Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

A composite material and polyamide technology, which is applied in the field of polyamide composite materials with high electrical conductivity and its preparation, can solve the problems of insufficient exfoliation of the expanded graphite layer, easy collapse of expanded graphite, limited application of expanded graphite, etc. The effect of percolation threshold, abundant mineral resources, and little influence on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of graphite oxide is:

[0048] Take 400 parts by mass of 98% concentrated sulfuric acid and place it in an ice bath, add 10 parts by mass of natural flake graphite, 5 parts by mass of sodium nitrate, and 30 parts by mass of potassium permanganate, keep stirring for 1 hour during this process, and prevent the mixture The temperature exceeds 20°C. The ice bath was removed, and the mixture was kept in a water bath at 35°C for 4 hours. It was diluted with 500 parts by mass of deionized water, and the temperature of the mixture was maintained at 90° C. for 15 minutes. Dilute with 900 parts by mass of deionized water, add 60 parts by mass of hydrogen peroxide and filter while hot. Wash with deionized water until SO-free 4 2- Ion can.

[0049] Among them, the particle size of natural flake graphite used as raw material is between 103 and 106 mesh. The thickness of the graphite oxide flakes obtained after oxidation and peeling is 1-20 nanometers, an...

Embodiment 1

[0051] Mix 0.25-5 parts by mass of graphite oxide, 100 parts by mass of caprolactam, and 6 parts by mass of 6-aminocaproic acid, and perform ultrasonic vibration treatment at 80° C. for 3 hours to obtain a premix.

[0052] Dry the premix for 2 hours under the condition of vacuum degree of 0.1MPa, after 2 hours of prepolymerization at 180°C and nitrogen atmosphere, polymerize at 250°C and nitrogen atmosphere for 8 hours, discharge under nitrogen atmosphere, and granulate , The product is obtained after extraction and drying.

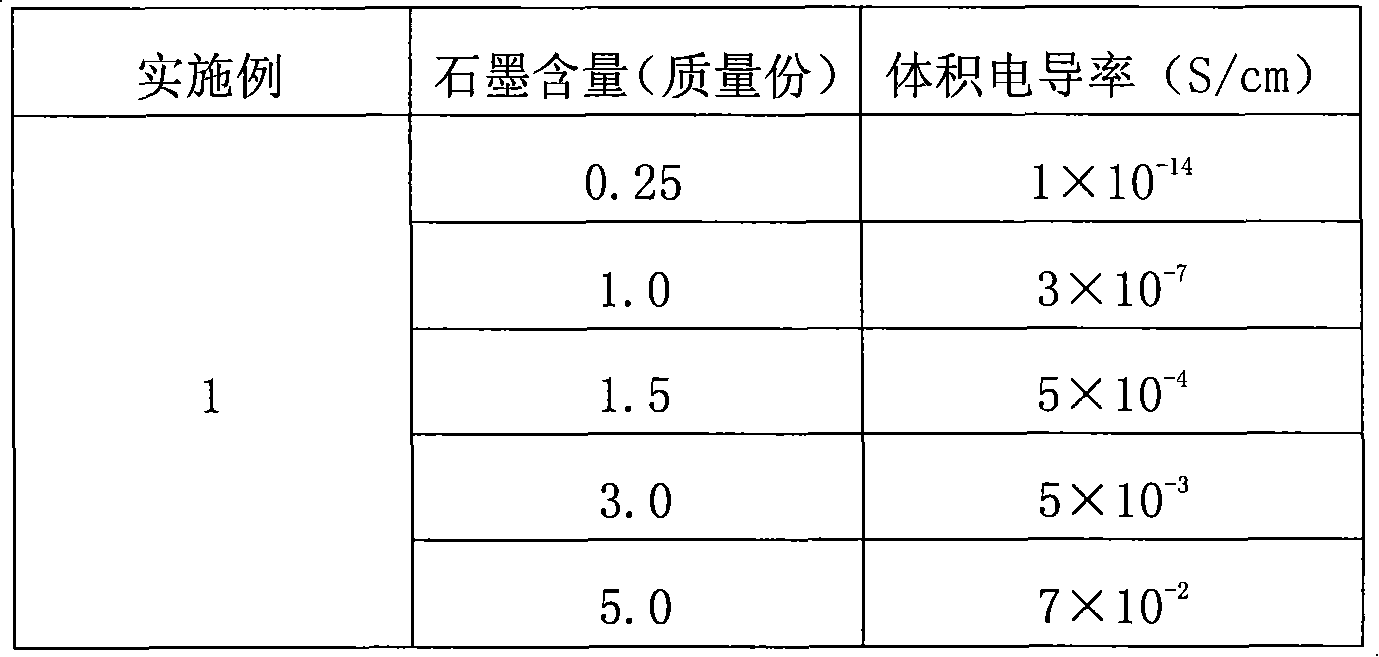

[0053] Measure the conductivity of the product with a megger or a four-electrode method, and the volume conductivity of the product is listed in Table 1.

[0054] Table 1 Conductivity of composite materials without dispersion medium

[0055]

Embodiment 2

[0059] 1.5 parts by mass of graphite oxide, 100 parts by mass of caprolactam, and 6 parts by mass of 6-aminocaproic acid were mixed, and the dispersion medium was 0-300 parts by mass. After ultrasonic vibration treatment at 80° C. for 3 hours, the premix was obtained.

[0060] Dry the premix for 2 hours under the condition of vacuum degree of 0.1MPa, after 2 hours of prepolymerization at 180°C and nitrogen atmosphere, polymerize at 250°C and nitrogen atmosphere for 8 hours, discharge under nitrogen atmosphere, and granulate , The product is obtained after extraction and drying.

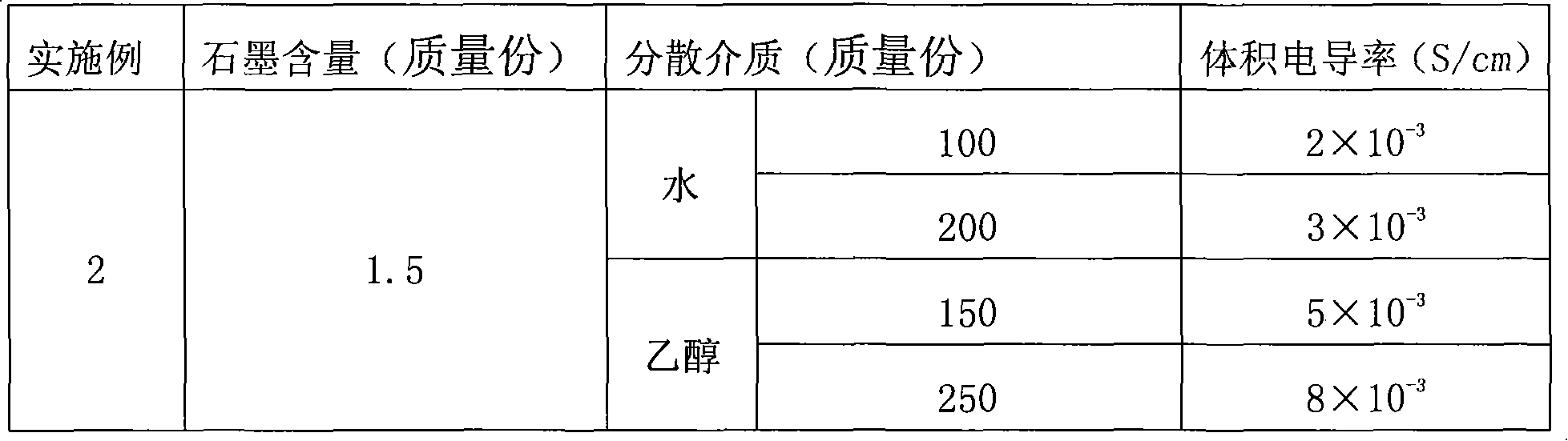

[0061] Measure the conductivity of the product with a megger or a four-electrode method, and the volume conductivity of the product is listed in Table 2.

[0062] Table 2 Conductivity of composites using different dispersion media

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com