Preparation method of F-MnTiO3

A technology of hydrothermal method and photocatalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as difficult to achieve efficient and cheap solar energy conversion, and achieve effective catalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

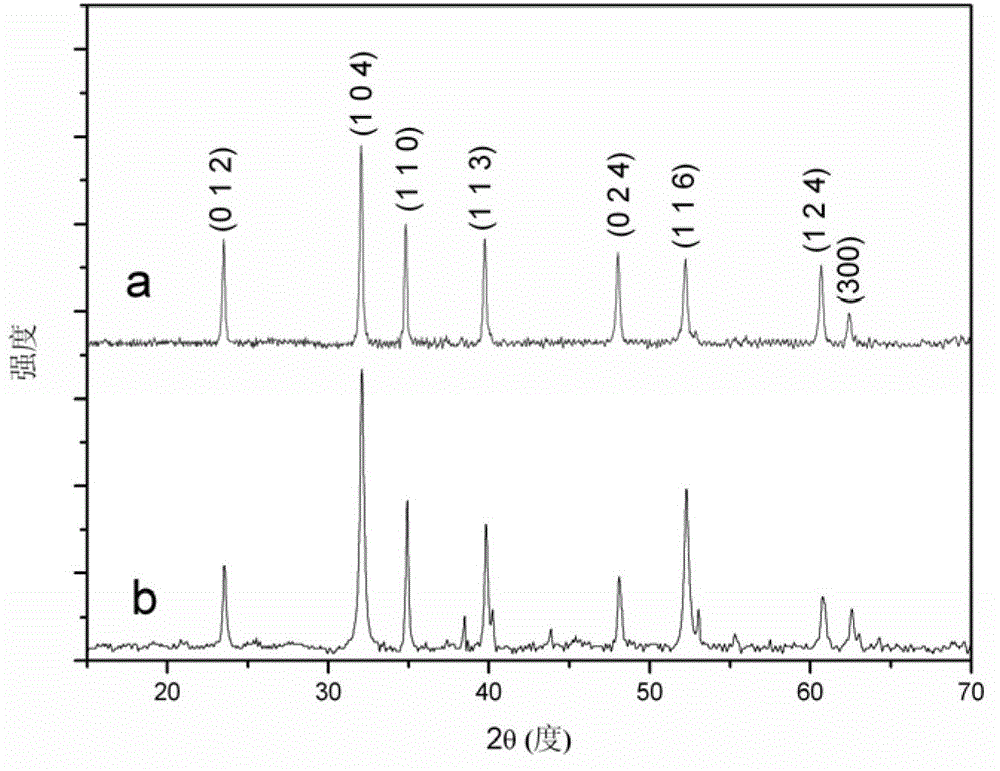

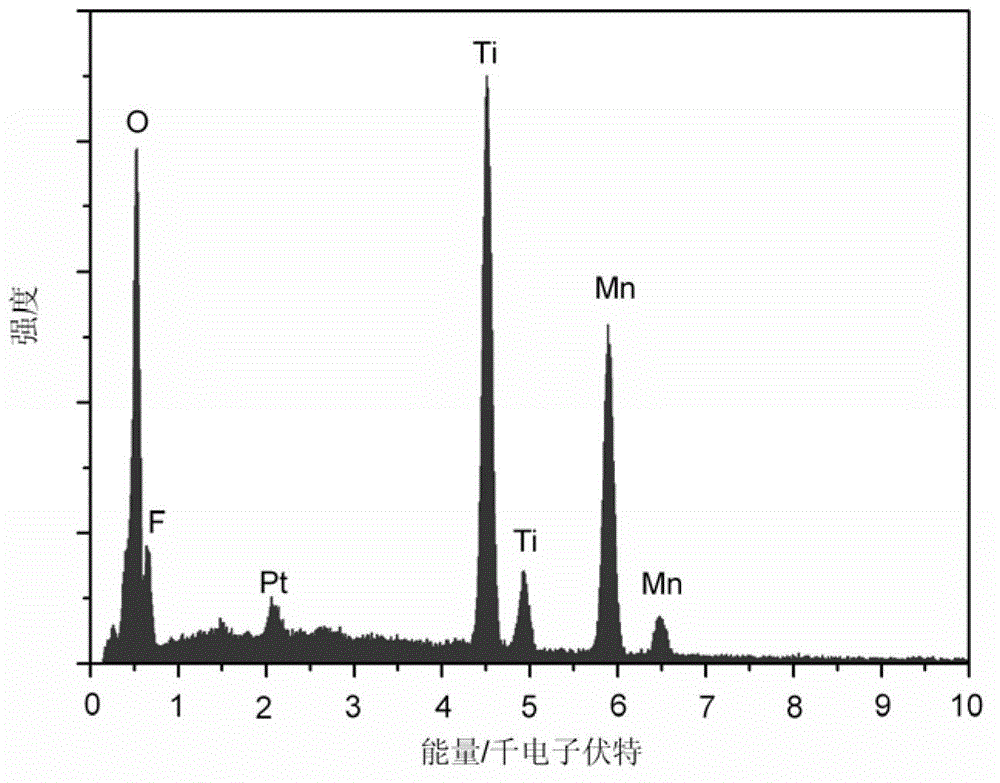

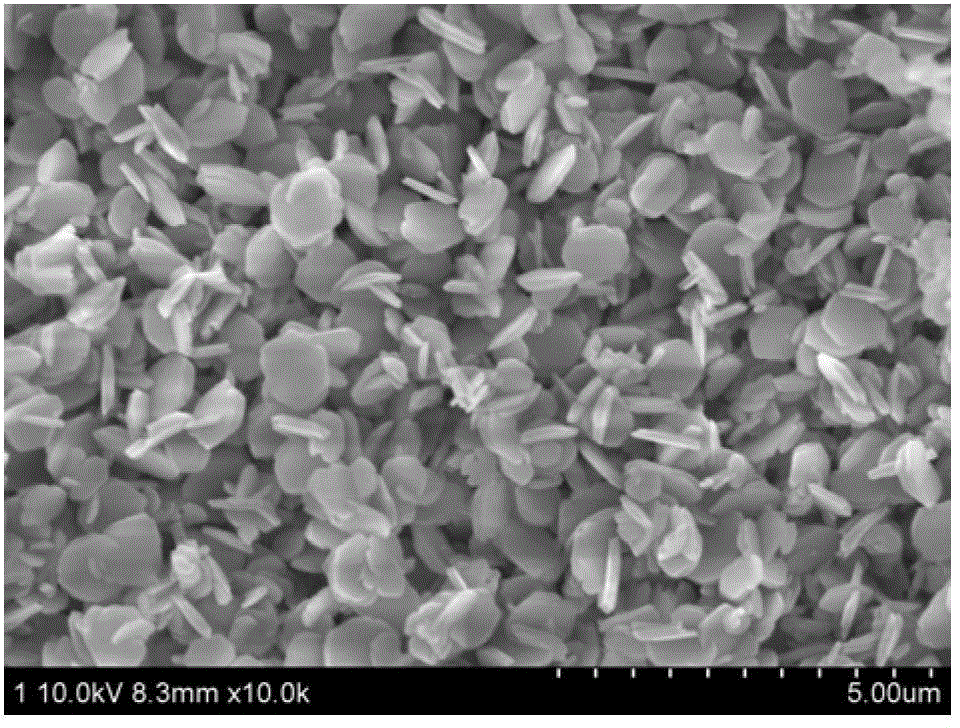

[0024] The present invention MnTiO 3 The preparation method of visible light photocatalytic material comprises the following steps:

[0025] 1. Preparation of titanate nanowires by hydrothermal method.

[0026] The steps are as follows: put a 0.15-0.3g Ti plate in a beaker filled with acetone and sonicate it for 15min, then rinse it with distilled water for 3 times; add 15-25mL NaOH solution with a concentration of 2mol / L into the polytetrafluoroethylene Lining the high-pressure reactor, then put the cleaned Ti plate into NaOH solution, seal the high-pressure reactor and put it in an oven at 220-240°C for 8-10 hours; after the reaction, take out the Ti plate and rinse it with distilled water for 3 times, and put it into a drying oven to dry, that is, titanate nanowires are obtained on the surface of the Ti plate.

[0027] 2. Preparation of MnTiO by hydrothermal method 3 Visible light photocatalytic materials.

[0028] This step is specifically: at room temperature, put 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com