Preparation method of flame retardation graphene coating layer material

A technology of flame-retardant coatings and flame-retardant coatings, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as unfavorable properties of polymer composite materials, reduce heat release rate, increase cross-linking density, and improve the preparation process The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

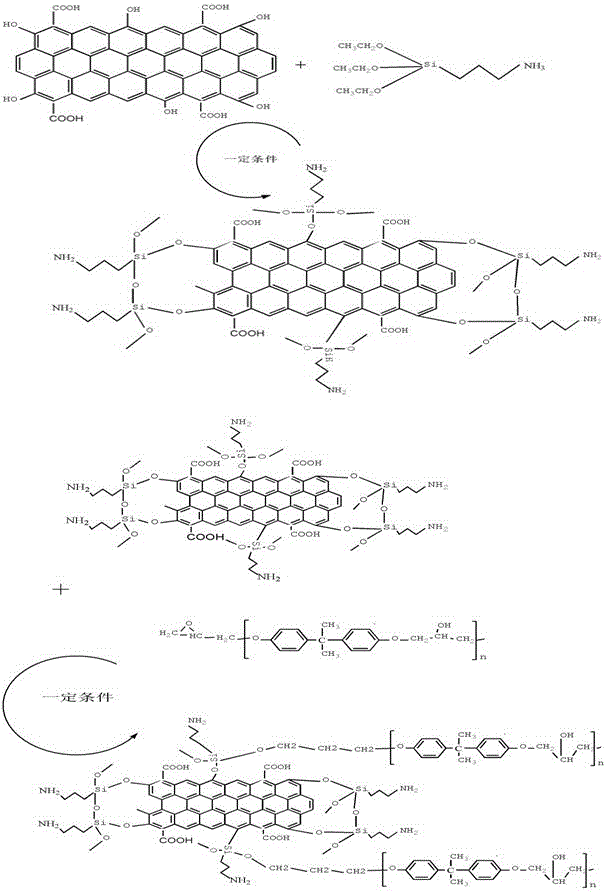

Image

Examples

Embodiment 1

[0022] see figure 1 , Table 1, the present embodiment provides a preparation method and test data of a graphene flame-retardant coating material, and the graphene flame-retardant coating material, its principle is proportioned as follows in parts by weight: graphene epoxy resin integrated material 50 parts, W651100 parts, TH-904 2.5 parts, GPE20 2 parts, water 50 parts.

[0023] The preparation method of the water-based anti-corrosion and fire-proof integrated coating specifically includes.

[0024] (1) Add 0.6g graphite (325 mesh) and 1.0g NaNO under water bath condition 3 ; Pour 35ml concentrated H 2 SO 4 and at a speed of 350 rpm -1 Under the condition of mechanical stirring for 40min; then weigh 3g of KMnO 4 Slowly add it into the three-necked flask and continue stirring for 2 hours; then remove the ice bath and raise the temperature of the reaction system to 35°C, and continue stirring under this condition for 30 minutes on ice; then slowly add 150 ml of deionized wa...

Embodiment 2

[0030] The principle of the water-based anti-corrosion and fire-proof integrated coating is as follows in parts by weight: 80 parts of graphene epoxy resin integrated material, 100 parts of W651, 2.5 parts of TH-904, 2 parts of GPE20, and 50 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com