Hybrid filler/silicone rubber flexible force-sensitive conductive composite material prepared by cyclic stretching method and preparation method of material

A conductive composite material and silicone rubber technology, applied in the field of flexible composite materials, can solve the problems of complex methods, poor conductivity, sensitivity and stability, and achieve the purpose of promoting orientation, improving resistivity and sensitivity, and improving the conductive network of fillers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

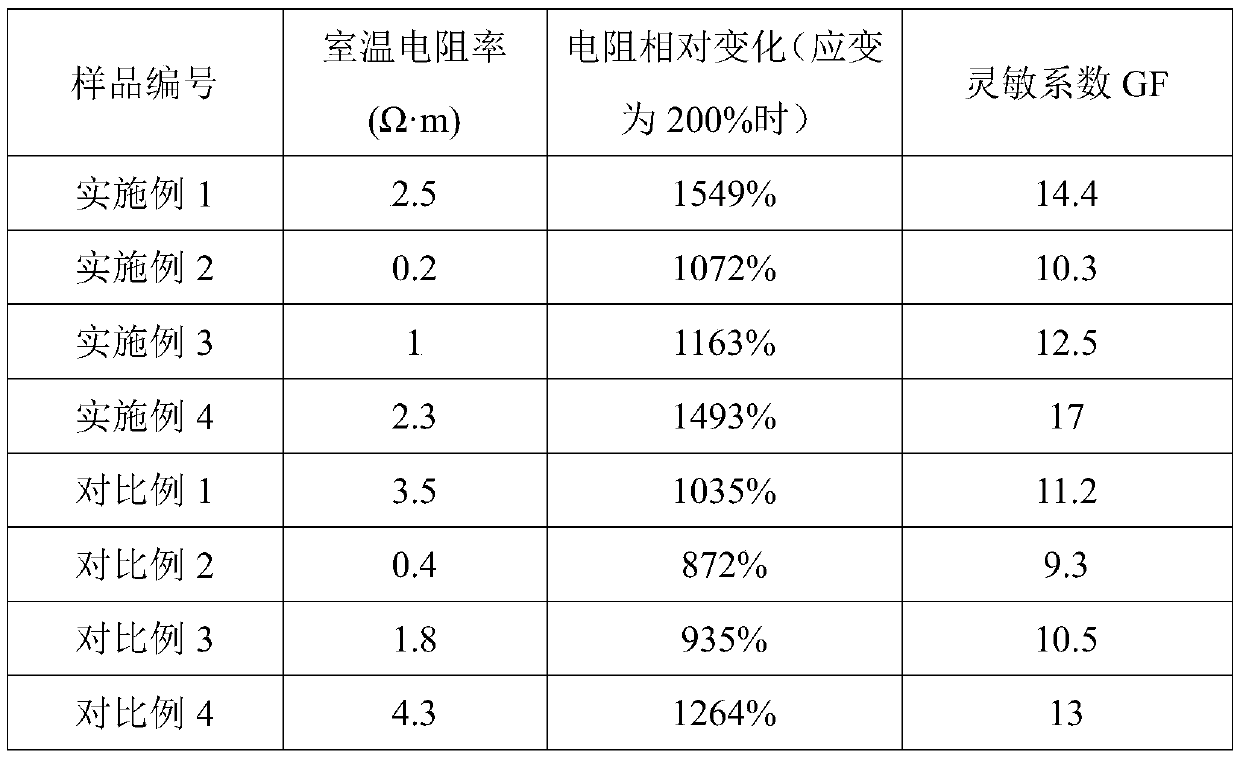

[0021] Example 1, weighing polydimethylsiloxane, 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, crosslinking agent, carbon fiber, and modified carbon nanotubes , ultrasonically dispersed and mixed evenly, poured into a tetrafluoroethylene mold, and vacuumized for 20 minutes to remove air bubbles, the vacuum degree was 0.06MPa, and then crosslinked at 100°C for 0.5h to form a crosslinked shape; the weight ratio of the components is silicone rubber:crosslinked Linking agent: carbon fiber: carbon nanotube=100:10:1:1; Wherein the carbon nanotube is modified by sodium cholate; the above sample is cut into splines whose length and width are 6cm and 2cm respectively, and then The test machine was stretched 100 times at a strain of 50% at 1 Hz.

Embodiment 2

[0022] Example 2. Weigh methylvinyl silicone rubber, dicumyl peroxide, carbon fiber, and modified carbon nanotubes, and after ultrasonic dispersion and mixing, pour them into a tetrafluoroethylene mold, and vacuumize for 20 minutes to remove air bubbles. The density is 0.06MPa, and then cross-linked at 100°C for 0.5h to form a cross-linked shape; the weight ratio of the components is silicone rubber: cross-linking agent: carbon fiber: carbon nanotubes = 100:10:5:5; where carbon nanotubes It was modified by sodium cholate; the above sample was cut into strips whose length and width were 6cm and 2cm respectively, and then cyclically stretched for 1000 times at 5Hz and 5% strain on a universal testing machine.

Embodiment 3

[0023] Example 3. Weigh methylphenylvinyl silicone rubber, dicumyl peroxide, carbon fiber, and modified carbon nanotubes, mix them uniformly by ultrasonic dispersion, pour them into a tetrafluoroethylene mold, and vacuumize for 20 minutes to remove air bubbles , the vacuum degree is 0.06MPa, and then cross-linked at 100°C for 0.5h to form a cross-linked shape; the weight ratio of the components is silicone rubber: cross-linking agent: carbon fiber: carbon nanotubes = 100:10:2:2; where carbon The nanotubes were modified by sodium cholate; the above samples were cut into strips with a length and width of 6cm and 2cm respectively, and then stretched cyclically for 2000 times at 10Hz and a strain of 10% on a universal testing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com