Preparation of carbapenem penicillin ertapenem intermediate

An intermediate and time technology, applied in the field of organic compound synthesis, can solve the problems of harsh conditions, high cost and high equipment requirements, and achieve the effect of mild reaction conditions and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

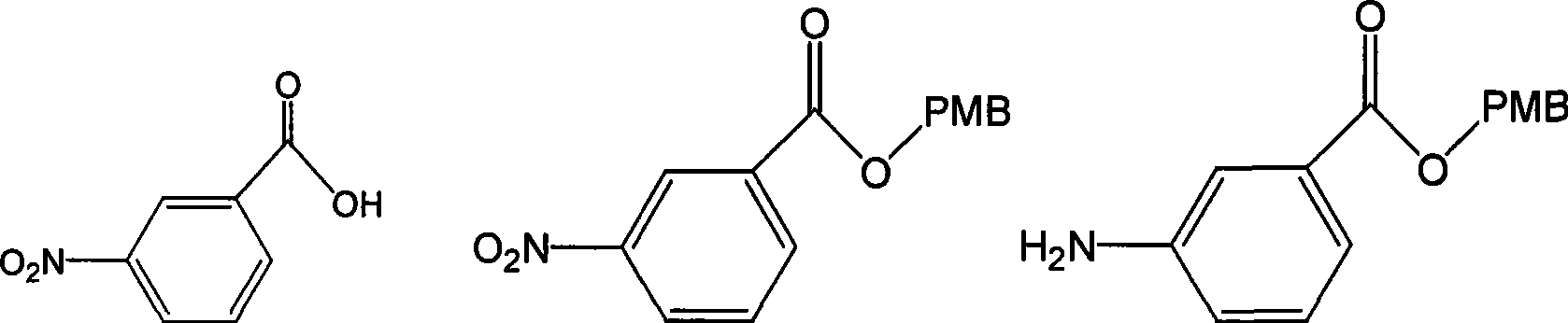

[0036] Example 1 Synthesis of 4-methoxybenzyl 3-nitrobenzoate (formula II)

[0037] Formula I compound (4.00g, 23.93mmol) in CH 2 Cl 2 50ml, add NEt 3 (4.84g, 47.91mmol), 4-methoxybenzyl chloride (PMBCl) (5.62g, 35.89mmol) was added dropwise at room temperature, the temperature was raised to 45°C, and the reaction was carried out for 3 hours. use CH 2 Cl 2 and water extraction, combined CH 2 Cl 2 layer with anhydrous NaSO 4 Dry, filter, and concentrate the filtrate to obtain a light yellow solid (Formula II) (6.29 g, yield 91.5%, purity >99%). Melting point: 82-84°C. The identification results are as follows:

[0038] NMR (CDCl 3)δ: 3.81(s, 3H); 5.35(s, 2H); 6.93(m, 2H); 7.40(m, 2H); 7.63(m, 1H); )

[0039] MS (CI): 287

Embodiment 2

[0040] Example 2 Synthesis of 4-methoxybenzyl 3-nitrobenzoate (formula II)

[0041] Formula I compound (150.00g, 0.898mol) in ethyl acetate 100ml, add NEt 3 (181.89g, 1.797mol), PMBCl (251.49g, 1.605mol) was added dropwise at room temperature, the temperature was raised to 60°C, and the reaction was carried out for 5 hours. use CH 2 Cl 2 and water extraction, combined CH 2 Cl 2 layer with anhydrous NaSO 4 Dry, filter, and concentrate the filtrate to obtain a light yellow solid, which is recrystallized from ethanol to obtain white crystals (Formula II) (256.53 g, yield 99.5%, purity 100%). Melting point: 83-85°C.

Embodiment 3

[0042] Example 3 Synthesis of 4-methoxybenzyl 3-nitrobenzoate (formula II)

[0043] Formula I compound (150.00g, 0.898mol) was added to 200ml of toluene, pyridine (106.41g, 1.35mol) was added, PMBCl (422.13g, 2.694mol) was added dropwise at room temperature, the temperature was raised to 40°C, and the reaction was carried out for 10 hours. use CH 2 Cl 2 and water extraction, combined CH 2 Cl 2 layer with anhydrous NaSO 4 Dry, filter, and concentrate the filtrate to obtain a light yellow solid, which is recrystallized from ethanol to obtain white crystals (Formula II) (256.00 g, yield 99.1%, purity >99%). Melting point: 83-85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com