A method for regenerating and treating organic wastewater using an enzyme-like magnetic catalyst

A magnetic catalyst, organic wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Increase the pretreatment process and other issues to achieve the effect of strong engineering application value, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention discloses a method for regenerating and treating organic wastewater by adopting an enzyme-like magnetic catalyst. The organic wastewater to be regenerated in this example is taken from the effluent after the secondary biochemical treatment of wastewater from a coking plant of an iron and steel complex: the COD value is 150-300 mg / L, the chroma is 300-400 times, and the pH value is 6.5-8.2.

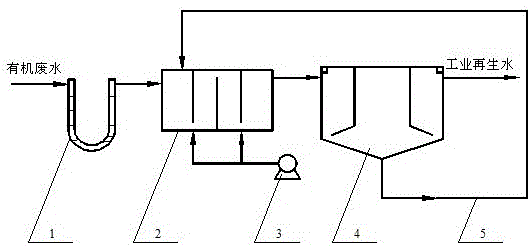

[0028] The method for regenerating the organic wastewater in this embodiment is as follows: figure 1 Shown:

[0029] Step 1: Add inorganic acid to the organic wastewater entering the cyclone mixer 1 to adjust the pH to 3.5-6, and the acidified organic wastewater after pH adjustment enters the catalytic degradation reactor 2.

[0030] Step 2, adding the imitative enzyme-type magnetic catalyst into the catalytic degradation reactor 2 equipped with acidified organic wastewater, and then adding H 2 o 2 , an enzyme-like magnetic catalyst: H 2 o 2 The mass ratio is 1:1....

Embodiment 2

[0037] The invention discloses a method for regenerating and treating organic wastewater by adopting an enzyme-like magnetic catalyst. The organic wastewater to be regenerated in this embodiment is taken from the effluent of an independent coking plant after secondary biochemical treatment, with a COD value of 250-450 mg / L, a chroma of 400-600 times, and a pH value of 6.2-8.5.

[0038] The method for regenerating the organic wastewater in this embodiment is as follows: figure 1 Shown:

[0039] Step 1: Add inorganic acid to the organic wastewater entering the cyclone mixer 1 to adjust the pH to 3.5-6, and the acidified organic wastewater after pH adjustment enters the catalytic degradation reactor 2.

[0040] Step 2, adding the imitative enzyme-type magnetic catalyst into the catalytic degradation reactor 2 equipped with acidified organic wastewater, and then adding H 2 o2 , an enzyme-like magnetic catalyst: H 2 o 2 The mass ratio is 1:1.5~2.0. Then, under the condition of...

Embodiment 3

[0047] The invention discloses a method for regenerating and treating organic wastewater by adopting an enzyme-like magnetic catalyst. The organic wastewater for regeneration treatment in this example is taken from the effluent after secondary biochemical treatment of wastewater from a new coal chemical coking plant: the COD value is 400-600 mg / L, the chroma is 500-700 times, and the pH value is 5.8-8.0.

[0048] The method for regenerating the organic wastewater in this embodiment is as follows: figure 1 Shown:

[0049] Step 1: Add inorganic acid to the organic wastewater entering the cyclone mixer 1 to adjust the pH to 3.5-6, and the acidified organic wastewater after pH adjustment enters the catalytic degradation reactor 2.

[0050] Step 2, adding the imitative enzyme-type magnetic catalyst into the catalytic degradation reactor 2 equipped with acidified organic wastewater, and then adding H 2 o 2 , an enzyme-like magnetic catalyst: H 2 o 2 The mass ratio is 1:2.0~2.5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com