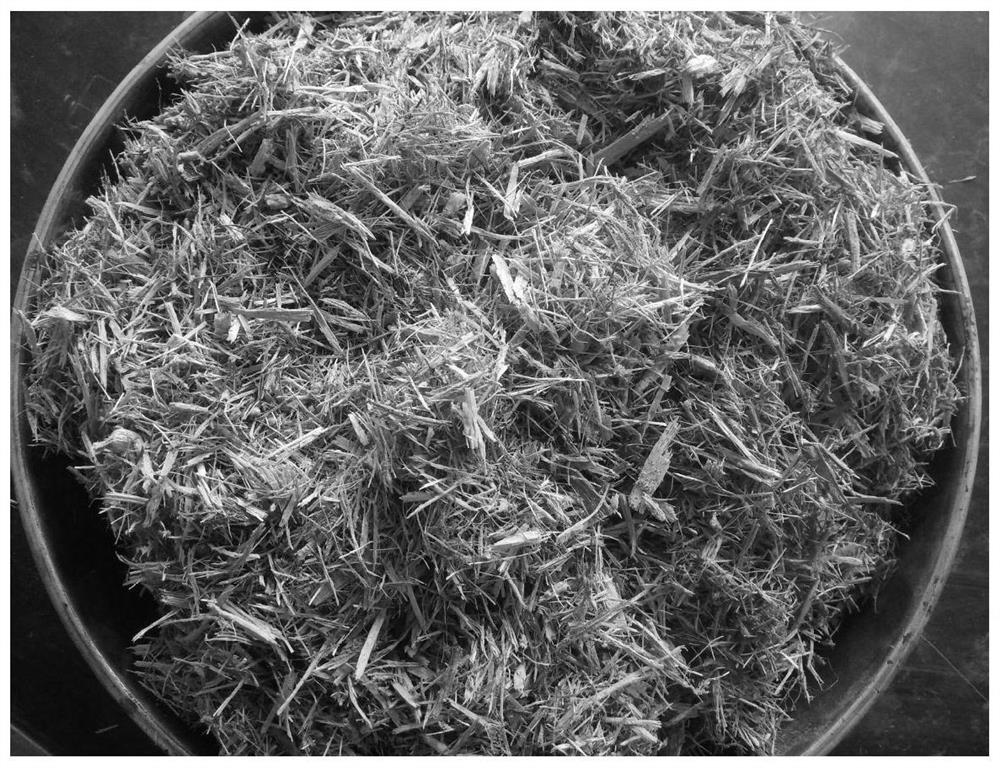

A kind of preparation method of bagasse fiber for asphalt pavement reinforcement

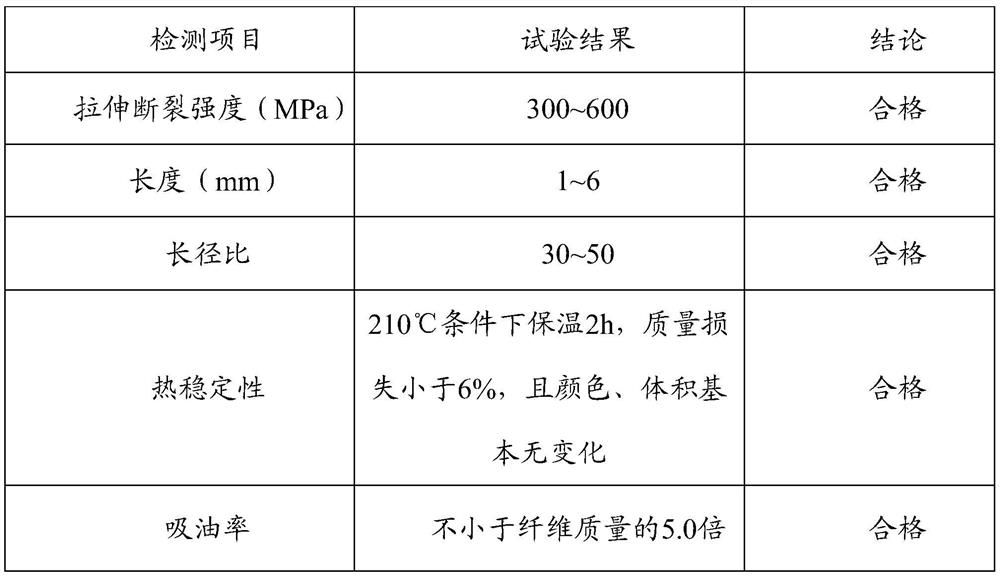

The technology of bagasse fiber and asphalt pavement is applied in the field of road engineering asphalt pavement material preparation, which can solve the problems that bagasse fibers are easy to agglomerate, the tensile breaking strength of bagasse fibers cannot meet the performance requirements of asphalt mixture, etc. Improve cellulose diffusivity and good oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) a kind of preparation method of asphalt pavement reinforcement bagasse fiber may further comprise the steps:

[0043] Step 1, at room temperature, purify and remove the bagasse raw material, soak it in 5% sodium hydroxide solution for 22 hours, take out the bagasse, adjust the pH to 7 with 5% dilute hydrochloric acid, until the bagasse surface is saturated with water, add saturated water The polygalacturonan hydrolase with 2% of the total mass of bagasse is subjected to surface activation treatment for 4 hours, and then fished out until the bagasse is saturated and surface-dry to obtain dry bagasse.

[0044] Step 2, add sodium methylene bis-naphthalene sulfonate dispersant and 3% expanded perlite micropowder respectively accounting for 2% of the dry bagasse mass of the saturated surface to the dry bagasse of the saturated surface, and mix under the condition of 60 rpm After 4 minutes, the mixture was obtained.

[0045] Step 3: Add water 2.5 times the mass of dry ba...

Embodiment 2

[0049] (1) a kind of preparation method of asphalt pavement reinforcement bagasse fiber may further comprise the steps:

[0050] Step 1, at room temperature, purify and remove the bagasse raw material, soak it in 5% sodium hydroxide solution for 22 hours, take out the bagasse, adjust the pH to 7 with 5% dilute hydrochloric acid, until the surface of the bagasse is saturated with water, mix with The polygalacturonan hydrolase with 2% of the total mass of the bagasse in the water state is subjected to surface activation treatment for 4 hours, and then fished out to a saturated surface-dry state to obtain dry bagasse.

[0051] Step 2, add sodium methylene bis-naphthalene sulfonate dispersant and 3% expanded perlite micropowder respectively accounting for 2% of the dry bagasse mass of the saturated surface to the dry bagasse of the saturated surface, and mix under the condition of 60 rpm After 4 minutes, the mixture was obtained.

[0052] Step 3: Add water 2.5 times the mass of d...

Embodiment 3

[0056] Step 1, at room temperature, purify and remove the bagasse raw material, soak it in 5% sodium hydroxide solution for 22 hours, take out the bagasse, adjust the pH to 7 with 5% dilute hydrochloric acid, until the surface of the bagasse is saturated with water, mix with The polygalacturonan hydrolase with 2% of the total mass of the bagasse in the water state is subjected to surface activation treatment for 4 hours, and then fished out to a saturated surface-dry state to obtain dry bagasse.

[0057] Step 2, add sodium methylene bis-naphthalene sulfonate dispersant and 3% expanded perlite micropowder respectively accounting for 2% of the dry bagasse mass of the saturated surface to the dry bagasse of the saturated surface, and mix under the condition of 60 rpm 4min, the mixture was obtained.

[0058] Step 3: Add water 2.5 times the mass of dry bagasse on the saturated surface to the mixture, use a blade-type crushing high-speed disperser with a blade rotation speed of 4000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com