High temperature resisting modified polyhexamethylene guanidine, preparation method and application thereof

A technology of polyhexamethylene guanidine and polyhexamethylene monoguanidine, which is applied in the field of high-temperature-resistant modified polyhexamethylene guanidine and its preparation, can solve the problems of reducing antibacterial efficacy and failing to meet antibacterial standards, etc. Achieve the effects of good antibacterial effect, wide application range and simple preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

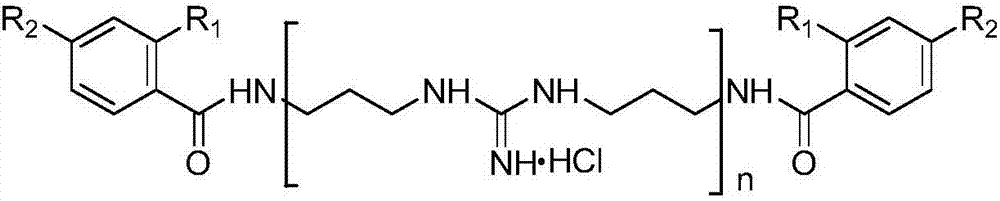

[0039]

[0040] R 1 = H; R 2 = H; n = 5

[0041] Use polyhexamethylene monoguanidine as raw material, add benzoic acid, the mass ratio of benzoic acid to polyhexamethylene monoguanidine is 0.01:1, carry out grafting reaction under the protection of nitrogen, the reaction temperature is 120°C, normal pressure Stir under low temperature, react for 3 hours, then cool down to 80° C., and the product is obtained after discharging. After grafting, the weight of polyhexamethylene monoguanidine increases by 1%. The melting point of the prepared compound is: the melting point reaches 130-150°C.

Embodiment 2

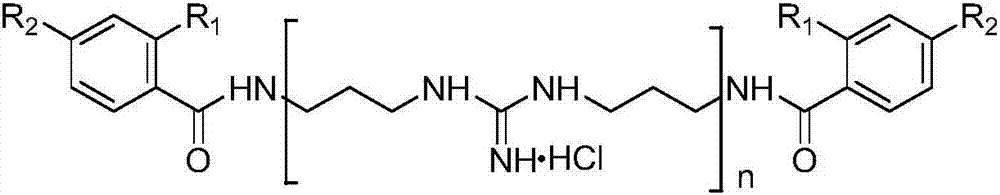

[0043]

[0044] R 1 = COOH; R 2 =NH 2 ;n=50

[0045] Use polyhexamethylene monoguanidine as raw material, add phthalic anhydride, the mass ratio of phthalic anhydride to polyhexamethylene monoguanidine is 0.001:1, carry out grafting reaction under the protection of nitrogen, the reaction temperature Stir at 180°C under normal pressure, react for 1 hour, then lower the temperature to 100°C, and get the product after discharging. After grafting, the weight of polyhexamethylene monoguanidine increases by 3%. The melting point of the prepared compound is: the melting point reaches 150-180°C.

Embodiment 3

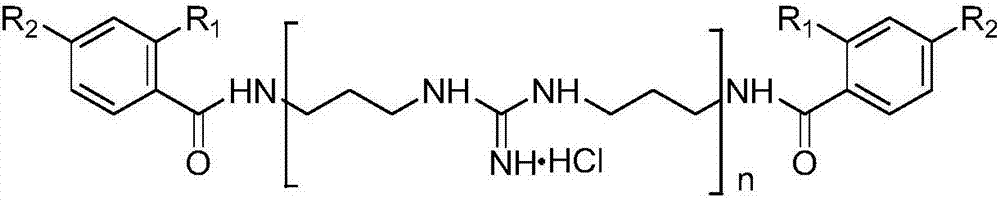

[0047]

[0048] R 1 = H; R 2 =NH 2 ;n=20

[0049] Use polyhexamethylene monoguanidine as raw material, add p-aminobenzoic acid, the mass ratio of aminobenzoic acid to polyhexamethylene monoguanidine is 0.0025:1, carry out grafting reaction under nitrogen protection, and the reaction temperature is 150°C , stirred under normal pressure, reacted for 3 hours, then lowered the temperature to 90° C., and obtained after discharging. After grafting, the weight of polyhexamethylene monoguanidine increased by 2%. The melting point of the prepared compound is: the melting point reaches 130-230°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com