Anti-fatigue modified asphalt and preparation method thereof

A modified asphalt and anti-fatigue technology, applied in building components, building thermal insulation materials, buildings, etc., can solve the problem that the anti-fatigue performance cannot meet the design requirements of the service life of the asphalt pavement, achieve excellent anti-fatigue cracking ability, improve Dispersion uniformity, the effect of improving fatigue cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

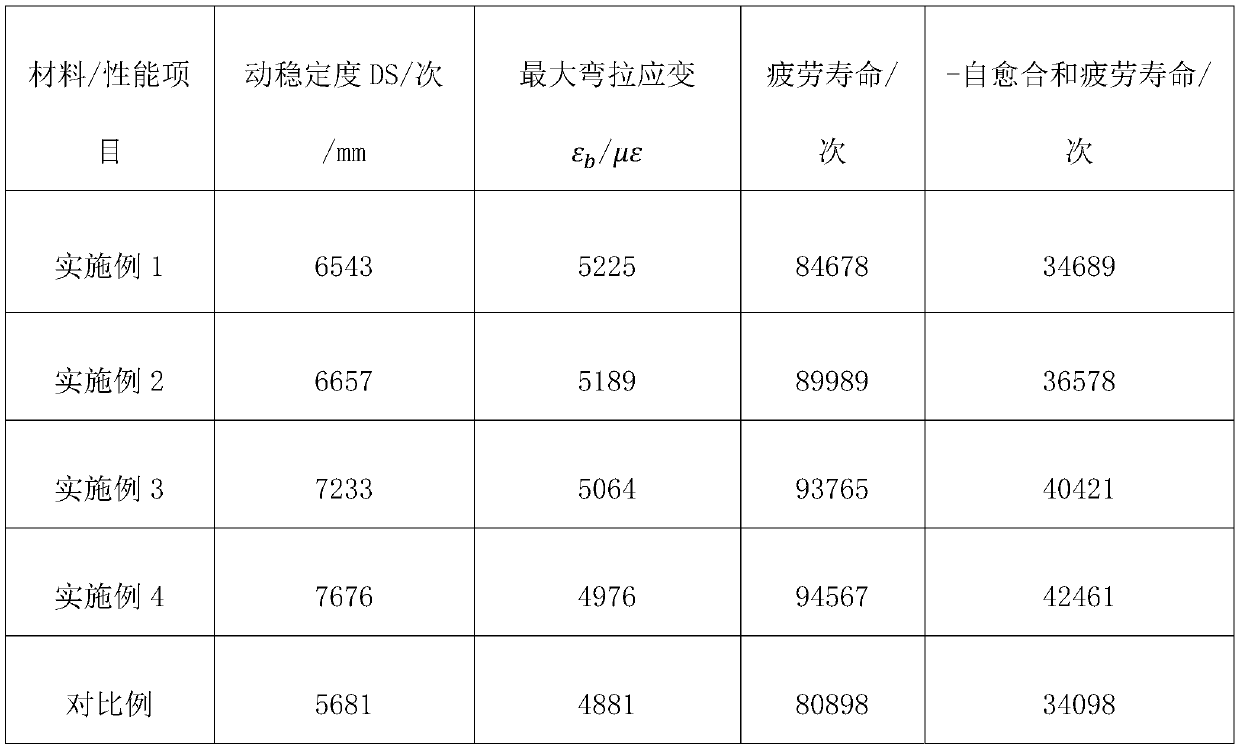

Examples

preparation example Construction

[0033] A kind of preparation method of anti-fatigue modified asphalt provided by the invention comprises the following steps:

[0034] Step 1, in parts by mass, weigh 100 parts of base asphalt, 18 to 22 parts of waste tire rubber powder, 0.5 parts of plasticizer, 0.4 to 1.6 parts of polyphosphoric acid, 0.2 parts of compatibilizer and 0.1 part of stabilizer agent;

[0035] Step 2, heating the weighed base asphalt to 160-165°C, then adding waste tire rubber powder into the base asphalt, and stirring at 160-165°C for 15 minutes;

[0036] Step 3: Continue to add compatibilizer and stabilizer on the basis of step 2, and keep stirring at 160-165°C for 10 minutes, and then use high-speed shearing machine to cut the above-mentioned asphalt for 45 minutes at 170-180°C , then add polyphosphoric acid and plasticizer and continue to shear at this temperature for 30 minutes, with a shear rate of 5000-6000 revolutions / min.

[0037] Step 4: On the basis of Step 3, put the prepared modifie...

Embodiment 1

[0039] A kind of anti-fatigue modified asphalt provided in this embodiment comprises 100 parts of base asphalt, 18 parts of waste tire rubber powder, 0.5 part of plasticizer, 0.4 part of polyphosphoric acid, 0.2 part of compatibilizer and 0.1 part of stabilizer agent. .

[0040] A preparation method of anti-fatigue modified asphalt, comprising the following steps:

[0041] Step 1: heating base asphalt to 160-165°C, then adding waste tire rubber powder into base asphalt, and stirring at 160-165°C for 15 minutes.

[0042] Step 2: Continue to add compatibilizer and stabilizer on the basis of step 1, and keep stirring at 160-165°C for 10 minutes, and then use a high-speed shear to shear the above-mentioned asphalt for 45 minutes at a temperature of 170-180°C , then add polyphosphoric acid and plasticizer and continue to shear at this temperature for 30 minutes, with a shear rate of 5000-6000 revolutions / min.

[0043] Step 3: On the basis of Step 2, put the prepared modified asp...

Embodiment 2

[0045] A kind of anti-fatigue modified asphalt provided in this embodiment comprises 100 parts of base asphalt, 22 parts of waste tire rubber powder, 0.5 part of plasticizer, 1.6 parts of polyphosphoric acid, 0.2 part of compatibilizer and 0.1 part of stabilizer agent.

[0046] A preparation method of anti-fatigue modified asphalt, comprising the following steps:

[0047] Step 1: heating base asphalt to 160-165°C, then adding waste tire rubber powder into base asphalt, and stirring at 160-165°C for 15 minutes.

[0048] Step 2: Continue to add compatibilizer and stabilizer on the basis of step 1, and keep stirring at 160-165°C for 10 minutes, and then use a high-speed shear to shear the above-mentioned asphalt for 45 minutes at a temperature of 170-180°C , then add polyphosphoric acid and plasticizer and continue to shear at this temperature for 30 minutes, with a shear rate of 5000-6000 revolutions / min.

[0049] Step 3: On the basis of Step 2, put the prepared modified aspha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com