Patents

Literature

90 results about "Imidogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imidogen is an inorganic compound with the chemical formula NH. Like other simple radicals, it is highly reactive and consequently short-lived except as a dilute gas. Its behavior depends on its spin multiplicity, i.e. the triplet versus singlet ground state.

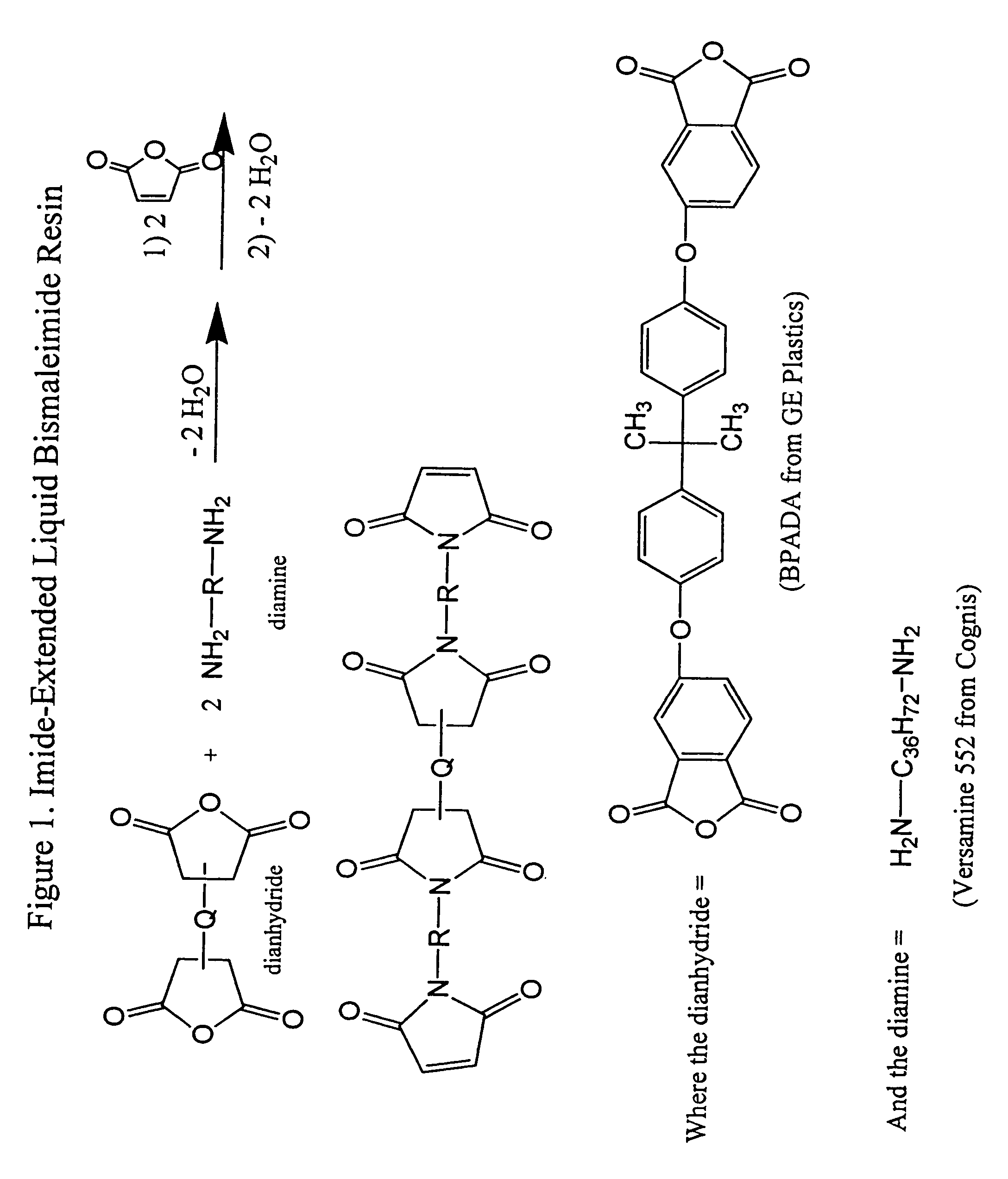

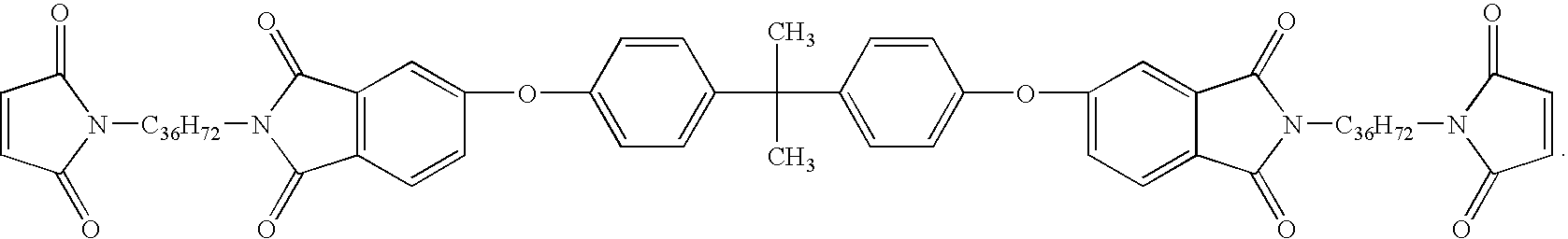

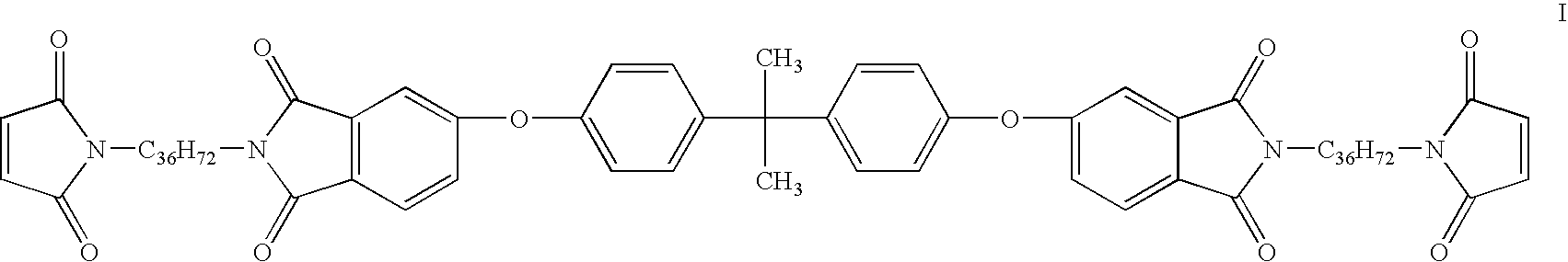

Imide-extended liquid bismaleimide resin

ActiveUS7157587B2Improve toughnessNot sacrificing thermal stabilityOrganic chemistrySynthetic resin layered productsImideDiamine

The invention is based on the discovery that a remarkable improvement in the performance of bismaleimide thermosets can be achieved through the incorporation of an imide-extended liquid bismaleimide monomer. This imide-extended liquid bismaleimide monomer is readily prepared by the condensation of an appropriate dianhydride with two equivalents of an appropriate diamine to give an amine terminated compound. This compound is then condensed with an excess of maleic anhydride to yield an imide-extended liquid bismaleimide monomer.

Owner:DESIGNER MOLECULES

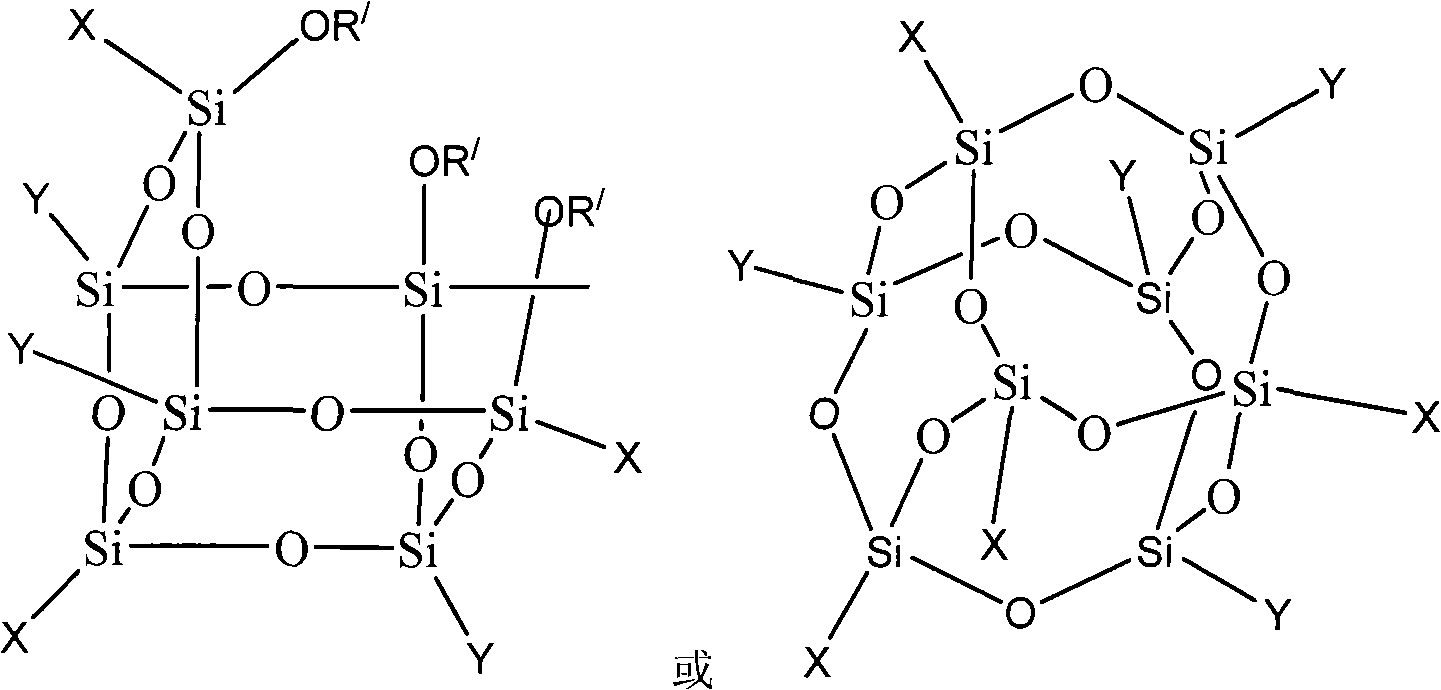

Heat-resistant flame-proof phosphorus- and silicon-containing hybrid curing agent for epoxy type electronic polymer material and preparation thereof

InactiveCN101274998AGood mechanical propertiesImprove flame retardant performanceEpoxyStructural formula

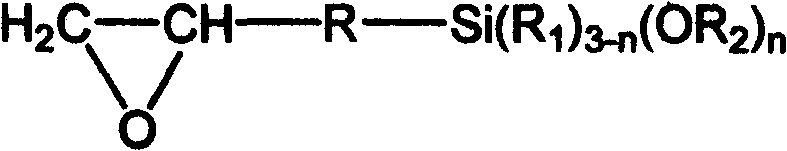

The invention pertains to the field of polymeric material and relates to an epoxy phosphorus-containing hybridization hardener with heat resistance and flame retardancy for electron polymer material and a preparation method thereof. The phosphorus-containing hybridization hardener is nanometer-sized organic / inorganic hybrid silicone of a hollow enclosed type or a partially enclosed type, wherein, the structure center of the silicone consists of inorganic skeleton Si-O bonds; the external end of the structure center consists of organic groups of organic phosphor or amidogen or imidogen and has a number average molecular weight of 600 to 10000 and the structural formula is as above, wherein, R< / > can be hydrogen, cymene, ethyl, n-propyl, isopropyl or butyl; X is organic containing phosphorus substituent ; Y is organic amino-containing substituent. The samples prepared with epoxy resin hardened by the hardener not only have a very good flame retardant performance, but also maintain good heat resistant and mechanical property, thus meeting the requirements for heat resistance and flame retardancy and mechanical aspects of the epoxy resin used for the electronic substrate material with high performance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Polishing system and method of its use

The invention provides a system for polishing one or more layers of a multi-layer substrate that includes a first metal layer and a second layer comprising (i) a liquid carrier, (ii) at least one oxidizing agent, (iii) at least one polishing additive that increases the rate at which the system polishes at least one layer of the substrate, wherein the polishing additive is selected from the group consisting of pyrophosphates, condensed phosphates, phosphonic acids and salts thereof, amines, amino alcohols, amides, imines, imino acids, nitriles, nitros, thiols, thioesters, thioethers, carbothiolic acids, carbothionic acids, thiocarboxylic acids, thiosalicylic acids, hydroxylates, carbonylates, carboxylates, and acids thereof, and mixtures thereof, (iv) at least one stopping compound, and (v) a polishing pad and / or an abrasive. The invention also provides a method of polishing a substrate comprising contacting a surface of a substrate with the system and polishing at least a portion of the substrate therewith. Moreover, the invention provides a method for polishing one or more layers of a multi-layer substrate that includes a first metal layer and a second layer comprising (a) contacting the first metal layer with the system, and (b) polishing the first metal layer with the system until at least a portion of the first metal layer is removed from the substrate.

Owner:CABOT MICROELECTRONICS CORP

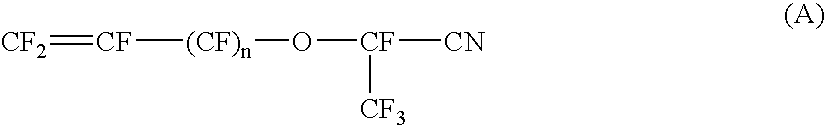

Fluorinated imidoylamidines vulcanizing agents

ActiveUS20080035883A1Improve thermal stabilityImprove mechanical propertiesOrganic chemistryOther chemical processesHydrogenEther

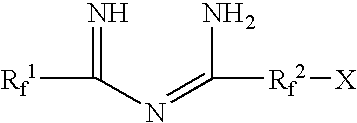

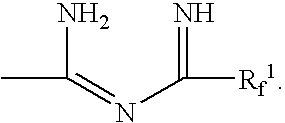

The invention provides a compound and tautomeric forms thereof having the formula: wherein Rf1 is selected from the group consisting of hydrogen, a straight chain, branched secondary or branched tertiary C1-C20 perfluoroalkyl group optionally containing ether or thioether linkages and C1-C10 perfluoroalicyclic group optionally containing ether or thioether groups; Rf2 is a straight or branched C1-C20 perfluoroalkylene group optionally substituted with ether and thiother linkages; and X is selected from the group consisting of fluorine and The invention also provides perfluoroelastomeric compositions cured with the perfluoroimidoylamidines of the invention as well as combinations of perfluoroimidoylamidines and other curing agents.

Owner:LODESTAR

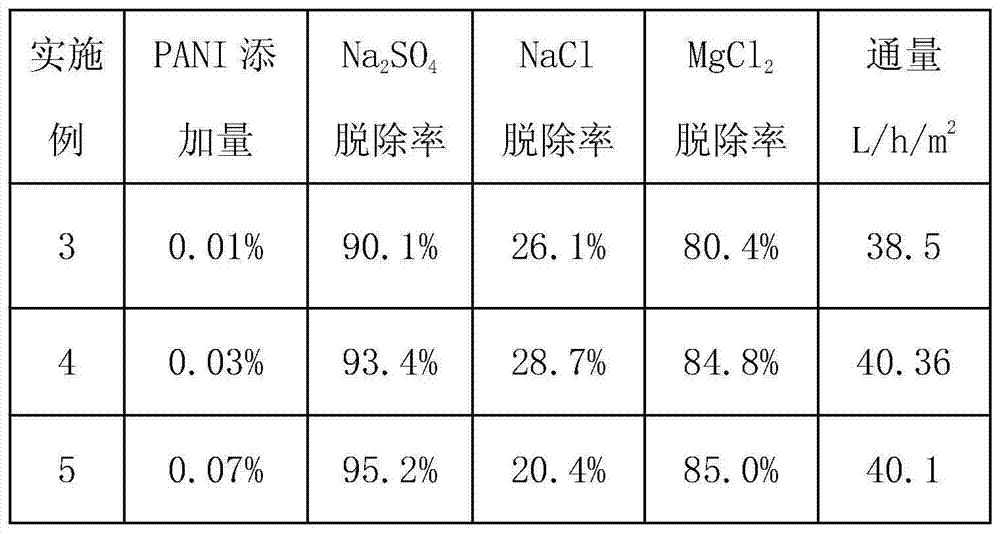

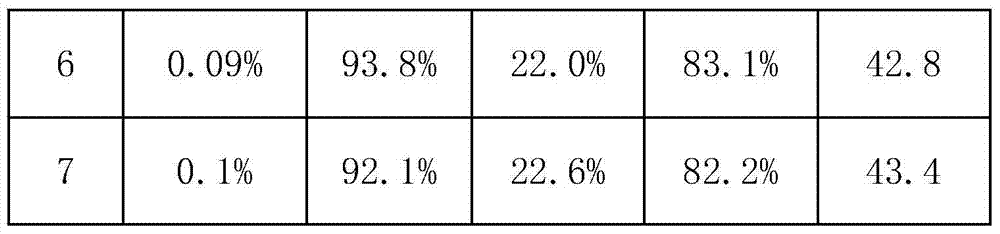

Preparation method of nano material modified poly piperazine amide nanofiltration membrane

ActiveCN103877872AHigh mechanical strengthHigh permeation fluxSemi-permeable membranesSodium sulfatePermeation

The invention discloses a preparation method of a nano material modified poly piperazine amide nanofiltration membrane. The preparation method comprises the following steps: adding conducting nano polyaniline into a piperazine water solution, carrying out ultrasound processing so as to disperse the conducting nano polyaniline uniformly, and then contacting the dispersed conducting nano polyaniline with an organic solution containing trimesoyl chloride and lipophilicity nano titanium dioxide to generate interfacial polymerization reaction so as to obtain a modified composite nanofiltration membrane. The nanofiltration membrane prepared by the method is improved in the rejection rate of sodium sulfate and magnesium chloride to the maximum of 97.2% and 88.5%, is low in rejection rate (less than 30%) of sodium chloride, and shows high selectivity to univalent salt and divalent salt, and meanwhile, the permeation flux and the antiseptic property of a membrane sheet are improved to a certain extent; additionally, the surface of the prepared membrane is endowed with amidogens, imidogen active groups, amide bonds and nano particles, so that the nano material modified poly piperazine amide nanofiltration membrane has the characteristics of favorable hydrophilia, pollution resistance, electric conductivity, mechanical intensity and the like, and can be widely applied to the separation of multiple salts.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Tri-(beta-diketone imidogen) rare earth metal complex and uses thereof

InactiveCN101343235AHigh molecular weightModerate molecular weight distributionGroup 3/13 element organic compoundsDiketoneRare earth

The invention discloses a tri-(Beta-Diketiminato) rare-earth metal complex, having the following chemical formula: Ln[(C6H4X)NC(Me)CHC(Me)N(C6H4X)]3, wherein, Ln represents rare earth metal; and X is a substituent selected from Cl, F, H, p-CH3 or o-CH3. Meanwhile, the invention discloses an application of the complex in the ring-opening polymerization reaction of Epsilon-caprolactone and L-lactide as a catalyst. The tri-(Beta-Diketiminato) rare-earth metal complex can take Beta-Diketiminato as an active group to initiate the ring-opening polymerization reaction of Epsilon-caprolactone and L-lactide, and can catalyze the ring-opening polymerization by extreme high activity under mild conditions, the obtained polycaprolactone and polylactic acid have rather high molecular weight, and the molecular weight distribution is moderate.

Owner:SUZHOU UNIV

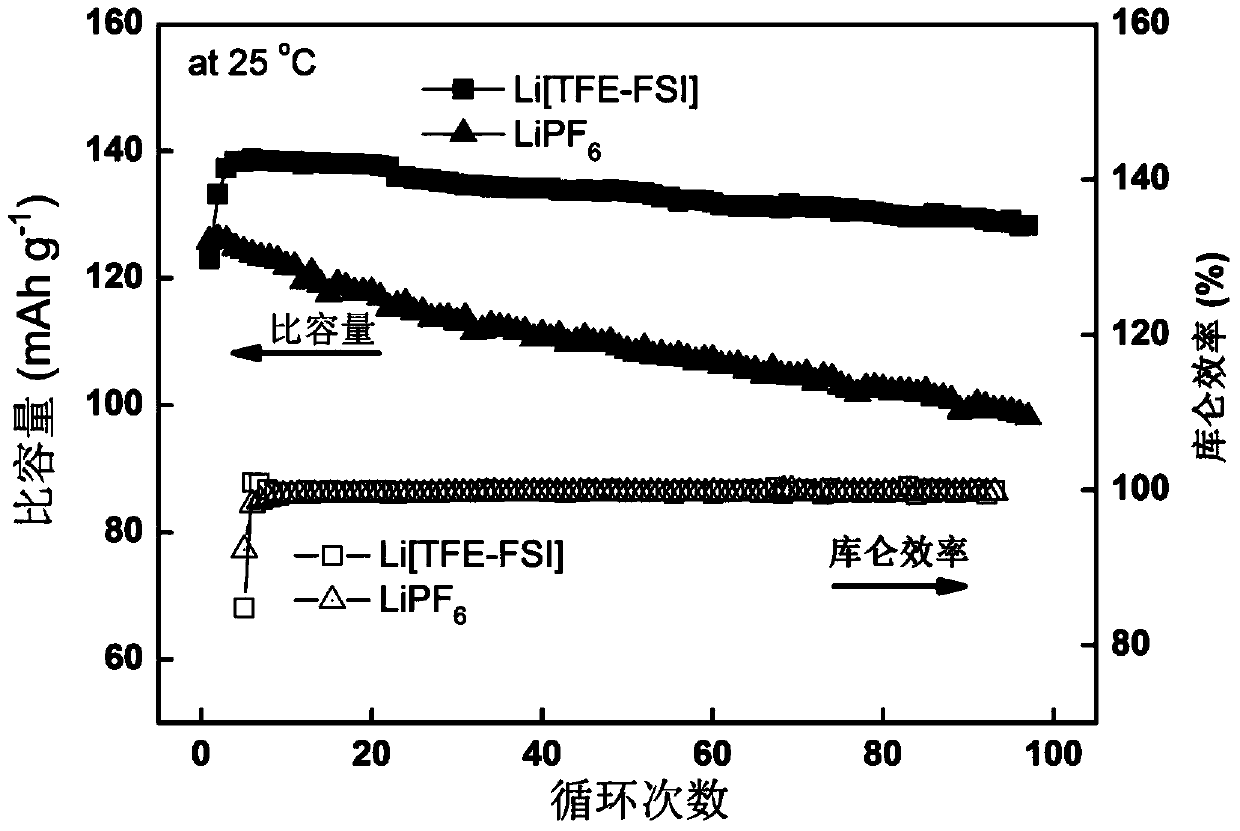

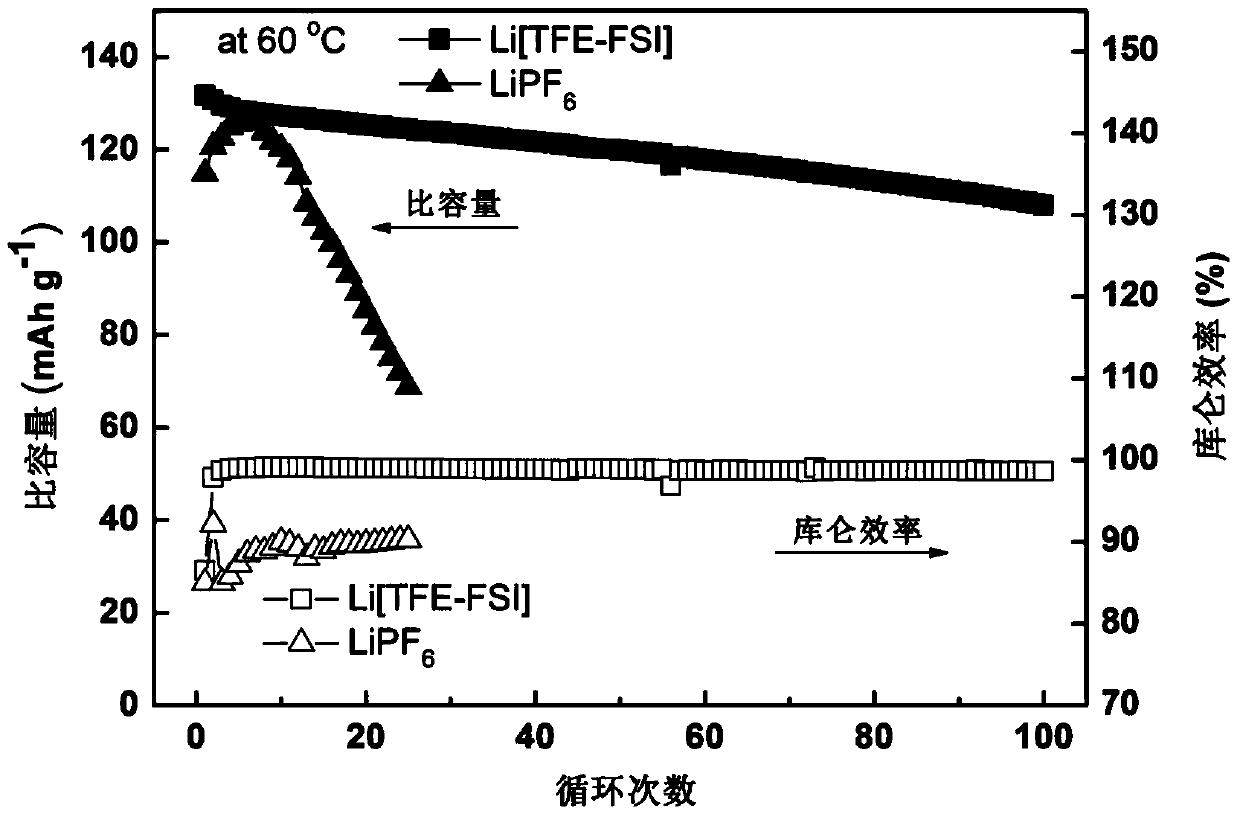

Nonaqueous electrolyte containing sulfonyl fluoride imidogen lithium salt as well as application of electrolyte

InactiveCN103794819AImprove thermal stabilityStrong redox resistanceCell electrodesSecondary cellsSulfonyl fluorideLithium-ion battery

The invention discloses nonaqueous electrolyte by taking asymmetrical (sulfonyl fluoride) (multi-fluorine alkoxy sulfonyl) lithium imide as conductive salt. The nonaqueous electrolyte has the characteristics of high thermal stability, high redox resistance, no aluminum foil corrosion and the like. Under the condition of no additive, the electrolyte material and the lithium ion battery electrode material have favorable compatibility; meanwhile, the electrolyte material has better room-temperature and high-temperature circulation stability than LiPF6, and can serve as a nonaqueous electrolyte additive for improving the high-temperature cycle and storage performances based on the LiPF6 electrolyte.

Owner:SUZHOU FLUOLYTE

Synthetic method of imidacloprid

The invention provides a synthetic method of imidacloprid, which comprises the synthetic steps of (1) sequentially adding an amine substance, 2-chlorine-5-chlorine picoline and a solvent into a reactor, conducting heating reflux for 2h, cooling, obtaining a catalyst solution, (2) sequentially adding a solvent, 2-nitryl imidogen imidazolidine and 1 / 5 alkali metal hydroxide into the catalyst solution, stirring, heating to 45 DEG C for heat preservation; (3) dropwise adding a solvent solution of 2-chlorine-5-chlorine picoline into reaction liquid for 30min each time and for four times totally after the heat preservation is over, adding 1 / 5 alkali metal hydroxide into the reaction liquid after dropwise adding the solvent solution each time, conducting heat preservation reaction for 1-2h after finishing the adding, and (4) conducting water washing for three times after the reaction is over, distilling the solvent out, crystallizing at 5 DEG C below zero, conducting suction filtration, drying, and obtaining a crude product of imidacloprid. According to the synthetic method, the reaction time is short; by-products are few; the purity of the crude product of imidacloprid reaches 98%; and a yield reaches 95.3%.

Owner:SHANDONG UNITED PESTICIDE IND CO LTD

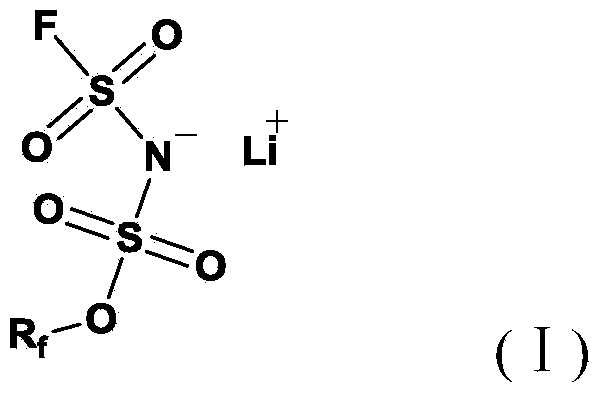

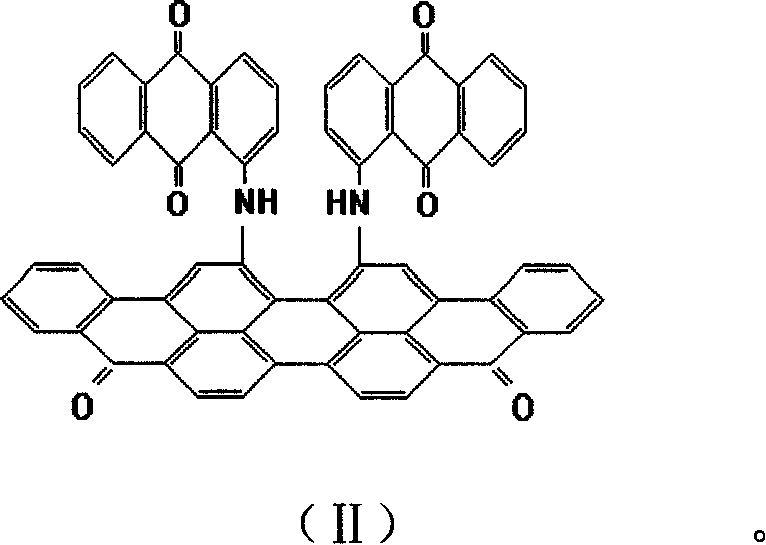

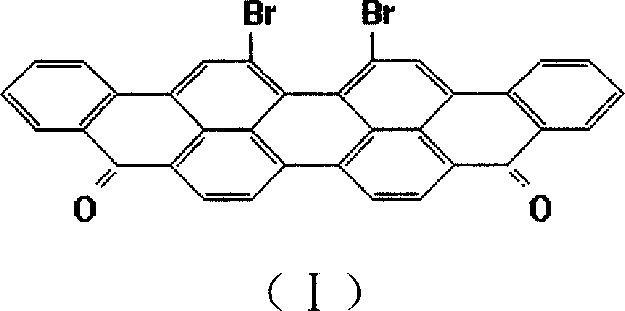

Anthraquinone vat dye 16,17- dibromviolanthrone and 16,17-di(1'-imdoanthraquinonyl) violanthrone and its preparation method

The invention discloses two dyes and making method, which is characterized by the following: the structure formula of reduced dye 16, 17-dianthrone dibromide is (I); the structure formula of reduced dye 16, 17-two (1'-imidogen anthraquinonyl) dianthrone is (II); the 16, 17-dianthrone dibromide (I) is made of brodianthrone, which condenses with 1-aminoanthraquinone to produce 16, 17-two (1'-imidogen anthraquinonyl) dianthrone is (II).

Owner:江苏嘉利精细化工有限公司

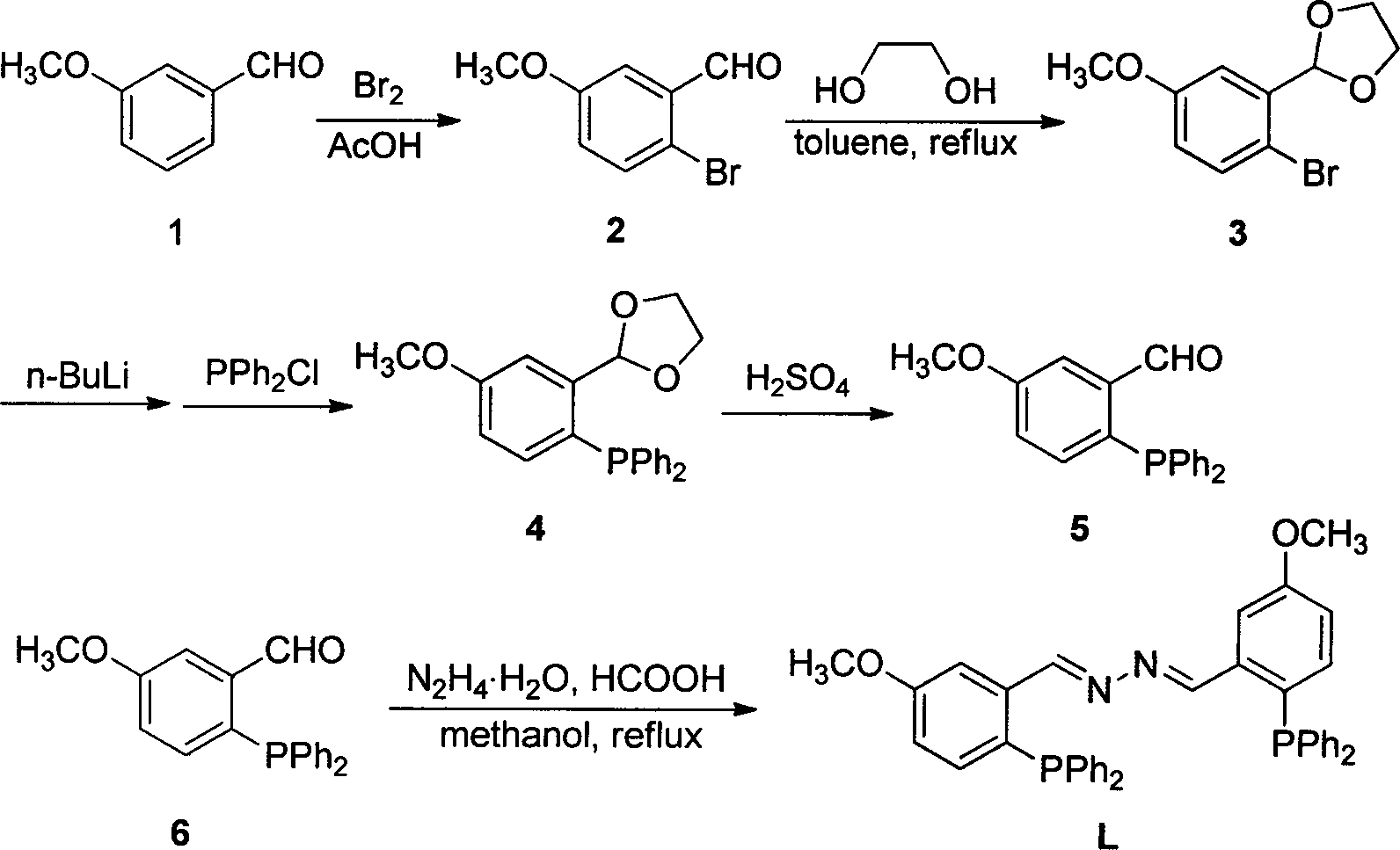

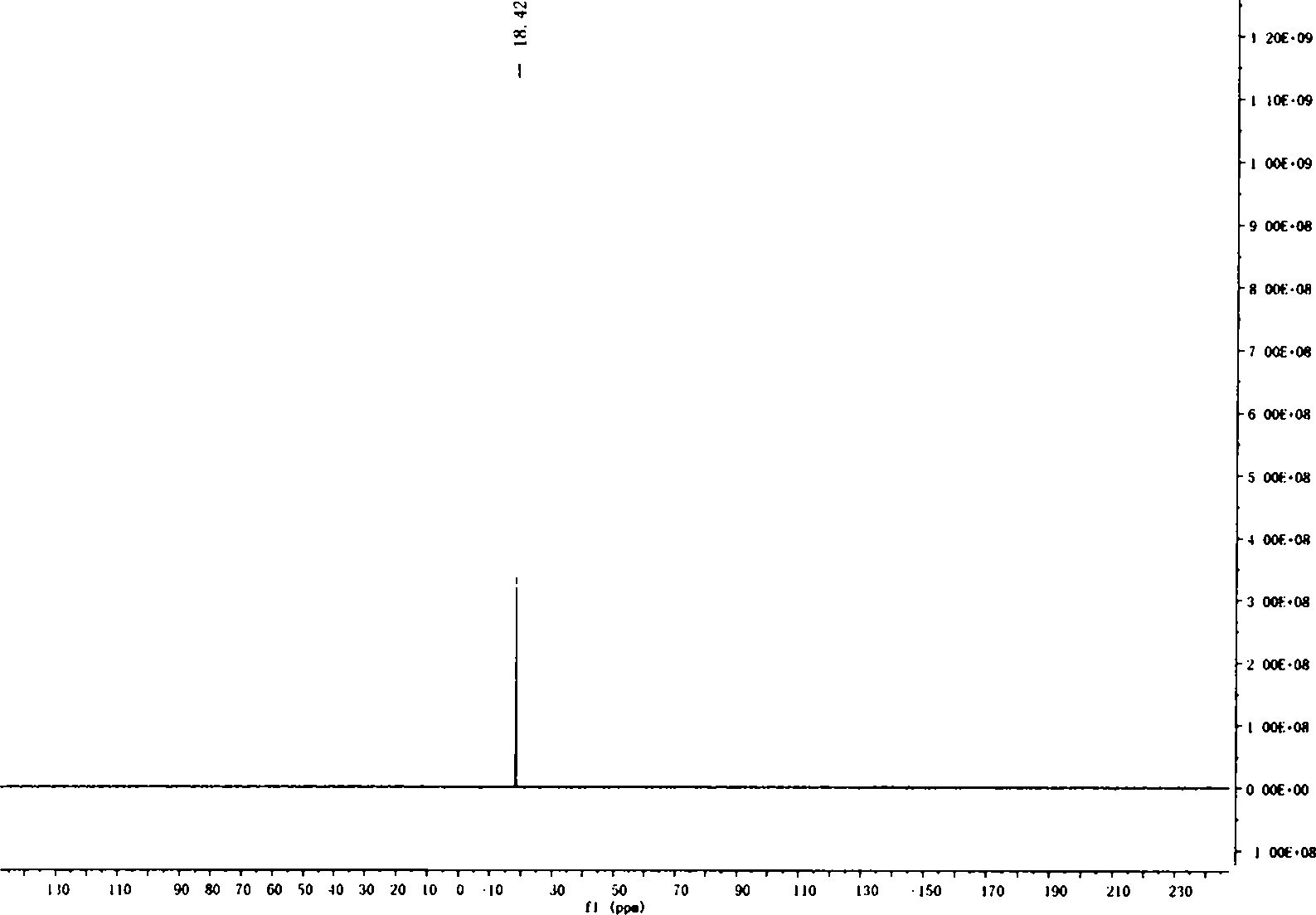

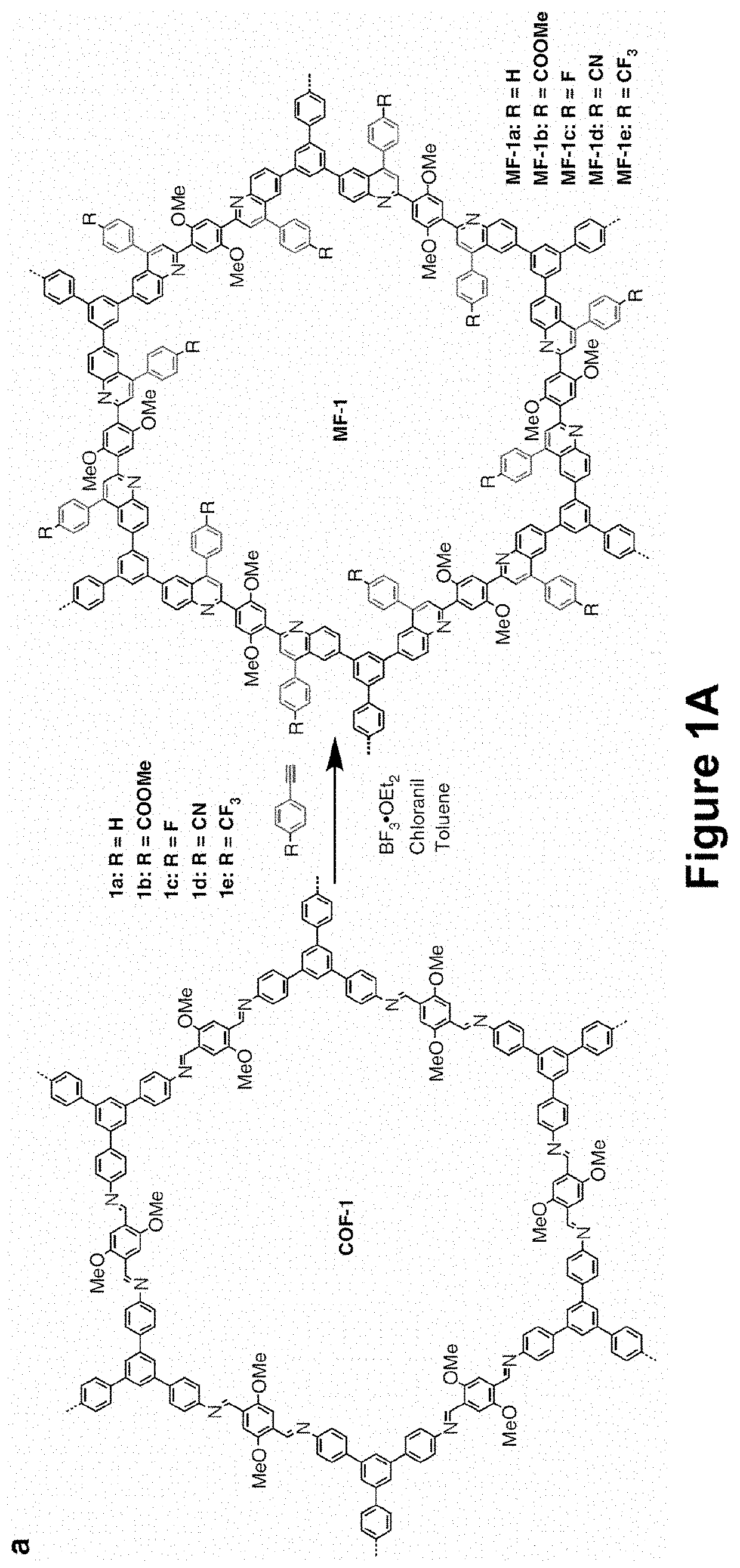

Synthetic method and application of (1E, 2E)-1,2-bi(5-methoxyl-2-diphenylphosphine benzylidene) hydrazine

InactiveCN103483383AHigh reactivityAvoid formingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalysts2-DiphenylphosphinobenzaldehydeBenzaldehyde

(1E, 2E)-1,2-bi(5-methoxyl-2-diphenylphosphine benzylidene) hydrazine is a dual-phosphine ligand containing an imine group. An aromatic ring has methoxyl which supplies electrons so that double metal has the stronger coordination capability. According to the synthetic method, intermediate 5-methoxyl-2-(diphenylphosphino)benzaldehyde and hydrazine hydrate serve as raw materials, formic acid serves as a catalyst, and the raw materials and the formic acid flow back in methyl alcohol to obtain bis-imine bis-phosphine four-tooth ligand L. Bis-imine bis-phosphine four-tooth ligand L and Cu(CH3CN)4CIO4 in-situ catalytic Sonogashira cross coupling reaction is carried out, the catalytic system is very high (the yield reaches to 99%) in reactivity to aryl iodide and is active to aryl bromide to some degree, alkyne self-coupling products can be well avoided, the reactive system is simple, and post-processing is convenient. Adopted Cu is low in cost, easy to obtain, economical and clean, and takes part in the Sonogashira coupled reaction instead of expensive and toxicant Pd. No rganic amine used as a solvent or alkali is used. The (1E, 2E)-1,2-bi(5-methoxyl-2- diphenylphosphine benzylidene) hydrazine has very good application prospects in industrial production in the future.

Owner:NANKAI UNIV

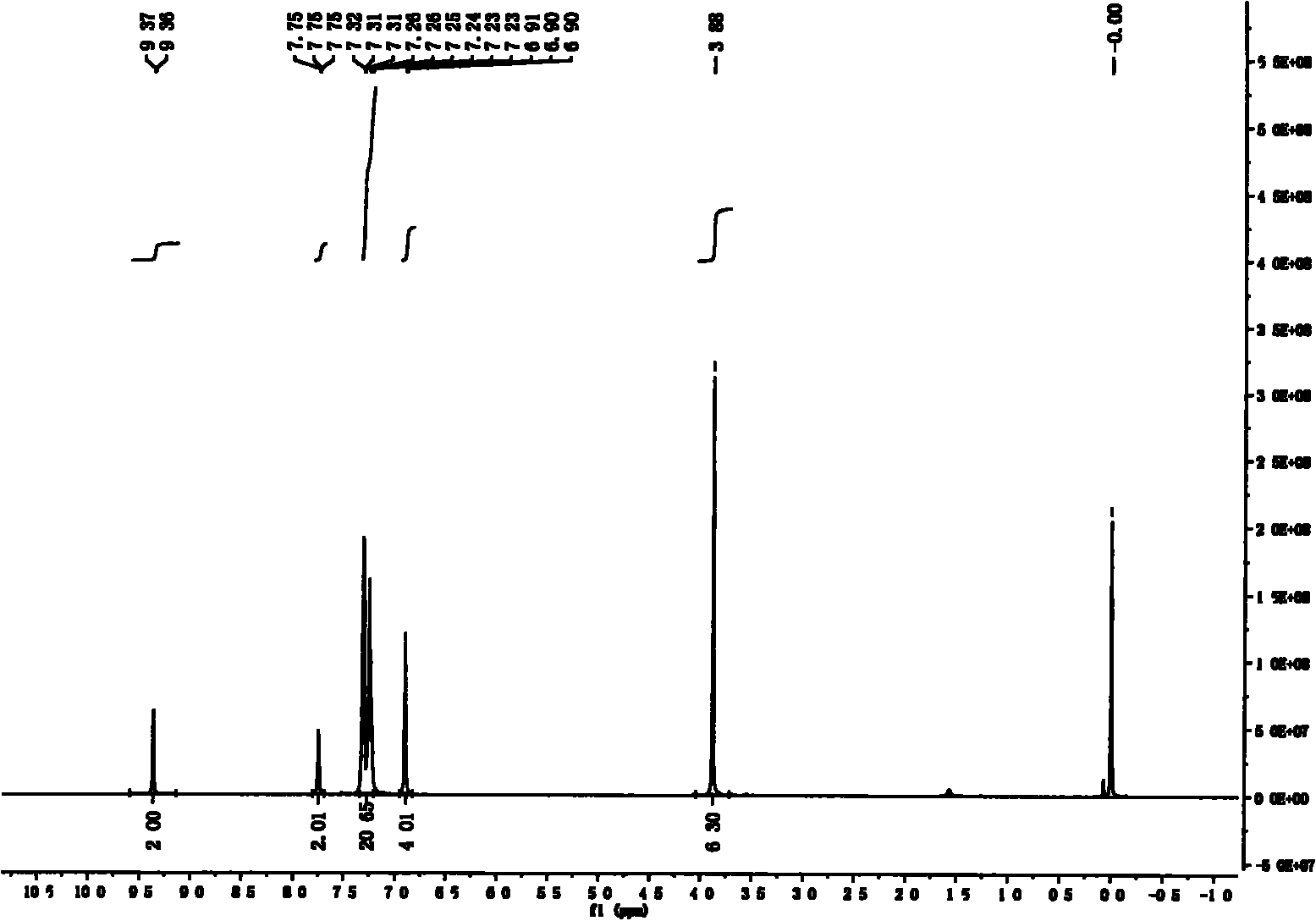

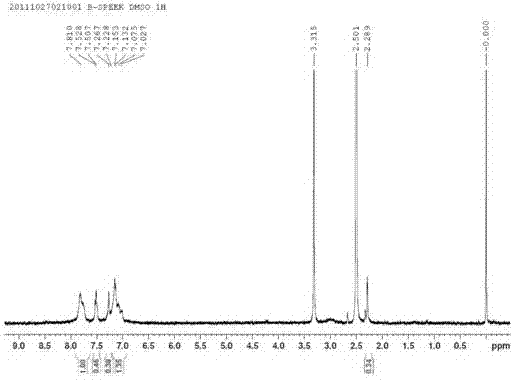

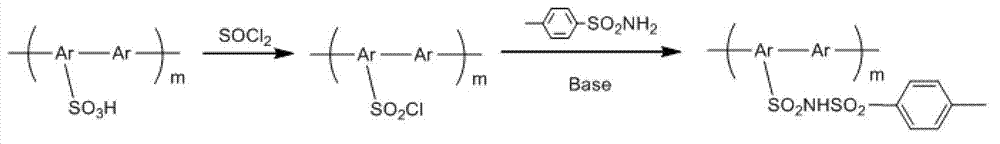

Organic polymer gelator and preparation method and application thereof

The invention discloses an organic polymer gelator and a preparation method and application thereof. The organic polymer gelator is excellent in gelation ability, takes an aromatic polymer as a main chain and is structurally modified to enable a side chain to contain benzenesulfonyl imidogen, so that the organic polymer gelator and polarity organic solvent molecules can efficiently form a hydrogen-bond cross-linked structure, and further, gel is formed. The organic polymer gelator has potential application value and development potentials in the fields of water treatment agents, oil spill at sea, biological tissue engineering, drug transportation, food, cosmetics, biological sensing and sensitive device preparation and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of preparing polyimide/inorganic nano hybridization material

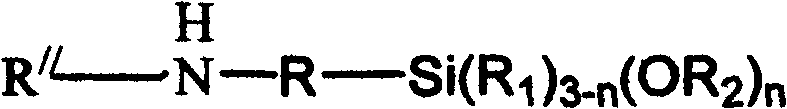

The invention provides a method preparing for a polyimide or an inorganic nanometer hybridized material, which comprises the following steps: synthesizing an imidogen cyclic silane adapting to the inorganic nanometer particle modifier; preparing for the inorganic oxidate nanometer particle with the sol-gel processing; adding the modifier-imidogen cyclic silane in the sol-gel reacting process; getting the organic and inorganic complex nanometer particle; making the organic and inorganic complex nanometer particle uniformly dispersing in the polyamic acid solution; getting the polyimide or the inorganic nanometer hybridized material. The invention dissolves the problem of dispersing the nanometer particles, which shows every property sufficiently.

Owner:HARBIN ENG UNIV

Environment-friendly high-efficient formaldehyde scavenger and preparation method thereof

InactiveCN107213783AEfficient degradationEffective absorptionGas treatmentDispersed particle separationScavengerEthylene urea

The invention discloses an environment-friendly high-efficient formaldehyde scavenger, which has a formula as below: 10 to 30 parts of sansevieria extracting solution, 10 to 30 parts of shaddock peel extracting solution, 10 to 30 parts of scindapsus aureus extracting solution, 5 to 15 parts of menthol, 30 to 50 parts of ethyl alcohol, 3 to 5 parts of formaldehyde scavenging microorganisms, 15 to 25 parts of penetrating agent, 10 to 20 parts of ethylene urea, 5 to 10 parts of flavor enhancer, and 100 to 130 parts of solvent. According to the environment-friendly high-efficient formaldehyde scavenger, the ethylene urea contains amidogen and imidogen with higher activity, so that the stability is good, and a product generated by reaction of the environment-friendly high-efficient formaldehyde scavenger and formaldehyde is safe and non-toxic; byssochlamys fulva and pseudomonas amygdalae can be used for effectively degrading the formaldehyde; the sansevieria extracting solution, the shaddock peel extracting solution and the scindapsus aureus extracting solution can effectively absorb the formaldehyde, and the flavor enhancer can enable the scavenger to emit fragrance. The environment-friendly high-efficient formaldehyde scavenger provided by the invention is environment-friendly and safe without secondary pollution, and suitable for production, popularization and application.

Owner:安徽桧元素生物科技有限公司

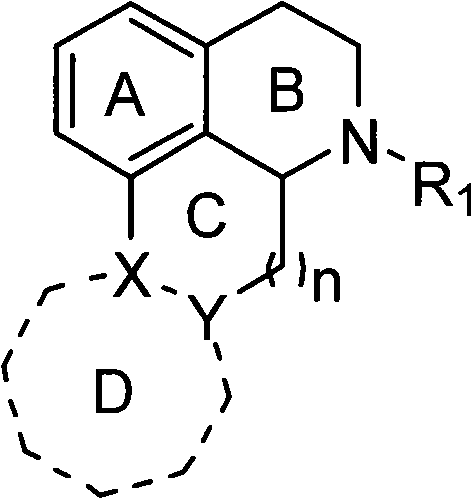

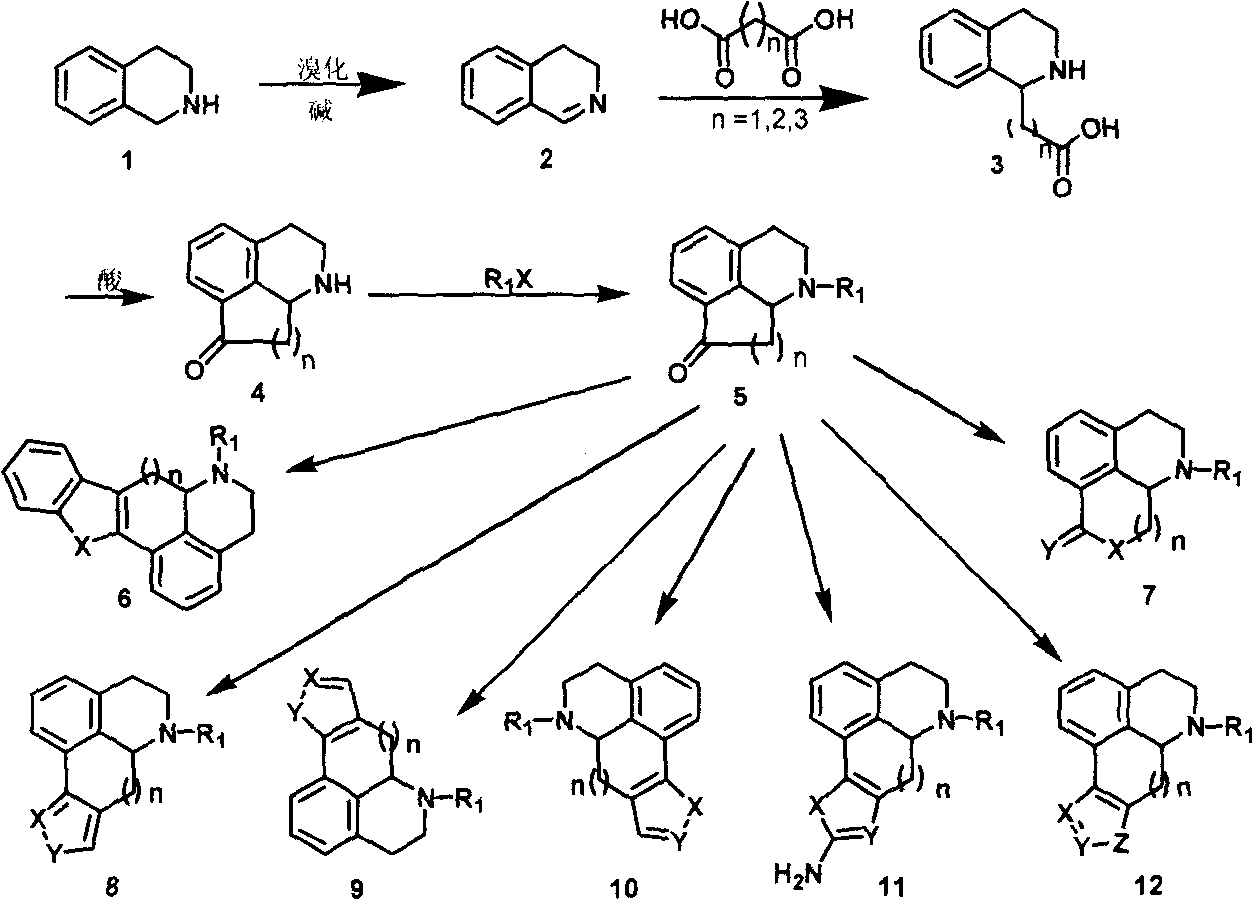

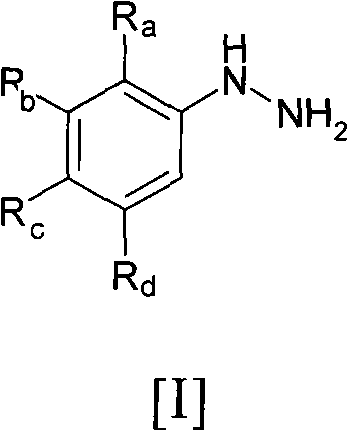

Isoquinoline compounds, preparation method and use thereof

The invention discloses a novel isoquinoline compound, and a synthetic method thereof as well as an application of the compound, which is used as an agonist or an inhibitor of dopamine receptors in the medicines for treating Parkinson's disease, schizophrenia, tristimania, Tourette syndrome, attention-deficit hyperkinetic syndrome, pituitary tumor, etc. The constitutional formula of the compound is as follows: wherein, R1 is the hydrocarbyl with a H, C1-C10 linear chain or fork chain, heteroatom-substituted hydrocarbyl and aromatic or fatty heterocycle or non-heterocycle substituted alkyl; X is carbonyl, methylene and imidogen, and is more than C-OH or more than C=; Y is carboxide, methylene and imidogen, and is more than C= or more than C=N-OH; the compound can have no D cycle or the D cycle can be various heterocycles of substituted five-membered fat and substituted six-membered fat or substituted five-membered aromatic and six-membered aromatic; n is 0-3.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

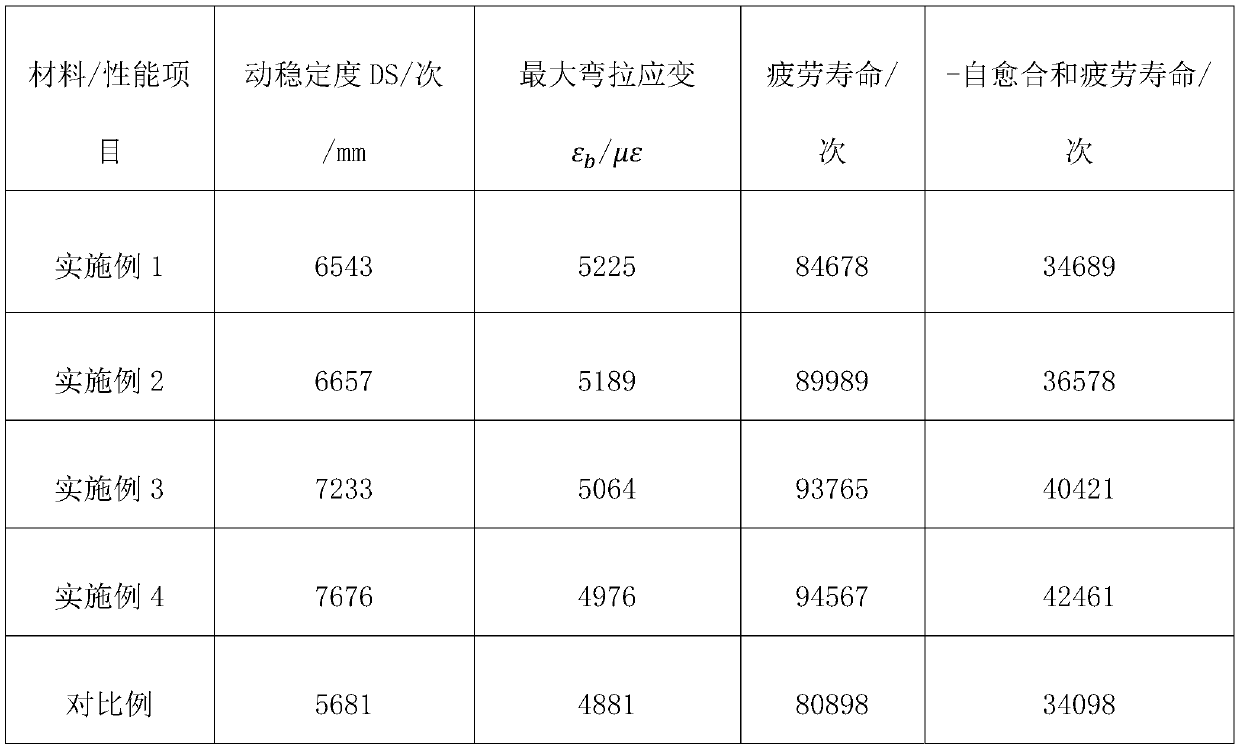

Anti-fatigue modified asphalt and preparation method thereof

InactiveCN110272632AHigh modulusGood viscoelastic propertiesBuilding insulationsChemical reactionPlasticizer

The invention provides anti-fatigue modified asphalt and a preparation method thereof. The anti-fatigue modified asphalt comprises 100 parts of matrix asphalt, 18-22 parts of waste tire rubber powder, 0.5 part of a plasticizer, 0.4-1.6 parts of polyphosphoric acid, 0.2 part of a compatilizer and 0.1 part of a stabilizer. On the basis of the waste tire rubber powder modified asphalt, by adding the plasticizer and the polyphosphoric acid, the disadvantage of low high-temperature stability of the waste tire rubber powder modified asphalt is well relieved, hydroxyl, imidogen, sulfydryl and other active groups in asphalt molecules chemically react with the polyphosphoric acid, the original micelle structure of asphaltene is broken, the dispersion uniformity of the asphaltene in asphalt light components is improved, a stable spatial network is easily formed, the modulus of the asphalt is enhanced, the viscoelastic properties of the asphalt are thus improved, and the high-temperature stability and the anti-fatigue performance of the asphalt are improved. The resistance to fatigue cracking is further improved, and on the premise of high high and low-temperature performance, the modified asphalt is high in resistance to fatigue cracking.

Owner:CHANGAN UNIV

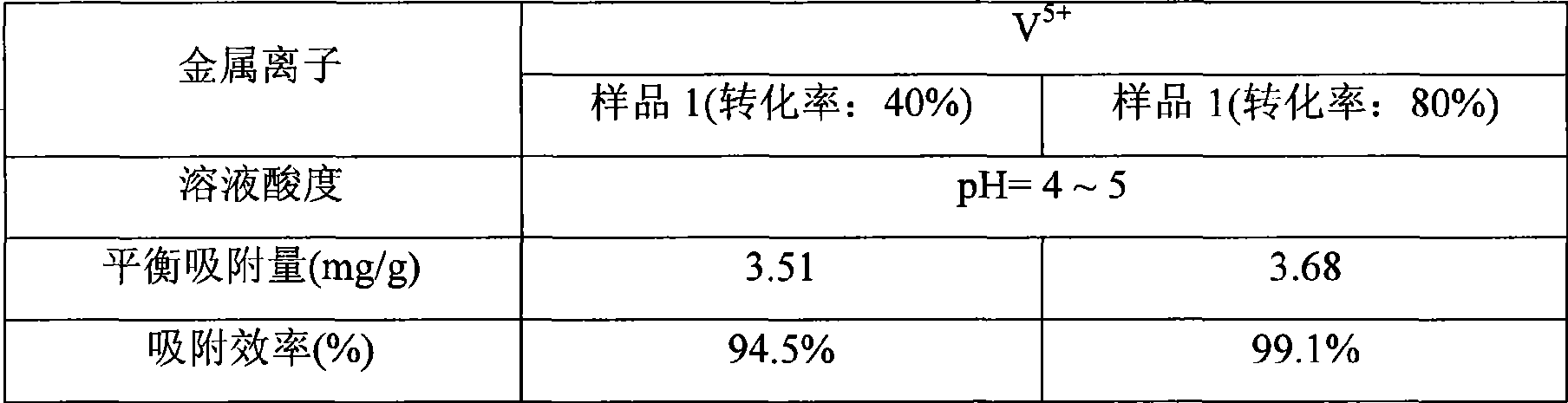

Method for preparing polypropylene ion chelating membrane by radiation grafting method

The invention relates to a method for preparing a polypropylene ion chelating membrane by adopting an electron beam radiation grafting method. The method comprises the following steps: using a polypropylene membrane (PP) as a skeleton; grafting nontoxic acrylonitrile (AN) on the membrane by adopting a method of pre-radiation grafting initiated by an electron beam; and preparing a chelating functional membrane containing imidogen through an amination reaction. The method has the characteristics of simple synthesizing steps, low price and easily-obtained raw materials, and the like. Besides, the ion chelating functional membrane synthesized by the method has the advantages of better chemical and mechanical stability, good coordinating and complexing abilities to metal ions, large adsorption capacity, easy regeneration and reusability, and can be applied to purifying industrial wastewater polluted by heavy metal ions or enriching noble metal ions.

Owner:SHANGHAI UNIV

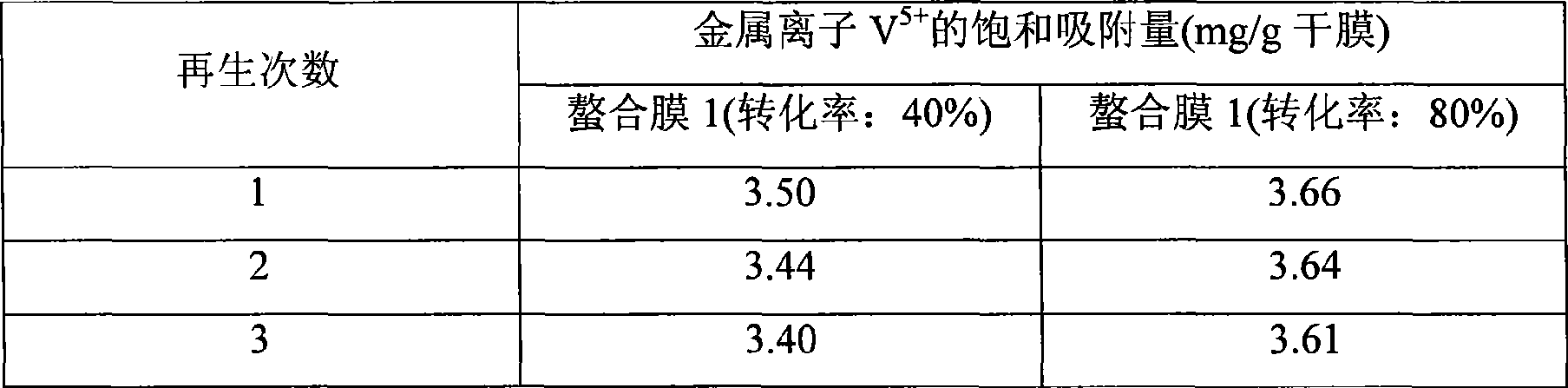

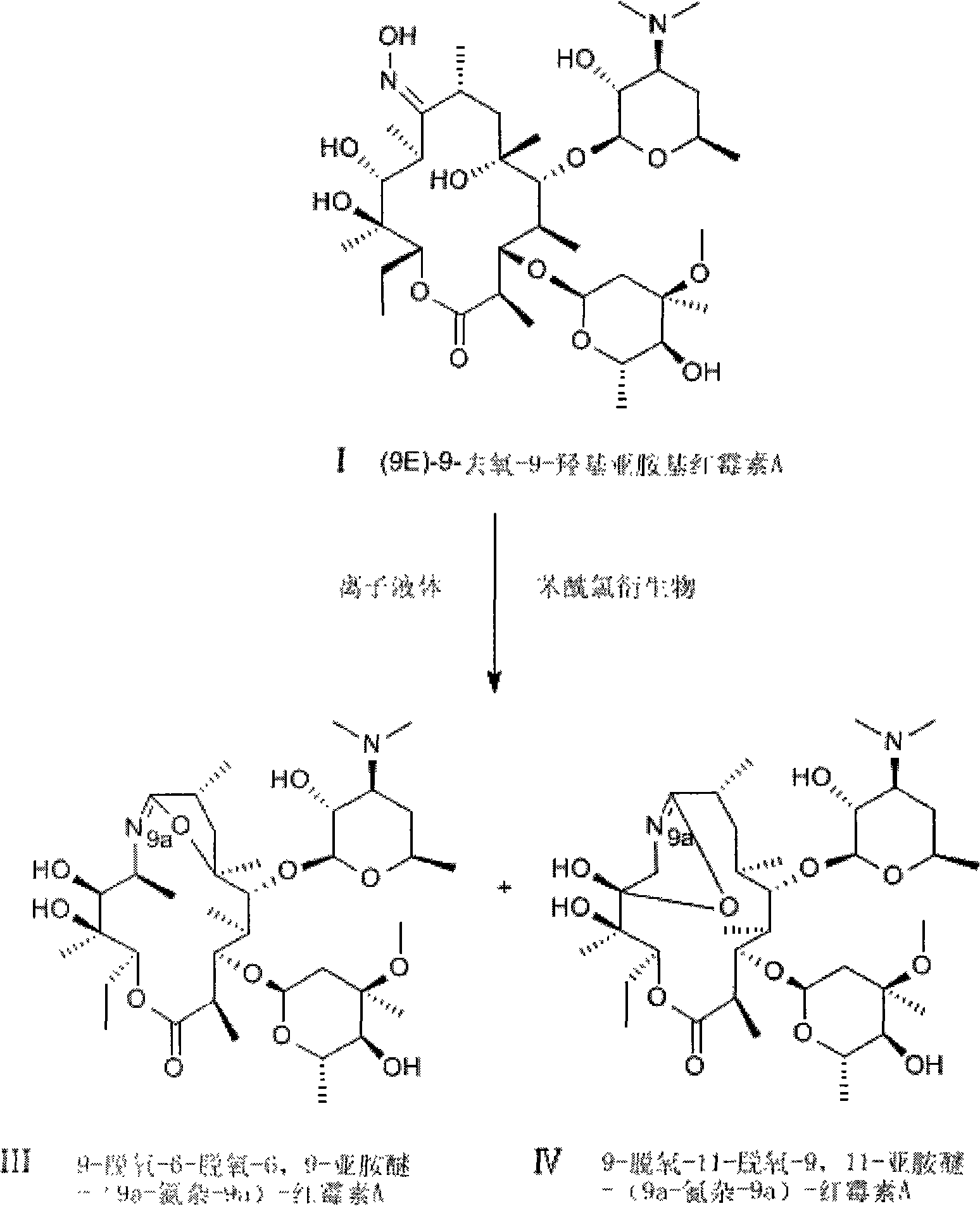

Method for preparing erythrocin A iminoether salt

ActiveCN101613389AEasy to installSimple reactivitySugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsBeckmann rearrangementSulfonyl chloride

The invention relates to a clean catalysis synthesizing method for preparing 9-deoxidized-6-deoxidized-6,9-iminoether-(9a-aza-9a)-erythrocin A and 9-deoxidized-11-deoxidized-9,11-iminoether-(9a-aza-9a)-erythrocin A by means of Beckmann rearrangement of (9E)-9-deoxidized-9-hydroxyl imidogen erythrocin A in a single-phase or two-phase room temperature ionic liquid system, or for preparing 9-deoxidized-6-deoxidized-6,9-iminoether-(8a-aza-8a)-erythrocin A and 9-deoxidized-12-deoxidized-9,12-iminoether-(8a-aza-8a)-erythrocin A by means of Beckmann rearrangement of (9Z)-9-deoxidized-9-hydroxyl imidogen erythrocin A in the single-phase or two-phase room temperature ionic liquid system. The catalyst used in the method is a benzene sulfonyl chloride derivative which can generate a corresponding target product in a mild and high-transformation-rate manner. Ionic liquid used for synthesis can be recycled. The method is simple and free of pollution.

Owner:江苏合纵思远生物科技有限公司

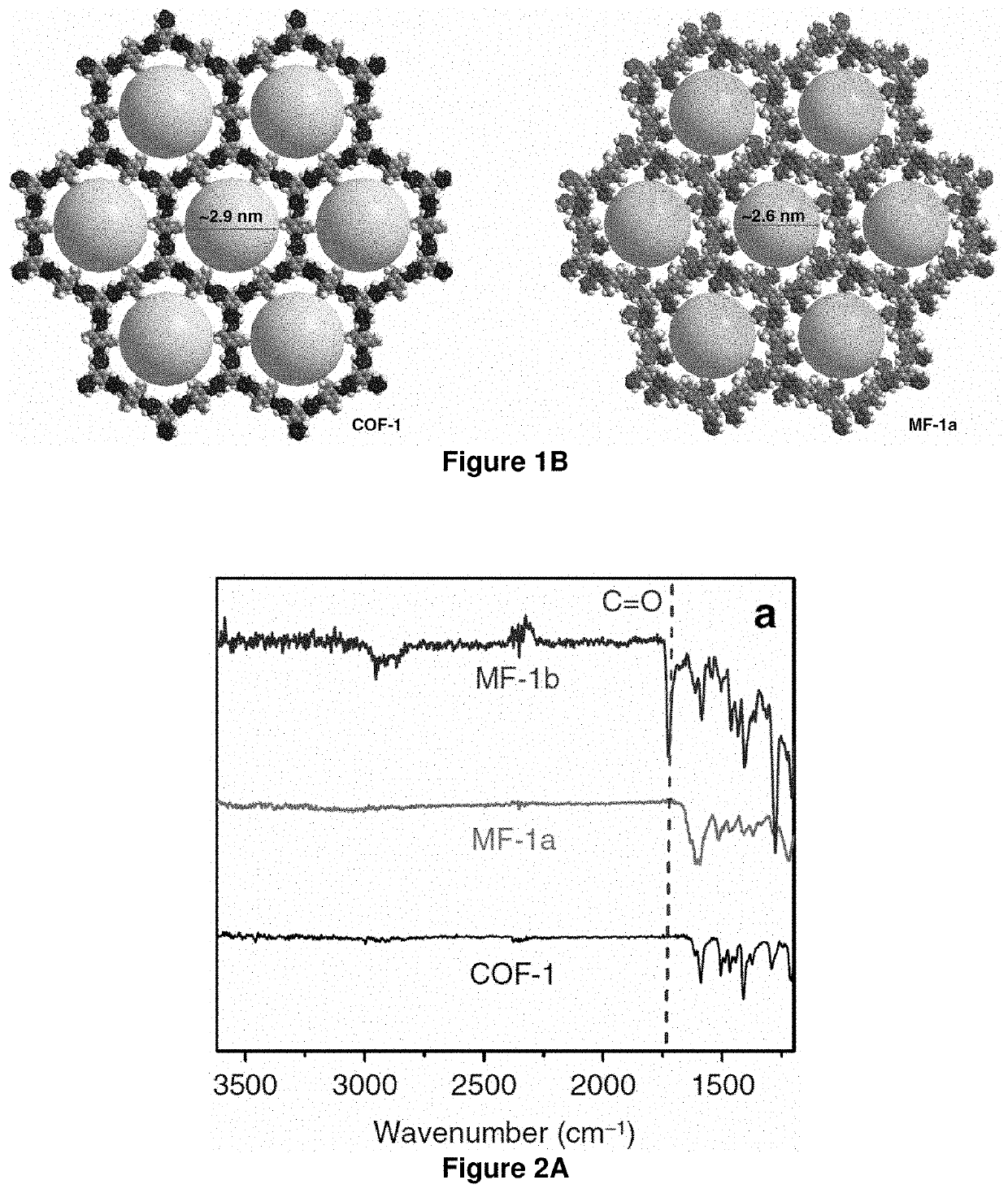

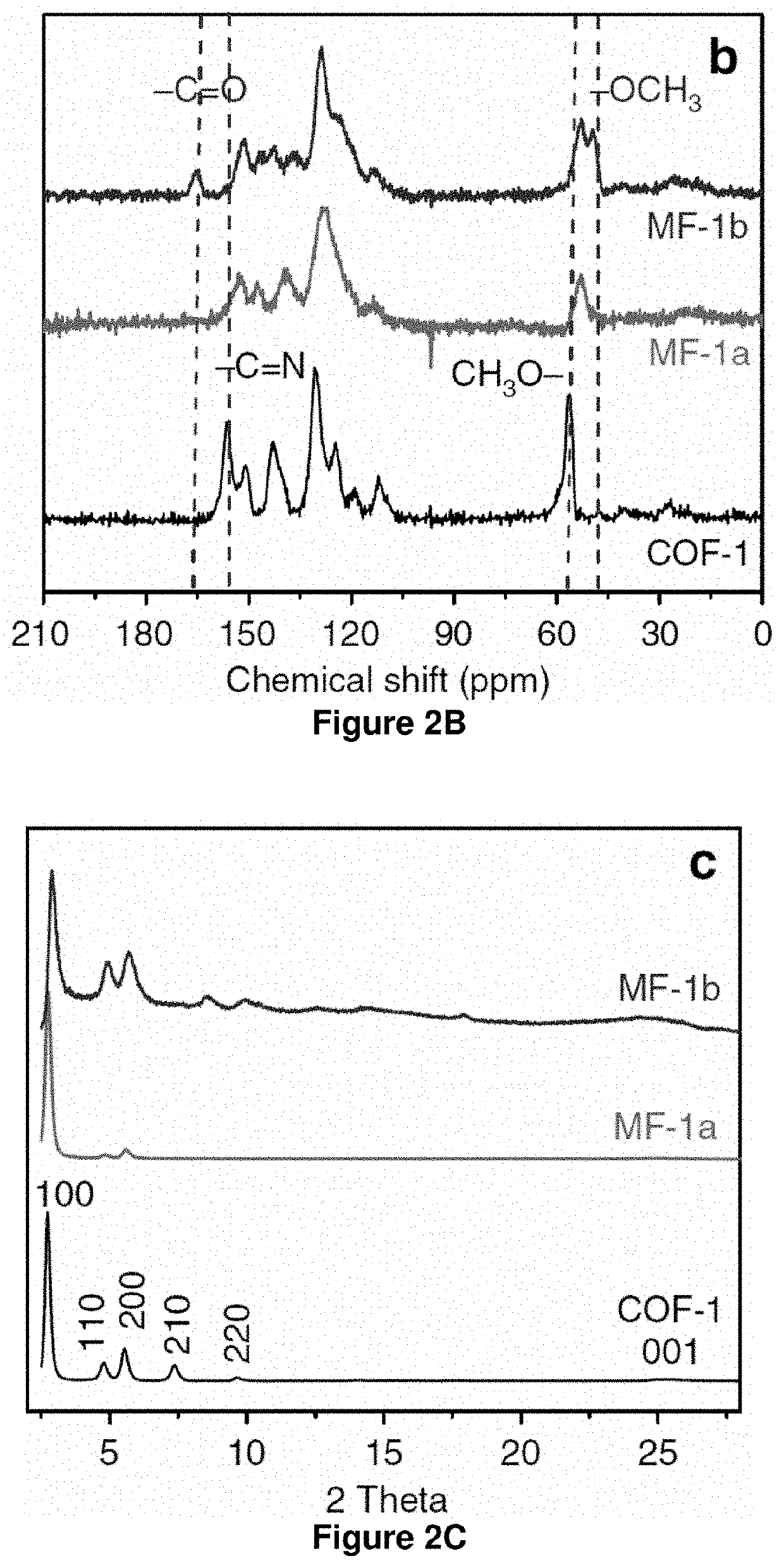

Compositions and methods for the modification of imine covalent organic frameworks (COFs)

Owner:RGT UNIV OF CALIFORNIA

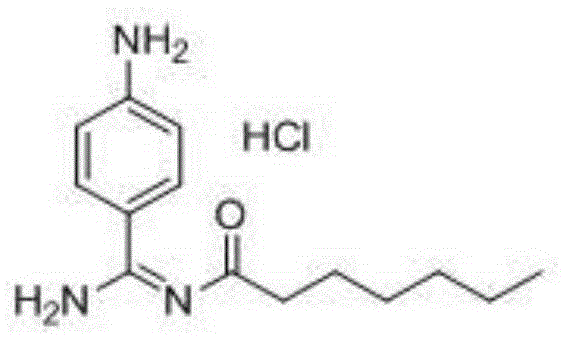

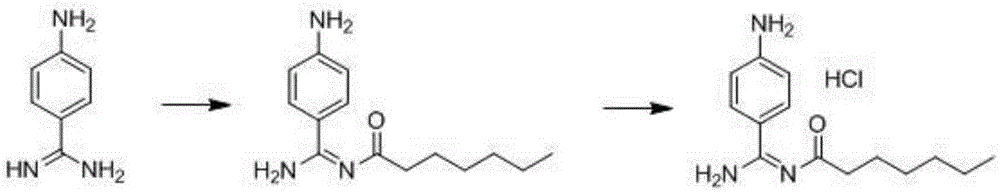

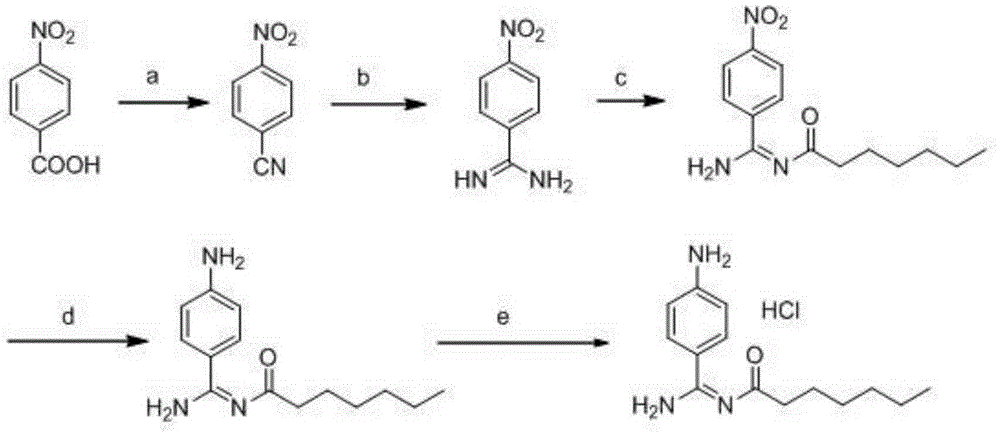

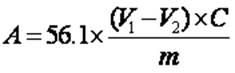

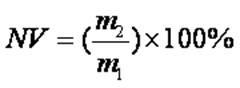

Preparation method for p-aminobenzamidine hydrochloride

InactiveCN105330568AEasy to operateEasy to controlPreparation by nitrogen oxide-organic compound reactionP-aminobenzamidineDrugs synthesis

The invention discloses a preparation method for p-aminobenzamidine hydrochloride, and belongs to the field of drug synthesis. The preparation method comprises the following steps: taking p-aminobenzamidine as a starting raw material, and enabling the p-aminobenzamidine and hydroxylamine hydrochloride to generate nitrobenzonitrile; then, enabling the nitrobenzonitrile to react with ammonium salt to generate p-aminobenzamidine; carrying out acylation and reduction on the p-aminobenzamidine to obtain p-aminobenzamidine imidogen n-hexyl formate; finally, performing salifying on the p-aminobenzamidine imidogen n-hexyl formate and hydrogen chloride to obtain the p-aminobenzamidine hydrochloride. Compared with the prior art, the preparation method for the p-aminobenzamidine hydrochloride disclosed by the invention has the characteristics of being simple to operate, easy to control in reaction, low in production cost and the like, and has a very good popularization and application value.

Owner:INST OF PHARMACY SHANDONG PROV ACAD OF MEDICAL SCI

Method for deeply purifying phosphate radicals in water body by utilizing imino resin

ActiveCN111422941ALarge amount of processingThe adsorption material is stableSpecific water treatment objectivesWater contaminantsDivinylbenzenePolystyrene

The invention discloses a method for deeply purifying phosphate radicals in a water body by using imino resin. The method comprises the following steps: adjusting the pH value of a phosphorus-containing water body; enabling the filtrate to pass through an adsorption tower filled with imino resin to obtain a deeply purified water body, wherein a skeleton of the imino resin is polystyrene-divinylbenzene, and an imino group is grafted on the skeleton; and after reaching an adsorption leakage point, desorbing by using a desorbing agent, and carrying out regeneration treatment. According to the method disclosed by the invention, resin taking polystyrene-divinylbenzene as a skeleton and grafted with an imine group is used as an adsorption material to carry out deep purification treatment on phosphate radicals in a water body; it is found that when the water body value is 3.0-10.0 and high concentrations of Cl <->, NO3 <->, HCO3 <->, SO4 < 2-> and SiO3 < 2-> coexist, the phosphate radical content (based on P) of effluent can still be reduced to 0.01 mg / L or below from 0.05-50 mg / L.

Owner:ZHEJIANG UNIV OF TECH

Imino-containing acrylic resin, its preparation method and application

The invention relates to an imino-containing acrylic resin, its preparation method and an application, specifically to an imino-containing acrylic resin, its preparation method and an application in automobile refinishing coatings. The invention discloses the imino-containing acrylic resin, methods for preparing an imino-containing acrylate monomer and a resin, and a method for preparing an automobile refinishing solid color paint by the utilization of the above resin dispersion. By the adoption of the steric hinderance effect, activity of hydrogen on imidogen nitrogen atoms is properly reduced, the contradiction between curing speed and period of use is successfully solved, and a super fast-drying system with excellent performance is established.

Owner:汤汉良

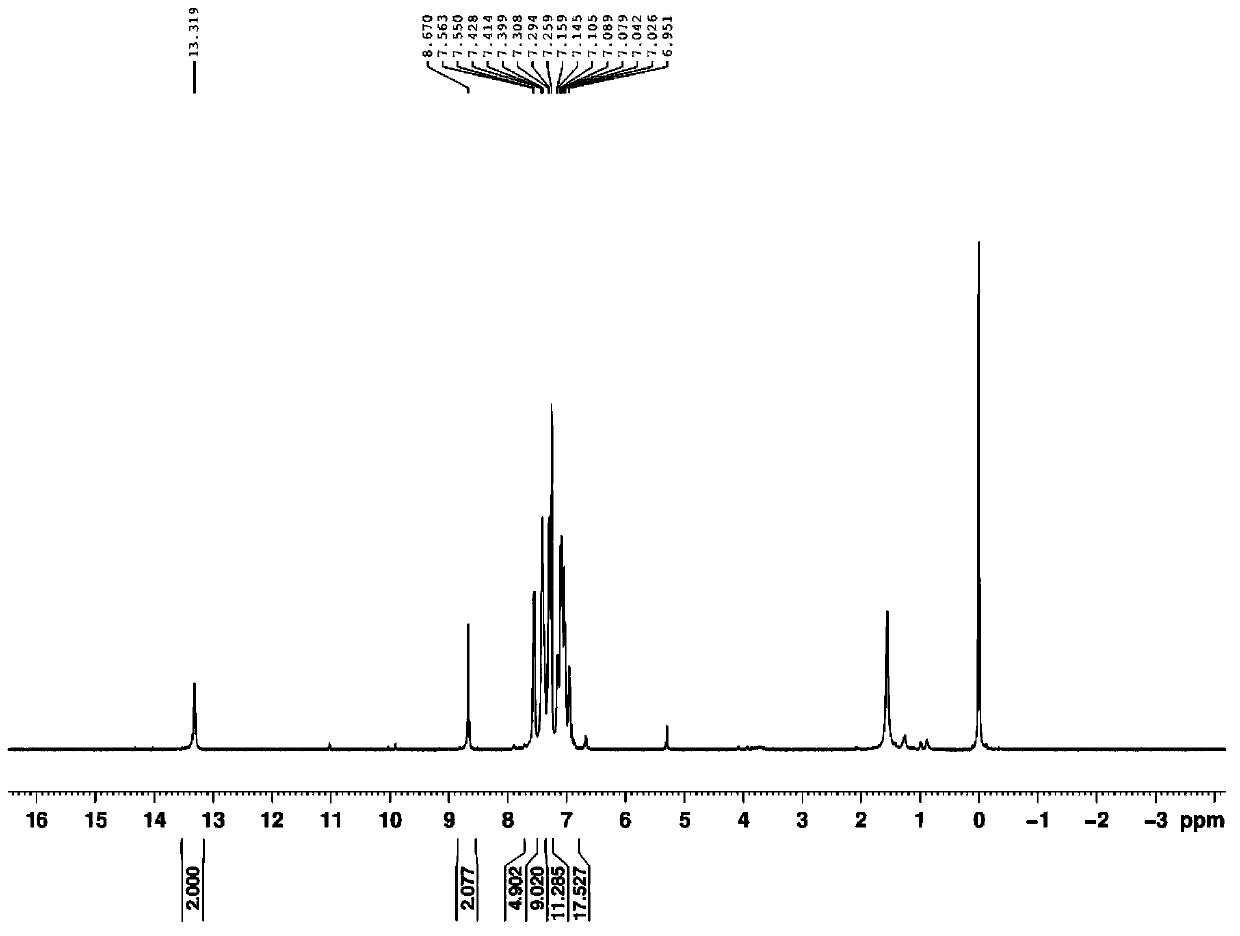

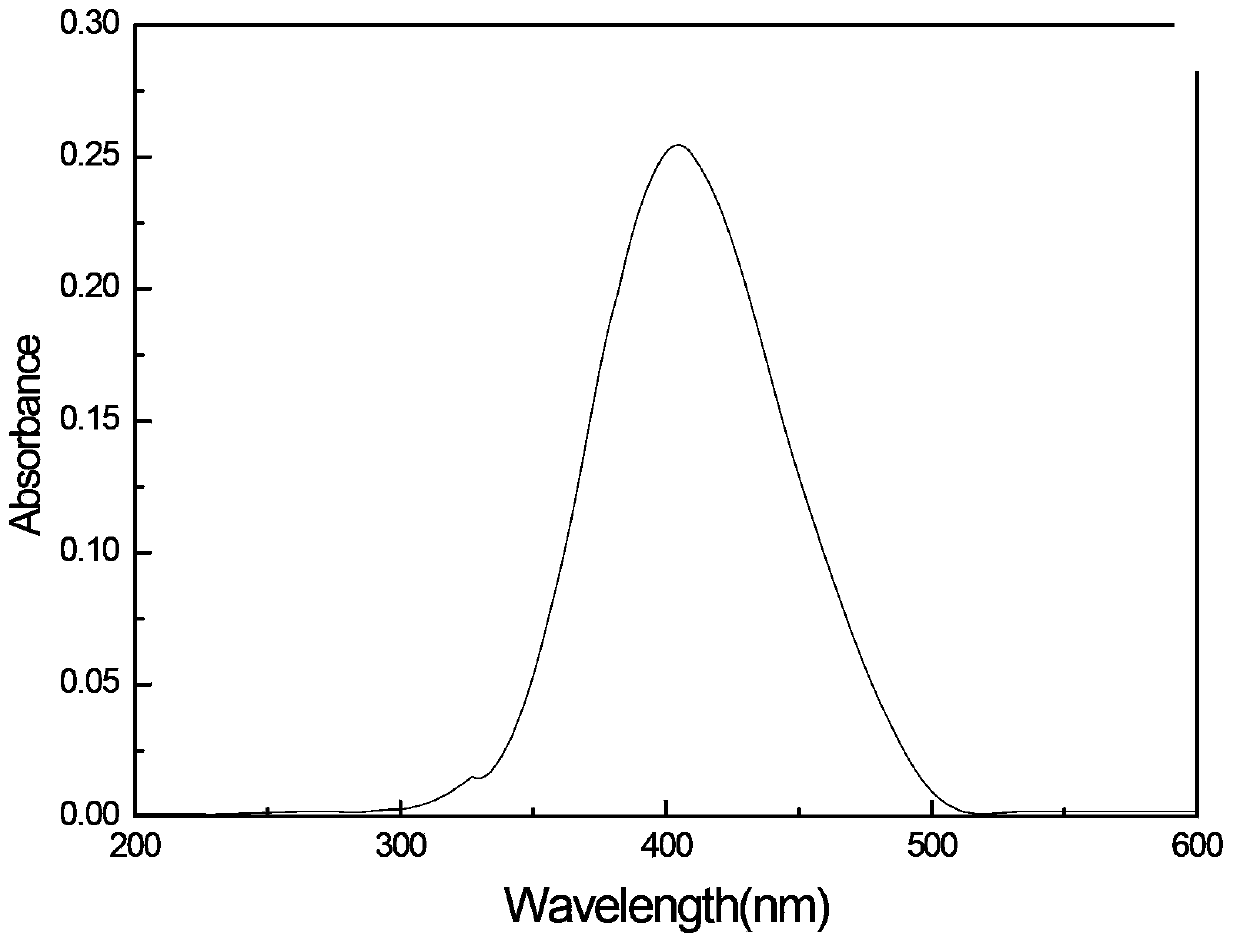

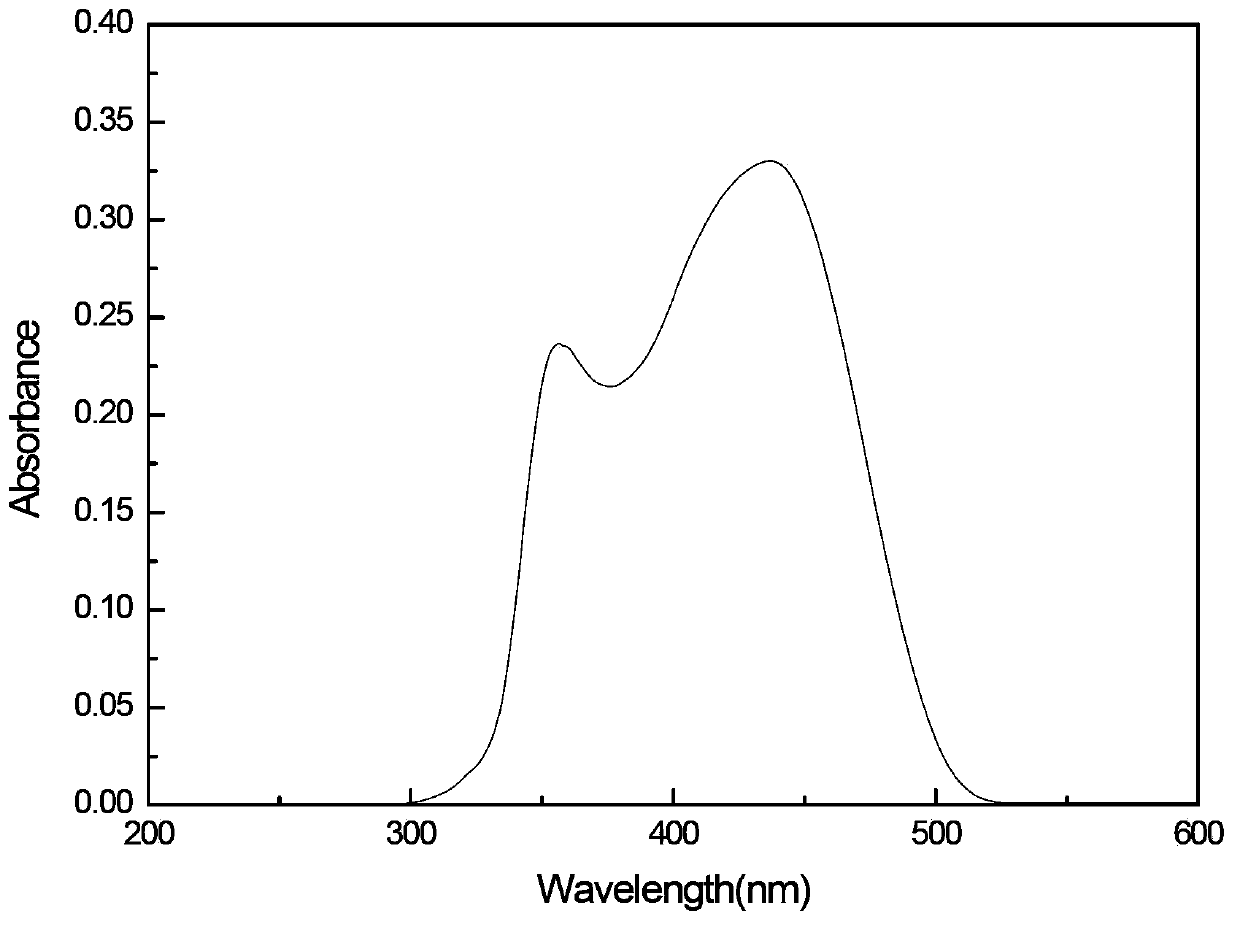

O-hydroxyl-imidogen containing all-conjugated visible light sensitizer with Y-shaped structure and synthesis thereof

The invention provides an o-hydroxyl-imidogen containing all-conjugated visible light sensitizer with a Y-shaped structure. The chemical general formula of the o-hydroxyl-imidogen containing all-conjugated visible light sensitizer is as shown in the specification, wherein R in the structural formula represents H, N(CH3)2, N(CH2CH3)2 or N(CH2CH2CH2CH3)2. The synthesis of the o-hydroxyl-imidogen containing all-conjugated visible light sensitizer comprises the following steps of: adding a diamino-triphenylamine derivative and an o-hydroxyl-benzaldehyde derivative to a three-neck glass bottle, wherein the mol ratio of the diamino-triphenylamine derivative to the o-hydroxyl-benzaldehyde derivative is 1: 2; by taking ethanol by a volume which is 40-100 times of the volume of the o-hydroxyl-benzaldehyde derivative as a solvent, magnetically stirring at normal temperature for 10 hours, and then finishing reaction; separating and purifying the mixture after the reaction, thereby obtaining the o-hydroxyl-imidogen containing all-conjugated visible light sensitizer with the Y-shaped structure. Tested by an ultraviolet-visible light spectrometer, the o-hydroxyl-imidogen containing all-conjugated visible light sensitizer with the Y-shaped structure has excellent absorption effect in the visible region.

Owner:CHONGQING UNIV

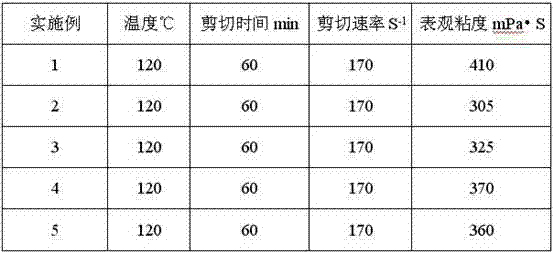

High-strength temperature resistant viscoelastic fracturing fluid copolymer

The invention discloses high-strength temperature resistant viscoelastic fracturing fluid copolymer which is characterized by comprising the following components in mass percent, 5 to 20 percent of acrylic acid, 10 to 30 percent of acrylic amide, 2 to 15 percent of 2-acrylamide-2-methyl-1-propane sulfonate, 1 to 10 percent of 3-acryloyl imidogen-3-methylbutyric acid, 0.1 to 2 percent of lauryl mercaptan, and the balance of deionized water. The copolymer does not have water-insoluble residue, and has good sand-carrying effect and high-temperature resistance and shearing resistance, the viscosity of the copolymer with the mass fraction being 0.45 percent is kept more than 70 percent after continuous shearing for 1 hour at 170S-1 and below 120 DEG C. Raw material of the copolymer adopts industrial products, and is not required to be purified before reaction. Organic solvent is not used, the copolymer does not pollute the environment, the product yield is high, the reaction process is simple, the operation is easy, and the price is low.

Owner:DAQING HUAYING CHEM IND

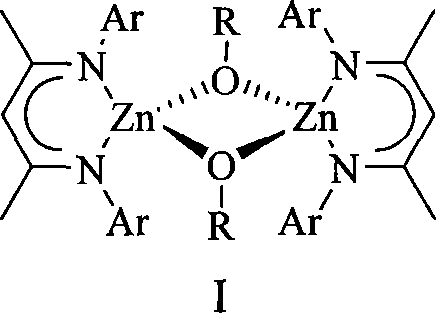

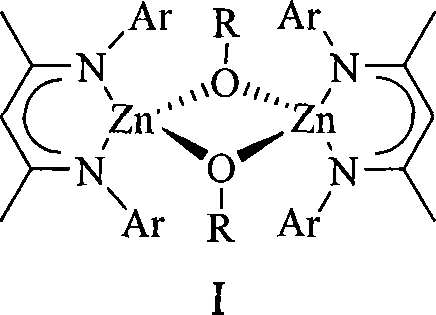

Alkoxyl compound of beta-ketone di-imidogen zincium, preparation and application thereof

The invention discloses an alkoxyl compound of beta-ketone di-imino zinc as well as preparation and application thereof, which belongs to the field of synthesis and catalysis technology of organic compounds of elements. The alkoxyl compound of the invention has the structure of general formula I, wherein R is (CH3)2CH, C6H5CH2 or C6H5; Ar is 2, 6-(CH3)2C6H3. The compound of the invention is prepared through reaction of hydrogen bridge compounds of beta-ketone di-imino zinc and an alcohol, an aldehyde or a ketone, wherein the alcohol has one to twenty carbon atoms and has preferable CH3OH, C6H5OH or C6H5CH2OH; the aldehyde and the ketone have one to twenty atoms, C6H5CHO and CH3COCH3 are preferably chosen. The alkoxyl compound of the invention can be used as the catalyst in ring-opening polymerization of ring-ester compounds or in alternating copolymerization of carbon dioxide and epoxy compounds. The invention has the advantages of simple preparation method, high yield and high catalytic activity.

Owner:BEIJING UNIV OF CHEM TECH

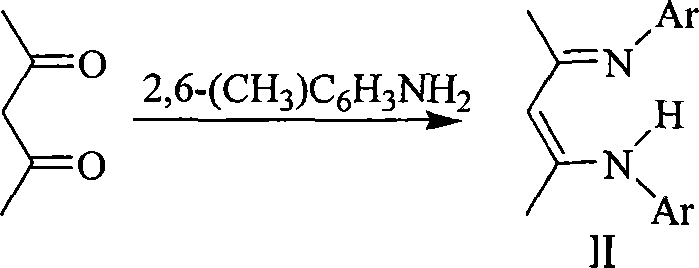

Covalent organic framework (COF) nanoparticles and preparation method thereof

The invention provides a preparation method of covalent organic framework (COF) nanoparticles, which comprises the following step: reacting imino COF with aniline in the presence of a solvent to obtain P-COF nanoparticles. The method comprises the following steps: mixing COF, a single-functional-group competitive monomer and an organic solvent, and carrying out molecular exchange under the ultrasonic action to obtain the COF nanoparticles. The method has the advantages of rapidness, size controllability, universality and the like. Compared with a traditional liquid phase stripping method, the method provided by the invention has the advantages that the speed is higher, and the uniformly dispersed COF nanoparticles can be prepared within 30 minutes; the preparation method disclosed by the invention can be used for selectively preparing the COF nano particles with the particle size of 20-150nm; the preparation method provided by the invention has general applicability to the imine COF. The prepared COF nanoparticles have important application value in the fields of biomedicine, gas separation, energy batteries and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

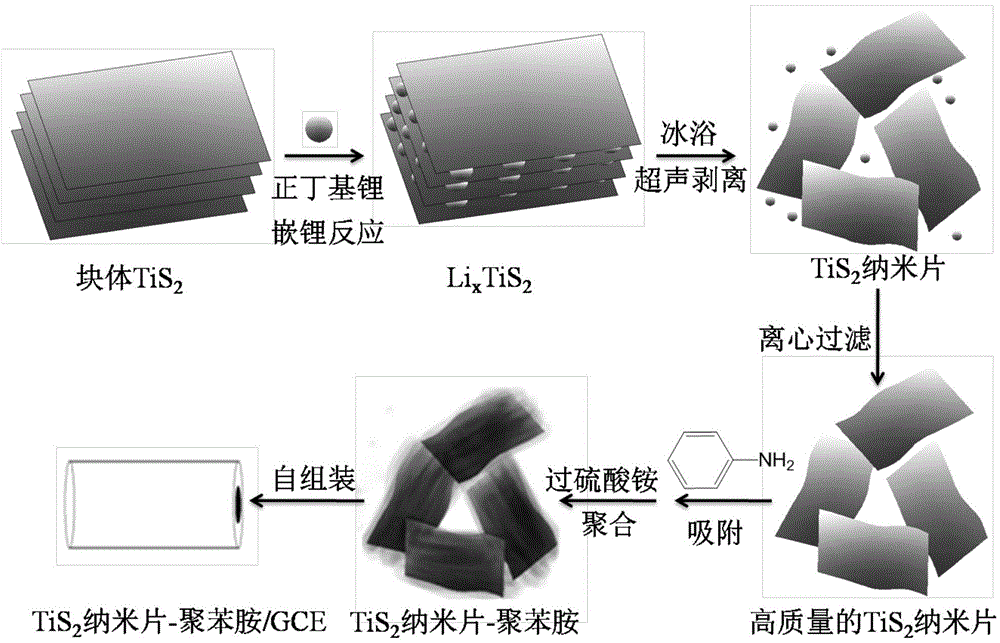

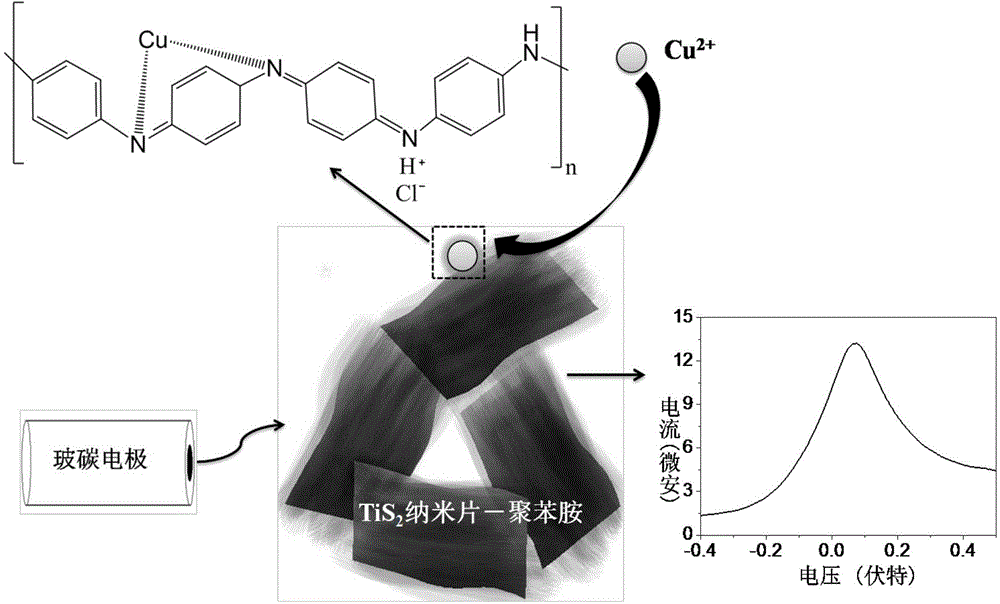

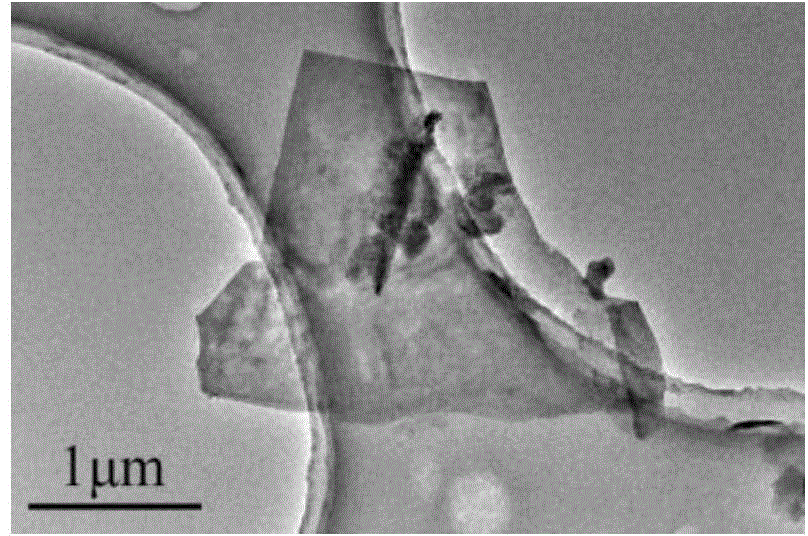

Preparation method and application of TiS2 nanosheet-polyaniline-based electrochemical sensor for trace copper ion detection

ActiveCN104569098AHigh sensitivityHigh selectivityMaterial electrochemical variablesLinearityElectron

The invention discloses a preparation method and application of a TiS2 nanosheet-polyaniline-based electrochemical sensor for trace copper ion detection, belonging to the field of environmental analysis. By utilizing high selectivity obtained by a complexing effect of nitrogen atoms and copper ions on imidogen in polyaniline and high conductivity of the TiS2 nanosheets, a signal amplification effect is achieved, and trace copper ion detection is realized. Due to the presence of the TiS2 nanosheets, the stability and the interface electron transfer rate of the sensor can be enhanced. According to the synergistic effect of the TiS2 nanosheets and polyaniline, the TiS2 nanosheet-polyaniline-based electrochemical sensing method has the characteristics of high sensitivity, high selectivity and the like, the detection linearity range of copper ions is 25 microns-5 microns, the detection limit is 0.7nM, the method for preparing the TiS2 nanosheet-polyaniline-based electrochemical sensor is controllable, and secondary pollution is avoided. The electrochemical sensor disclosed by the invention has wide application prospects of monitoring copper ions in the water body in situ in real time.

Owner:DALIAN UNIV OF TECH

Equipartition type beta-diketone imidogen rareearth complexes-sec-propyl alcohol system and uses thereof

InactiveCN101343283AHigh activityLong active lifeGroup 3/13 element organic compoundsDiketoneAlcohol

The invention discloses a homoleptic Beta-Diketiminato rare earth complex-isopropyl alcohol system, the homoleptic Beta-Diketiminato rare earth complex has the following chemical formula: Ln[p-Cl-C6H4NC(Me)CHC(Me)NC6H4-p-Cl]3, wherein, Ln represents rare earth metal. Meanwhile, the invention discloses applications of the complex -isopropyl alcohol system in the controllable ring-opening polymerization reaction of L-lactide as a catalyst. The homoleptic Beta-Diketiminato rare earth complex-isopropyl alcohol system can controllably catalyze the ring-opening polymerization reaction of L-lactide under mild conditions, and can obtain poly-lactide acid that can predict the molecular weight and narrowness of molecular weight distribution, and has extreme high catalytic activity.

Owner:SUZHOU UNIV

Method of preparing polyimide/inorganic nano hybridization material

The invention provides a method preparing for a polyimide or an inorganic nanometer hybridized material, which comprises the following steps: synthesizing an imidogen cyclic silane adapting to the inorganic nanometer particle modifier; preparing for the inorganic oxidate nanometer particle with the sol-gel processing; adding the modifier-imidogen cyclic silane in the sol-gel reacting process; getting the organic and inorganic complex nanometer particle; making the organic and inorganic complex nanometer particle uniformly dispersing in the polyamic acid solution; getting the polyimide or the inorganic nanometer hybridized material. The invention dissolves the problem of dispersing the nanometer particles, which shows every property sufficiently.

Owner:HARBIN ENG UNIV

Non-cyanogen plate silver plating solution

The invention discloses a non-cyanide silver-gilt electroplate liquid, which comprises a cylinder opening agent, an extender and a potassium hydroxide solution. The cylinder opening agent comprises following raw materials by weight: 1 to 5 percent of silver nitrate, 2 to 10 percent of isonicotinic acid, 5 to 20 percent of tri-imidogen di-phosphate ammonium, 2 to 12 percent of potassium acetate and residual quantity of pure water; the extender comprises following raw materials by weight: 0.1 to 5 percent of a compound of propanetriol and epoxy ethane, 0.01 to 9 percent of ammonium polyethylene with low polymerization degree, 10 to 20 percent of potassium acetate, 20 to 40 percent of isonicotinic acid and residual quantity of pure water; consequently, the electroplate liquid produced does not contain harmful substances such as cyanide and heavy metal, etc., and has low cost and good use effect.

Owner:江门市瑞期精细化学工程有限公司

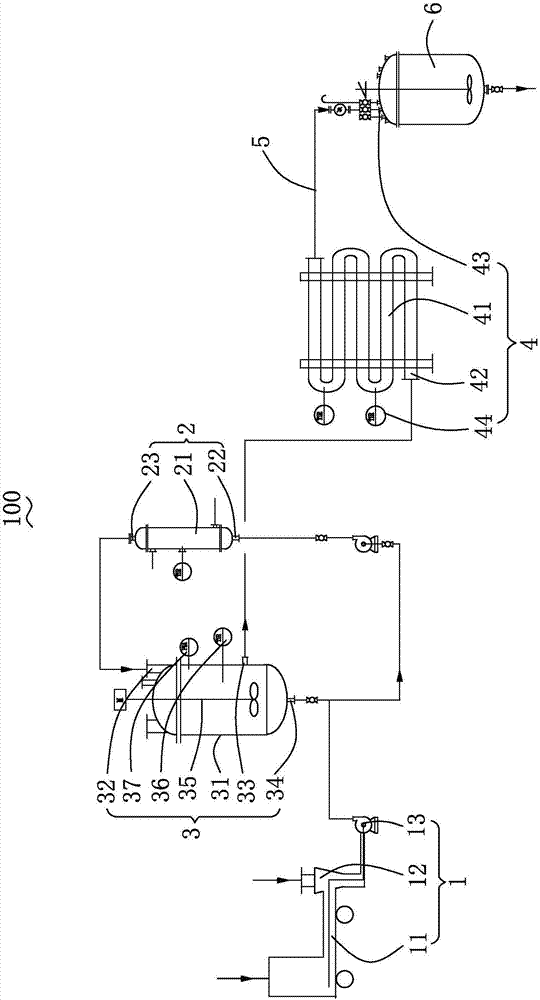

Method for preparing iminodiacetic acid through continuous hydrolysis and self-oscillating reactor

ActiveCN106905176AHigh yieldEnhanced mass transferProcess control/regulationSequential/parallel process reactionsIminodiacetic acidOscillatory reaction

The invention discloses a method for preparing iminodiacetic acid through continuous hydrolysis. The method comprises the following steps: mixing reaction material imidogen diacetonitrile and water in proportion; providing a perfectly mixed reactor, conveying the reaction material into the perfectly mixed reactor, so as to perform hydrolysis reaction; providing a tubular reactor, and conveying reaction liquid in the perfectly mixed reactor into the tubular reactor under the action of liquid level difference pressure; providing a product storage tank, ensuring that the reaction material performs periodic self-oscillating flowing between the tubular reactor and a product storage tank, discharging a product into the product storage tank after reaction. The method for preparing iminodiacetic acid through continuous hydrolysis improves the reaction yield. The invention further provides a self-oscillating reactor.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com