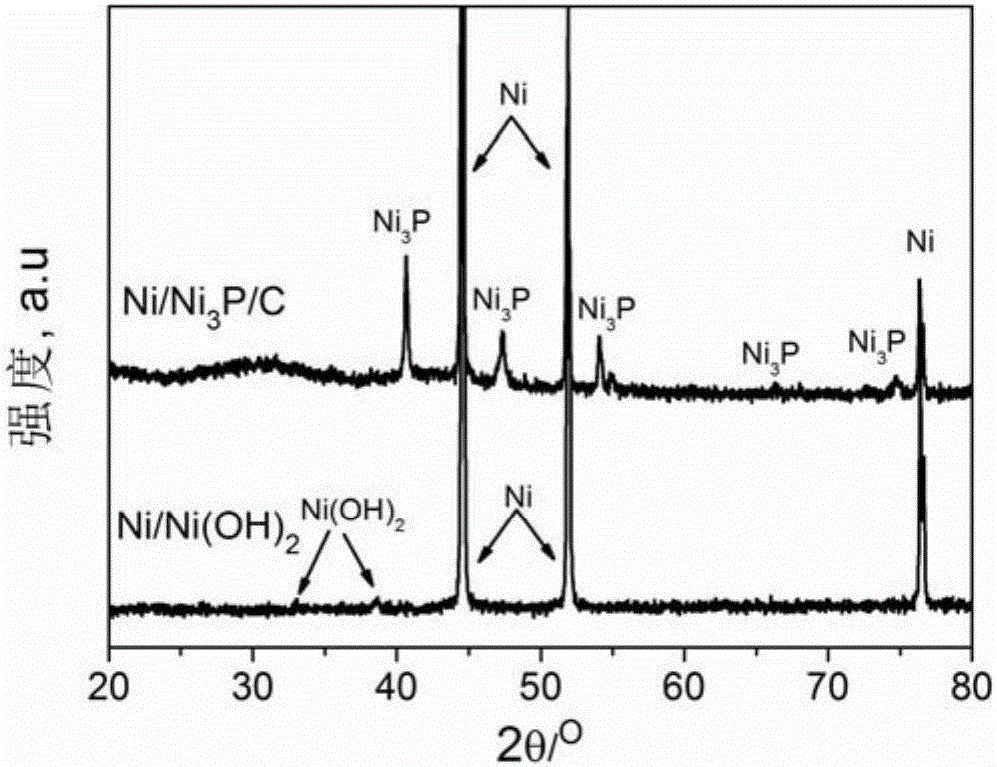

Foamed nickel self-supported flake-shaped Ni3P/C composite material for sodium ion battery negative electrode and preparation method for composite material

A sodium-ion battery and composite material technology, which is applied to battery electrodes, negative electrodes, active material electrodes, etc., can solve the problems of low electronic conductivity of nickel phosphide, affecting rate performance, and unstable structure, and achieves a simple and feasible preparation method. , the effect of high specific capacity and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

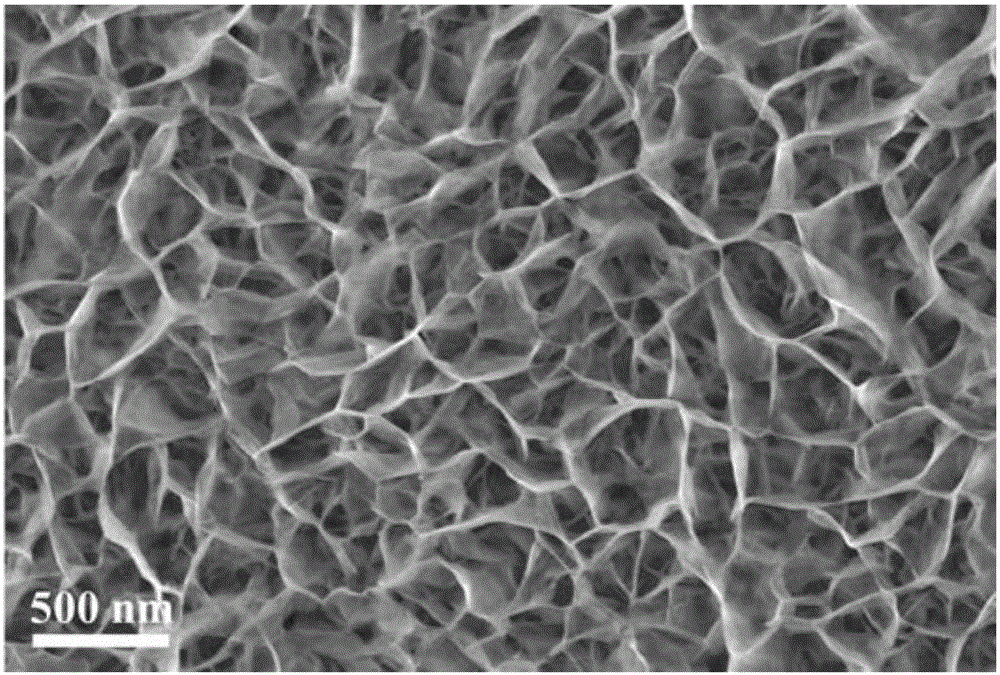

[0036] 1. Will 2 * 4cm nickel foam was ultrasonicated in 0.5mol / L sodium hydroxide aqueous solution, absolute ethanol and deionized water for 0.5 hours in sequence.

[0037] 2. Weigh 2.91g of nickel nitrate and dissolve it in 20mL of deionized water to prepare a salt solution with a concentration of 0.5mol / L.

[0038] 3. Add 2.0 g of hexamethylenetetramine to the above salt solution, and stir at 50° C. for 0.5 hour to obtain a mixed solution.

[0039] 4. Put the above mixed solution in an autoclave, and place the treated nickel foam in the autoclave, and keep it warm at 100°C for 24 hours.

[0040] 5. After the autoclave is naturally cooled to room temperature, take out the nickel foam, ultrasonically in deionized water and ethanol for 0.5 hours, and then dry at 80°C for 12 hours to obtain nickel foam self-supporting Ni(OH) 2 .

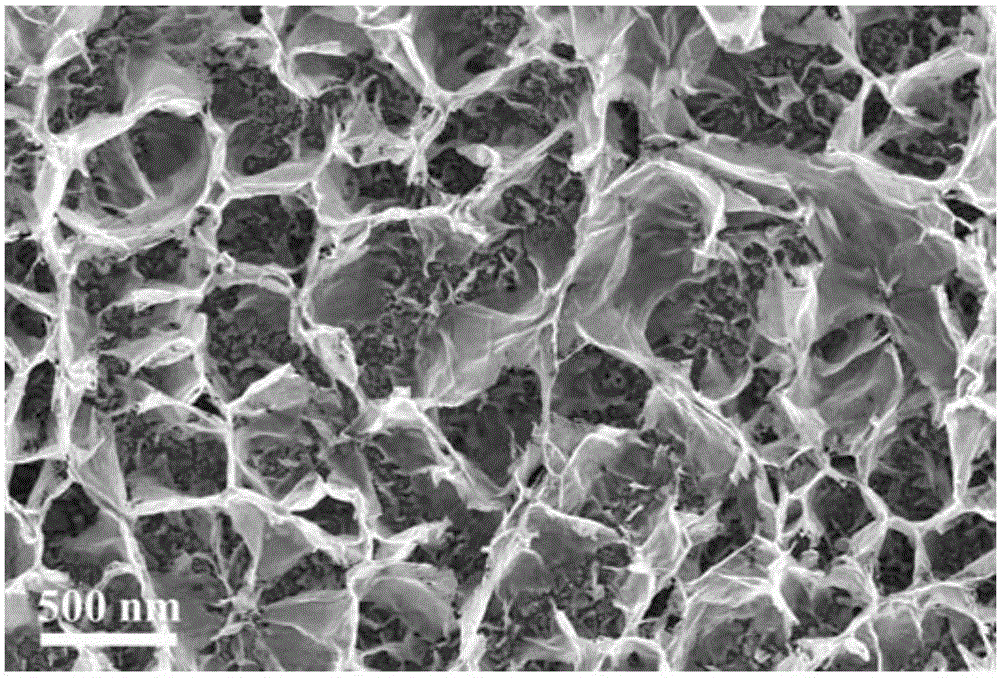

[0041] 6. Weigh 1.0g of sodium hypophosphite as the phosphorus source and add the above nickel foam self-supporting Ni(OH) 2 middle , In an argo...

Embodiment 2

[0047] 1. Sonicate 2*4cm nickel foam in 2mol / L sodium hydroxide aqueous solution, absolute ethanol and deionized water for 1 hour.

[0048] 2. Weigh 10.52g of nickel sulfate and dissolve it in 20mL of deionized water to prepare a salt solution with a concentration of 2mol / L.

[0049] 3. Add 1.0 g of PEG to the above salt solution and stir at 80° C. for 1 hour to obtain a mixed solution.

[0050] 4. Put the above mixed solution in an autoclave, and put the treated nickel foam into the autoclave, and keep it warm at 200°C for 5 hours.

[0051] 5. After the autoclave is naturally cooled to room temperature, take out the nickel foam, ultrasonically in deionized water and ethanol for 1 hour, and dry at 120°C for 4 hours to obtain the nickel foam self-supporting Ni(OH) 2 .

[0052] 6. Weigh 2.0g of sodium hypophosphite as the phosphorus source and add the above nickel foam self-supporting Ni(OH) 2 In the argon atmosphere, the temperature was raised to 600°C at a rate of 5°C / min a...

Embodiment 3

[0056] 1. Sonicate 2*4cm nickel foam in 1.2mol / L sodium hydroxide aqueous solution, absolute ethanol and deionized water for 0.7 hours.

[0057] 2. Weigh 6.23g of nickel acetate and dissolve it in 20mL of deionized water to prepare a salt solution with a concentration of 1.25mol / L.

[0058] 3. Add 3.0 g of sodium dodecyl hydroxysulfonate to the above salt solution, and stir at 65° C. for 1.3 hours to obtain a mixed solution.

[0059] 4. Put the above mixed solution in an autoclave, and put the treated nickel foam into the autoclave, and keep it warm at 150°C for 14.5 hours.

[0060] 5. After the autoclave is naturally cooled to room temperature, take out the nickel foam, sonicate in deionized water and ethanol for 0.7 hours, and dry at 100°C for 8 hours to obtain nickel foam self-supporting Ni(OH) 2 .

[0061] 6. Weigh 3.0g of sodium hypophosphite as the phosphorus source and add the above nickel foam self-supporting Ni(OH) 2 In the argon atmosphere, the temperature was rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com