Patents

Literature

51results about How to "Improved resistance to fatigue cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

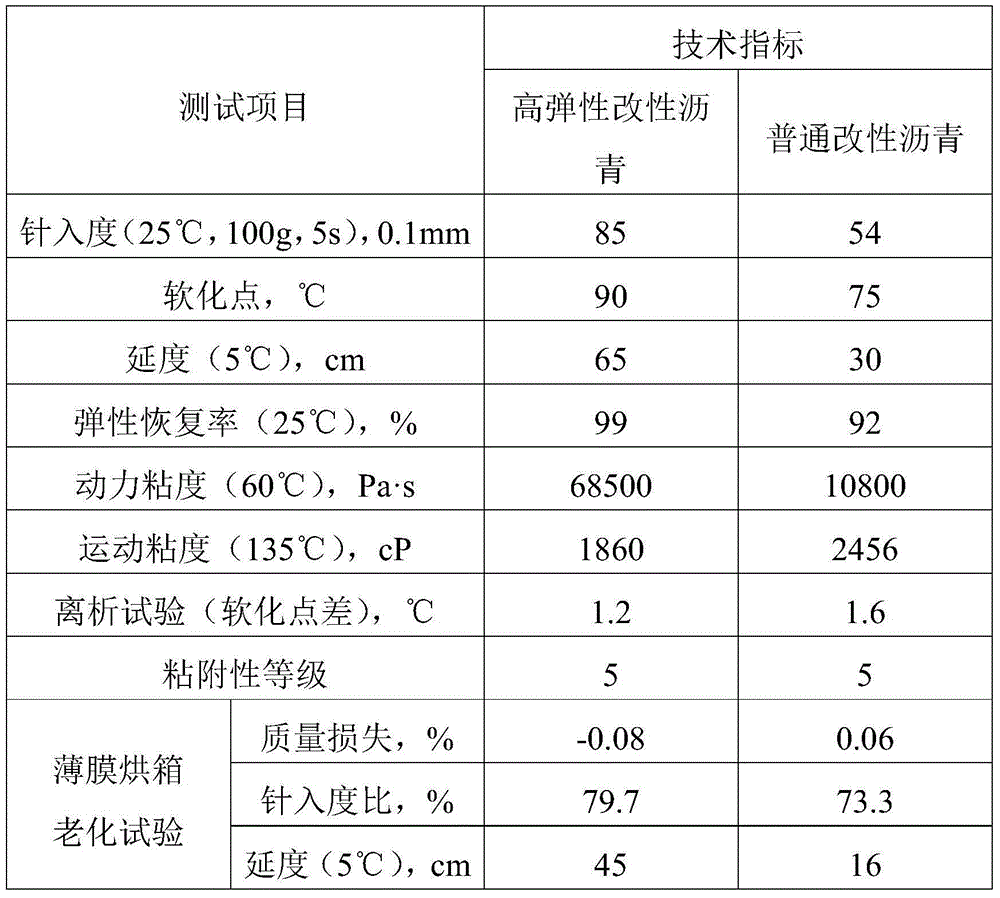

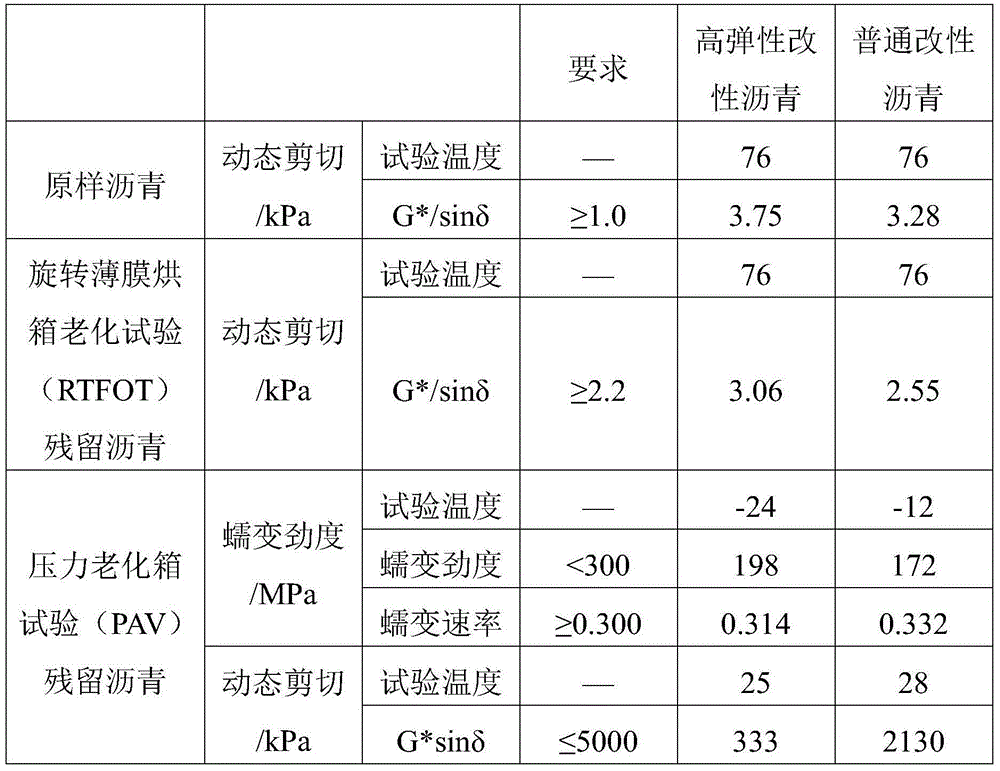

High-elasticity asphalt modified composition, modifier, modified asphalt, modified asphalt mixture and preparation method

ActiveCN104629391AImproved high temperature stability and elastic recoveryReduce melt viscosityBuilding insulationsButadiene-styrene rubberPlasticizer

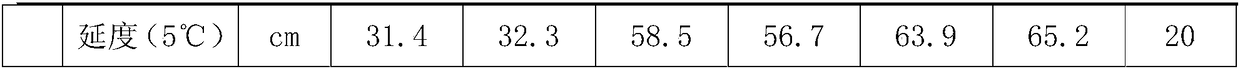

The invention relates to a high-elasticity asphalt modified composition, a modifier, modified asphalt, a modified asphalt mixture and a preparation method. The modified composition comprises 100 parts of a styrene-butadiene-styrene segmented copolymer, 20-40 parts of a tackifier, 20-40 parts of a softener, 3-8 parts of a warm mixing agent, 15-40 parts of a plasticizer and 2-6 parts of a stabilizer. The preparation method of the modifier comprises the following steps: (1) mixing the styrene-butadiene-styrene segmented copolymer, the tackifier and the warm mixing agent according to a formula to obtain a melt; and (2) mixing the softener, the plasticizer and the stabilizer with the melt, and then extruding, cooling and dicing. The modified asphalt is prepared by doping the modifier into matrix asphalt and uniformly mixing. The modified asphalt mixture is prepared by mixing the modified asphalt and a raw material of a mineral mixture. The modified asphalt provided by the invention has good high-temperature and low-temperature stabilities and anti-fatigue capacity, and the modified asphalt mixture is strong in construction workability and good in pavement performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Rejuvenation of reclaimed asphalt

ActiveUS20140338565A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementCrack resistanceFatty acid

Asphalt compositions comprising reclaimed asphalt and a rejuvenating agent are disclosed. The reclaimed asphalt comprises aggregate and an aged binder. The rejuvenating agent, which has a cyclic content of at least 5 wt. %, comprises an ester or ester blend derived from an acid selected from aromatic acids, fatty acids, fatty acid monomers, fatty acid dimers, fatty acid trimers, rosin acids, rosin acid dimers, and mixtures thereof. The rejuvenating agent revitalizes the aged bitumen binder of reclaimed asphalt and restores its physical properties to those of the original performance-grade bitumen. Improvements include desirable softening, low-temperature cracking resistance, better fatigue cracking resistance, good elevated temperature performance, improved miscibility, and restored temperature sensitivity. The rejuvenating agents enable the use of higher levels of recovered asphalt, particularly RAP, in asphalt mixtures, reduce binder and aggregate costs, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:KRATON CHEM LLC

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

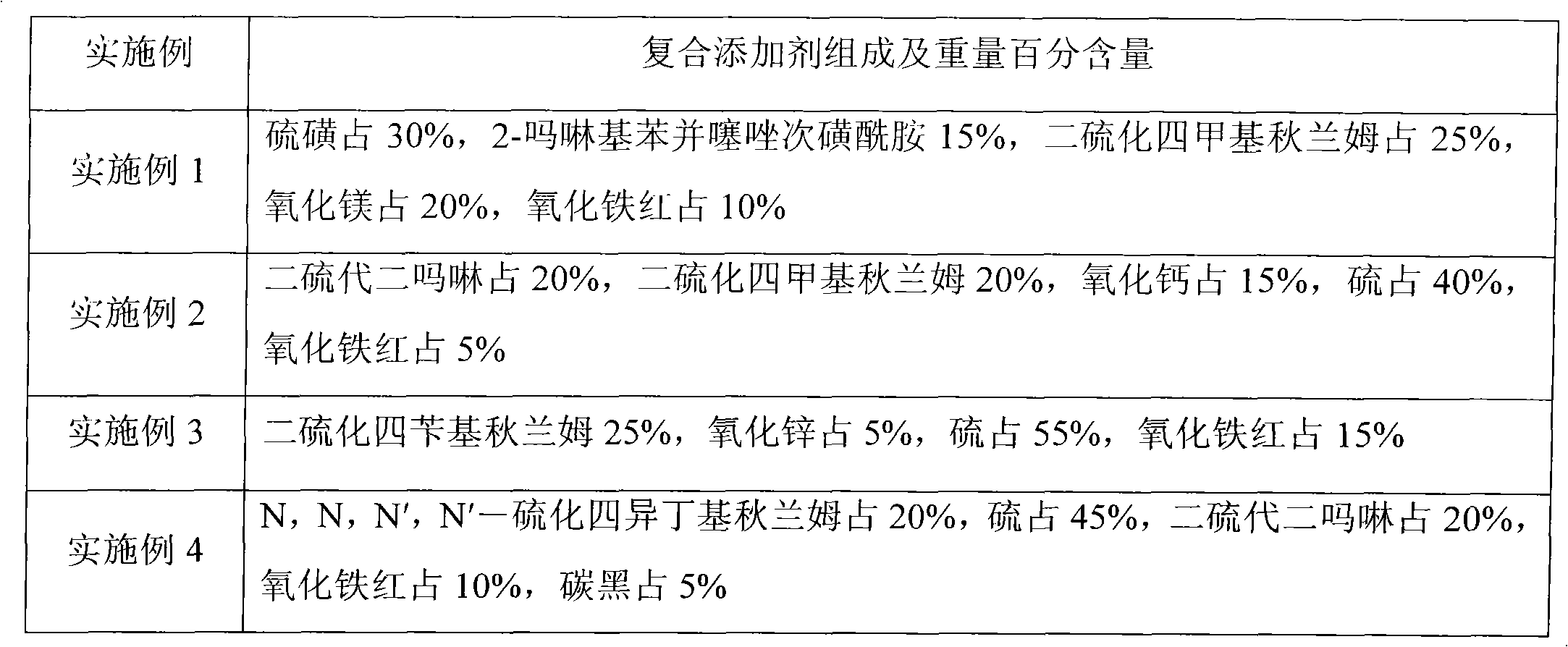

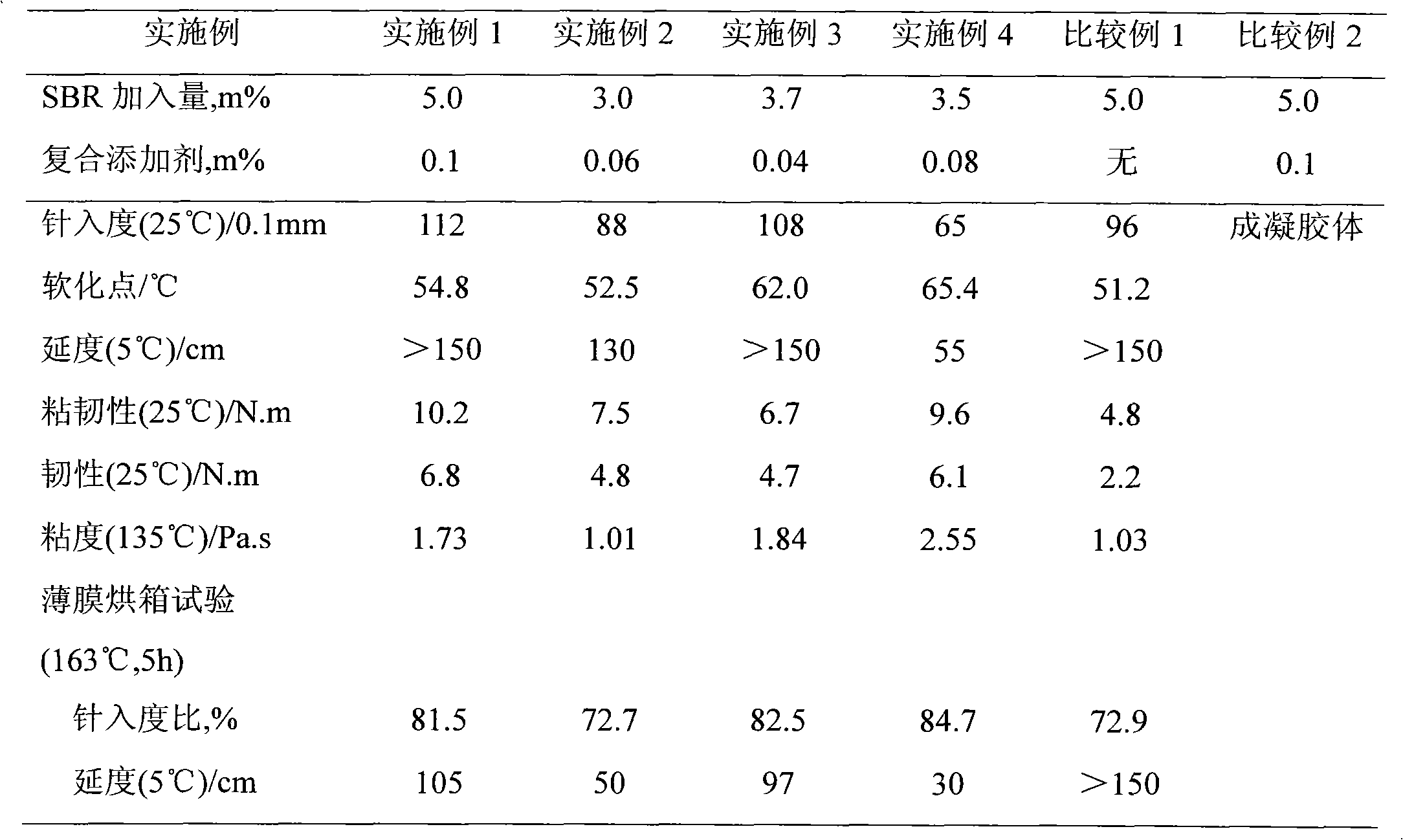

Styrene-butadiene rubber modified asphalt composition and preparation method thereof

ActiveCN102051056AFast crosslinkingGuaranteed uniformityBuilding insulationsCross-linkPolymer science

The invention provides a styrene-butadiene rubber modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps of: grinding styrene-butadiene rubber grains or powder by using special equipment such as a high-shear equipment, colloid mill or the like at the temperature of between 150 and 230 DEG C, and uniformly dispersing in base asphalt to prepare a modified asphalt composition; adding a composite additive in an amount which accounts for 0.01 to 0.2 percent of the total weight of asphalt with the common stirring or stirring by using a high-shear emulsifying machine; and performing cross-linking reaction to prepare a styrene-butadiene rubber modified road asphalt product. The styrene-butadiene rubber modified asphalt has a simple production process; and the asphalt product has higher toughness and tenacity, high high-temperature performance and high low-temperature performance and is suitable for building high-grade highways.

Owner:CHINA PETROLEUM & CHEM CORP +1

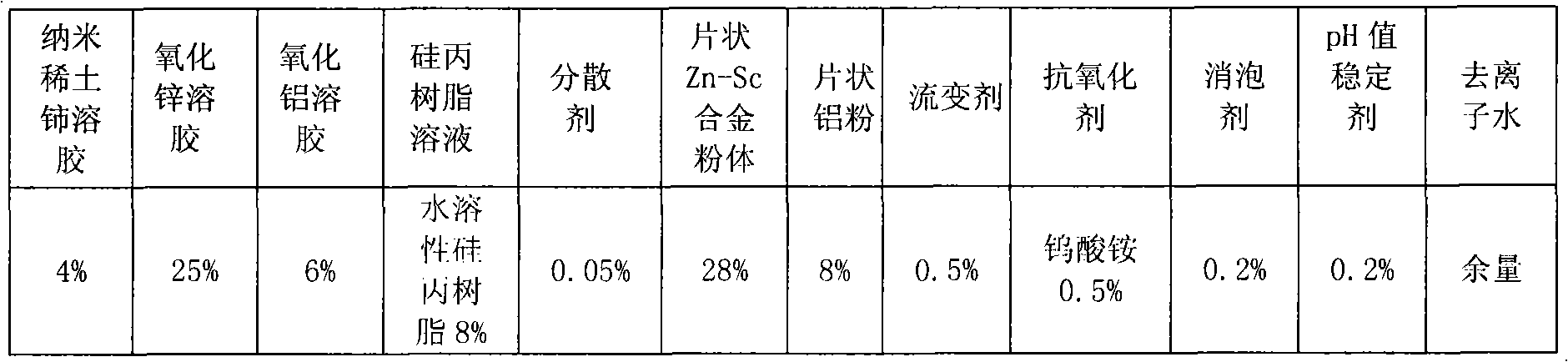

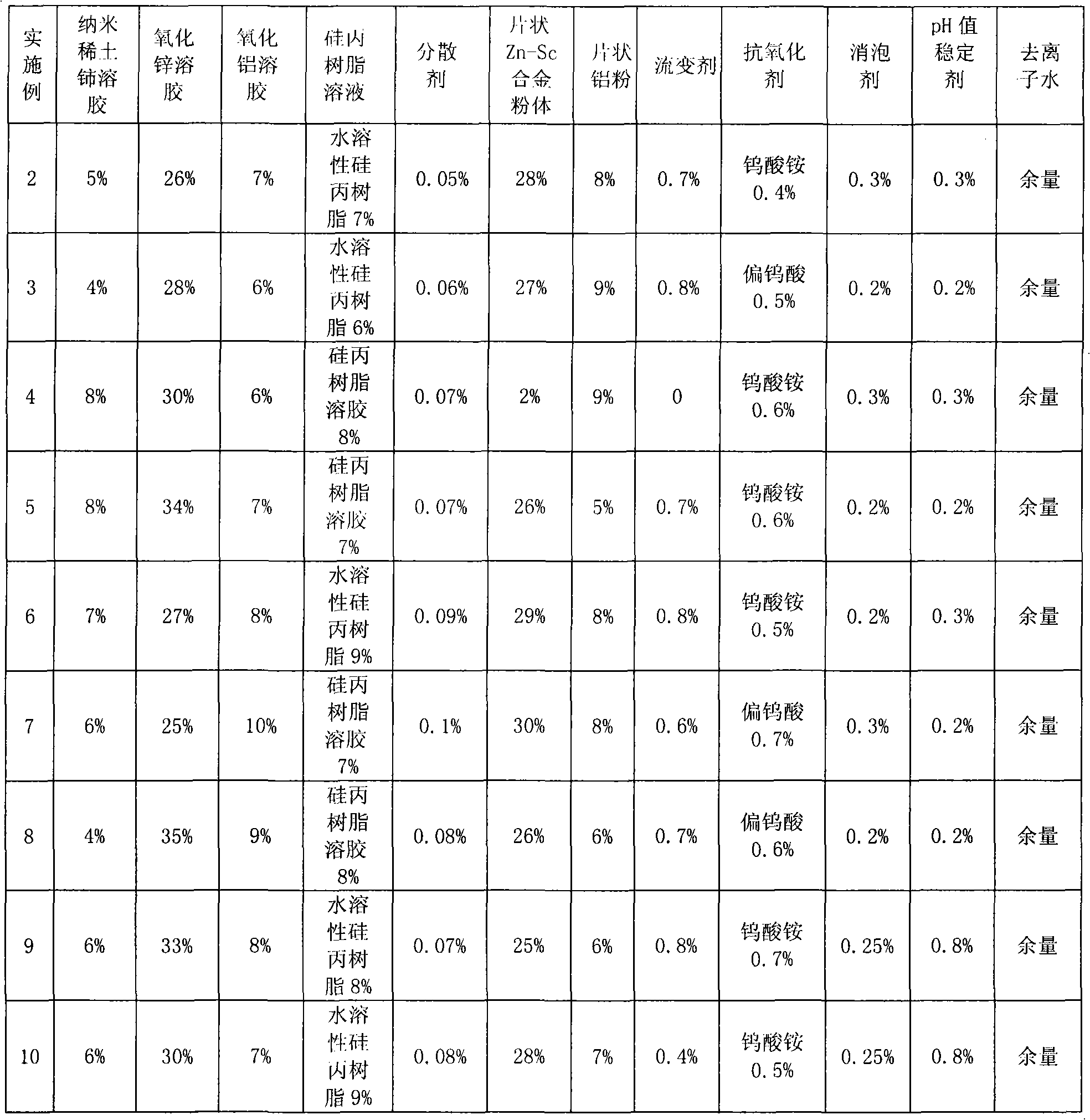

Rare-earth sol modified composite zinc-aluminum low-temperature sintered coating slurry

ActiveCN101880485AAchieving the goal of chrome-free DacrometLow curing and sintering temperaturePretreated surfacesCoatingsAcrylic resinCerium

The invention provides rare-earth sol modified composite zinc-aluminum low-temperature sintered coating slurry. Zinc oxide-alumina sol is modified by using rare-earth sol and mixed with water-soluble silicon acrylic resin to form an inorganic / inorganic composite rare earth-zinc oxide-alumina ternary sol bonding material system. The slurry is prepared from the following raw materials in percentage by weight: 4 to 9 percent of nano rare-earth cerium sol, 25 to 35 percent of zinc oxide sol, 6 to 10 percent of alumina sol, 8 to 13 percent of water-soluble silicon acrylic resin, 0.05 to 0.1 percent of dispersant, 0.3 to 0.5 percent of rheological agent, 0.3 to 0.8 percent of antioxidant, 25 to 30 percent of laminar Zn-Sc alloy powder, 5 to 8 percent of laminar aluminum powder and the balance of deionized water. The slurry realizes the non-chromate Dacromet goal, and has the advantages of low curing and sintering temperature, bright and durable coating metal luster and good comprehensive mechanical property; and the integral process has the characteristics of lower carbon, more environmental protection, more energy conservation and the like.

Owner:CHONGQING HANGLI IND

Surface treatment method of powder metallurgy part

InactiveCN102115865AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingHigh resistanceChromium Compounds

The invention discloses a surface treatment method of a powder metallurgy part. The method comprises the following steps of: firstly, performing complex cementation on the powder metallurgy part with nitrogen gas, sulfur gas and chromium gas to form a dense coating tissue of a nitrogen-sulfur-chromium compound with the size of between 15 microns and 45 microns on the surface of the powder metallurgy part; secondly, polishing the surface of the powder metallurgy part; and lastly, oxidizing the powder metallurgy part at low temperature to form a dense oxide layer. The compound coating tissue is a dense oxide layer covered by a polynary ultra-hard nitrogen-sulfur-chromium compound, so that the powder metallurgy part has high wear resistance, corrosion resistance and high temperature resistance, the friction coefficient is greatly lowered, the seizing resistance magnitude order is raised, the working quality of the powder metallurgy part is remarkably enhanced, and the service life is prolonged.

Owner:杭州力合金邦表面技术有限公司

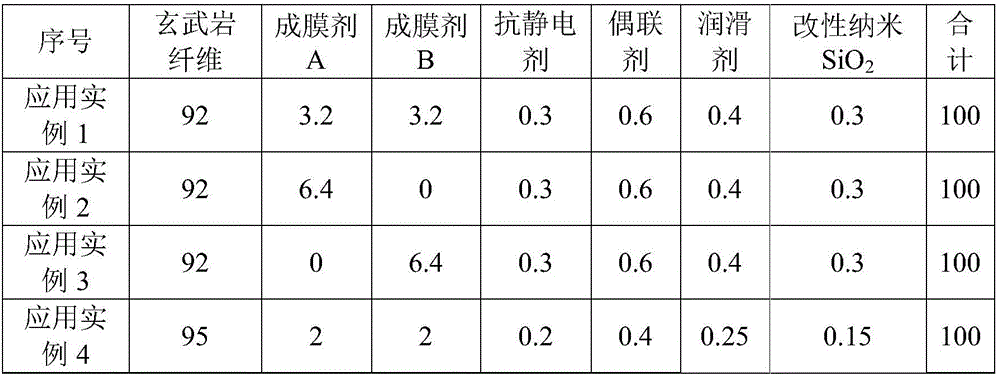

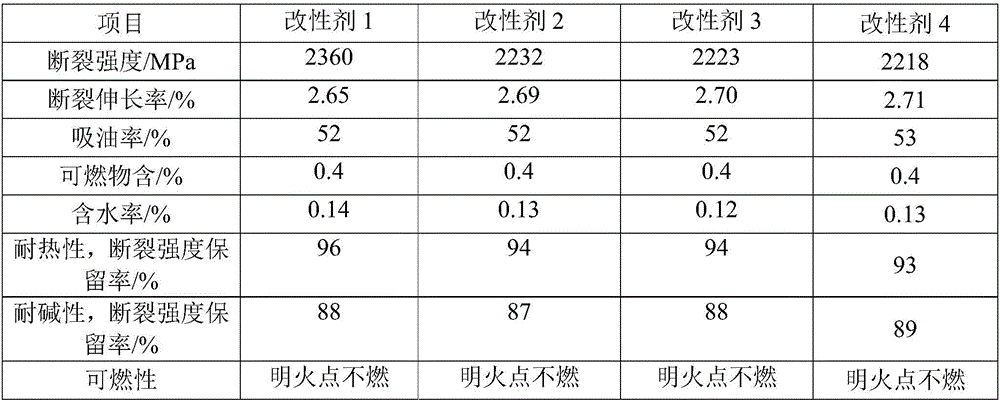

Novel modifier with basalt fibers for asphalt mixtures and method for preparing novel modifier

The invention discloses a novel modifier with basalt fibers for asphalt mixtures and a method for preparing the novel modifier. The novel modifier is made of the basalt fibers and high-adhesion wetting agents. The novel modifier comprises, by weight, 85-98 parts of the basalt fibers, 0-10 parts of film-forming agents A, 0-10 parts of film-forming agents B, 0.1-0.6 part of antistatic agents, 0.2-3.5 parts of coupling agents, 0.1-2 parts of lubricants and 0.1-1.3 parts of modified nanometer SiO2. The method includes mixing the film-forming agents A, the film-forming agents B, the antistatic agents, the coupling agents, the lubricants and the modified nanometer SiO2 with one another to obtain mixtures and stirring the mixtures; wetting and wrapping the basalt fibers and cutting the basalt fibers into short pieces so as to obtain the novel modifier. The novel modifier and the method have the vantages that irritating odor rarely can be generated in modifier preparation procedures; the novel modifier can be added into the asphalt mixtures, accordingly, various road properties of the asphalt mixtures can be effectively improved, the anti-rutting performance and the fatigue cracking resistance of pavements can be improved, and the service lives of roads can be greatly prolonged.

Owner:YANGZHOU UNIV

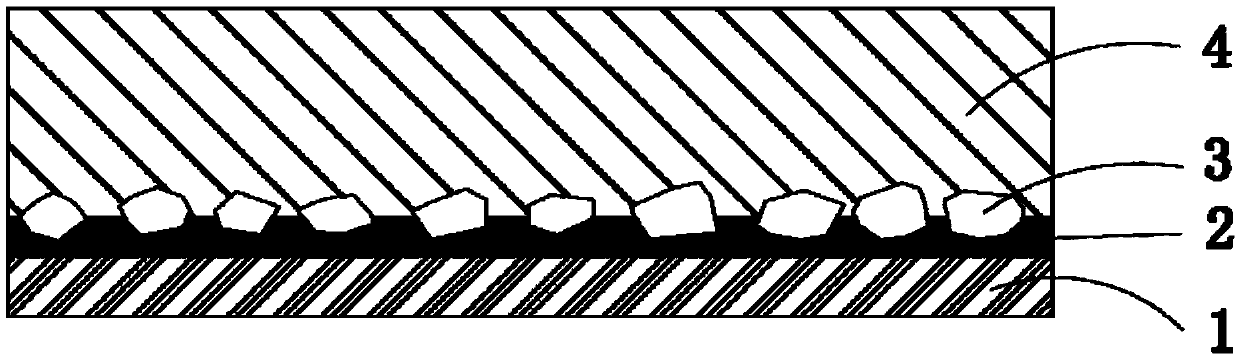

Bridge deck pavement method for orthotropic steel bridge

ActiveCN104652270AImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxyFull life cycle

The invention discloses a bridge deck pavement method for an orthotropic steel bridge. The pavement method comprises the following steps: (1) performing sand-blasting and de-rusting treatment on a steel bridge panel, and coating a mica-containing epoxy anti-corrosion layer; (2) coating a solvent-free epoxy resin water-proof layer; (3) spreading a hot melt particle bonding layer which is partially sunken into the solvent-free epoxy resin water-proof layer, wherein the hot melt particles are high-polymer particles of which the softening point is greater than 150 DEG C; (4) paving a fine-particle asphalt mixture to form a high-elasticity modified asphalt pavement lower layer; (5) spreading a modified emulsified asphalt bonding layer; (6) paving a fine-particle or medium-particle asphalt mixture to form a high-elasticity modified asphalt pavement upper layer. By adopting the pavement method, the construction difficulty is lowered greatly, later maintenance is easy, the universality is high, a pavement lower structure is durable and long in service life, only the surface needs to be maintained in daily use, overall repeated maintenance is avoided, and the investment in a full life cycle is lowered.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

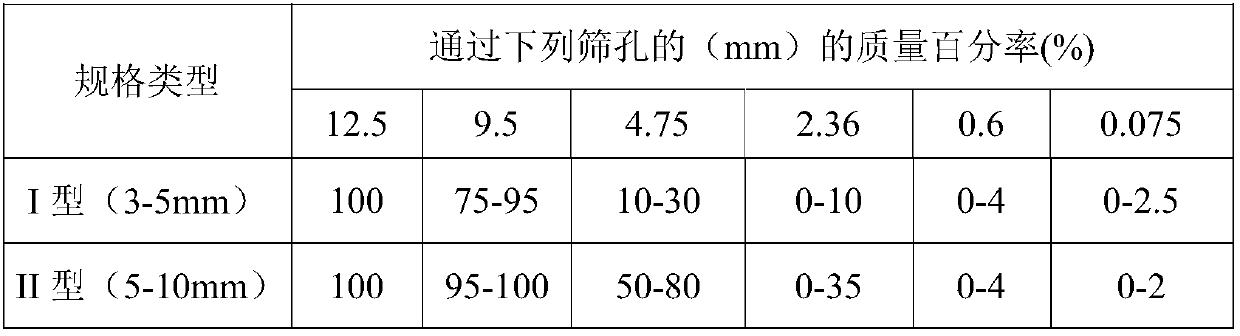

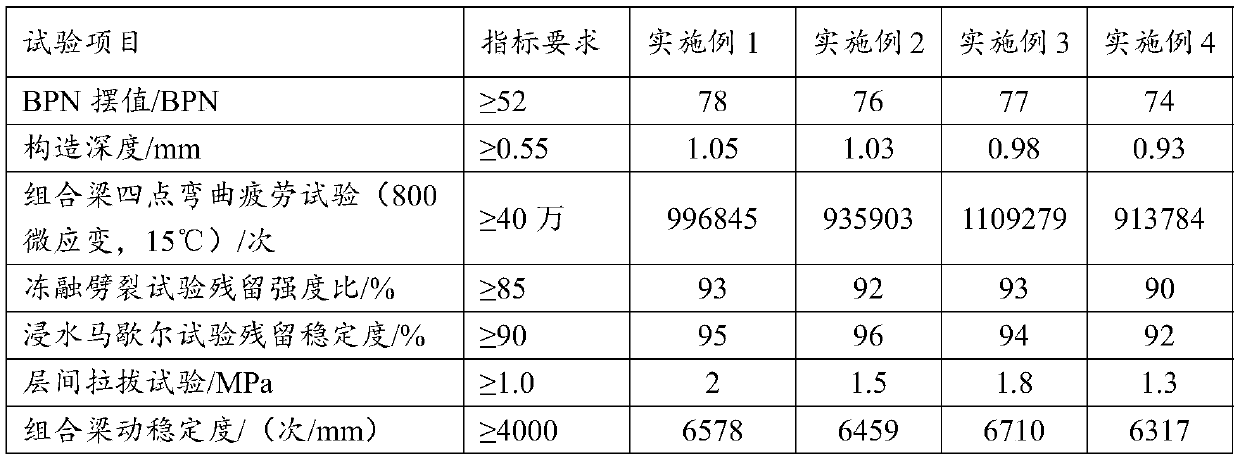

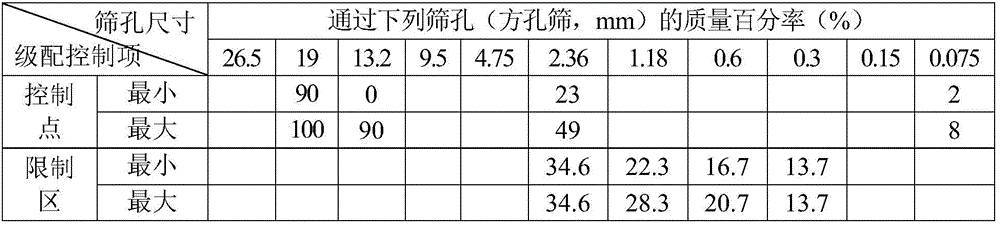

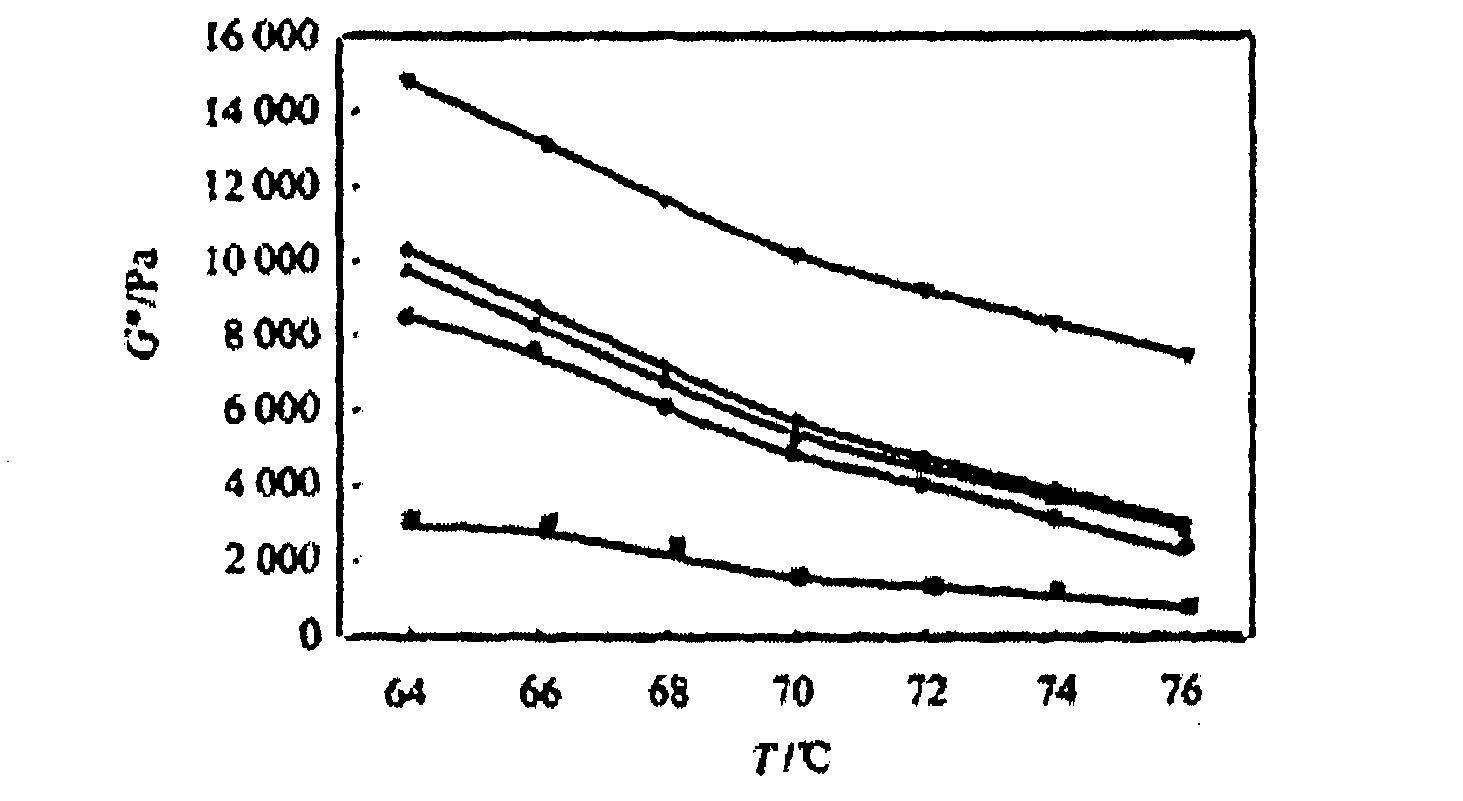

Design method of a high-toughness ultrathin asphalt wearing layer mixture

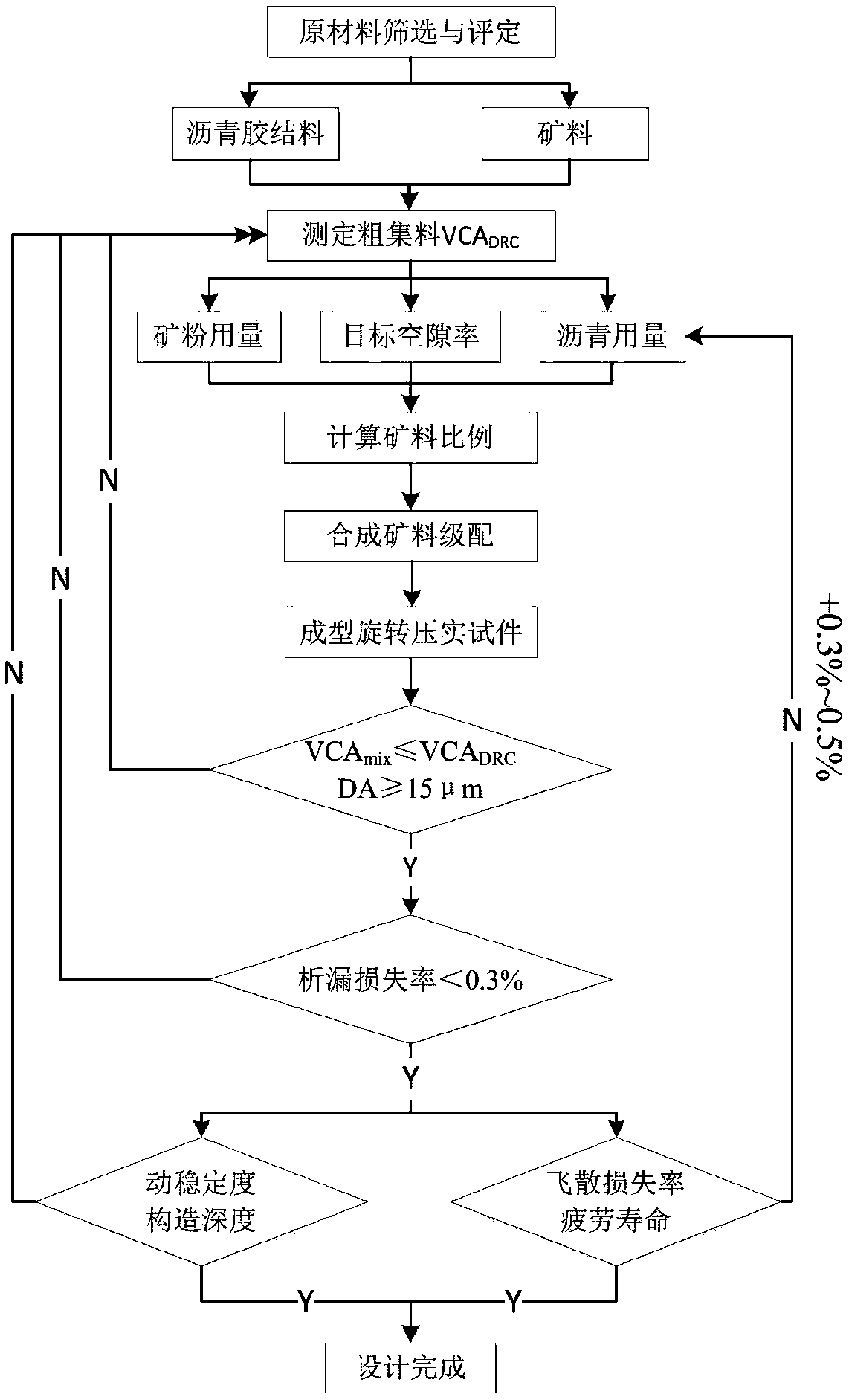

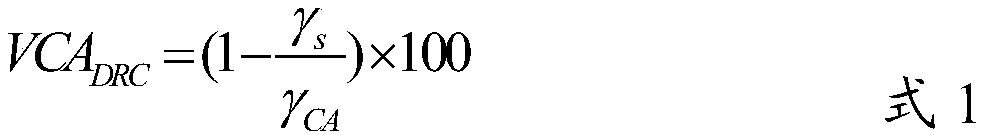

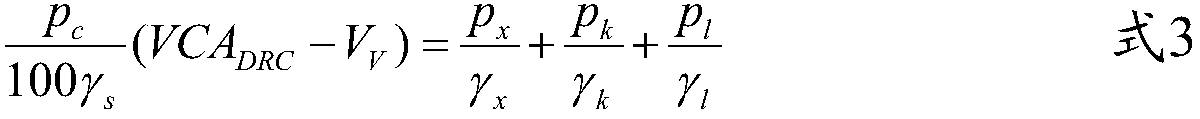

ActiveCN109657421AEmphasis on embedding stabilizationEmphasis on strong anti-cracking effectDesign optimisation/simulationSpecial data processing applicationsRoad engineeringDistribution method

The invention provides a design method of a high-toughness ultrathin asphalt wearing layer mixture, and belongs to the technical field of road engineering. The invention provides a brand new dual design principle that VCAmix is less than or equal to VCADRC and the thickness of the asphalt film is more than or equal to 15m; a coarse skeleton volume distribution method is combined; road performanceverification is combined and design correction is guided; the mixed material design of the high-toughness ultrathin asphalt wearing layer is more purposeful; Standardization and flexibility, VCAmix <= VCADRC and the thickness of the asphalt film are controlled to be greater than or equal to 15m; and the framework embedding and extruding stabilizing effect and the strong anti-cracking effect of ahigh-asphalt oil film are emphasized, it is ensured that the mixture has the good structural performance of track deformation resistance, fatigue cracking resistance and shear deformation resistance,and the functional attributes of the pavement such as the anti-sliding performance, the noise reduction performance, the dense water performance and the flatness can be remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH +1

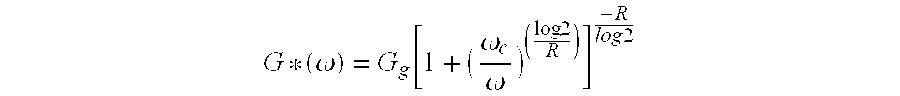

Rejuvenation of reclaimed asphalt

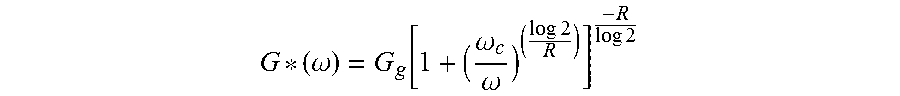

ActiveUS20150240081A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementRheometryVitrification

Asphalt compositions comprising reclaimed asphalt and an ester-functional rejuvenating agent derived from tall oil are disclosed. Rejuvenated binder compositions are also included. The rejuvenating agents restore to reclaimed asphalt desirable properties of virgin asphalt. Reduced glass-transition onset temperatures and improved creep stiffness in the rejuvenated binders translate to improved low-temperature cracking resistance in the asphalt. The rejuvenating agents impart desirable softening at low dosage while also maintaining acceptable penetration values. Dynamic shear rheometry results demonstrate that criteria for asphalt compositions under low, intermediate, and high temperature conditions can be achieved, and the asphalt will have good fatigue cracking resistance and rutting avoidance. The rejuvenating agents reduce the temperature needed to compact or mix asphalt compositions, which conserves energy and reduces cost. The rejuvenated asphalt and binder compositions enable greater use of reclaimed asphalt, especially RAP, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:ARIZONA CHEM CO

Modified asphalt binder material using crumb rubber and methods of manufacturing a modified asphalt binder

InactiveCN101218304AImprove consistencyImprove performanceBuilding insulationsBituminous coatingsPolymer scienceTruck

In a first aspect, bituminous asphalt binder materials which are modified by the addition of crumb rubber or ground tire rubber are described. In a second aspect, the present invention is directed to methods of producing a modified asphalt binder containing crumb rubber or ground tire rubber. The modified asphalt binders comprise neat asphalt, crumb rubber, one or more synthetic polymers, and one or more acids. The crumb rubber may be obtained from recycled truck and / or automobile tires.

Owner:INNOPHOS INC

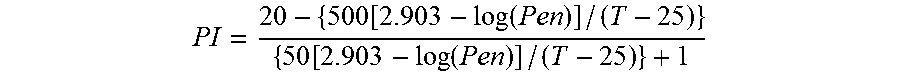

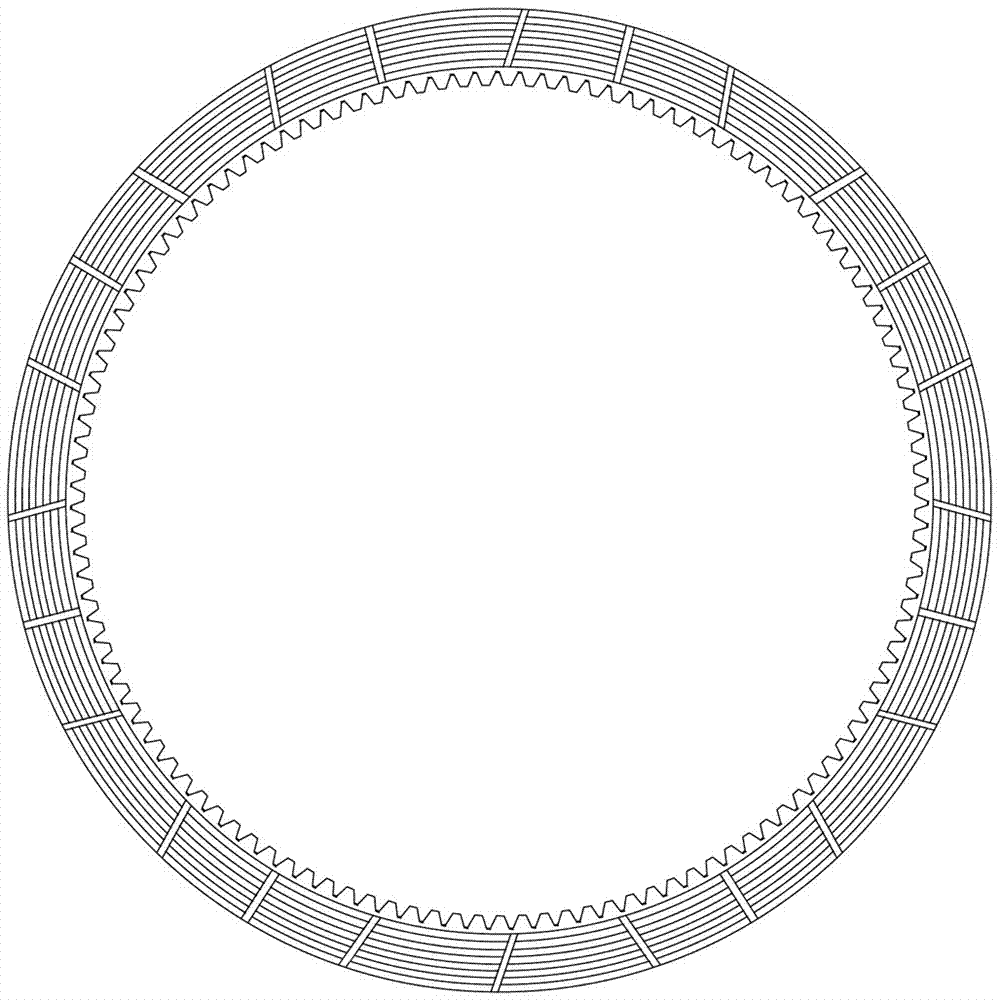

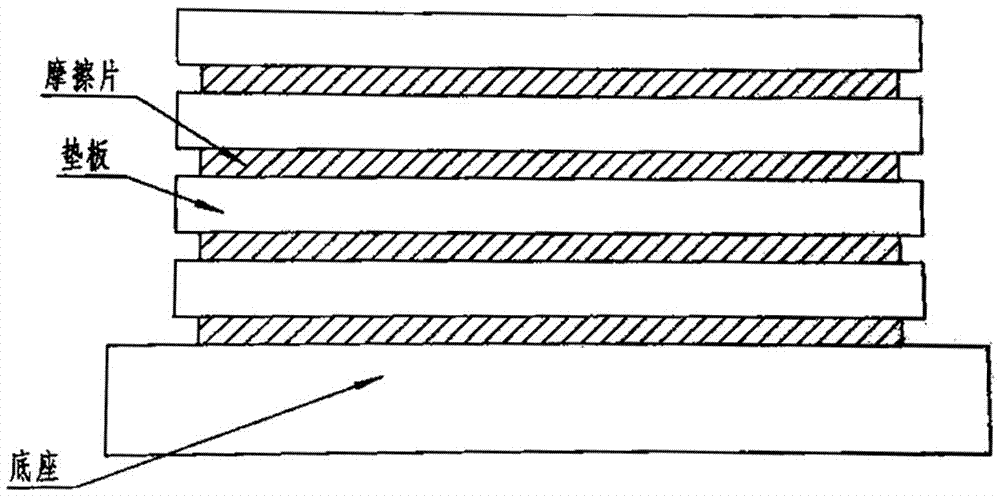

Manufacturing method for copper-based friction plate provided with core plate with overall hardness and high spline precision

Provided is a manufacturing method for a copper-based friction plate provided with a core plate with overall hardness and high spline precision. The manufacturing method for the copper-based friction plate comprises the following steps that (a) materials are prepared for a friction layer; (b) material mixing and compacting are carried out, wherein the materials are mixed in a V-shaped material mixer according to the formula and compacted into a blank needed for the friction plate; (c) the blank and the core plate are sintered under the condition that no spline is machined, and the core plate and the blank of the friction plate are alloyed and adhered firmly; (d) surface grinding is conducted, wherein grinding is conducted on the surface of the friction layer of the blank of the sintered friction plate; (e) overall strengthening treatment is conducted on the friction plate, wherein the blank of the friction plate is heated to 840-860 DEG C in a well-type heat treatment furnace and subjected to decarbonization protection; (f) stacked mounting tempering treatment is conducted on the friction plate, wherein the processed friction plate is put in a bell jar type pressurizing furnace and subjected to furnace feeding tempering treatment, and the hardness of the core plate is controlled at HRC30-38; (g) splines of the core plate with the friction layer are machined, and an oil groove is machined; (h) friction plate tooth shot blasting treatment is conducted; and (i) the surface of the friction layer is accurately grounded, and a finished product is made out.

Owner:HANGZHOU ADVANCE GEARBOX GRP

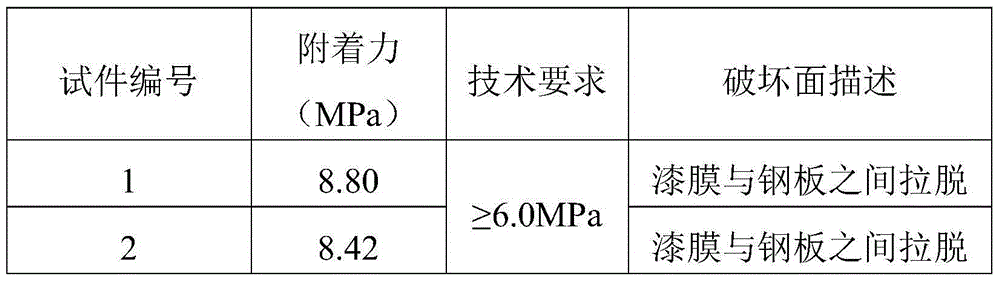

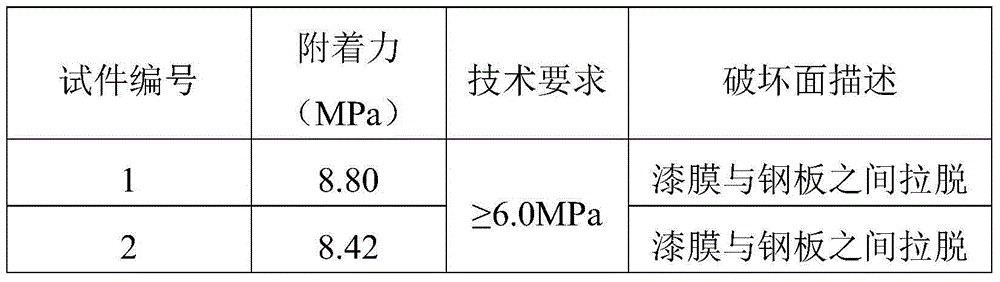

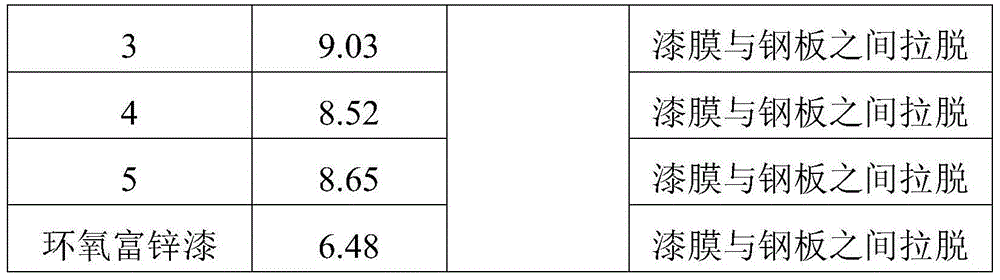

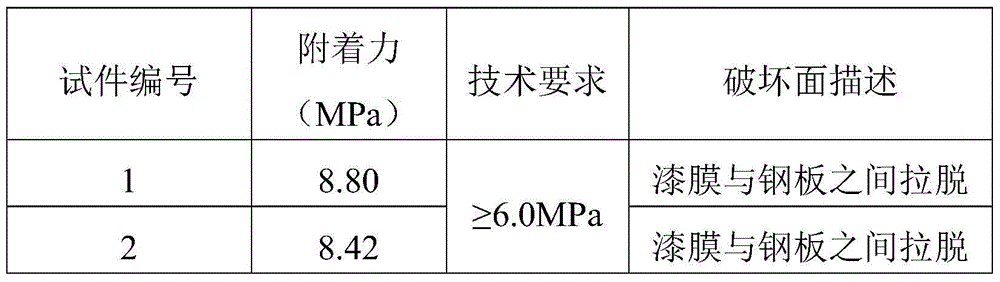

Novel epoxy resin adhesive for paving steel bridge deck and preparation method thereof

The invention discloses a novel epoxy resin adhesive for paving a steel bridge deck and a preparation method thereof. The novel epoxy resin adhesive is prepared by stirring and compacting a resin adhesive and a stone material at normal temperature. The resin adhesive is prepared from components A and B in percentages by mass: X of the component A and (1-X) of the component B, wherein X is 0.6-0.9; the component A contains the following components in parts by weight: 50-80 parts of epoxy resin, 10-20 parts of a diluent and 10-25 parts of a polyurethane prepolymer; the component B contains the following components in parts by weight: 20-50 parts of an imidazole curing agent, 25-60 parts of an alicyclic ammonia curing agent, 10-30 parts of a thickener, 1-5 parts of a coupling agent and 1-3 parts of an accelerant. The resin adhesive and the stone material account for 7-13% by mass. The novel epoxy resin adhesive provided by the invention has the advantages of high strength, good high- and low-temperature property, certain deformation ability, no need of heating and stirring and the like, can be cured at a constant temperature, and is relatively short in curing time, and the open traffic time can be greatly shortened during construction.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

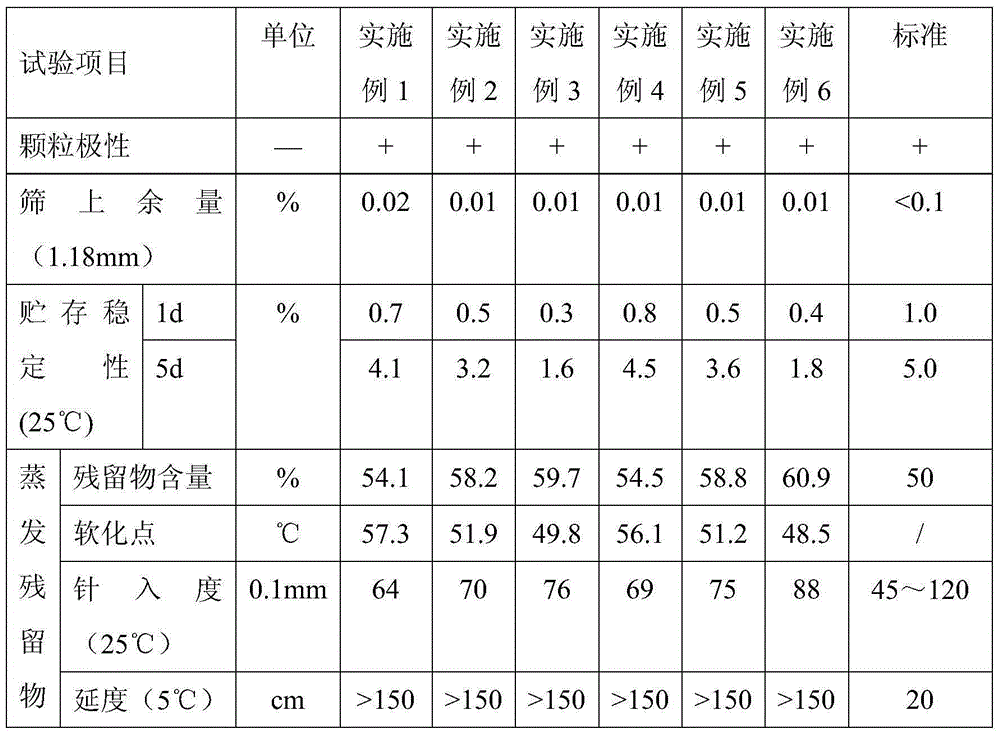

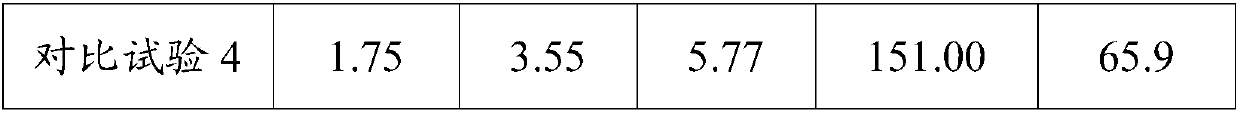

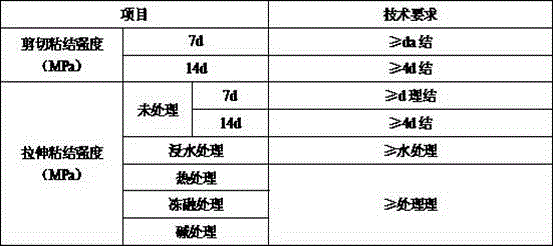

High-solid-content emulsified asphalt for stress absorbing layer, preparation method and construction method thereof

InactiveCN109535751AFix reflection cracksReduce construction proceduresIn situ pavingsRoads maintainenceChipsealColloid

The invention discloses a high-solid-content emulsified asphalt for a stress absorbing layer, a preparation method and a construction method thereof. The high-solid-content emulsified asphalt is prepared from ordinary asphalt, asphalt additive, emulgator, modifier, water and pH regulator; the solid content is 67-75%; the raw materials by weight percent are as follows: 50-70% of ordinary asphalt, 1-12% of asphalt additive, 0.2-3.0% of emulgator, 2.0-10.0% of modifier and the balance of water and pH regulator. The preparation method comprises the following steps: heating ordinary asphalt; addingasphalt additive into ordinary asphalt at a ratio and uniformly stirring, thereby acquiring a mixture of ordinary asphalt and asphalt additive; preparing emulgator into an aqueous solution, and thenadding modifier, thereby acquiring an emulgator liquid soup; using pH regulator for regulating pH value of the emulgator liquid soup, and then heating; successively putting the emulgator liquid soup and the mixture of ordinary asphalt and asphalt additive into a colloid mill, and then milling, thereby acquiring an end product of emulsified asphalt. According to the invention, a synchronous macadamseal coat vehicle is adopted for spraying / spreading emulsified asphalt and macadam; a 'prime coat and stress absorbing layer' effect can be achieved through once construction; construction process isreduced; construction cost is lowered.

Owner:山东高速建材集团有限公司

Sulfur-modified emulsified asphalt and preparation method thereof

InactiveCN106554632AAvoid high temperature heatingAvoid bodily harmBuilding insulationsSocial benefitsSulfur

The invention relates to sulfur-modified emulsified asphalt and a preparation method thereof. The sulfur-modified emulsified asphalt is prepared from 40 to 50 parts by mass of asphalt, 5 to 20 parts by mass of sulfur, 2 to 10 parts by mass of styrene-butadiene latex, 0.3 to 1 part by mass of a nonionic emulsifier, 0.5 to 3 parts by mass of a cationic composite emulsifier, 0.03 to 2 parts by mass of a stabilizer, 0.5 to 3 parts by mass of an acid and 35 to 50 parts by mass of water. The sulfur-modified emulsified asphalt improves a softening point of the asphalt, improves the high temperature performances of the asphalt, has good low temperature performances, can improve the strength and stability of the asphalt pavement, and improves rutting and fatigue cracking resistance of the pavement. The sulfur-modified emulsified asphalt is prepared through simple processes, is free of heating, prevents generation of harmful gas, reduces the energy consumption and discharge, is beneficial to construction and the health of the construction personnel, and has great economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

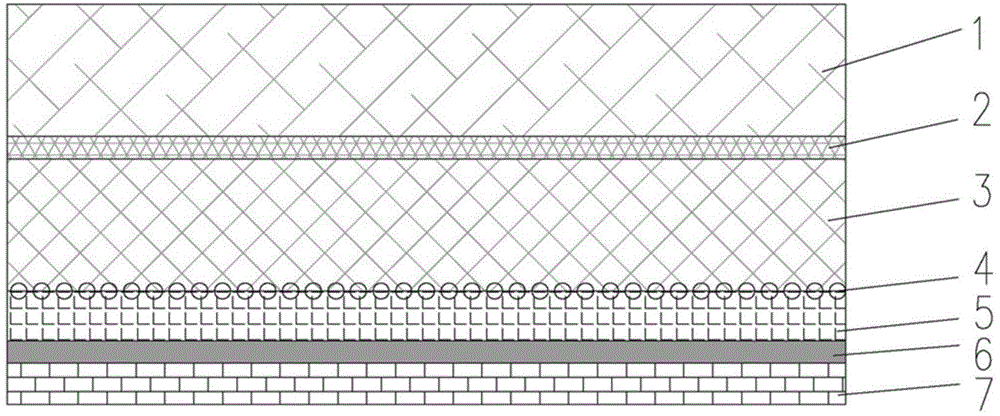

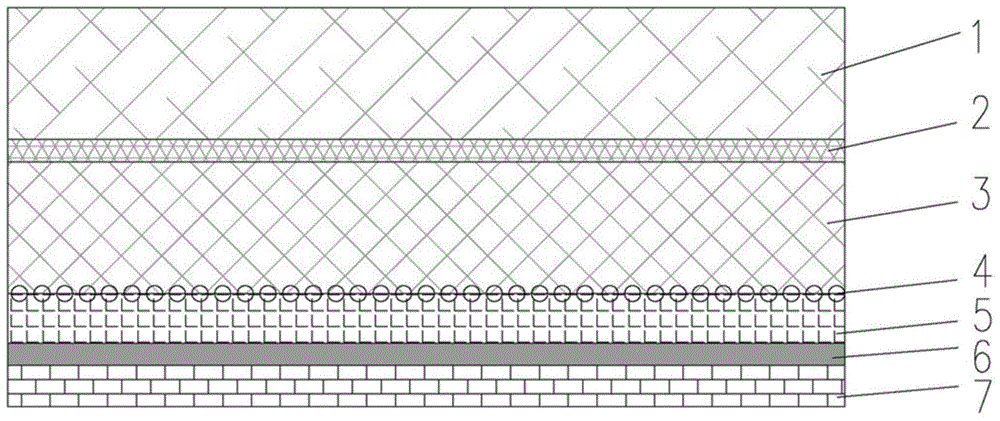

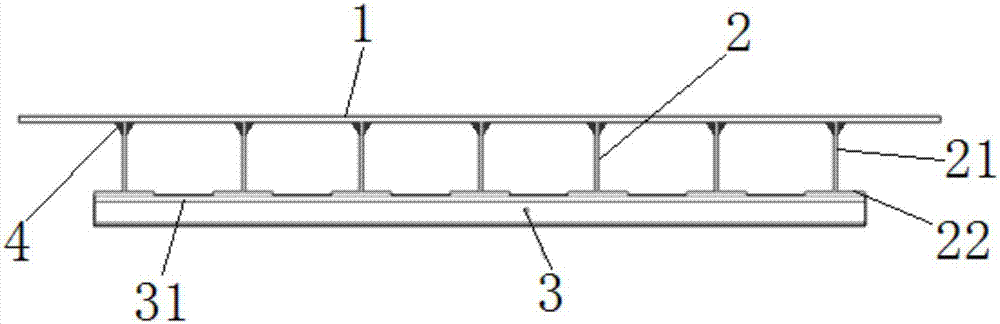

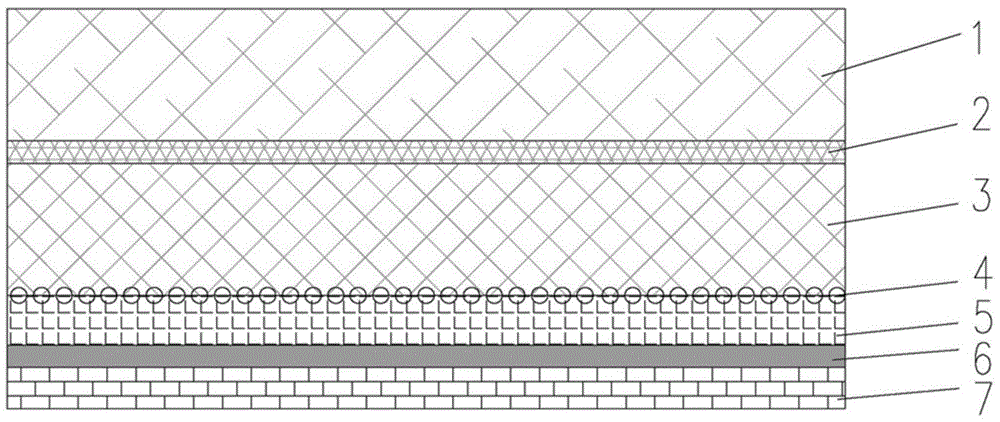

Bridge deck pavement structure for orthotropic steel bridge

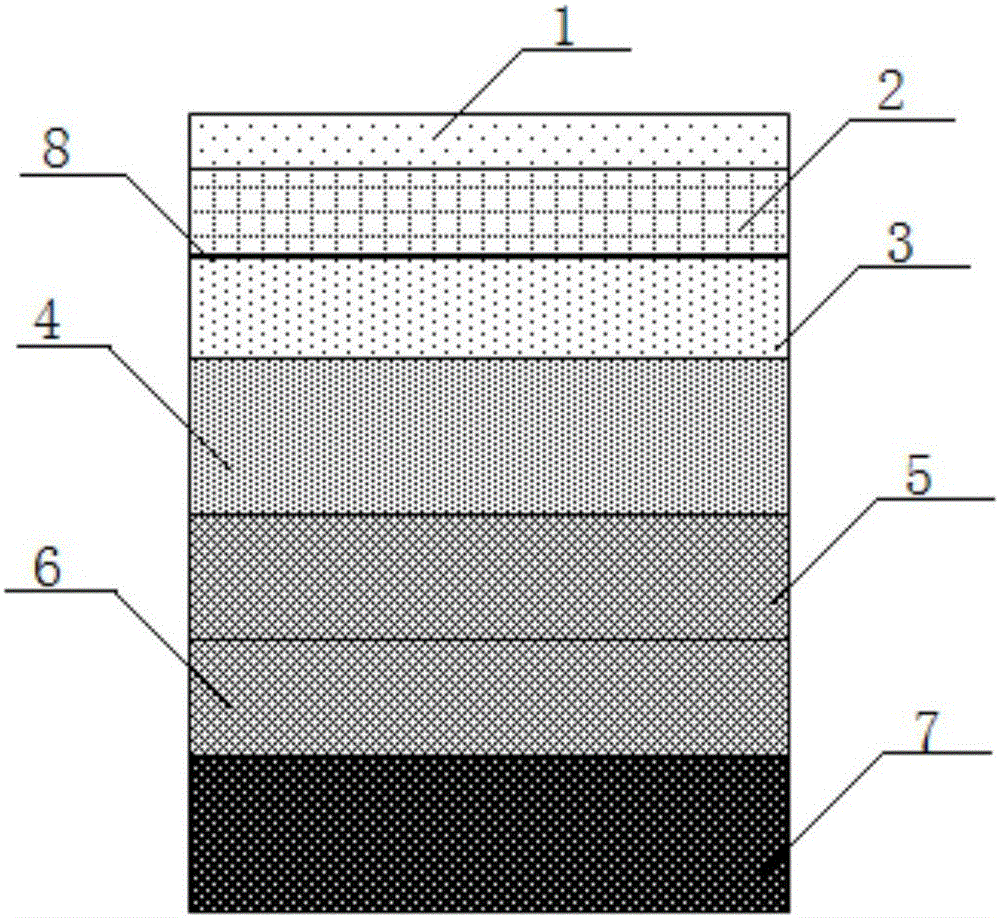

ActiveCN104652269AImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxySolvent free

The invention discloses a bridge deck pavement structure for an orthotropic steel bridge. The pavement structure comprises a mica-containing epoxy anti-corrosion layer, a solvent-free epoxy resin water-proof layer, a hot melt particle bonding layer, a high-elasticity modified asphalt pavement lower layer, a modified emulsified asphalt bonding layer and a high-elasticity modified asphalt pavement upper layer from bottom to top, wherein the total pavement thickness is 6-8 centimeters; the hot melt particles are high-polymer particles of which the softening point is greater than 150 DEG C; the high-elasticity modified asphalt is modified asphalt of which the elastic recovery is over 95 percent at 25 DEG C; the pavement lower layer is formed by paving a fine-particle asphalt mixture prepared by mixing the high-elasticity modified asphalt with a mineral mixture; the pavement upper layer is formed by paving a fine-particle or medium-particle asphalt mixture prepared by mixing the high-elasticity modified asphalt with the mineral mixture. By adopting the pavement structure, the water-proof layer and the asphalt pavement layer are combined integrally through the hot melt particle bonding layer, so that the shearing strength and durability of the pavement structure are ensured.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

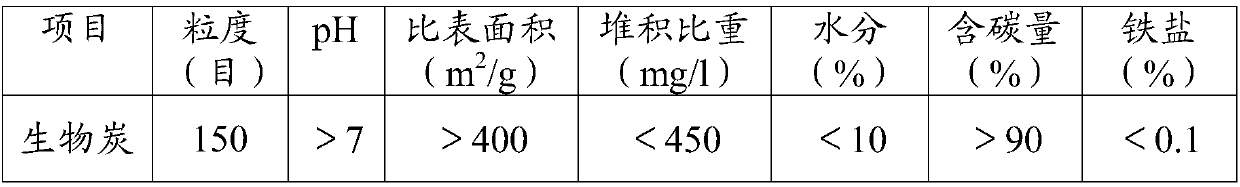

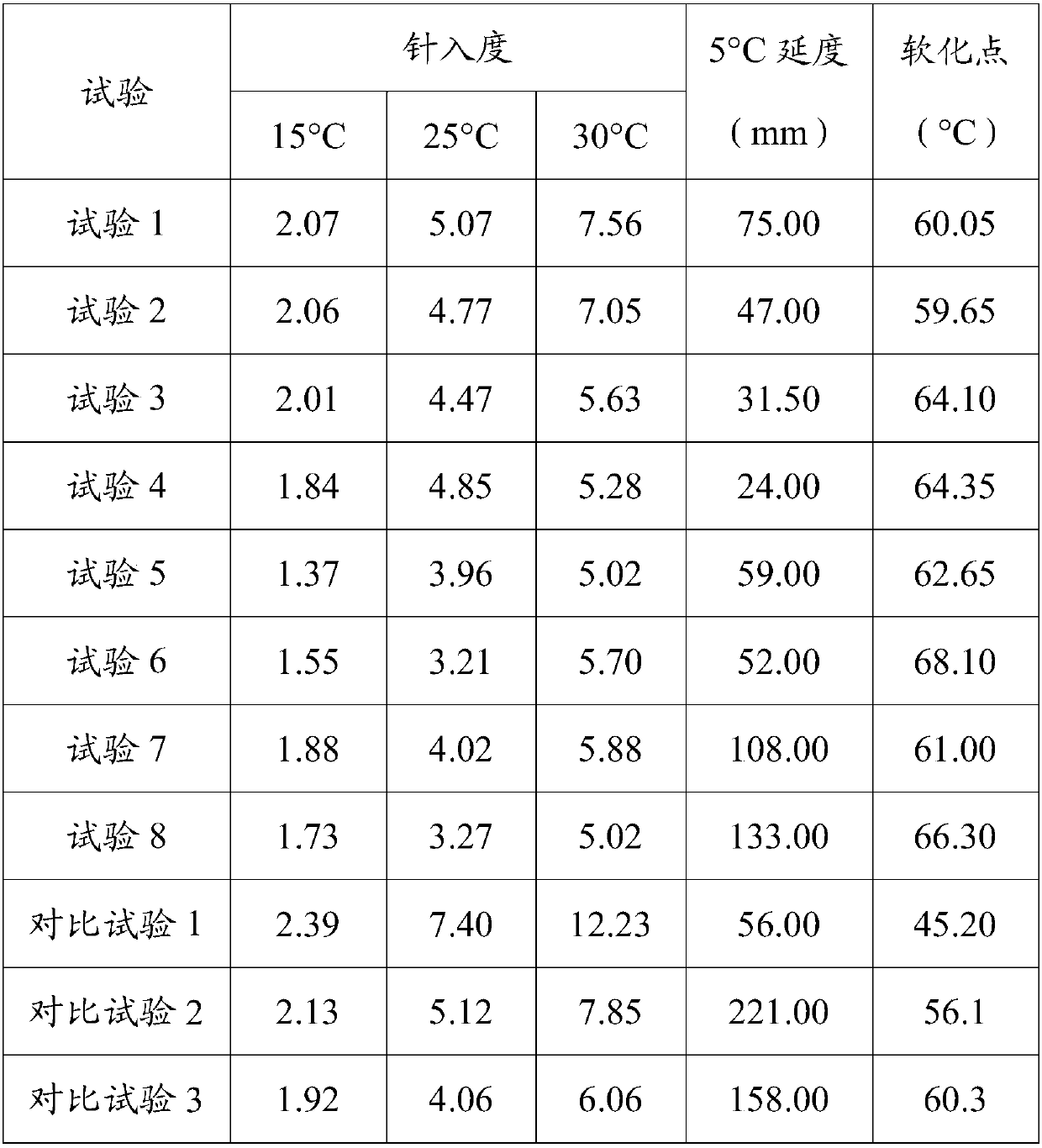

SEBS/biochar compound modified asphalt and preparation method thereof

InactiveCN107739520AImprove high temperature stabilityImprove low temperature crack resistanceBuilding insulationsCrack resistanceRoom temperature

The invention discloses SEBS / biochar compound modified asphalt and a preparation method thereof. The SEBS / biochar compound modified asphalt is prepared from SEBS, biochar and matrix asphalt. The preparation method comprises the steps: heating the matrix asphalt, adding the SEBS into the heated matrix asphalt, stirring, shearing and swelling to obtain modified asphalt for standby application; stoving the biochar and cooling to room temperature to obtain cooled biochar for standby application; adding the cooled biochar into the modified asphalt and stirring and shearing to obtain the SEBS / biochar compound modified asphalt. The compound asphalt disclosed by the invention has the advantages of higher high-temperature stability, no effect on self low-temperature crack resistance, suitability for use in high-temperature plateau areas with strong ultraviolet rays and especially suitability for open-graded roads with higher requirements for aging performance. The preparation method has the advantages of simpleness, ability in reasonably utilizing the biochar, economical effect and environmental friendliness.

Owner:CHANGAN UNIV

Modified emulsified asphalt and preparation method thereof

ActiveCN108342089AHigh softening pointImprove high temperature performanceBuilding insulationsSulfurRoad surface

The invention relates to modified emulsified asphalt and a preparation method thereof. The modified emulsified asphalt comprises, by mass, 40-50 parts of asphalt, 6-16 parts of sulfur, 2-10 parts of styrene-butadiene latex, 2-5 parts of a cationic emulsifier, 0.1-2 parts of a stabilizer, 0.5-3 parts of an acid and 35-40 parts of water. The modified emulsified asphalt improves high temperature andlow temperature performances of the asphalt, saves the asphalt, reduces a production cost, improves the high temperature stability of the asphalt pavement, prevents the rutting and peeling of the asphalt pavement under a load and improves the anti-fatigue cracking performances of the pavement.

Owner:CHINA PETROLEUM & CHEM CORP

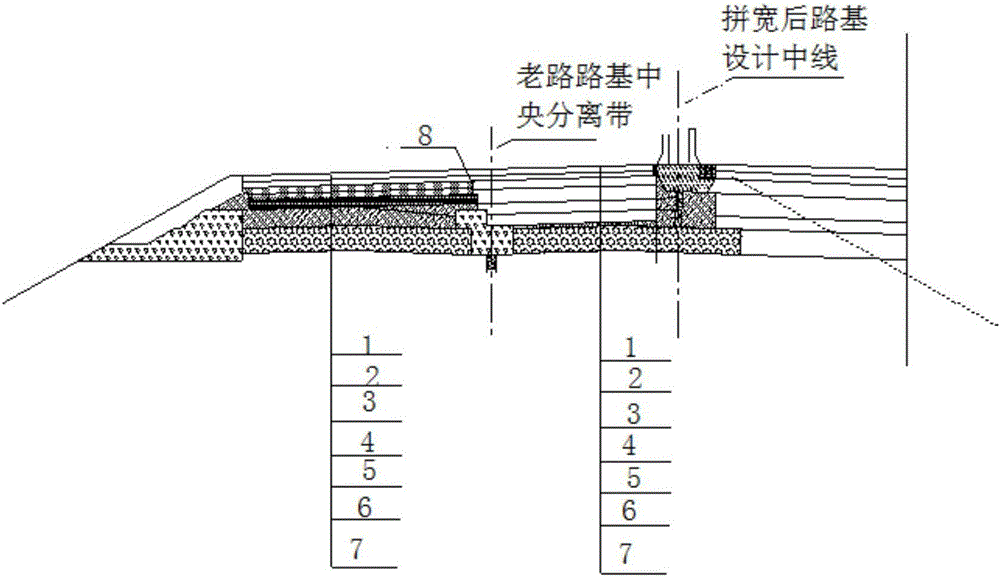

Single-side joint structure and single-side joint method for expressway extension

InactiveCN106065555AIncreased durabilityImprove toughnessIn situ pavingsClimate change adaptationSurface layerRoad surface

The invention discloses a single-side joint structure and a single-side joint method for expressway extension. The structure includes, from top to bottom successively, an upper surface layer, a middle surface layer, a lower surface layer, a cold regeneration basic layer, a water stability sub-base layer, and a cushion layer. The water stability sub-base has a double-layer composite structure and comprises an upper water stability sub-base layer and a lower water stability sub-base layer. At a joint position, the joint structure has step-like arrangement. In the method, an original medium separation area is removed and the pavement of a to-be-extended half side of the old road until the cushion layer is milled and planed. The two-direction slope of the old road is modified into a one-direction slope to ensure the top surfaces of the two water stability sub-base layers in the old road to be one-directional, thereby effectively enabling a drainage system on the surface of the pavement and inside the pavement to be unobstructed. Two basic layers of the old road are jointed to each other in a semi-rigid manner, so that by means of the method, the deformation of the two basic layers are cooperated, thus prolonging the service life of the pavement. The structure and the method improve anti-reflective crack capability of the pavement structure, wherein the joint seam is arranged at the lane line between a second lane and a third lane. A warp-knitted composite reinforced anti-cracking fabric is employed so as to avoid a load concentration position of wheel track tapes and avoid a large load on the weak positions in the joint seams, thereby improving durability of the pavement structure.

Owner:JIANGXI GANYUE EXPRESSWAY

Steel slag stress absorption layer material and preparation method thereof

The invention discloses a steel slag stress absorption layer material and a preparation method thereof. The method comprises the following steps of: (1) respectively weighing 7-14 parts by weight of mineral powder, 100-200 parts by weight of steel slag aggregate, 9-19 parts by weight of SBS modified asphalt and 0-0.4 parts by weight of brucite mineral fibers; (2) heating the aggregate and the mineral powder at a constant temperature of 170-180 DEG C for more than 4 hours for later use; (3) heating the SBS modified asphalt to 170-180 DEG C, and fully and uniformly stirring for later use; and (4) carrying out dry mixing on the steel slag aggregate subjected to constant-temperature heating for 25-35 seconds, then adding brucite mineral fibers, carrying out dry mixing for 8-12 seconds, then adding the heated SBS modified asphalt, carrying out wet mixing for 85-95 seconds, and finally adding mineral powder, and carrying out mixing for 15-25 seconds. The stress absorption layer material manufactured by the method is high in viscoelasticity and good in fatigue cracking resistance. The preparation method is simple in process, economical and environment-friendly, and has important practicalsignificance and economic value.

Owner:内蒙古综合交通科学研究院有限责任公司 +2

High-toughness, durable and anti-skid steel bridge deck pavement structure and construction method thereof

InactiveCN110952447AIncrease stiffnessImprove stabilityBridge structural detailsBridge erection/assemblyEpoxyBridge deck

The invention discloses a high-toughness, durable and antiskid steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridgedeck steel plate; a bonding bottom layer, a buffer layer, an adhesion layer and a wearing layer are sequentially laid on the surface of the steel bridge deck steel plate from bottom to top; the buffer layer and the wearing layer are both made of high-toughness modified asphalt concrete composed of aggregate, filler and asphalt cement, the thickness of the buffer layer is 1-3 cm, and the thicknessof the wearing layer is 2-3 cm. The bridge deck pavement structure has good high-temperature rut resistance, fatigue durability, skid resistance, bonding strength and deformation compliance, comparedwith epoxy asphalt concrete, the engineering cost is greatly reduced, the construction process is simple, and later maintenance is convenient.

Owner:广州市市维新材料科技有限公司

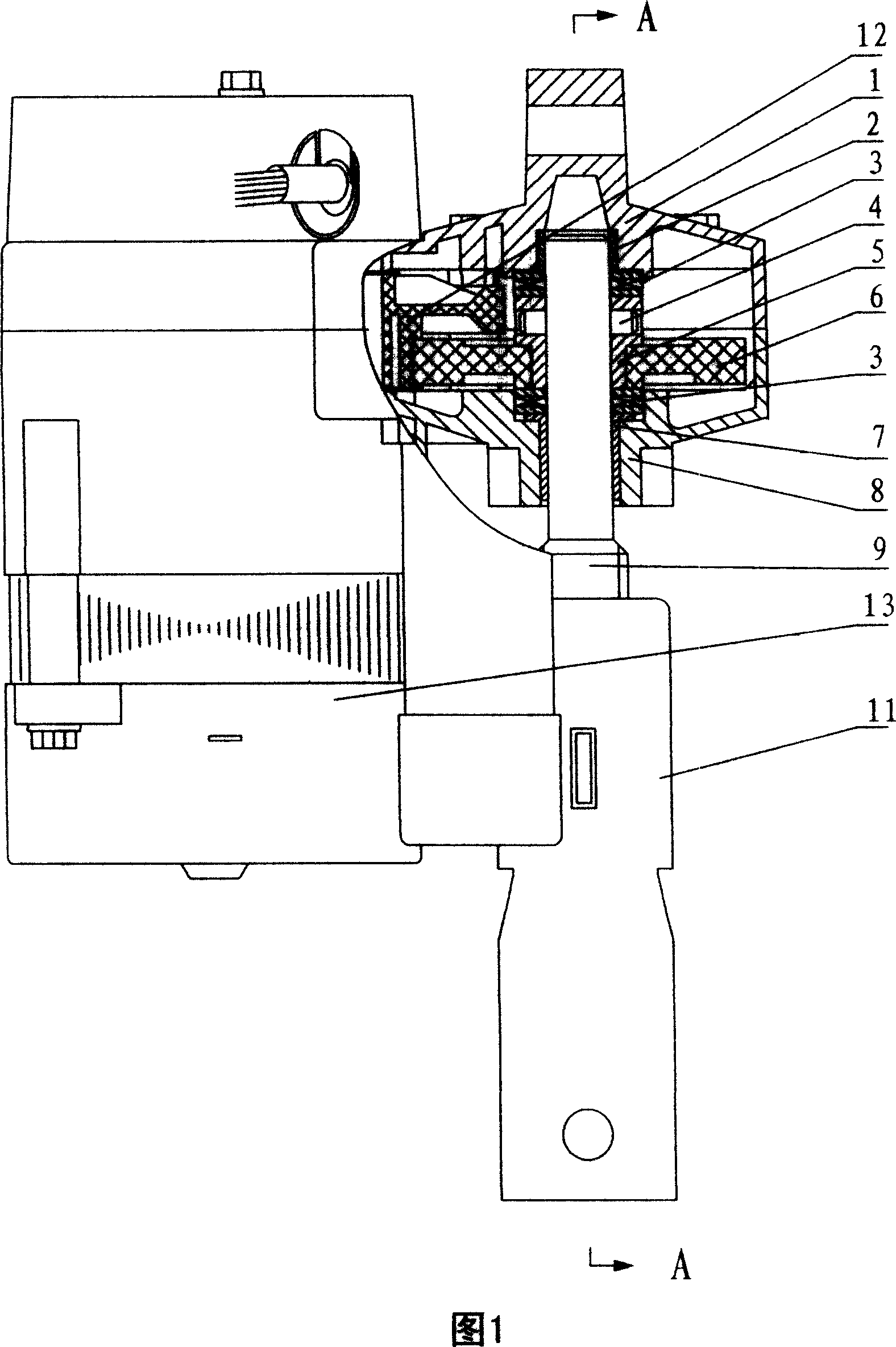

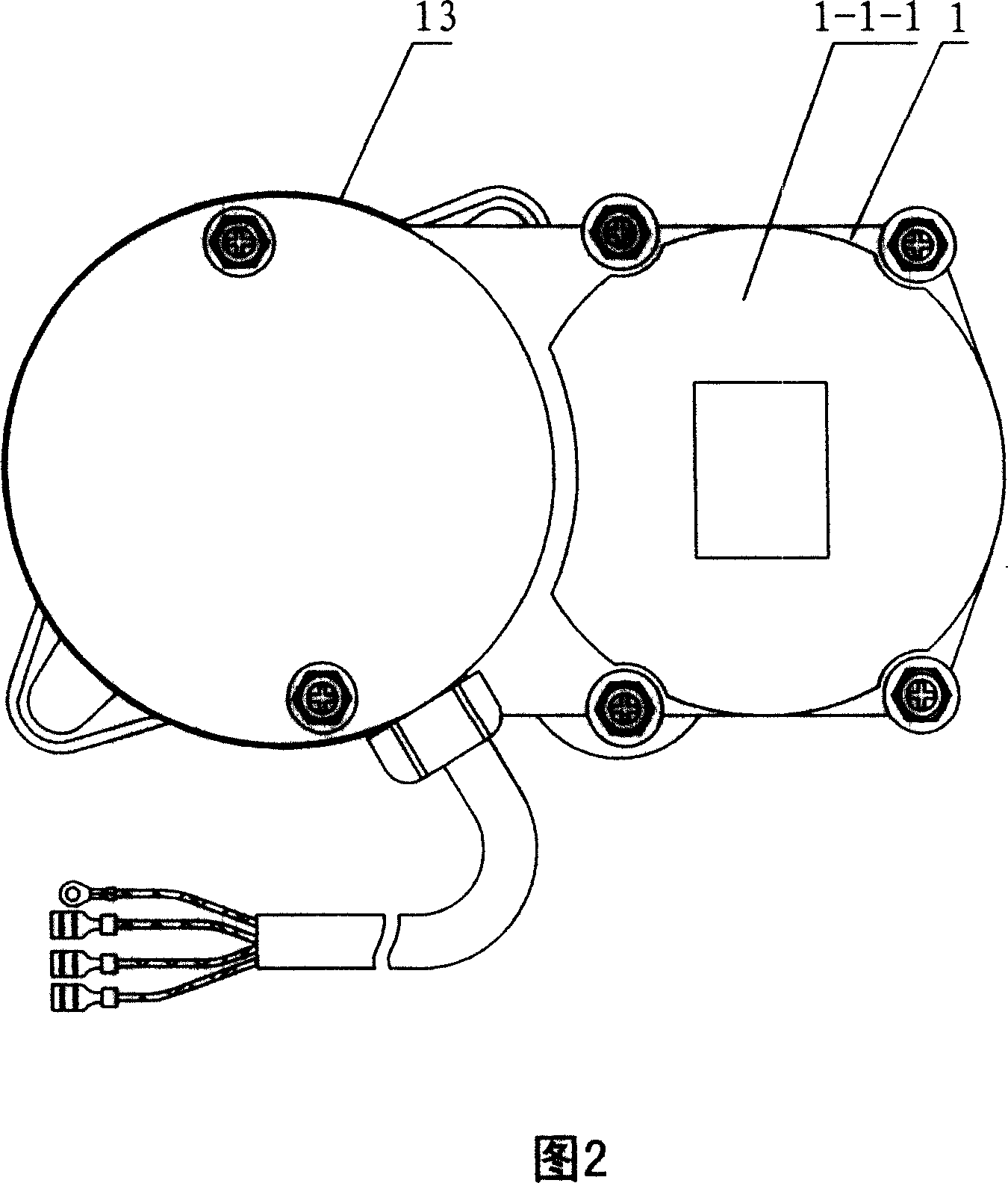

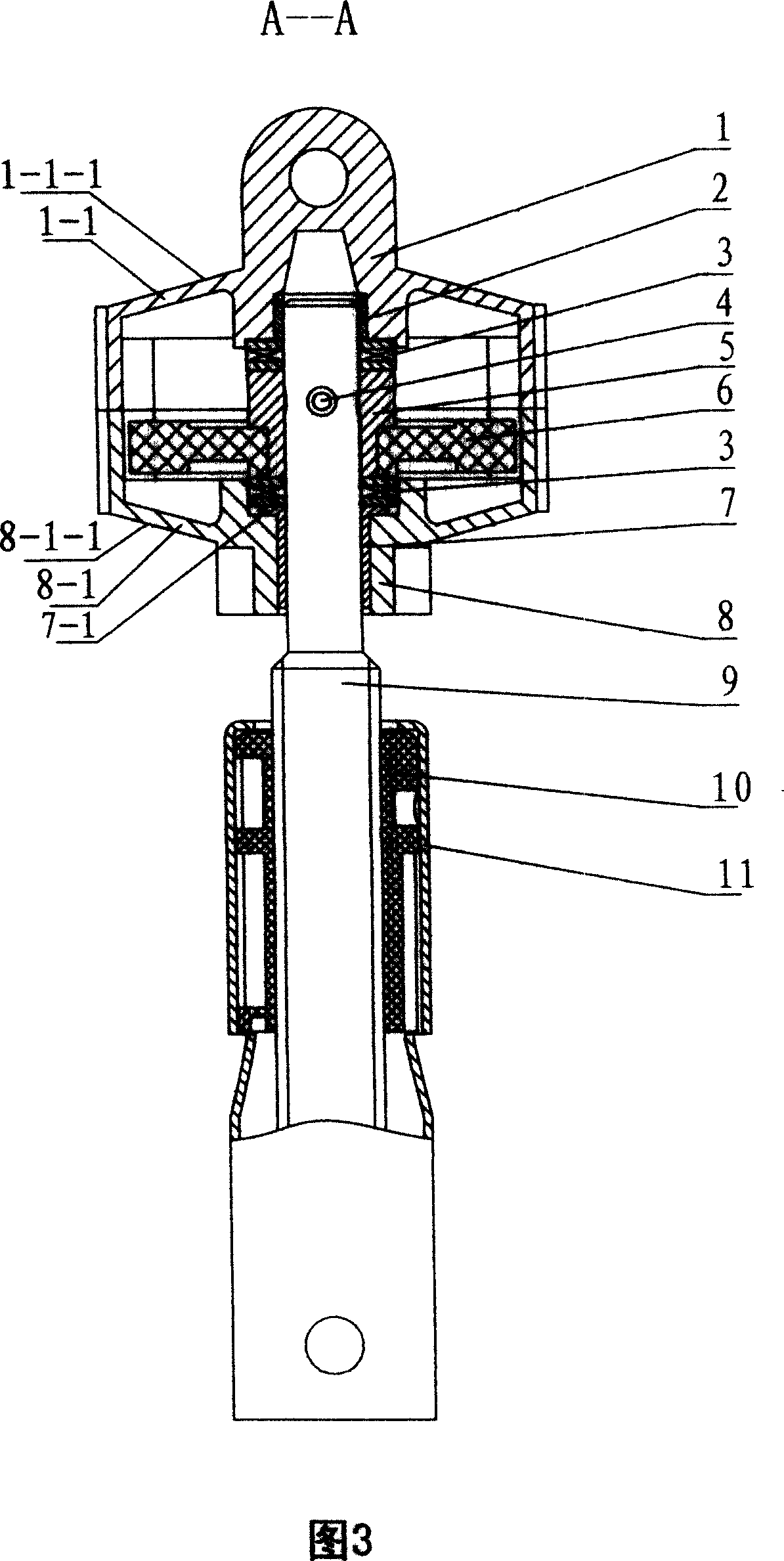

Screw lifter

InactiveCN101016142AImproved resistance to fatigue crackingLittle changeLifting devicesHoisting equipmentsEngineeringReducer

The invention discloses a screw lifter which can convert rotation into straight motion, comprising an upper case, a lower case, a motor, a speed reducer, a bearing, a lead screw and a nut, wherein the upper and lower cases are fixed, the motor via the speed reducer is geared with the lead screw meshed with a nut, the outer wall of the case around the bearing base of the upper and lower cases is in taper shape whose outer wall can be taper face or taper face disposed with bars. The invention has reasonable force on upper and lower cases, with long service life.

Owner:戴焕平 +1

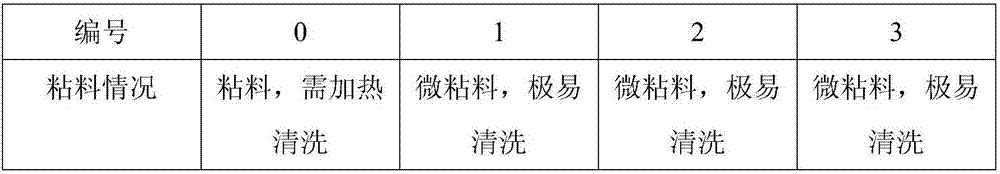

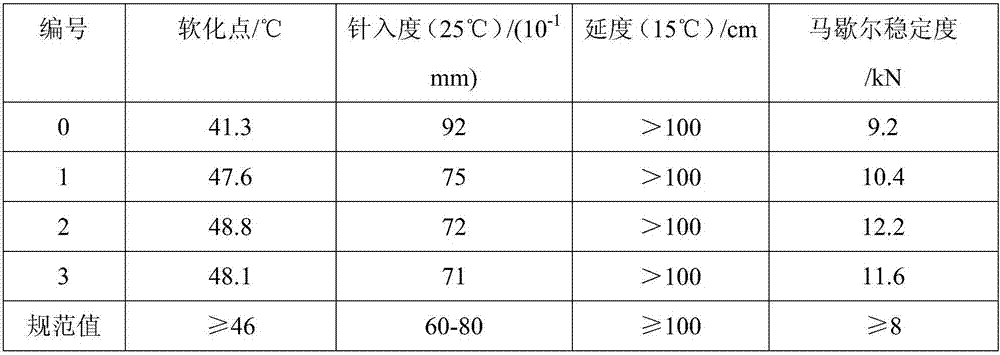

A micro-repair type release agent for asphalt mixture rolling and preparation method thereof

The invention provides a micro-repair type separating agent for grinding of a bituminous mixture. The separating agent is prepared from 10%-15% of waste cooking oil, 6%-8% of carbon black, 15%-20% of emulsified silicone oil, 6%-10% of sodium dodecyl benzene sulfonate, 3%-5% of organic acid, 4%-7% of polyethylene glycol, 2%-4% of mica powder and the balance of water, and the sum of weight percentages of raw materials is 100%. The waste cooking oil, the carbon black and the emulsified silicone oil are mixed, and a mixture A is obtained; the organic acid, polyethylene glycol and the mica powder are mixed, and a uniform mixture B is obtained; the obtained mixture B is added to the mixture A, and a uniform mixture C is obtained through mixing; sodium dodecyl benzene sulfonate and the water are mixed to form a dilute solution, then the dilute solution is added to the mixture C at 60-70 DEG C, and the micro-repair type separating agent is obtained. Communicating gap and whitening phenomena of a bituminous layer surface can be avoided, the separating agent plays a micro-repair role on a bituminous pavement, and the water stability, ageing resistance and fatigue cracking resistance of the bituminous pavement can be effectively improved.

Owner:CHANGAN UNIV

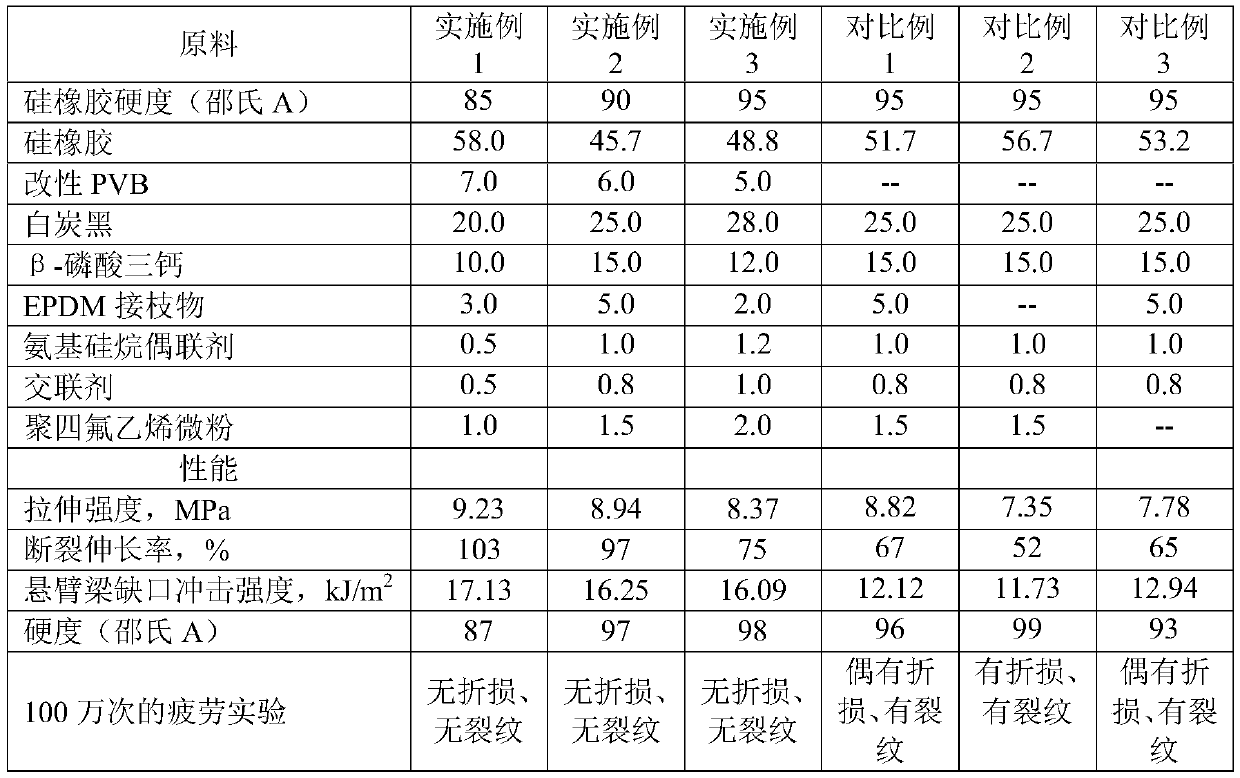

Silicone rubber composite material for fused deposition 3D printing and preparation method thereof

ActiveCN110527297AImprove adhesionImproved resistance to fatigue crackingAdditive manufacturing apparatus3D object support structuresCalcium biphosphatePolymer science

The invention discloses a silicone rubber composite material for fused deposition 3D printing and a preparation method thereof. The invention discloses the silicone rubber composite material which canbe used in a fused deposition 3D printing process, has adjustable hardness, and has a fatigue resistant function, and a preparation method thereof. The composite material comprises the following components in parts by mass: 45.7-58.0 parts of a silicone rubber, 5.0-7.0 parts of a modified PVB, 20.0-28.0 parts of white carbon black, 10.0-15.0 parts of calcium phosphate, 2.0-5.0 parts of a EPDM graft, 0.5-1.2 parts of an amino-silane coupling agent, 0.5-1.0 part of a crosslinking agent, and 1.0-2.0 parts of a lubricant. Through rheological extruder blending and reaction compatibilization, compatibility of the silicone rubber, the bonding resin PVC with the inorganic reinforcing materials is improved, so that the silicone rubber composite material is endowed with good mechanical properties,fatigue resistance and adjustable hardness. The product is particularly suitable for production of fused deposition 3D printed dental medical equipment.

Owner:SOUTH CHINA UNIV OF TECH

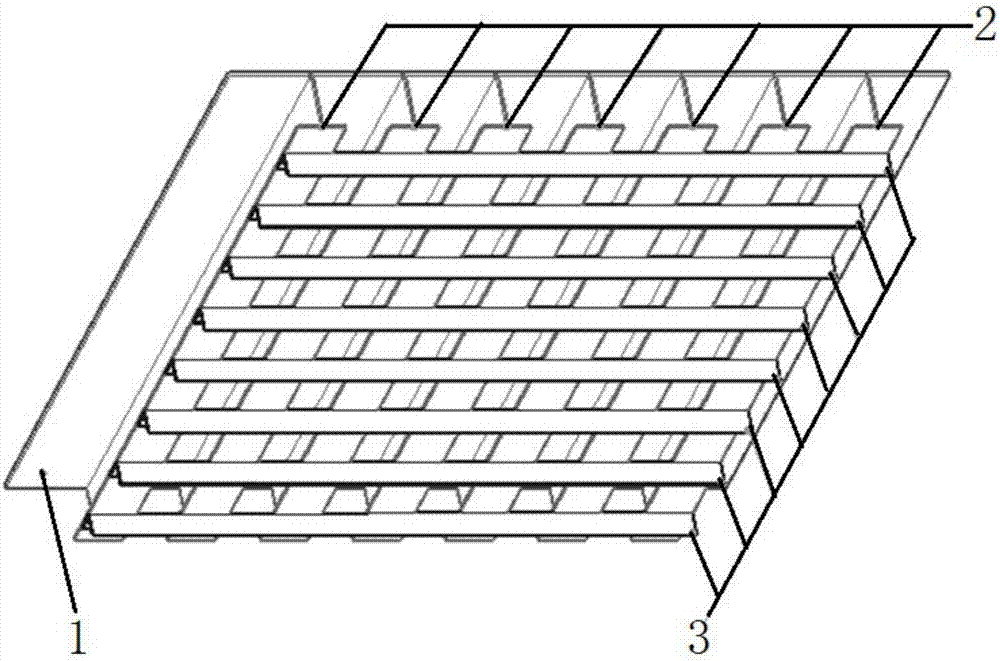

Orthotropic steel bridge deck structure with transverse straining beam

ActiveCN106948262AReduce stress concentrationImproved resistance to fatigue crackingBridge structural detailsBridge deckStress concentration

The invention relates to an orthotropic steel bridge deck structure with a transverse straining beam. The structure comprises a cover plate, a plurality of longitudinal reinforcing ribs which are arranged on the lower surface of the cover plate in parallel and a plurality of transverse reinforcing ribs which are arranged on the lower surfaces of the longitudinal reinforcing ribs in parallel and are vertical to the longitudinal reinforcing ribs, wherein the longitudinal reinforcing ribs are opening reinforcing ribs; tops of vertical parts of the longitudinal reinforcing ribs are fixedly connected with the cover plate through double-faced welding lines; the transverse straining beam is used for fixedly connecting the plurality of longitudinal reinforcing ribs through horizontal parts of the longitudinal reinforcing ribs. Compared with the prior art, the opening reinforcing ribs are used as the longitudinal reinforcing ribs, so that the longitudinal reinforcing ribs and the cover plate can be fixedly welded together through the double-faced welding lines and stress concentration is reduced; an anti-fatigue cracking performance of the structure is effectively improved, the service life of the structure is prolonged and the safety is good; the longitudinal opening reinforcing ribs, which are arranged in parallel, are fixedly connected together through the transverse straining beam so that the whole stress performance of the structure is improved.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

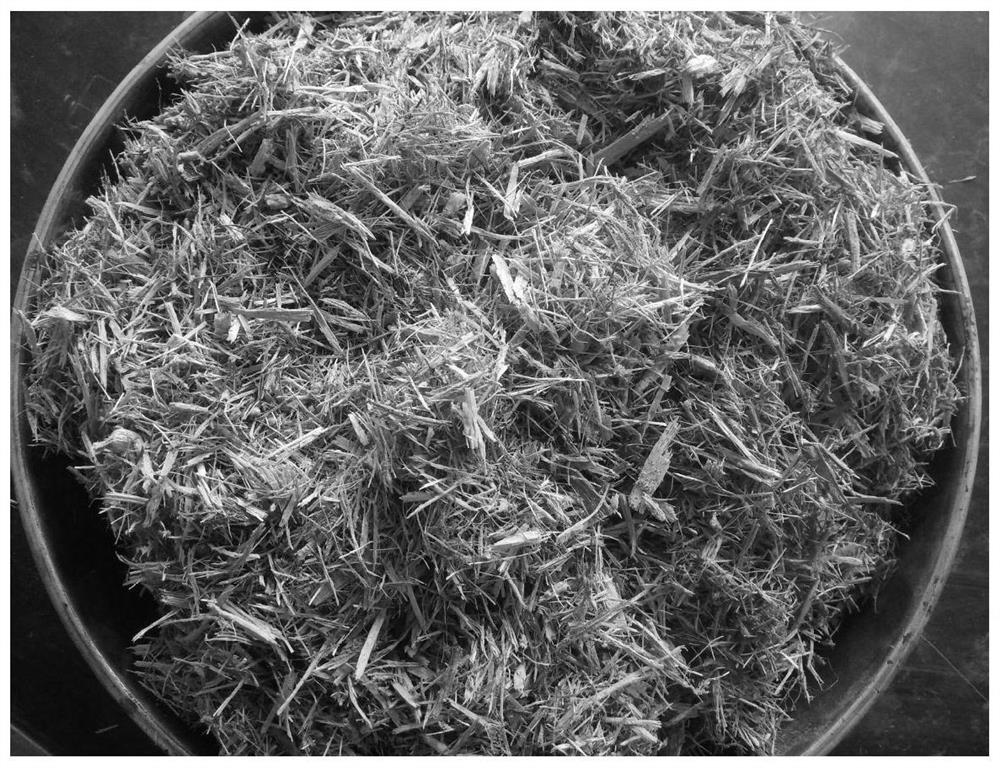

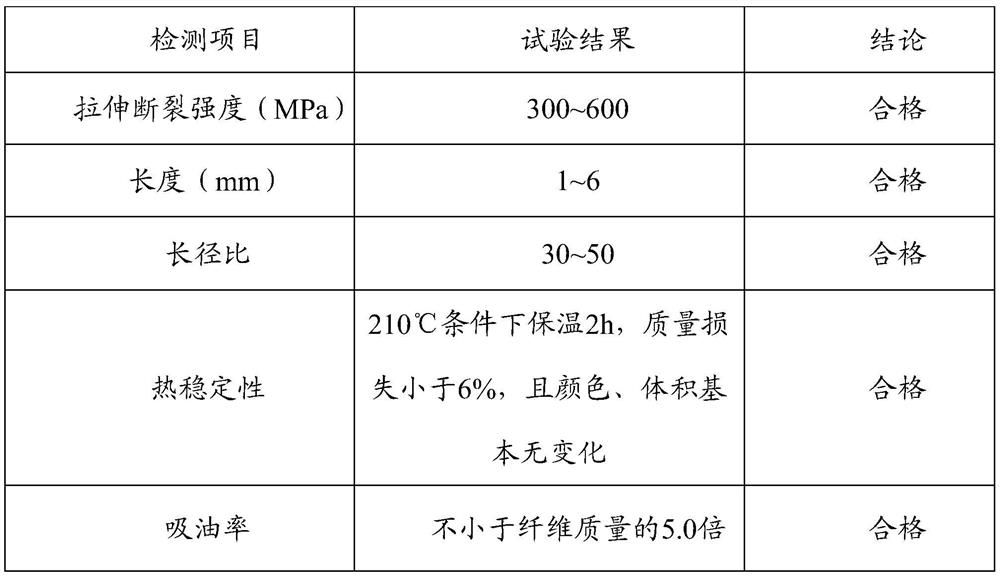

A kind of preparation method of bagasse fiber for asphalt pavement reinforcement

The invention discloses a preparation method of bagasse fibers for asphalt pavement reinforcement, which comprises the following steps: purifying and removing impurities from bagasse raw materials, soaking in alkaline solution, taking out bagasse, adjusting pH to obtain saturated bagasse; adding bagasse to saturated bagasse Carry out hydrolysis with enzyme, take out, get saturated surface dry bagasse; add chemical dispersant and expanded perlite micropowder to saturated surface dry bagasse, mix to get mixture; add water to the mixture, mechanically disperse, get mechanical dispersion ; Dry and sieve the mechanical dispersion to obtain. The length of the bagasse fiber obtained by the preparation method is 1-6 mm, the aspect ratio is 30-50, the tensile breaking strength is 300-600 MPa, and the thermal stability and oil absorption of the bagasse fiber are good; the bagasse fiber is mixed into the asphalt In the mixture, the high-temperature stability, low-temperature crack resistance and fatigue cracking resistance of the asphalt mixture can be significantly improved, and the raw material cost of the asphalt mixture is low, low-carbon, and environmentally friendly.

Owner:CHANGAN UNIV +1

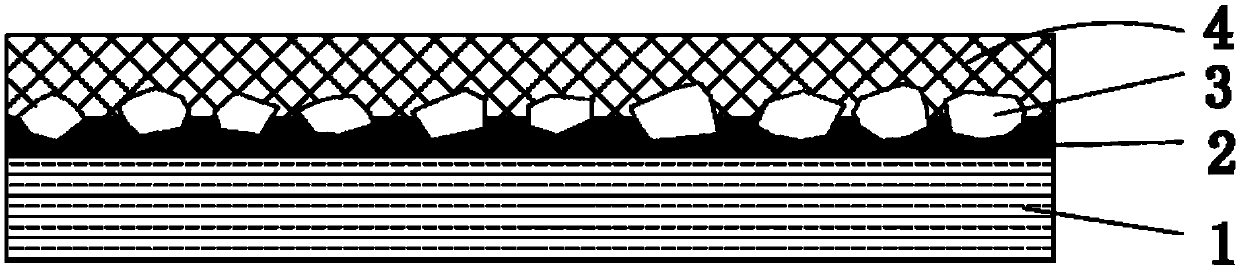

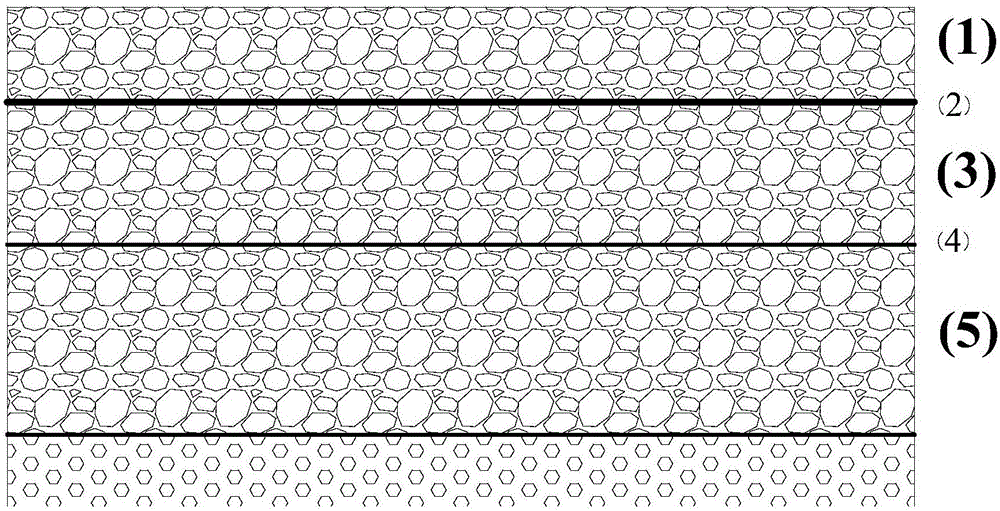

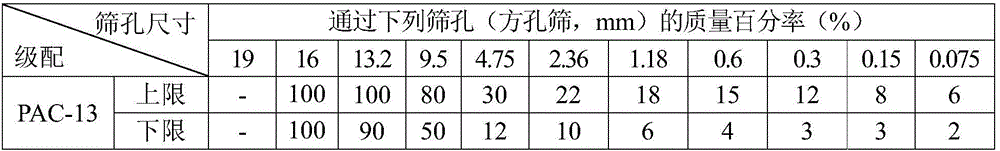

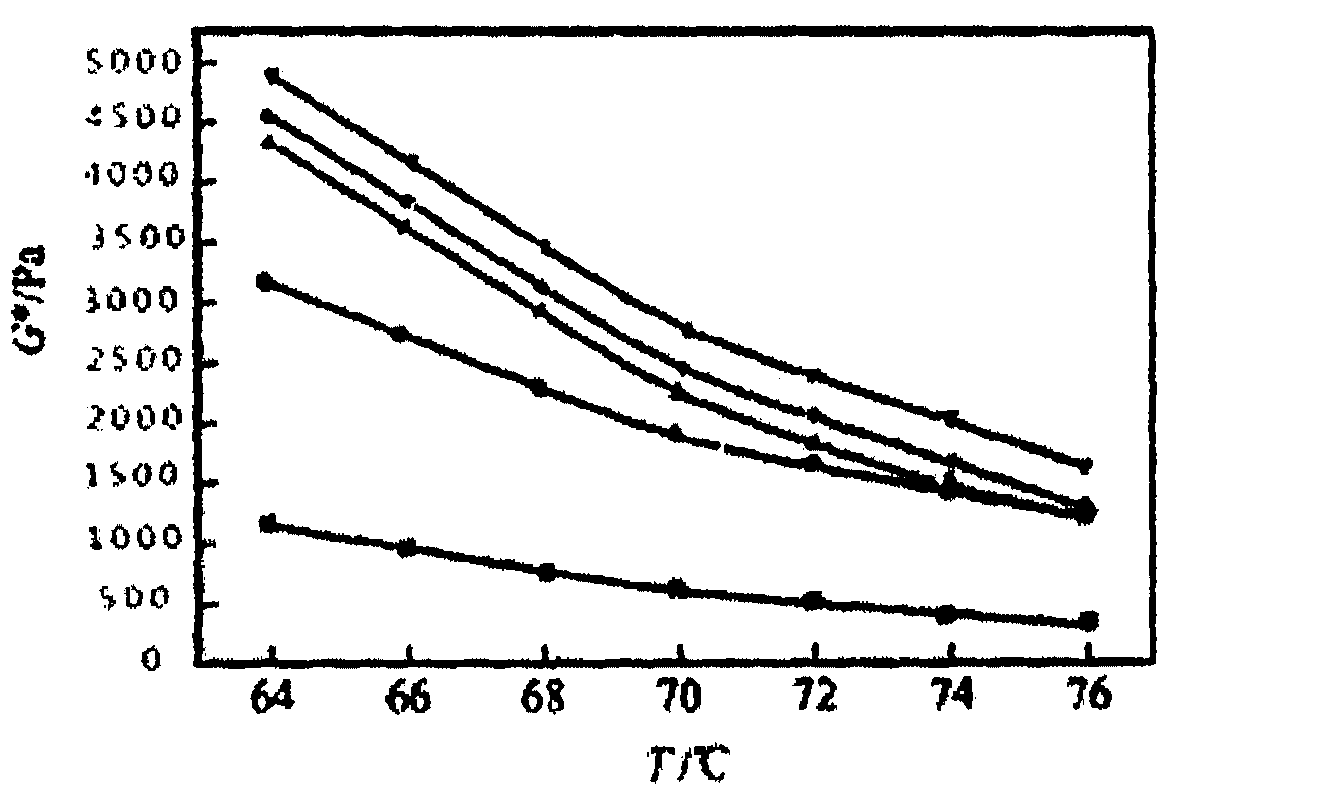

Drainability bituminous pavement

InactiveCN106592370AImproved resistance to fatigue crackingImprove road performanceIn situ pavingsCeramicwareSurface layerRoad surface

The invention discloses a drainability bituminous pavement. The drainability bituminous pavement comprises an upper surface layer (1), a middle surface layer (3) and a lower surface layer (5), a sealing layer (2) is spread between the middle surface layer (3) and the upper surface layer (1), a bonding layer (4) is spread between the middle surface layer (3) and the lower surface layer (5), the upper surface layer (1) is a porous asphalt mixture PAC-13, the middle surface layer (3) is an asphalt mixture Superpave-20, and the lower surface layer (5) is the asphalt mixture Superpave-25. The drainability bituminous pavement has long usage life.

Owner:YANGZHOU UNIV

Sealant for pavement cracks

InactiveCN102876055AImproved high temperature composite modulusReduce temperature sensitivityPaving detailsBuilding insulationsPolymer scienceRoad surface

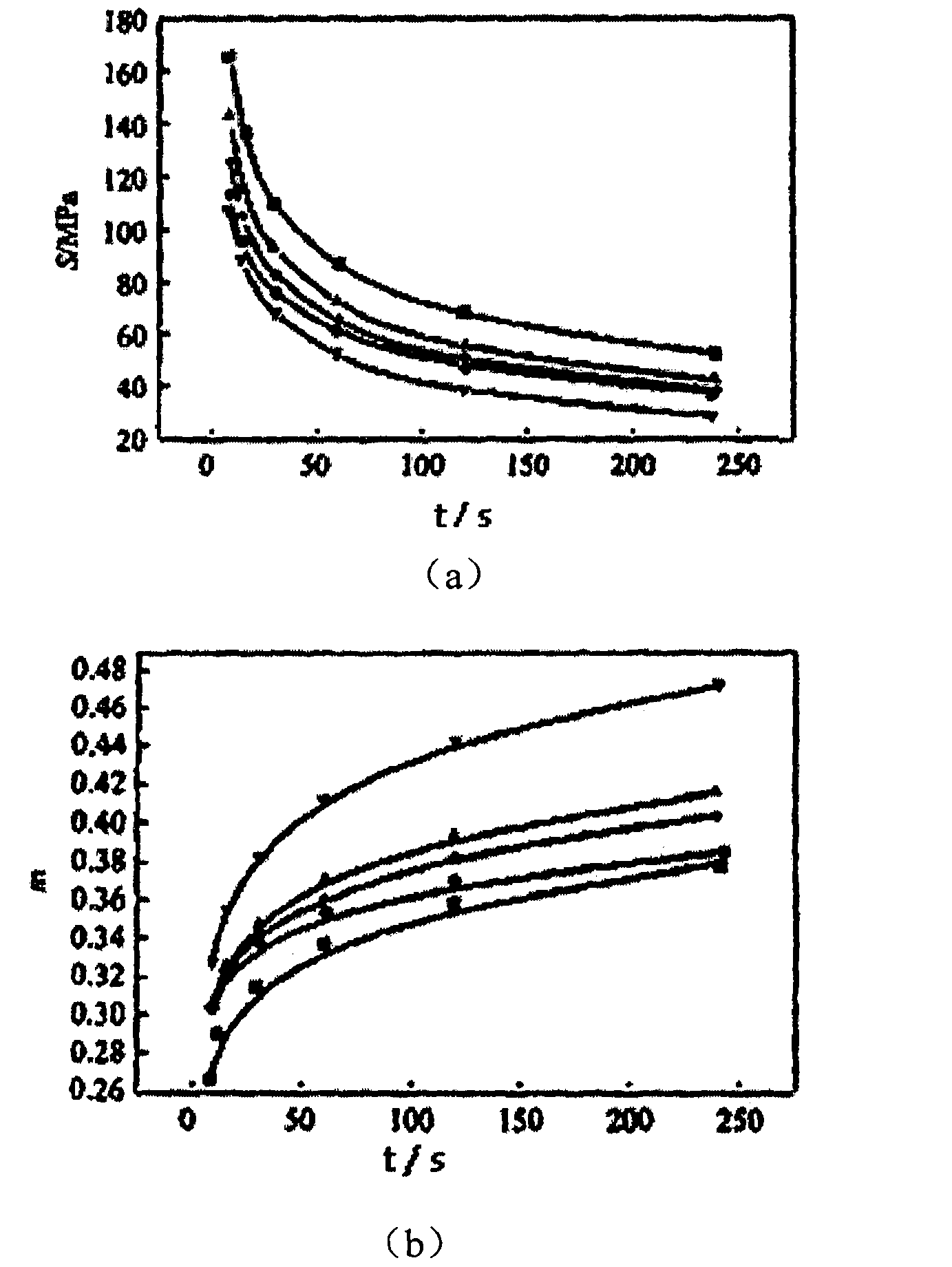

The invention discloses a sealant for pavement cracks, characterized by compounding organo-bentonite with SBS modified asphalt to prepare the sealant. Results of studying the impact of the modifier and its amount on the high temperature performance and low temperature performance of the modified asphalt show that by adding organo-bentonite and the SBS composition, the high temperature composite modulus of the asphalt is raised, the temperature sensitivity is significantly weakened, thus the high temperature performance of the asphalt is improved; simultaneously the creep stiffness of the modified asphalt after aging is reduced, the creep rate is increased, the low temperature performance of the asphalt after aging is raised, and in the long-term use process, good fatigue cracking resistance is achieved.

Owner:赵金叶

A bridge deck pavement method for orthotropic steel bridges

ActiveCN104652270BImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxySolvent free

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

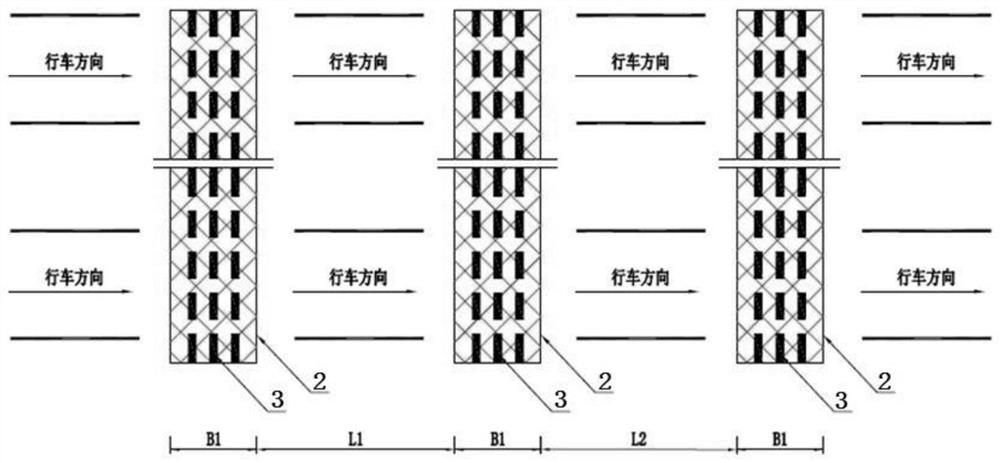

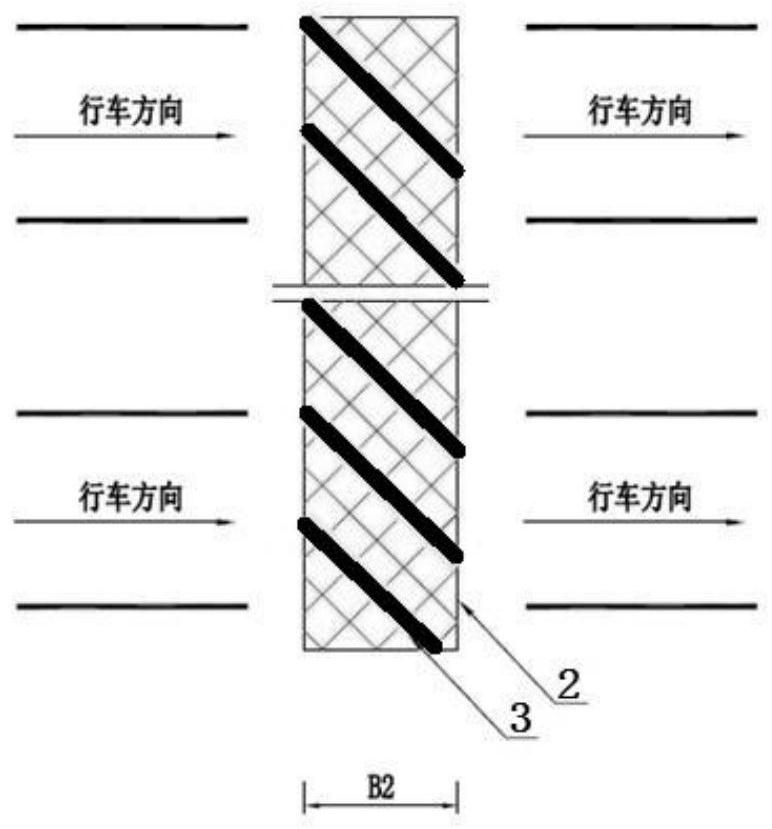

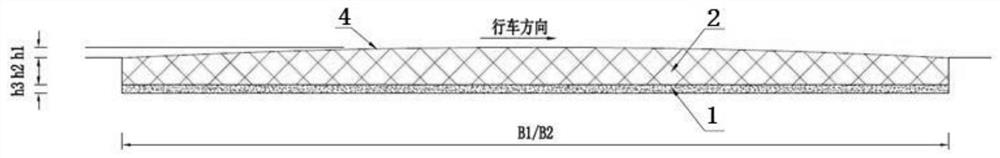

One-time molding asphalt concrete speed bump and its construction technology

ActiveCN108999103BShorten speedImprove deceleration effectTraffic signalsRoad signsStructural engineeringRoad surface

Owner:CENT & SOUTHERN CHINA MUNICIPAL ENG DESIGN & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com