Apparatus and method for processing coiled sheet-like material

a technology of apparatus and material, applied in the field of apparatus and methods for processing coils of sheet-like materials, can solve the problems of reducing the efficiency of processing or production, affecting the production rate of processed end products, and affecting the quality of finished products, so as to achieve the effect of accumulating slack in the material during processing operations and completing processing operations more quickly and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

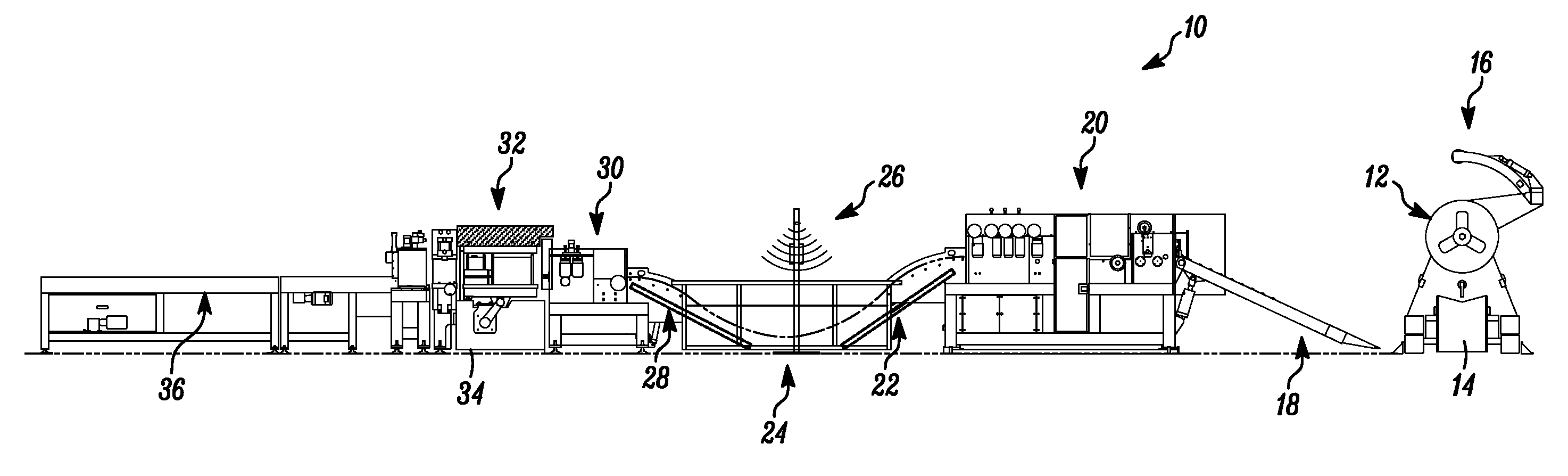

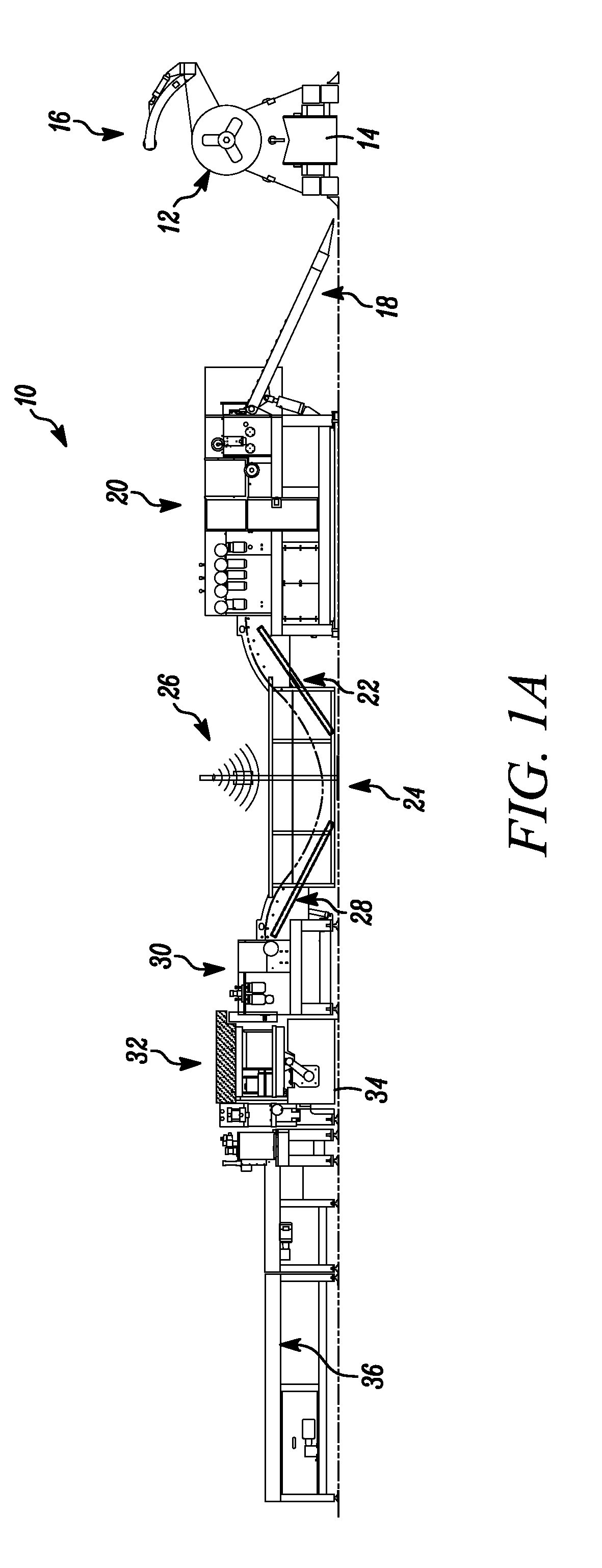

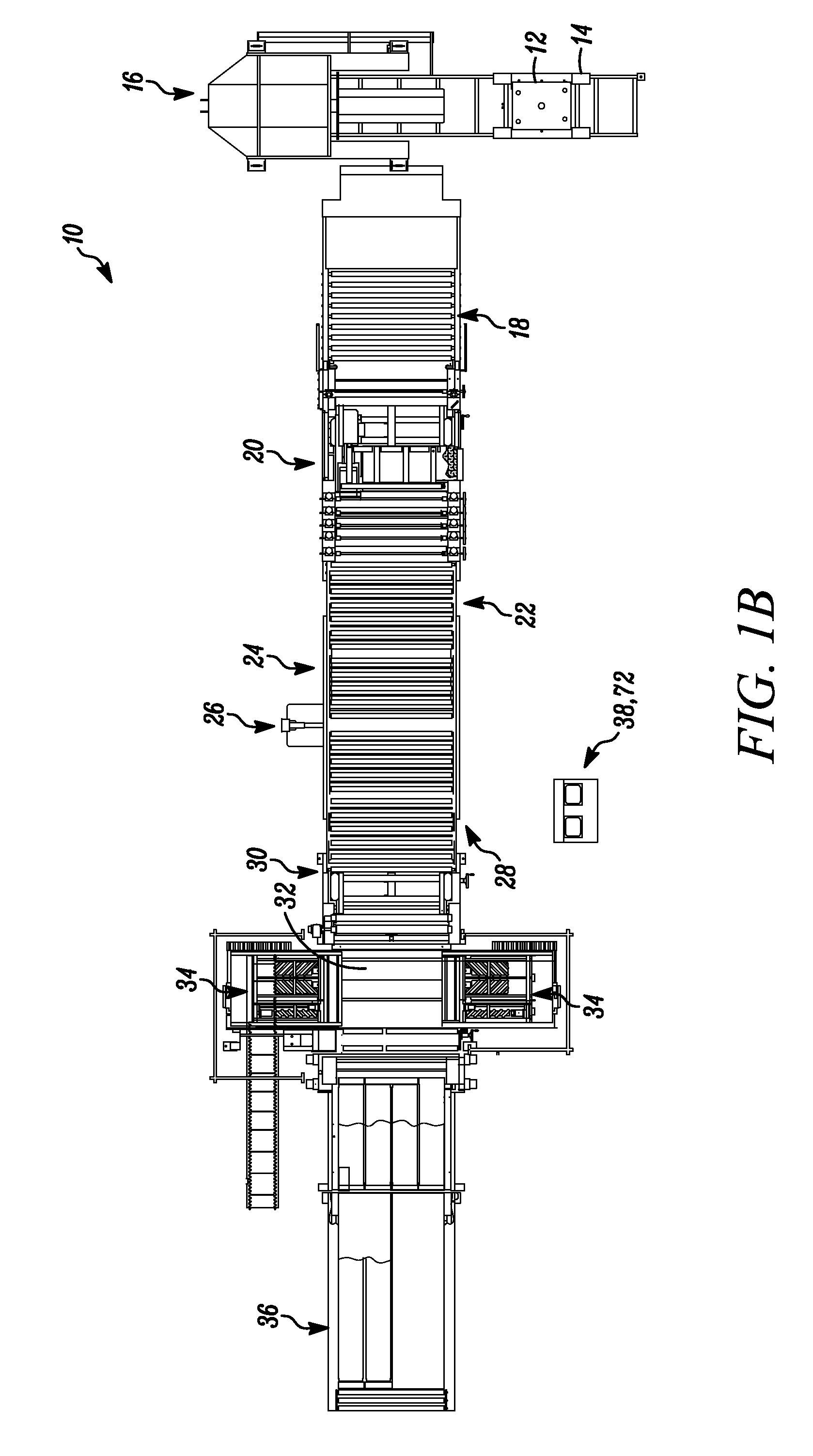

[0029]In FIGS. 1-6 a coil processor embodying the present invention is indicated generally by the reference numeral 10. The apparatus 10 comprises a plurality of components in series. A coil 12 containing coiled sheet-like material is positioned within an uncoiler assembly 16, which permits the coiled material to rotate and feed therefrom in a longitudinal or x-coordinate first direction toward a straightener 20, which is positioned to straighten the sheet-like material after it is unrolled from the uncoiler assembly 16. The straightened material leaving the straightener 20 is then fed in the x-coordinate direction to a conveyor unit 30, which translates the material either forward or backward in the x-coordinate direction. Material leaving the conveyor unit 30 enters into the processing unit 32, which includes at least one tool carrier 34, and undergoes the desired processing operation(s) within the processing unit 32. The processed material may then be prepared for storage, shippi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com