bent when glass is relatively thin and can be conveniently fixed while decorative functions of glassy materials are maintained. The metal-reinforced composite decorative glass plate comprises a glassy sheet layer (1), a metal-reinforced layer (2) and a bonding layer (3), wherein the glassy sheet layer is bonded with the metal-reinforced layer via the bonding layer. The glassy sheet layer (1) is a sheet layer prepared from brittle glassy materials such as glass plates, tempered glass plates, glass-ceramic plates and the like. The original state of the sheet layer is in the shape of a sheet and the sheet layer is arranged by one or more sheets with the total thickness less than three millimeters. The metal-reinforced layer (2) is a structure layer prepared from metal materials which have relatively high strength and fine processing property. The metal materials mentioned above are copper, aluminum, iron, and corresponding alloy materials. And the metals can be plate-shaped, corrugated, or in the shape of engraved sheet materials, or the metals can be sheet materials which are braided or arranged in a longitudinal and a latitudinal manner, for example, copper plates, aluminium plates, aluminium alloy plates, iron plates, galvanized steel plates, steel wire sheets, stainless steel plates.

Owner:吕孟龙

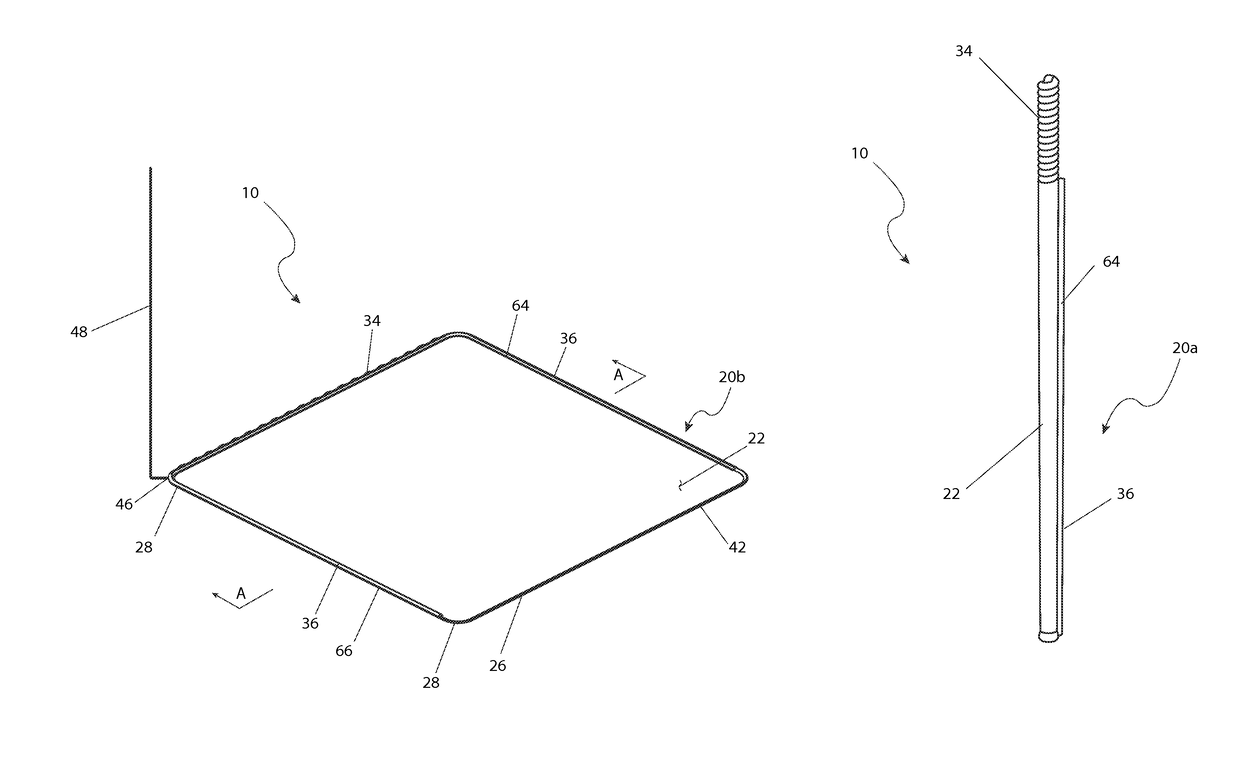

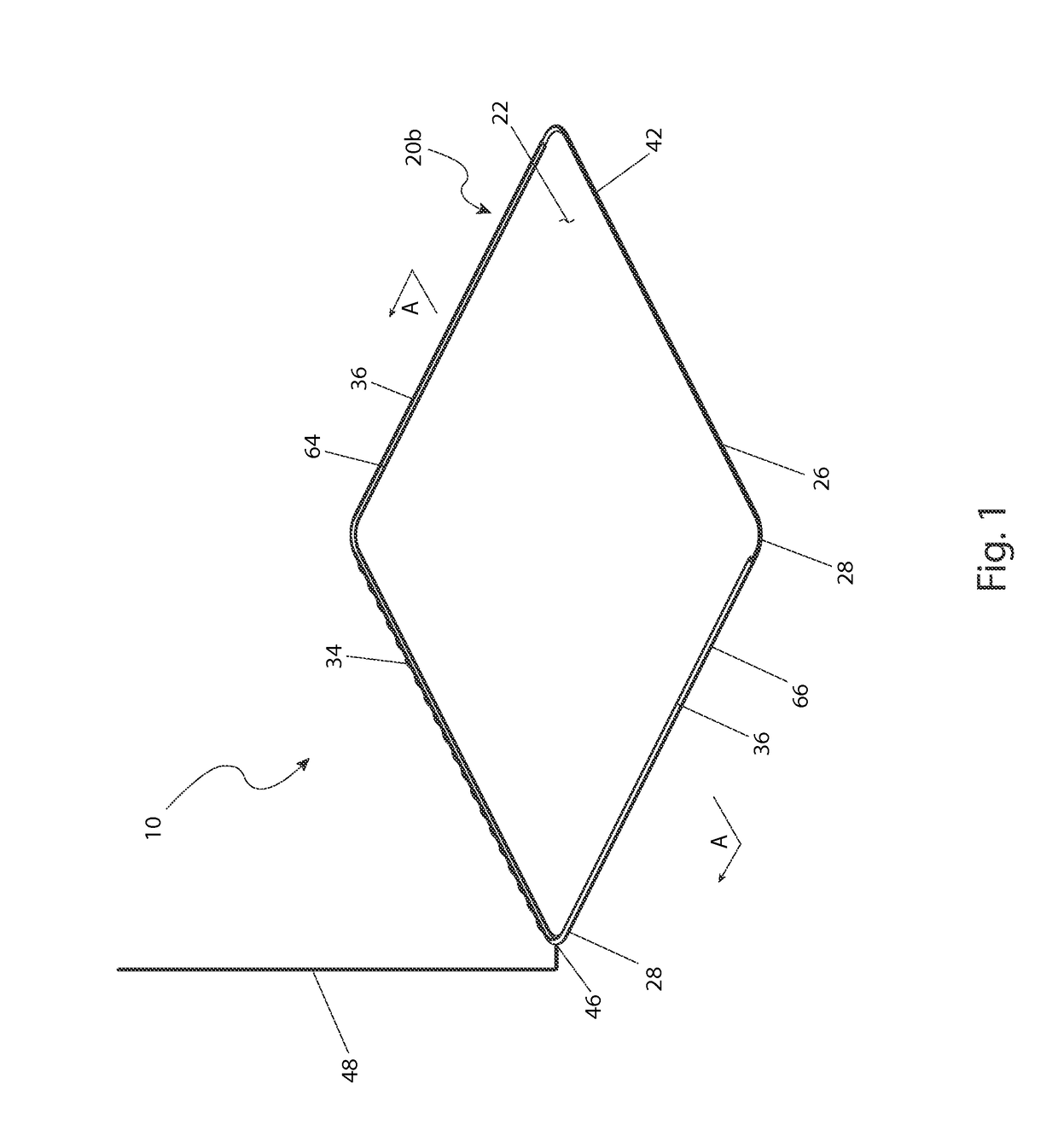

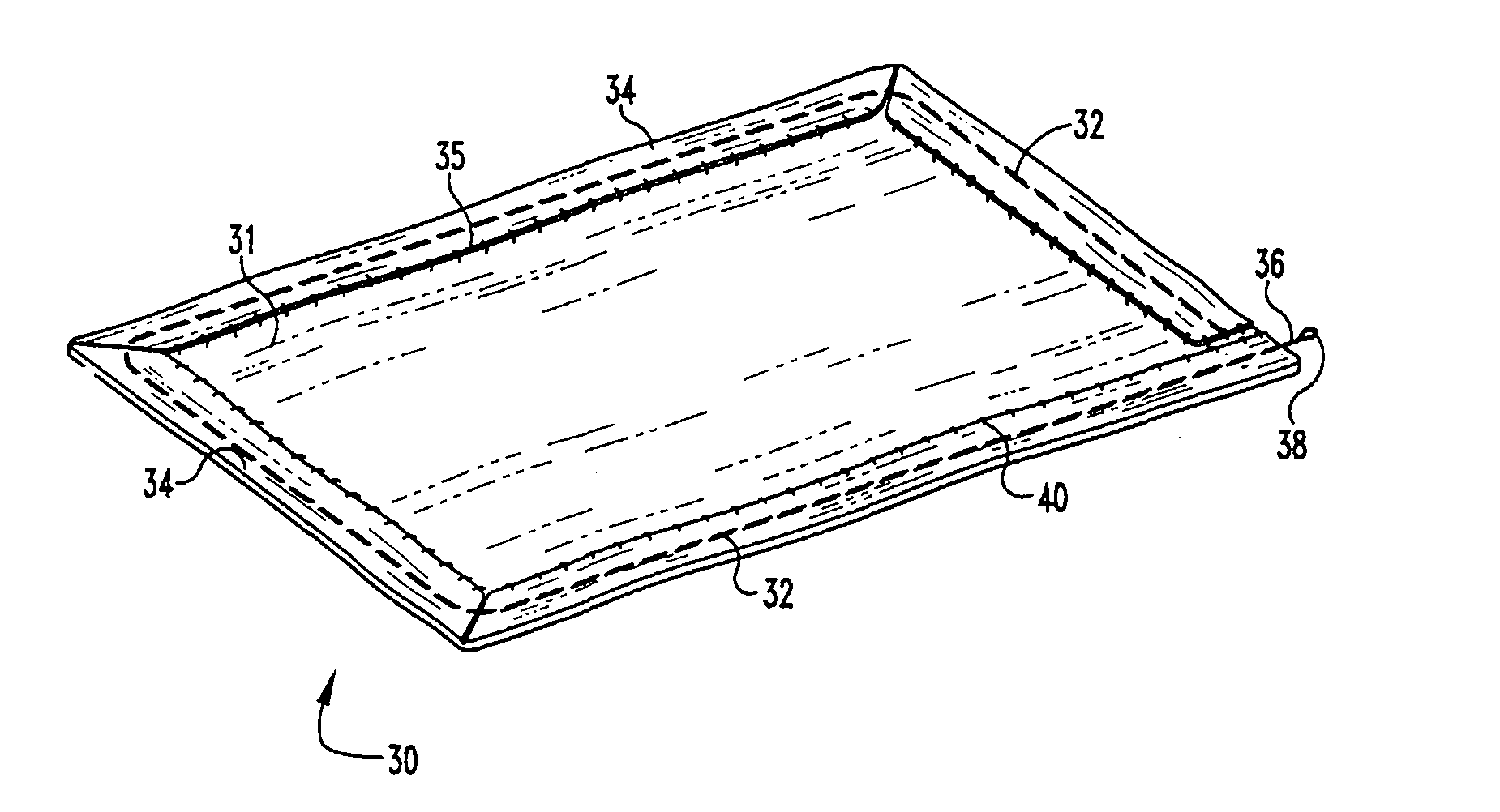

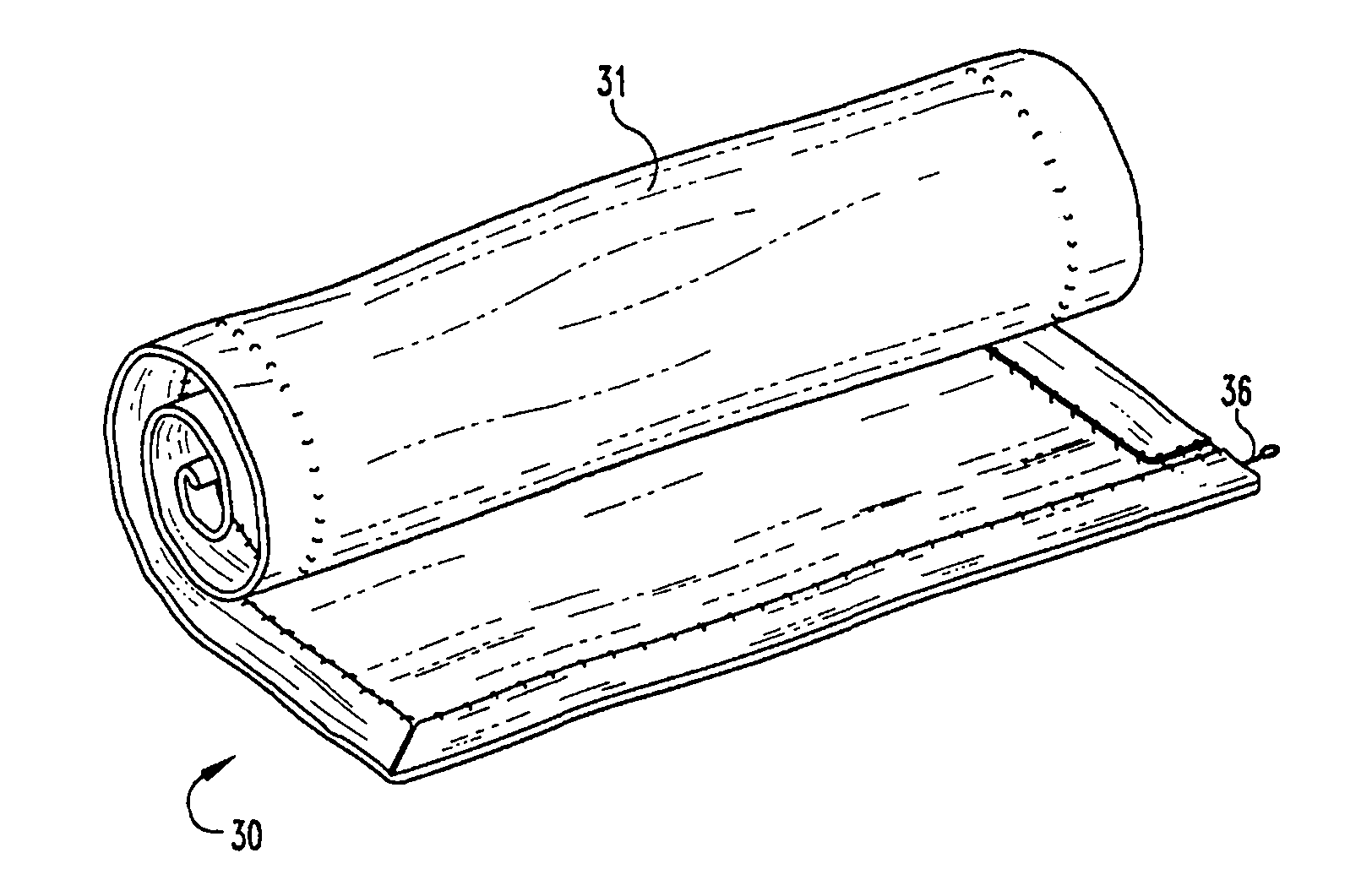

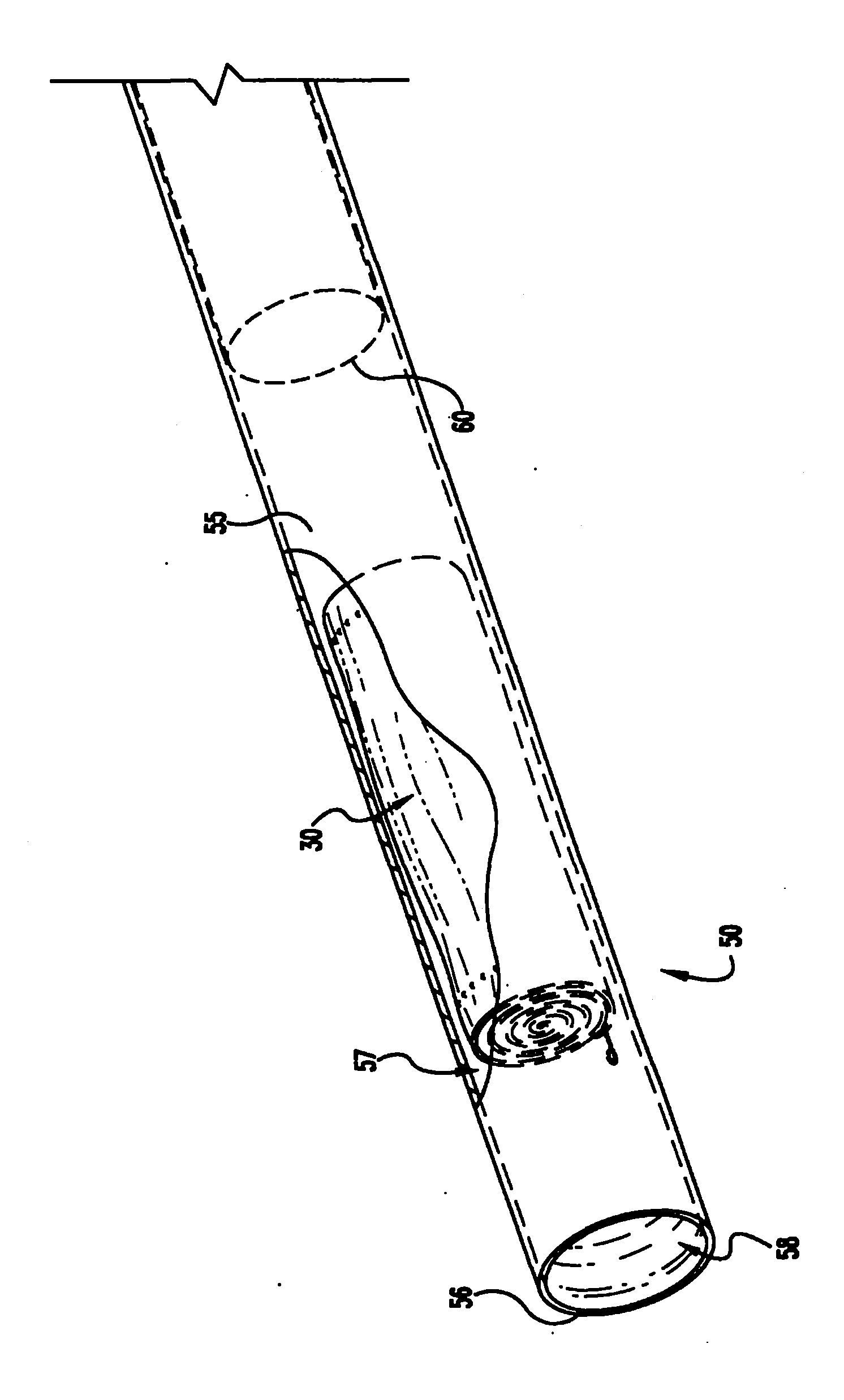

Morcellated tissue collection pouch

An apparatus for collection and removal of morcellated tissue includes a flexible sheet material including a top surface and a bottom surface. The sheet material is configurable from a roll configuration, to a substantially planar mat configuration, to a pouch configuration.

Owner:CARRIER VICKI J

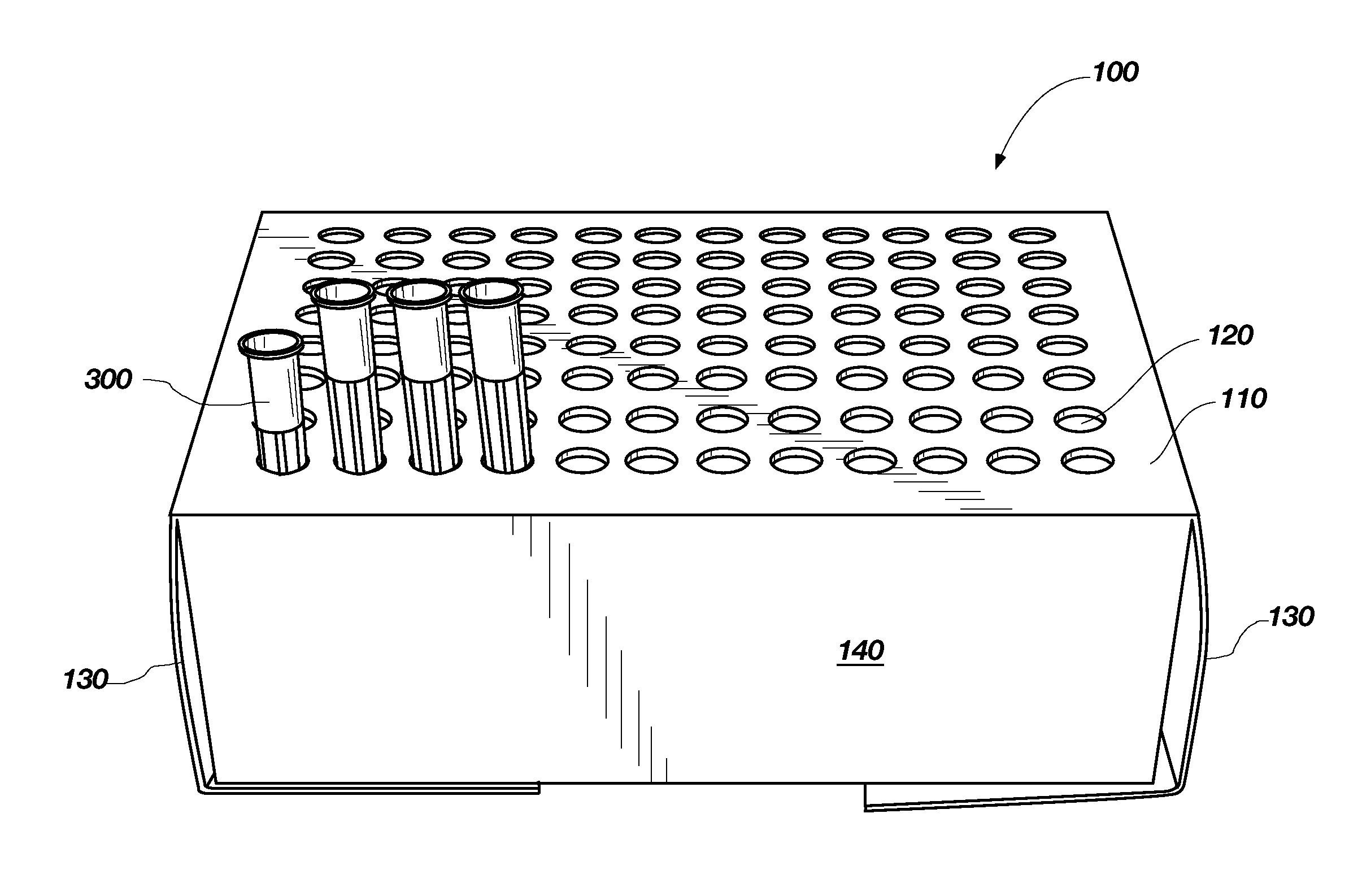

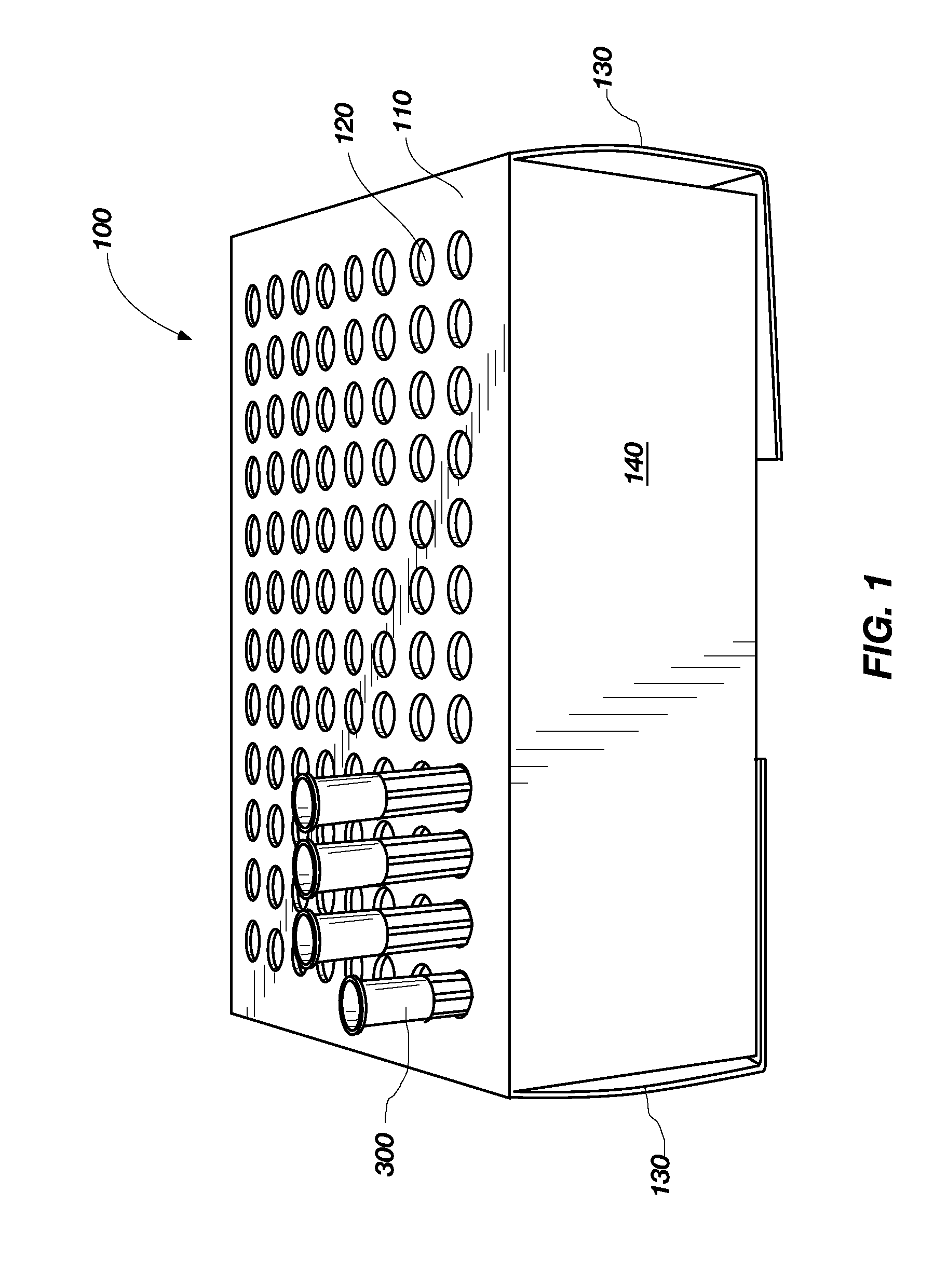

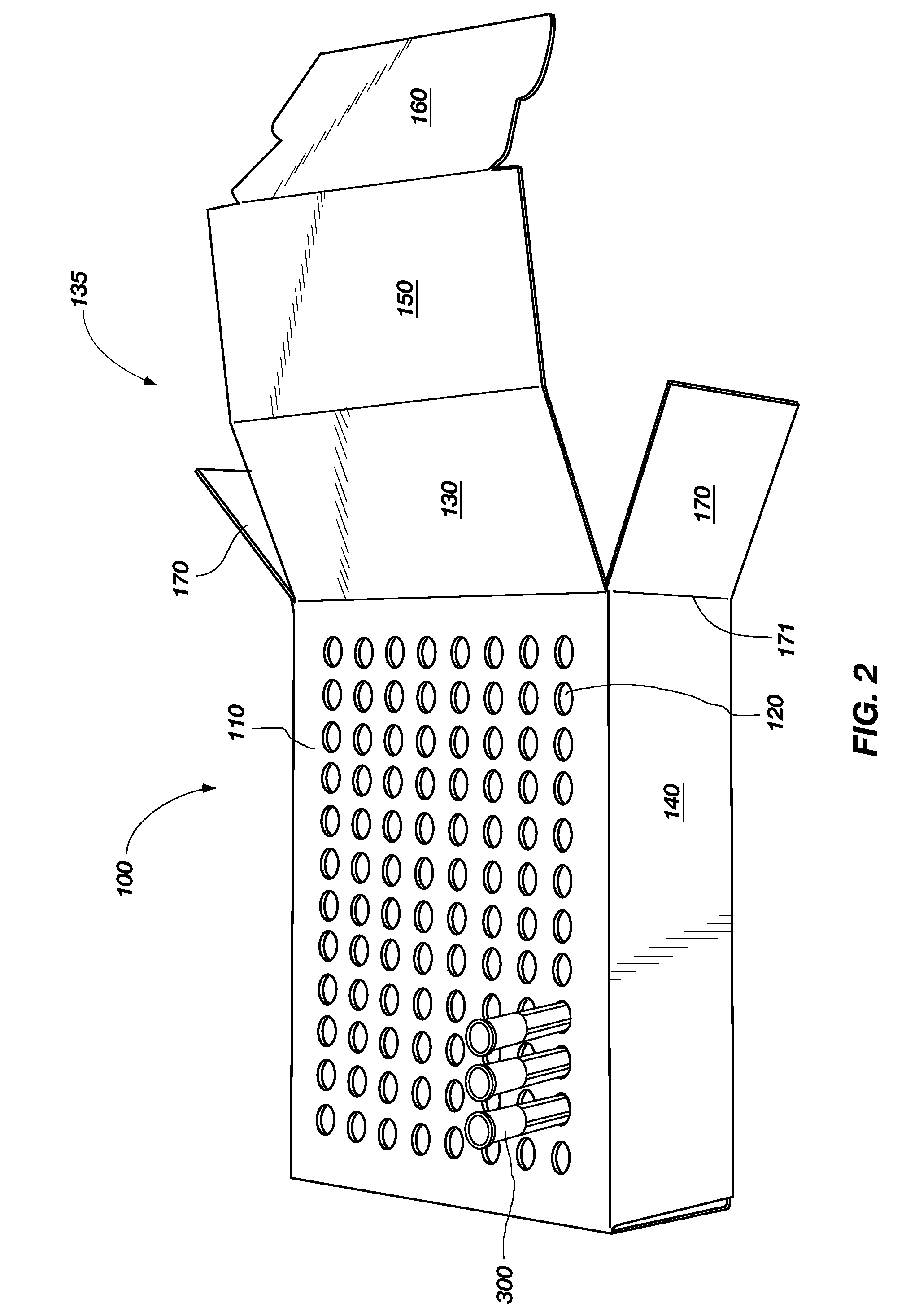

Pipette tip rack and associated methods

InactiveUS20100166616A1Sufficiently robustSufficient resistanceAnalysis using chemical indicatorsBio-packagingTest tubeTime frame

Described is a pipette tip rack (100) and methods of making the same. The pipette tip rack is constructed of biodegradable material so that it can be disposed of in a landfill without significant environmental impact. The rack may be structured from folded sheet material, generally in the manner of a cardboard box, such that it is sufficiently rigid for practical use in pipetting procedures. The rack may be fashioned in various other configurations, such as any of the known arrangements used to hold test tubes or pipettes (300) in a specified orientation. The tip racks are sufficiently robust to withstand the loads inherently encountered as a pipette probe engages tips stored in them and are biodegradable within a practical time frame. Pipette tip racks of the type conventionally constructed and arranged to hold a plurality of pipette tips in a specified arrangement for engagement by a probe is improved by constructing the rack from a biodegradable material selected and configured to resist forces applied by that probe during a tip-mounting operation.

Owner:PRICE WEST L

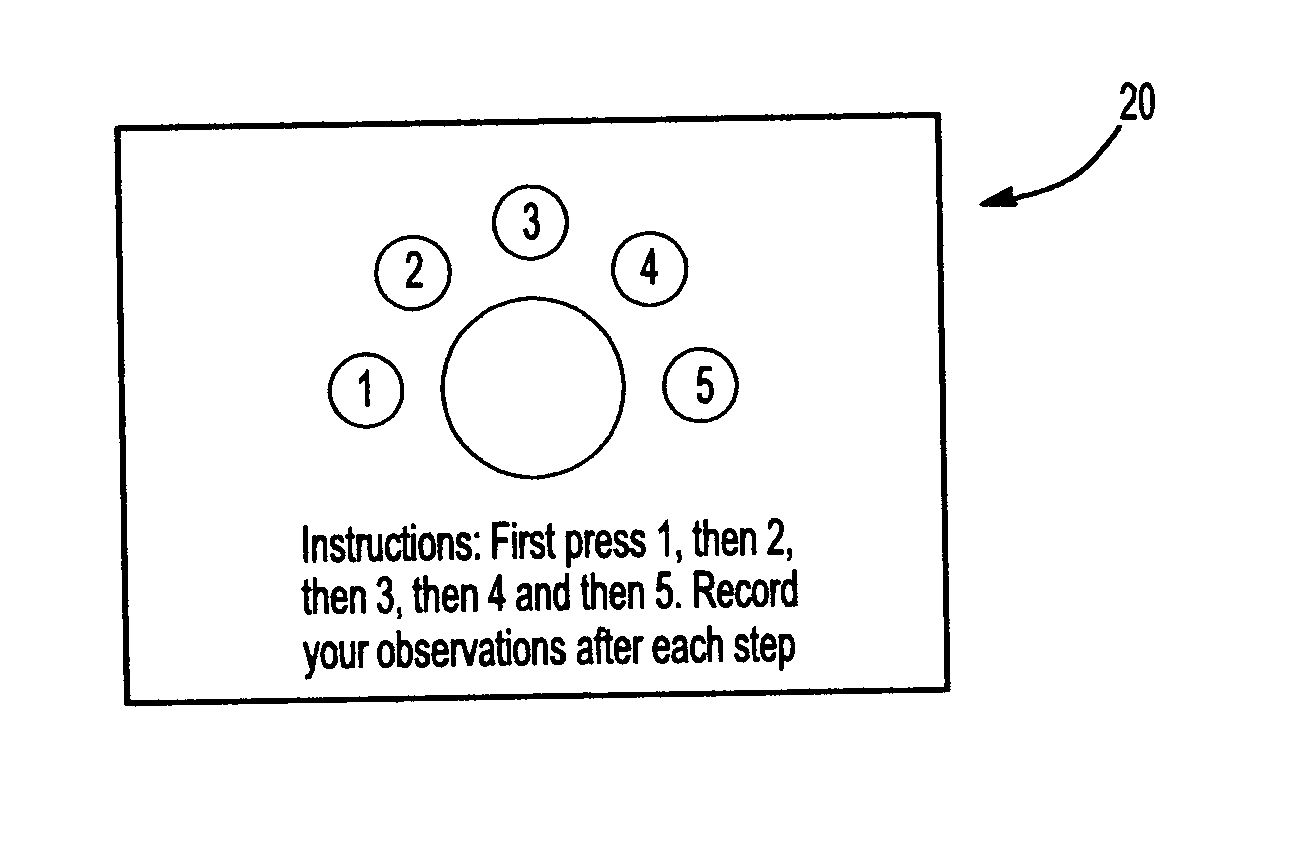

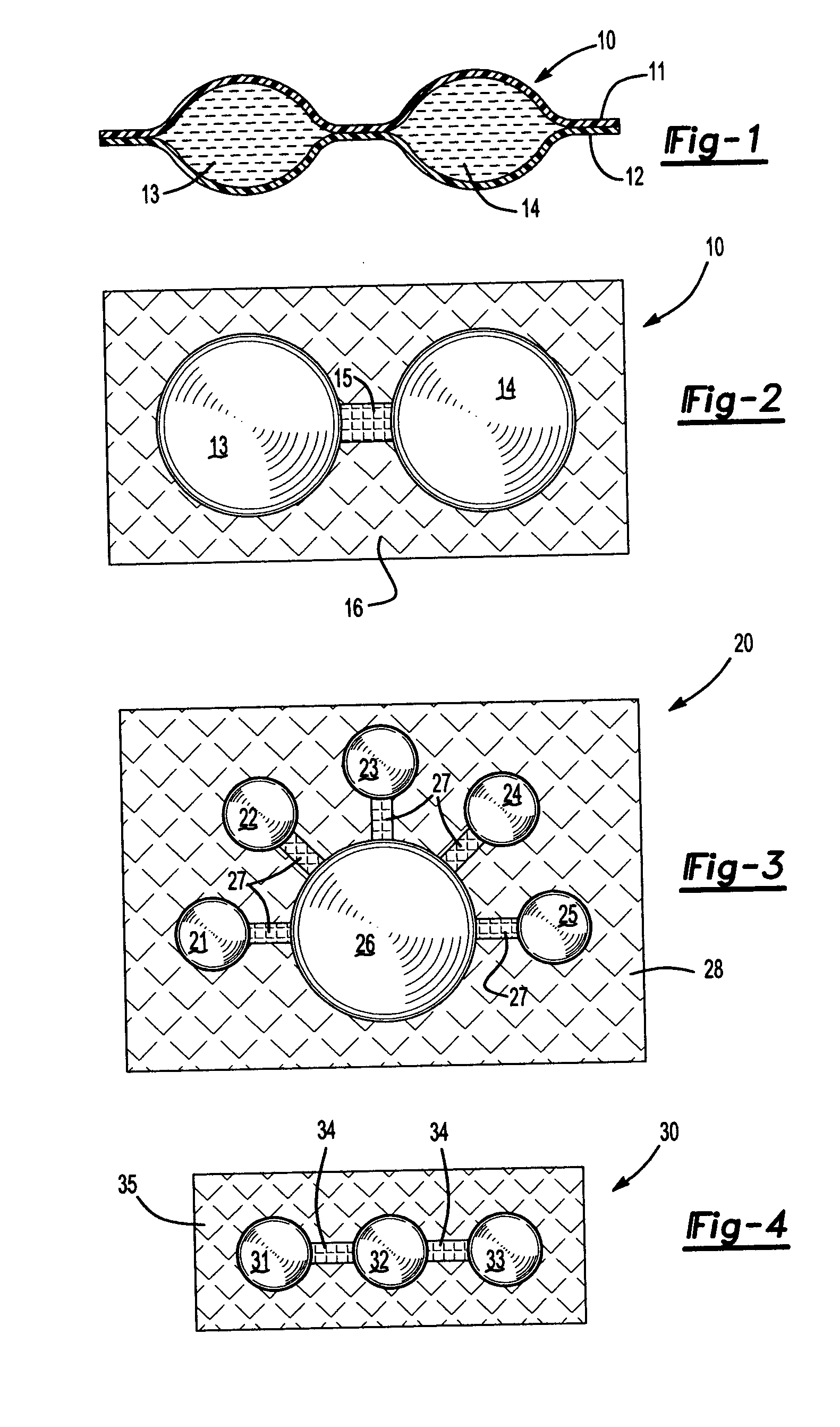

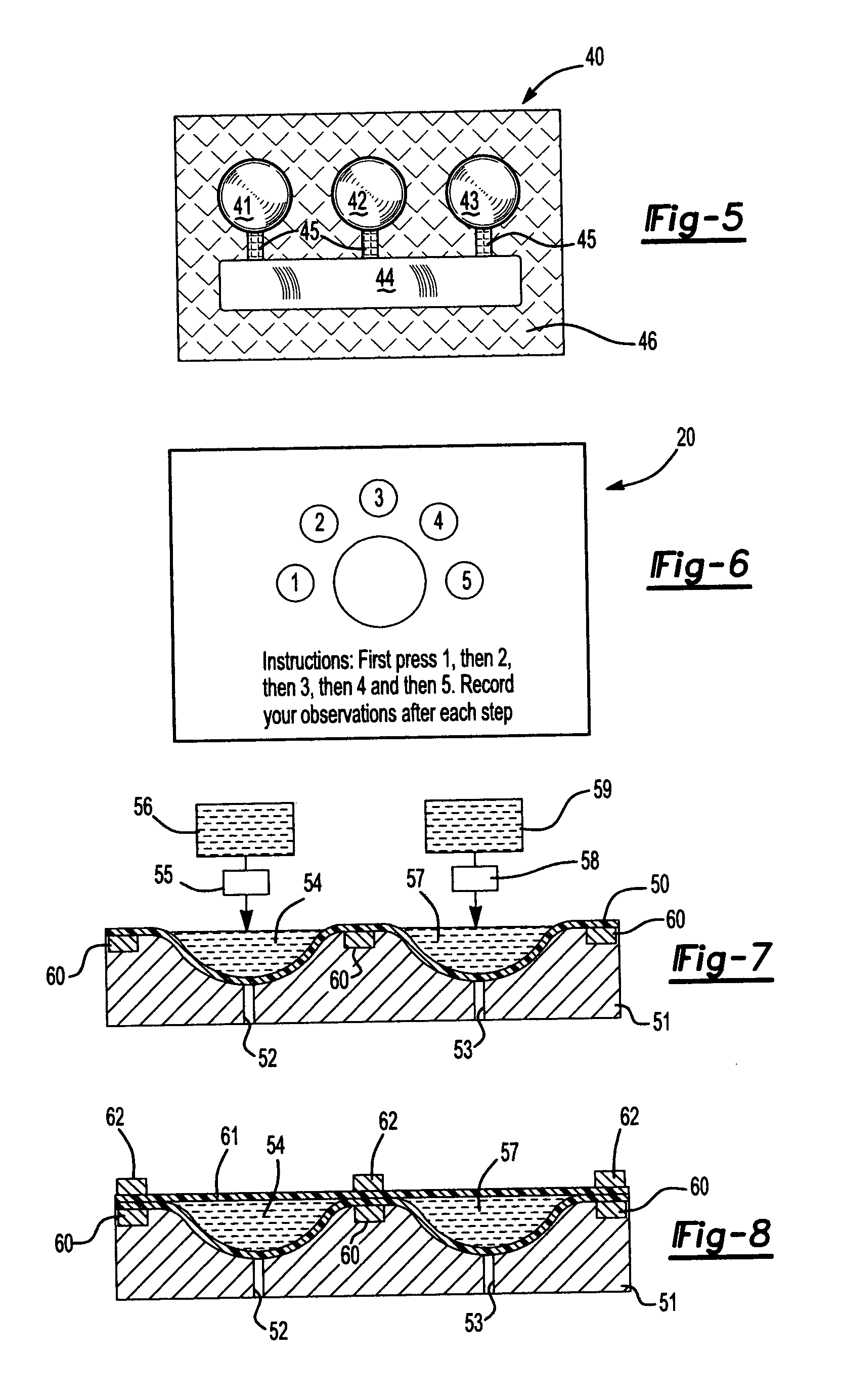

Method for students to carry out chemical reactions

An improved method for students to carry out and observe chemical reactions by mixing a fluid reactant with a reactive component to produce a reaction product. The improvement is the provision of a package fabricated of upper and lower sheet material defining at least a first closed chamber containing a first fluid reactant and an adjacent second closed chamber containing a reactive component, the package formed by sealing the upper sheet material to the lower sheet material at the periphery of the chambers so that when the first chamber is pressed, then the first fluid reactant will break the seal between the first and second chambers and flow into the second chamber to react with the reactive component in the second chamber to produce an observable reaction product or condition. For example, the fluid reagent can be a dilute aqueous solution of sodium chloride and the reactive component can be a dilute aqueous solution of silver nitrate, the silver nitrate reacting with the sodium chloride to form silver chloride precipitate which is easily observed by the student through the flexible sheet material.

Owner:CENTRAL MICHIGAN UNIVERSITY

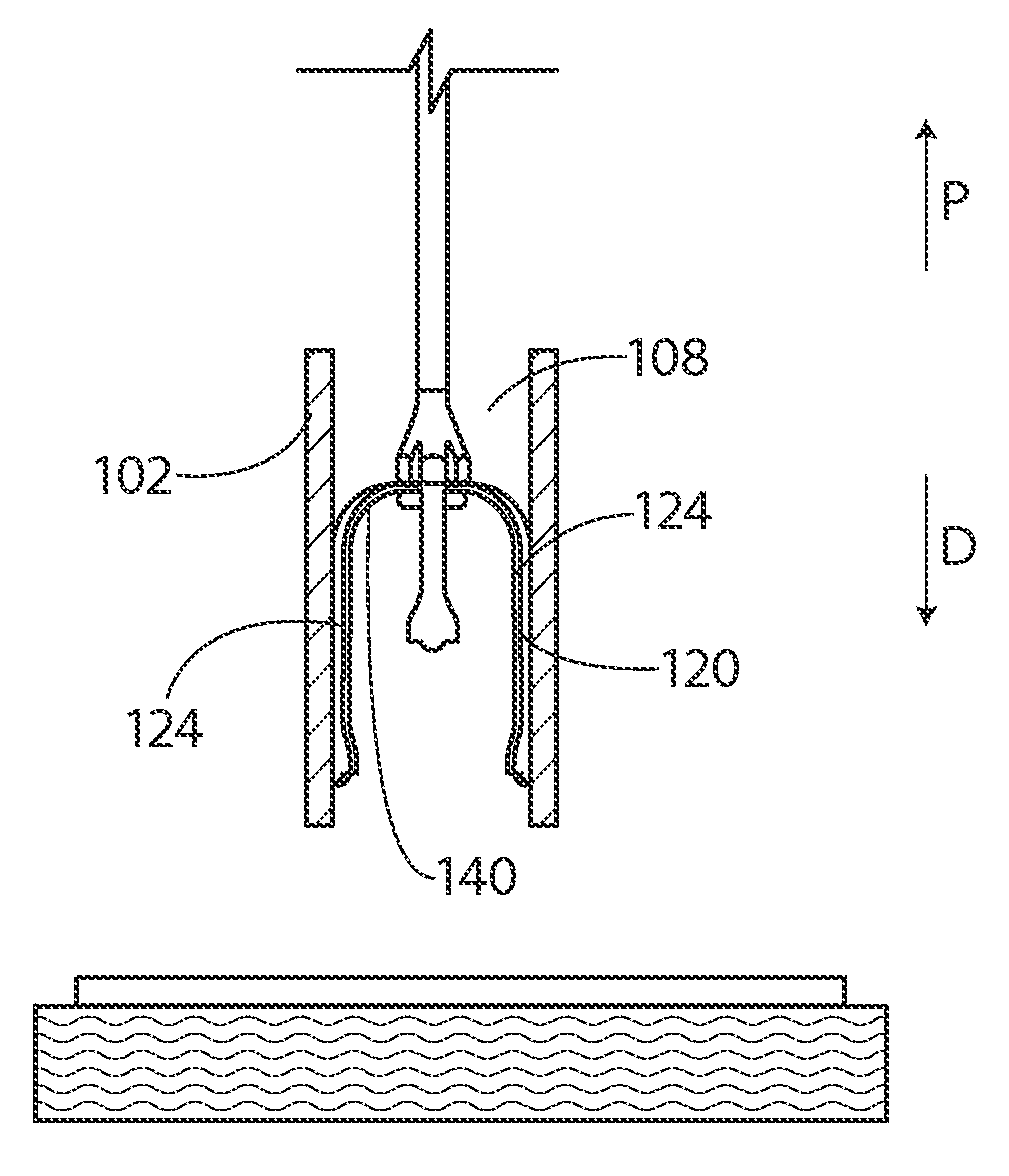

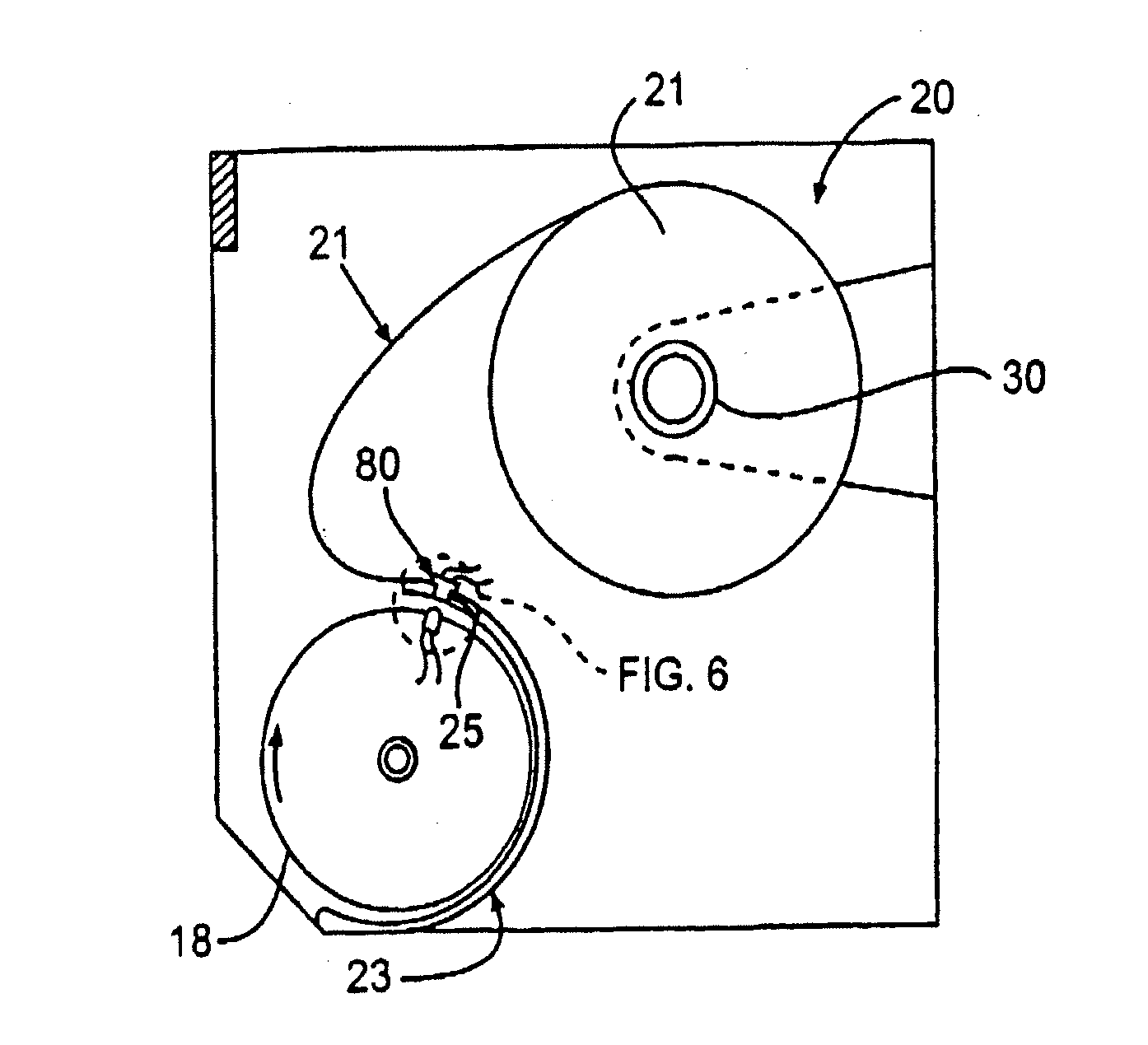

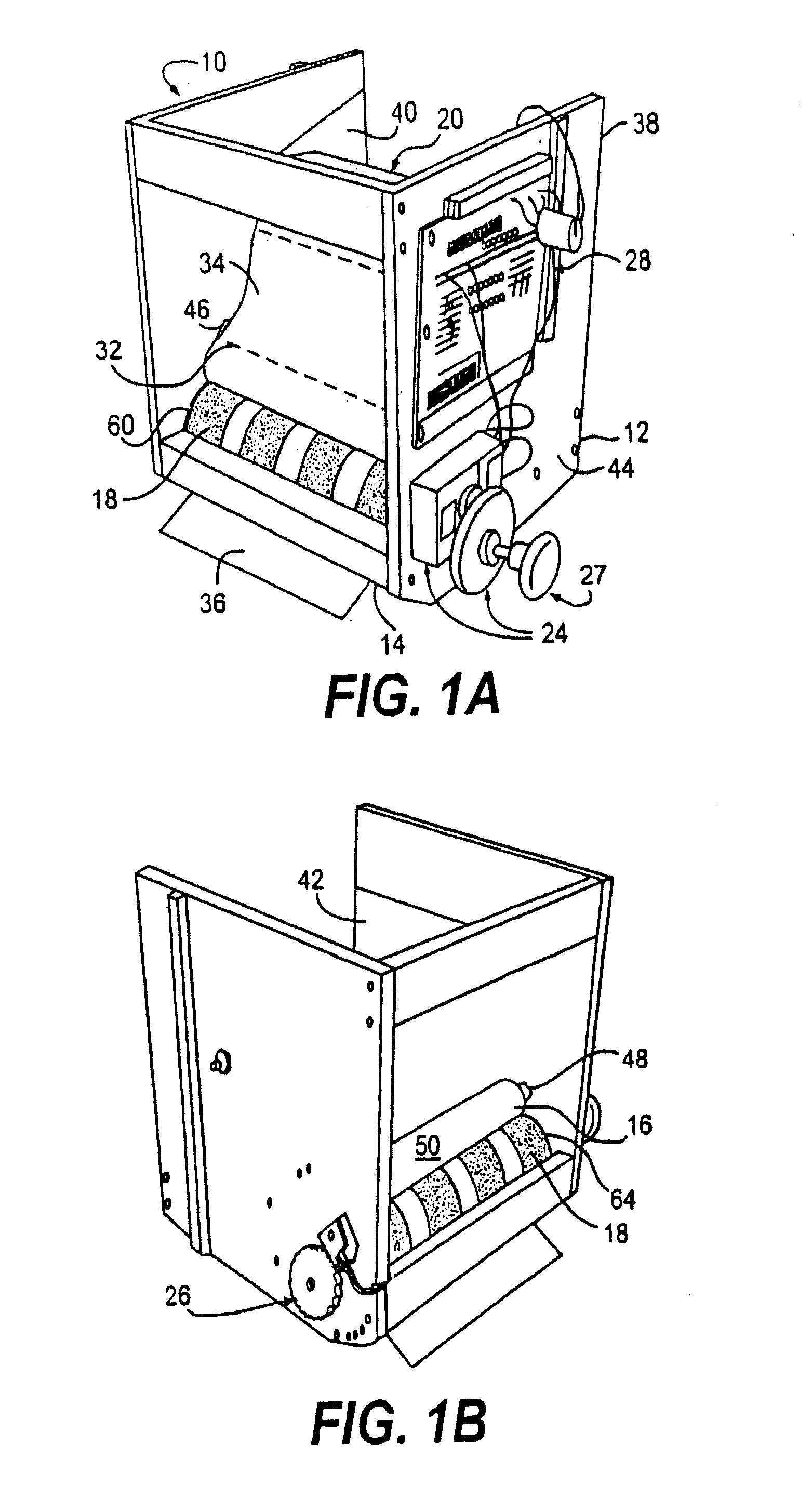

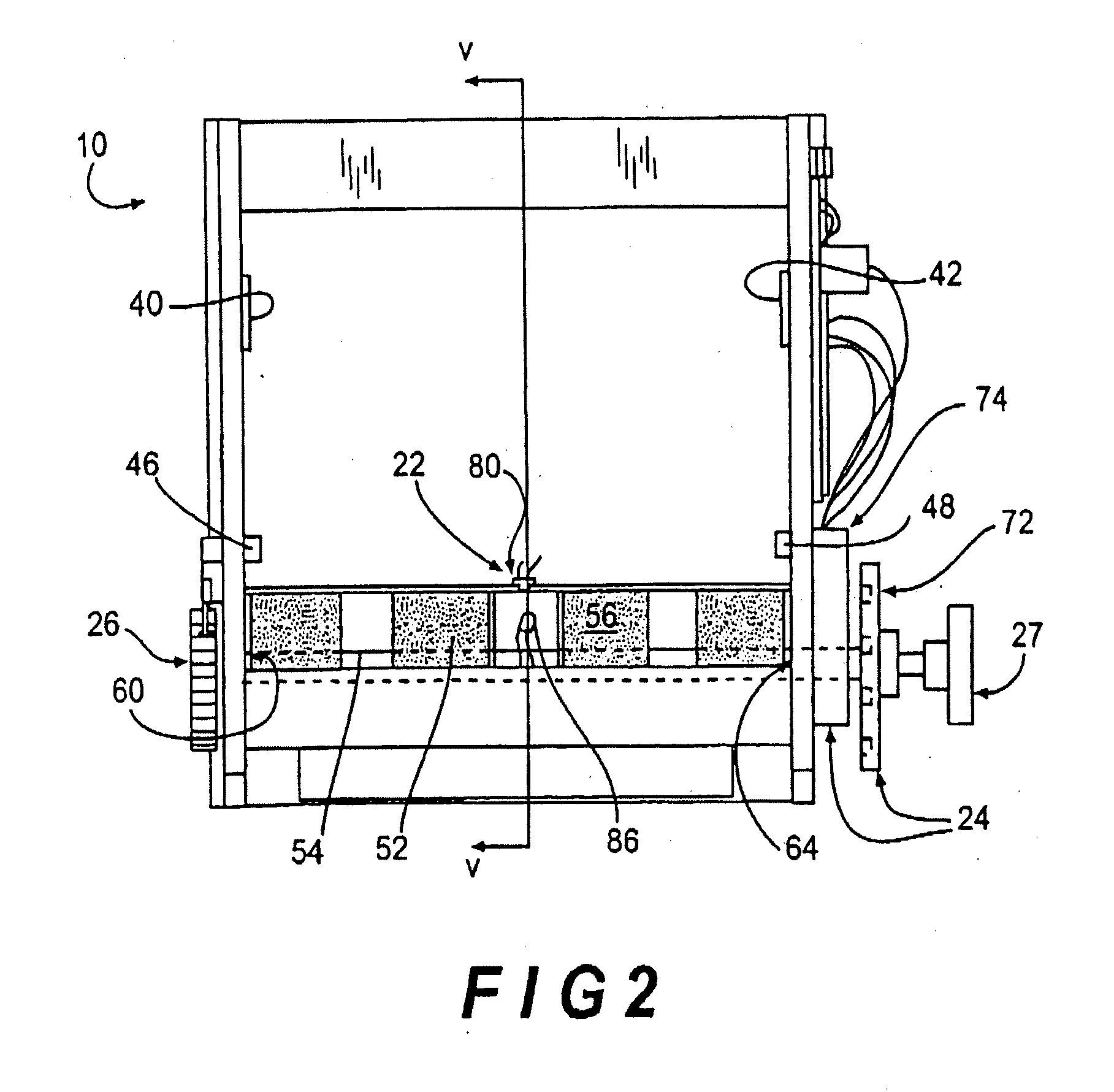

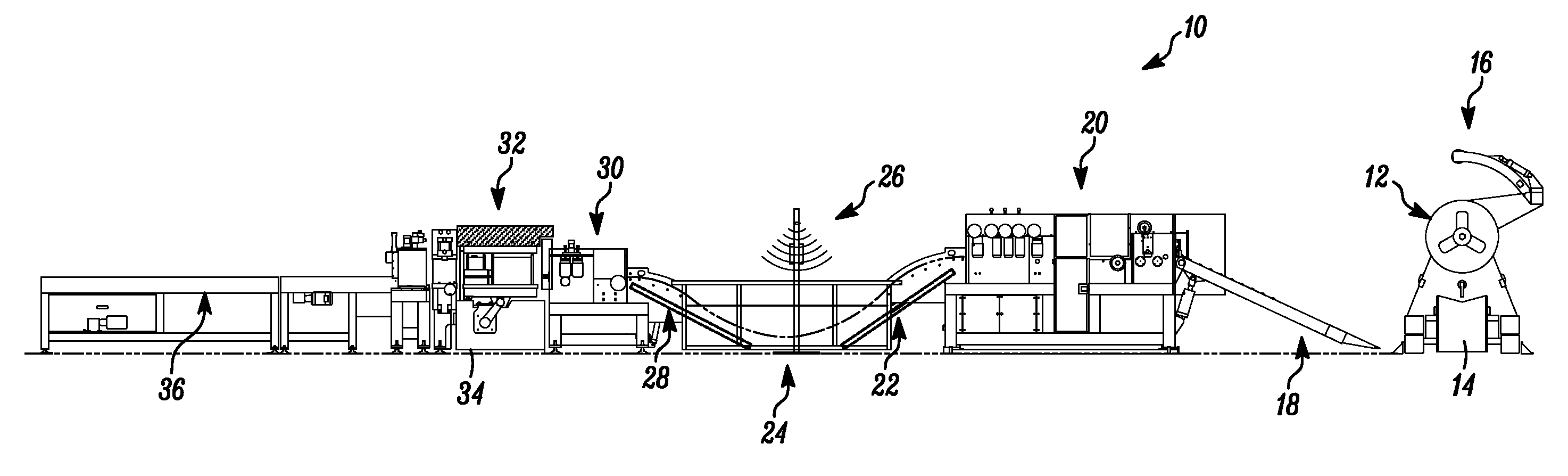

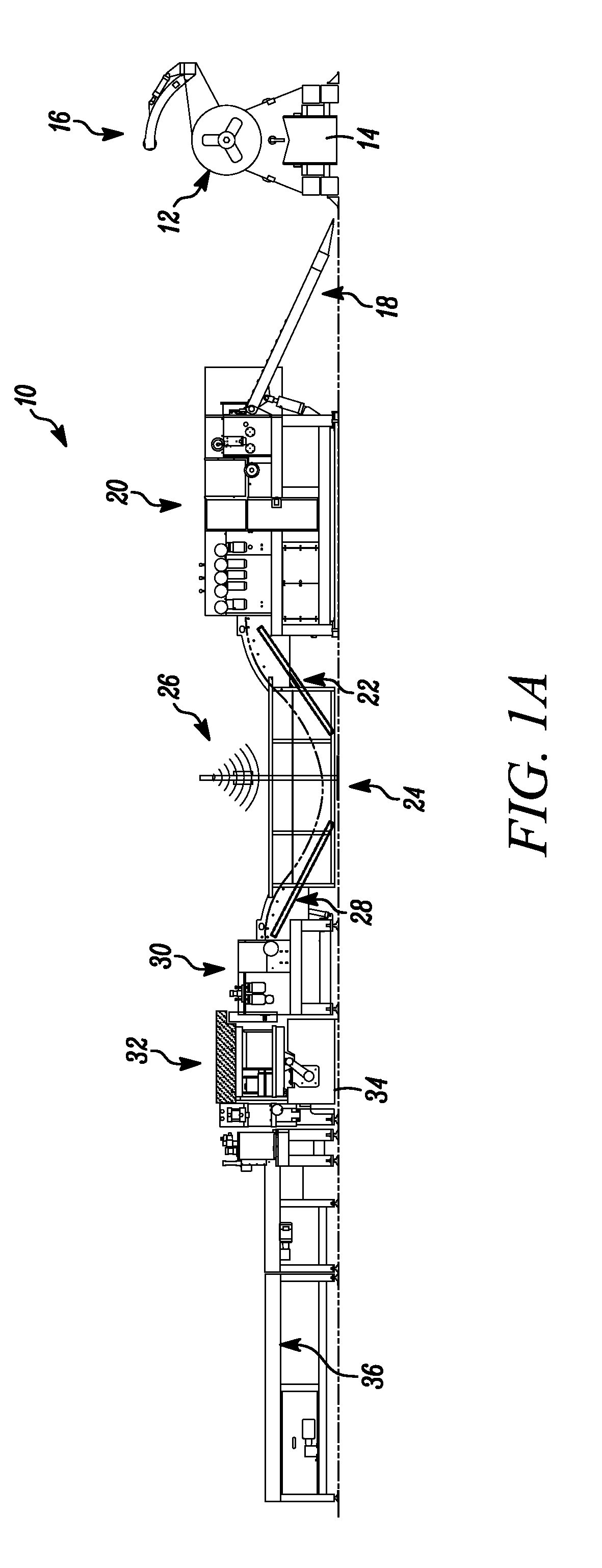

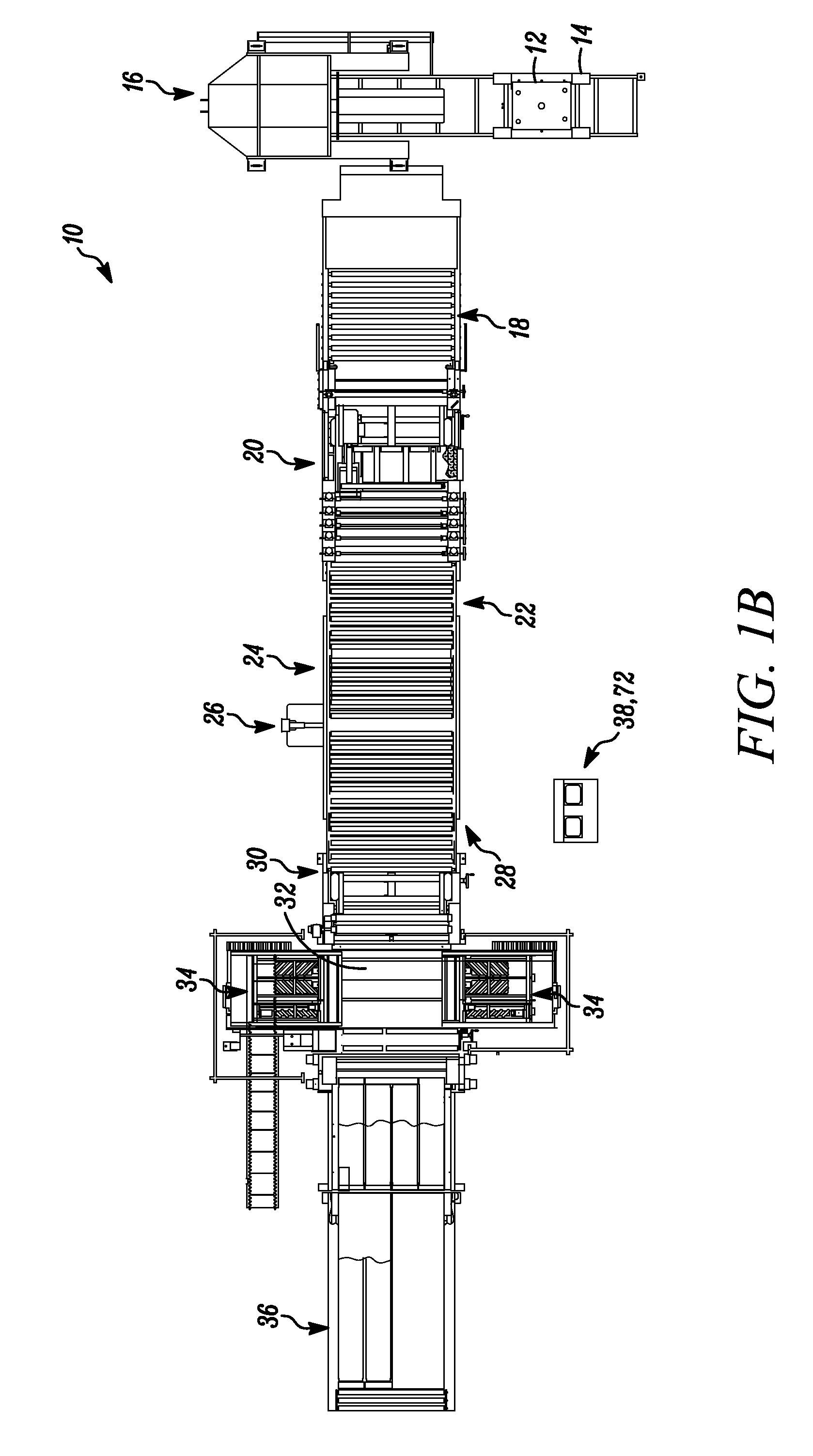

Apparatus and method for processing coiled sheet-like material

InactiveUS20090224021A1Easy to relaxReduce accumulationMetal-working feeding devicesFunction indicatorsPunchingEngineering

A coil processor is provided for performing processing operations on coiled sheet-like material, such as sheet metal, plastics or other materials. The coil processor uncoils and straightens the material before performing desired operations on the material and transferring it for packaging, shipping or further processing. Various features improve the overall efficiency of the coil processor, including its ability to move material forward and backward through the unit without slowing down the overall operation, as well as the versatility of its mobile tool carriers, which can perform multiple complex processing applications, including cutting, punching, stamping, bending or others. Additionally, processing efficiency may be further enhanced by the use of a computer, which determines the most efficient sequence for performing processing operations, and controls the coil processor's various features to process material in that sequence.

Owner:FORMTEK

Hernia patch with removable resilient element

The present invention provides, in certain aspects, grafting devices deliverable into the body for repairing defects in bodily structure walls. One such grafting device comprises a compliant sheet-form material, and a removable resilient element that is retained in association with the sheet-form material. In some forms, the resilient element is adapted for delivery in its entirety into the body, and thereafter, can be disassociated from the sheet-form material for removal from the body. The sheet- form material may be formed with one or more of a variety of biocompatible materials including some that are naturally derived and some that are non-naturally derived. Illustratively, the sheet-form material may be comprised of a remodelable, angiogenic material, for example, a remodelable extracellular matrix (ECM) material. In additional embodiments, the invention provides methods and apparatuses for delivering these and other inventive grafting device into the body.

Owner:COOK INC

Guide roller with flanges for a dispenser

ActiveUS7222816B2Reliable distributionProjector film strip handlingCamera film strip handlingEngineeringFlange

An apparatus adapted for use with a dispenser housing for rolled sheet material to provide reliable dispensing of sheet material therefrom is provided. The apparatus is adapted for a dispenser housing which includes a roll support configured to hold at least one cylindrical roll of sheet material and a dispensing assembly. The dispensing assembly includes an exit port to permit sheet material to be withdrawn therefrom. The cylindrical roll of sheet material is desirably mounted on a portion of the roll support. The roll includes opposing flat surfaces and an outer circumference, the apparatus comprises a guide roller including an elongated central portion positioned between two opposing ends and a flange positioned near each end of the guide roller. The central portion is configured to be positioned adjacent the outer circumference of a roll of sheet material when the roll is a new roll disposed in the dispenser housing. At least a portion of an inner surface of each flange is positioned adjacent a flat surface of the roll of sheet material when the roll is a new roll. The guide roller is positioned such that sheet material flows from the roll between the flanges and over the central portion of the guide roller to the dispensing assembly. The flow of sheet material is aligned on its path to the dispensing assembly such that bunching and jamming of non-aligned sheet material is eliminated. A system is provided as well.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Methods and Apparatus for Transport of Objects

InactiveUS20130168933A1Easy to transportCarriage/perambulator with single axisSledgesFlat glassMetal sheet

A apparatus and method for transporting oversized objects, particularly substantially flat or planar objects. In certain embodiments the object is a material in sheet form, such as a wood sheet, metal sheet, dry wall, and the like, or a narrow object such as bed mattresses, tabletops, mirrors and plate glass, doors and the like. Preferably the object is capable of being transported by a single person. In certain embodiments the apparatus is structured to be capable of transporting a mattress through an open doorway without unloading the object.

Owner:WATZKE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com