Preparation method for aqueous anticorrosion coating

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as flash corrosion, metal corrosion, and high water conductivity, achieve good weather resistance and corrosion resistance, avoid agglomeration, The effect of increasing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

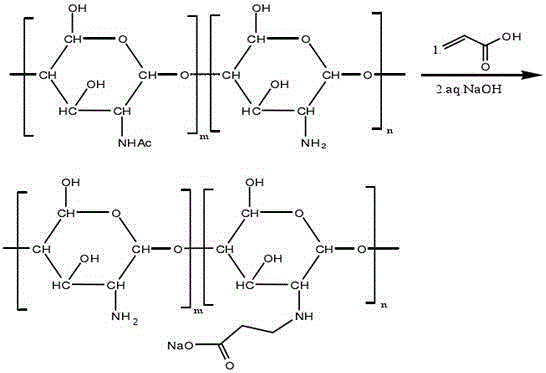

[0026] 1. Preparation of N-carboxyethyl chitosan:

[0027] Add 4.0g chitosan (molecular weight less than 50,000) into 200mL water containing 2.8mL acrylic acid, and keep stirring for 2 days at 50°C. After the reaction was completed, 1 mol / L NaOH solution was added to the reaction mixture to adjust the pH value of the solution to 10, so that all carboxylic acids were converted into sodium salts. Pour the mixed solution into acetone for reprecipitation, and then dialyze in aqueous solution (dialysis membrane cut-off molecular weight is 8000-12000 g / mol) to remove unreacted acrylic acid. After two days of dialysis, freeze-dry to obtain 3.6 g of N-carboxyethyl chitosan.

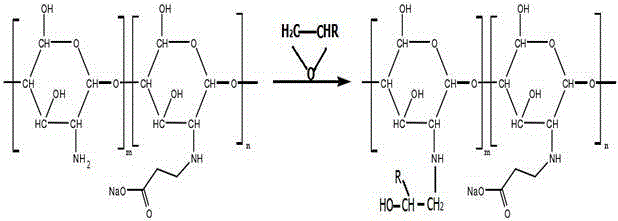

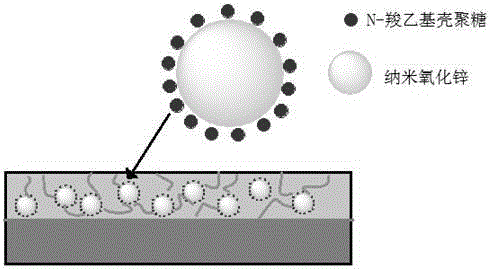

[0028] 2. Preparation of chitosan / nano zinc oxide composite material:

[0029] 3.6 g of the obtained N-carboxyethyl chitosan was added into 300 mL of deionized water, vigorously stirred at room temperature for 0.5 h, and fully dissolved to obtain a water-soluble chitosan solution. The above-mentioned water-sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com