Nanometer zinc oxide photocatalyst and preparation method and application thereof

A nano-zinc oxide and photocatalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high cost and achieve low cost and innovation Strong, fast catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of nano ZnO particles:

[0017] (1) Preparation of precursors

[0018] Dissolve 0.5065g (3mmol) terephthalic acid in 20mL N,N-dimethylformamide solvent, and slowly add this solution to 1.78g (6mmol) Zn(NO 3 ) 2 ·6H 2 O in 30mL of N,N-dimethylformamide solution, then add 0.85mL of triethylamine, stir for 40min, and filter with suction to obtain a white Zn(II) precursor complex.

[0019] (2) Preparation of nano ZnO particles

[0020] Take 0.2 g of the above-mentioned Zn(II) precursor complex and calcinate at 500° C. for 2 h under a nitrogen atmosphere to prepare nano-zinc oxide photocatalyst.

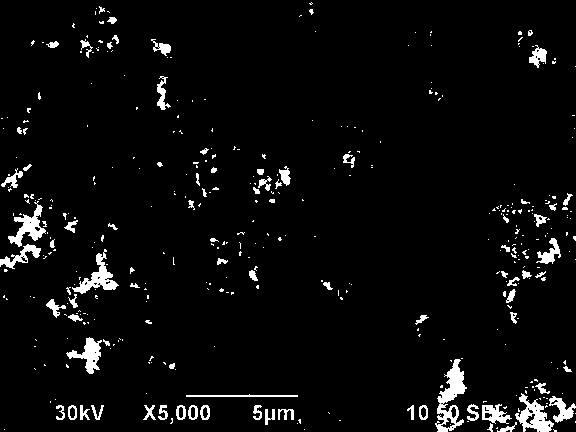

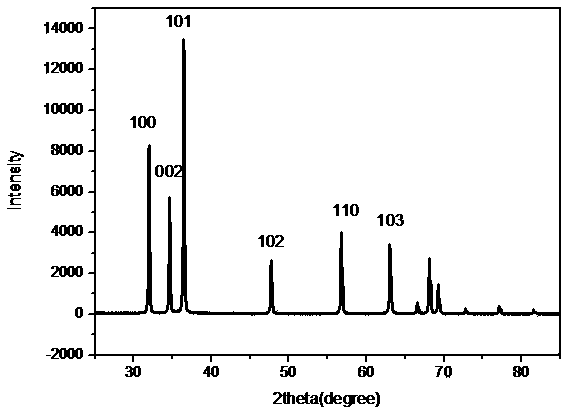

[0021] figure 1 The scanning electron microscope image of the ZnO nanoparticles prepared for this example is a small particle structure with an average particle size of about 80 nm. image 3 The powder X-ray diffraction spectrum of the ZnO nanoparticles prepared for this example, the diffraction peaks in the spectrum correspond to the diffraction data of ZnO.

Embodiment 2

[0023] Preparation of nano ZnO particles:

[0024] (1) Preparation of precursors

[0025] Dissolve 0.5065g (3mmol) terephthalic acid in 20mL N,N-dimethylformamide solvent, slowly add this solution to the solution containing 0.45g (1.5mmol) Zn(NO 3 ) 2 ·6H 2 O in 30mL of N,N-dimethylformamide solution, then add 0.85mL of triethylamine, stir for 60min, and filter with suction to obtain a white Zn(II) precursor complex.

[0026] (2) Preparation of nano ZnO particles

[0027] Take 0.2 g of the above-mentioned Zn(II) precursor complex and calcinate it at 800° C. for 1 h in an air atmosphere to prepare nano-zinc oxide photocatalyst.

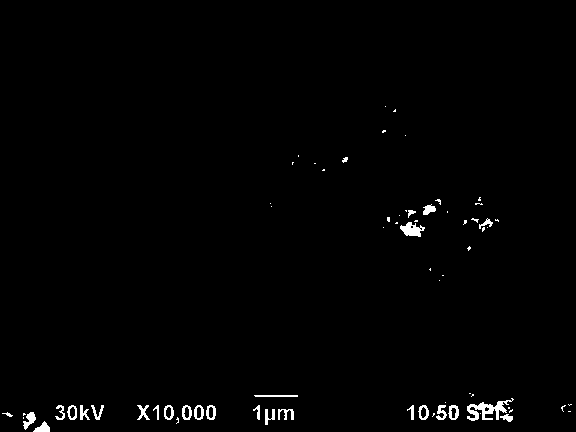

[0028] figure 2 The scanning electron microscope image of the ZnO nanoparticles prepared for this example is a small particle structure with an average particle size of about 80 nm. Figure 4 The powder X-ray diffraction spectrum of the ZnO nanoparticles prepared for this example, the diffraction peaks in the spectrum correspond to the diffracti...

Embodiment 3

[0030] (1) Preparation of precursors

[0031] Dissolve 0.18g (3mmol) formic acid in 20mL N,N-dimethylformamide solvent, slowly add this solution to the solution containing 0.9g (3mmol) Zn(NO 3 ) 2 ·6H 2 O in 30mL of N,N-dimethylformamide solution, then add 0.85mL triethylamine, stir for 120min, and filter with suction to obtain a white Zn(II) precursor complex.

[0032] (2) Preparation of nano ZnO particles

[0033] Take 0.2 g of the above-mentioned Zn(II) precursor complex and calcinate at 400° C. for 1 h in an air atmosphere to prepare nano-zinc oxide photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com