Biological template method for preparing tubular ZnO-SnO2 composite nano material

A composite nanomaterial, zno-sno2 technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve ecological environment and human health hazards, affect aquatic life Plant photosynthesis, difficult biodegradation and other problems, to achieve the effect of good repeatability, high catalytic activity and stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare the template

[0028] Purchase fresh bean sprouts and wash off the visible stains on the surface, cut the stalks into about 2cm in length, soak them in 0.1mol / L hydrochloric acid solution for 12 hours, wash them with deionized water until neutral, and form a bean sprout template .

[0029] (2) Dip template

[0030] Disperse 10g of bean sprouts template in 200mL of absolute ethanol to form A mixed solution. Dissolve zinc nitrate and tin tetrachloride in water to prepare an aqueous solution with a molar ratio of 1:0.2, which is referred to as solution B; and the total concentration of the metal salt solution in the aqueous solution is 0.2mol / L. Take 200mL of solution B, add it dropwise to solution A under magnetic stirring, and keep stirring and impregnating for 12h.

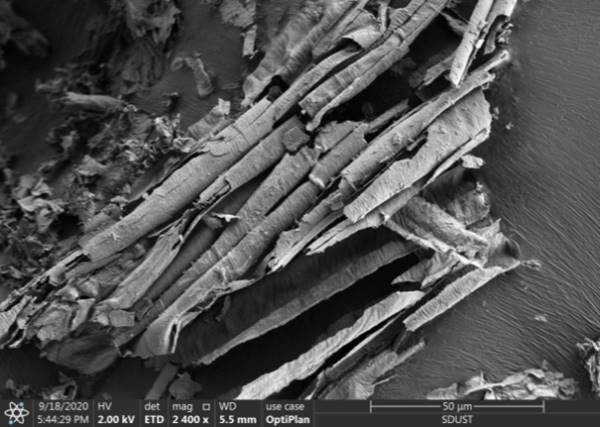

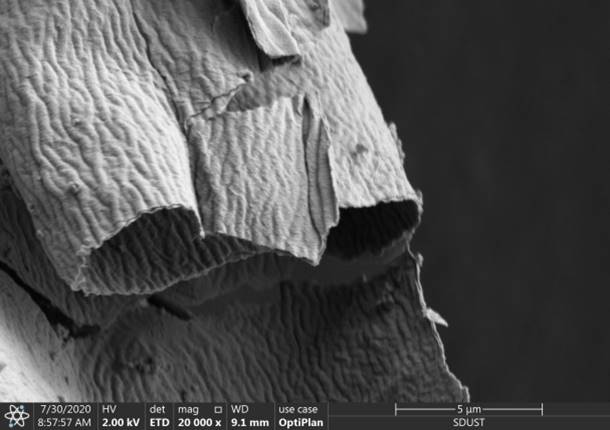

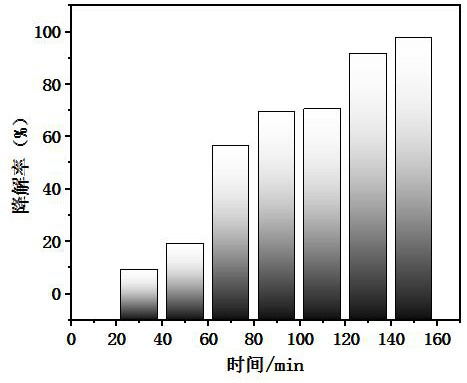

[0031] (3) Preparation of a tubular ZnO-SnO 2 Composite Nanomaterials

[0032] The impregnated template was taken out, washed several times with deionized water, dried at 60°C, calcined at ...

Embodiment 2

[0035] (1) Prepare the template

[0036] Purchase fresh bean sprouts and wash off the visible stains on the surface, cut the stalks into about 2cm in length, soak them in 0.1mol / L hydrochloric acid solution for 12 hours, wash them with deionized water until neutral, and form a bean sprout template .

[0037] (2) Dip template

[0038] Disperse 10g template in 200mL absolute ethanol to form A mixed solution. Dissolve tin chloride and zinc chloride in water to prepare an aqueous solution with a molar ratio of 1:0.4, denoted as solution B; and the total concentration of the metal salt solution in the aqueous solution is 0.4mol / L. Take 200mL of solution B, add it dropwise to solution A under magnetic stirring, and keep stirring for 24 hours.

[0039] (3) Preparation of a tubular ZnO-SnO 2 Composite Nanomaterials

[0040] The impregnated template was taken out, washed several times with deionized water, dried at 60°C, calcined in a muffle furnace at 650°C for 3 hours, and coole...

Embodiment 3

[0043] (1) Prepare the template

[0044] Purchase fresh bean sprouts and wash off the visible stains on the surface, cut the stalks into about 2cm in length, soak them in 0.1mol / L hydrochloric acid solution for 12 hours, wash them with deionized water until neutral, and form a bean sprout template .

[0045] (2) Dip template

[0046] Disperse 5 g of bean sprouts template in 100 mL of absolute ethanol to form A mixed solution. Dissolve tin chloride and zinc sulfate in water to prepare an aqueous solution with a molar ratio of 1:0.2, denoted as solution B; and the total concentration of the metal salt solution in the aqueous solution is 0.6mol / L. Take 100mL of solution B, add it dropwise into solution A under magnetic stirring, and keep stirring and impregnating for 6-48h.

[0047] (3) Preparation of a tubular ZnO-SnO 2 Composite Nanomaterials

[0048] The impregnated template was taken out, washed several times with deionized water, dried at 60°C, calcined in a muffle furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com