Method for preparing tin reduced nano titanic oxide catalyst

A nano-titanium dioxide and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes and other directions, can solve the problems of complex processes, flammable and explosive, difficult to achieve industrialization, and high equipment investment costs, and achieve the The process is safe and reliable, the process parameters are easier to control, and the effect of significant photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of tin-reduced nano-titanium dioxide catalyst comprises: weighing 1-100 parts of nano-titanium dioxide powder according to the ratio of parts by weight, adding the nano-titanium dioxide powder into the solution of stannous dichloride at room temperature, dipping After 1-60 minutes, filter with suction, wash with water three times, and dry to obtain a tin-reduced nano-titanium dioxide catalyst. The reduction method used is the chemical reduction method of divalent tin.

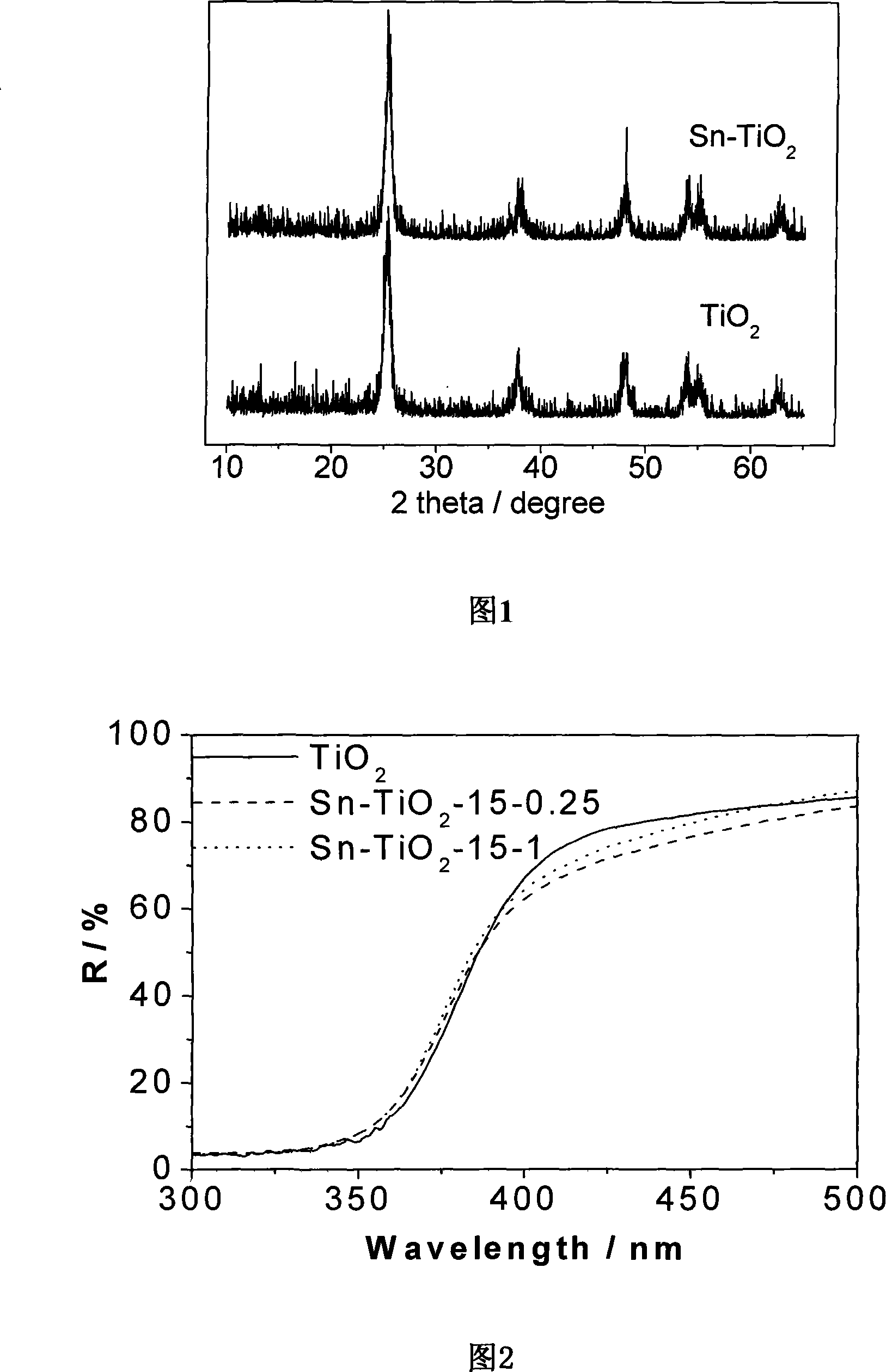

[0021] In the preparation method of the tin-reduced nano-titanium dioxide catalyst, the nano-titanium dioxide powder is composed of one or more of anatase phase, rutile phase, and brookite phase, and the weight of the nano-titanium dioxide powder is 1-100 g / L.

[0022] In the preparation method of the tin-reduced nano-titanium dioxide catalyst, the concentration of the stannous dichloride solution is 0.1-5mol / L, the volume fraction of the stannous dichloride solution is 0.1-1 part,...

Embodiment 2

[0024] Nano titanium dioxide powder was prepared by sol-gel method. Add 10mL of ethanol to a beaker, then slowly add 7.6mL of tetrabutyl titanate dropwise into the ethanol under vigorous stirring, the above mixed solution is electromagnetically stirred for 2 hours, then add 1-5mL of twice distilled water and continue to stir until a gel is formed . The gel is dried at 100°C and calcined at 400°C to obtain anatase phase nano titanium dioxide powder with a particle size of 10-30nm.

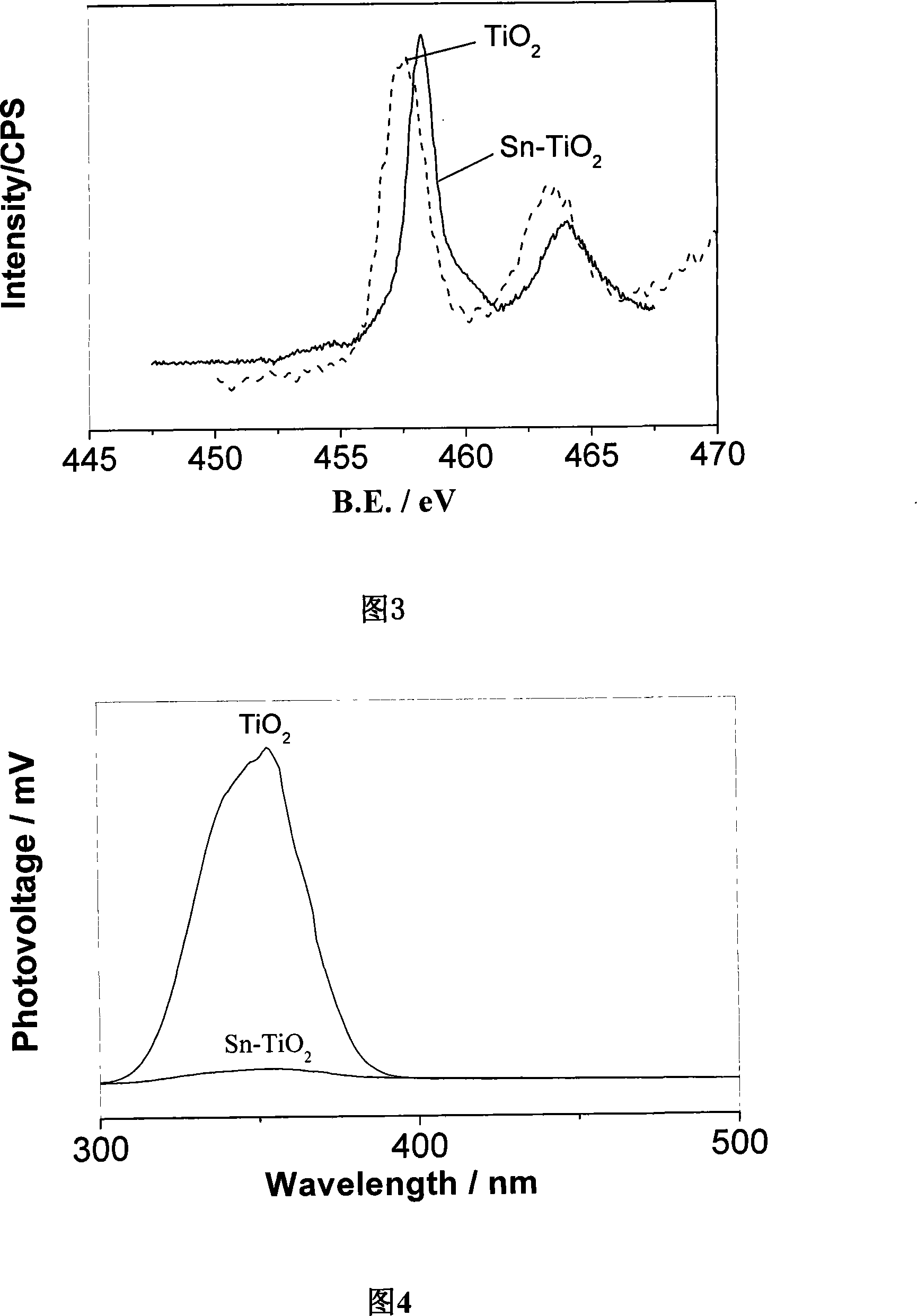

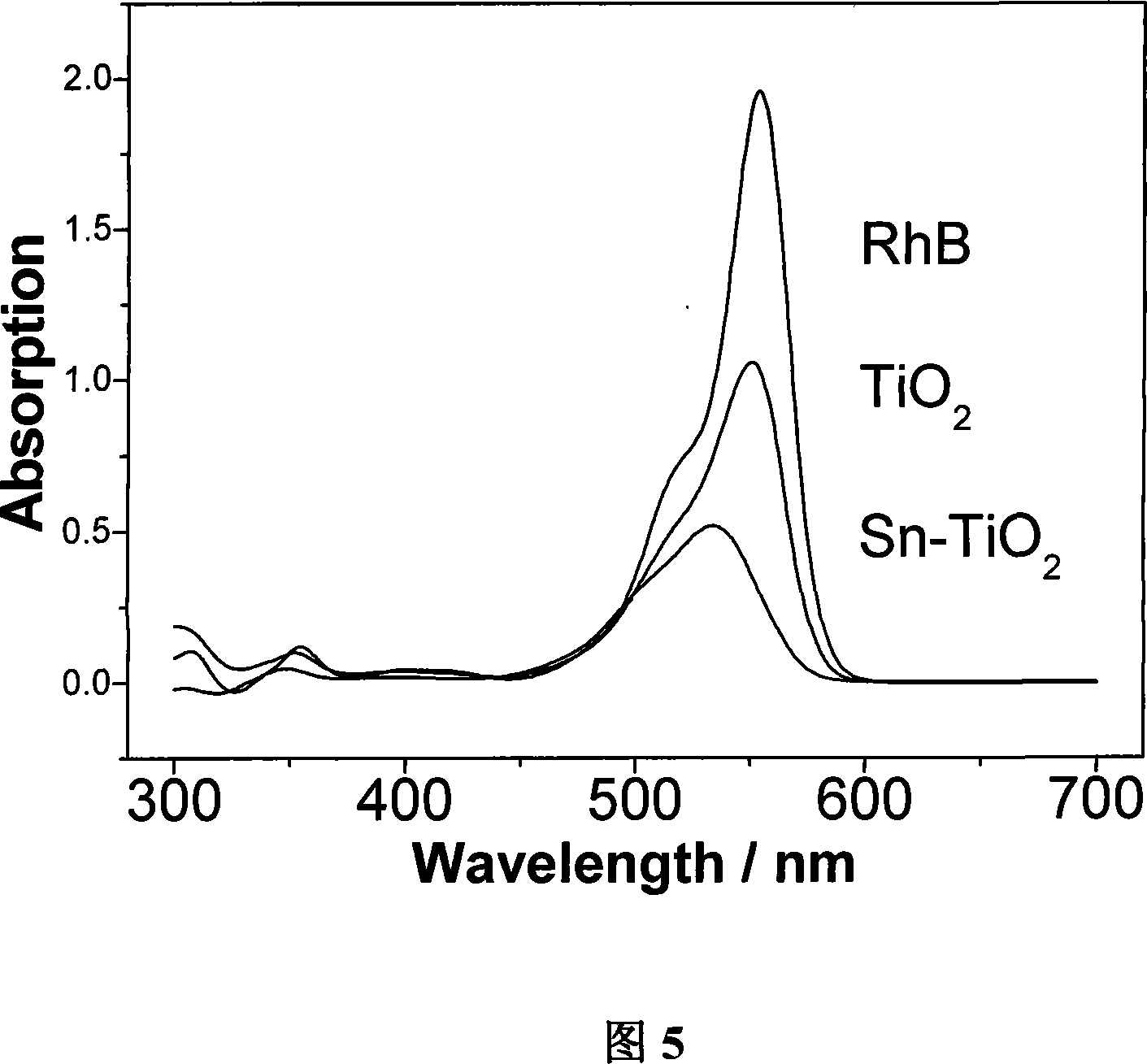

[0025] Prepare a stannous chloride solution with a concentration of 0.1-5mol / L, weigh 1.0g of the above-prepared nano-titanium dioxide powder and add it to 50mL of a stannous chloride solution with a concentration of 0.1-5mol / L and immerse it for 1-60 minutes, then Suction filter and wash three times with distilled water. Then transfer to a Petri dish and dry at 100°C for 2 hours. Take out and grind to obtain a series of Sn-reduced nano titanium dioxide powders. Respectively named: Sn-TiO 2 -A-...

Embodiment 3

[0030]Nano titanium dioxide powder was prepared by hydrothermal method. Take a dropping funnel and add 30mL of tetrabutyl titanate and 4mL of isopropanol respectively, and mix well. Take a 250mL three-necked bottle and add 120mL of secondary water, add 2mL of nitric acid to adjust the pH to about 1, and use an ice-water cooling bath to control the reaction temperature below 5°C. The solution of tetrabutyl titanate and isopropanol was slowly added dropwise into the three-neck flask under electric stirring (the dropping time takes about 1 hour, and the whole process is completed in an ice-water bath). After the dropwise addition was completed, the temperature was raised to reflux for 2 hours. After the reflux is completed, cool to room temperature and separate layers, use a separatory funnel to remove the milky white liquid in the lower layer, adjust the pH value to 3-12 with ammonia water, then add it to a hydrothermal kettle for 2-48 hours at 180°C for hydrothermal reaction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com