Sealant for pavement cracks

A technology for pavement cracks and sealants, which is applied to roads, roads, pavement details, etc., can solve the problems that the performance of modified asphalt cannot be fully reflected, and achieve the effects of improving anti-aging performance, good anti-fatigue cracking performance, and improving low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

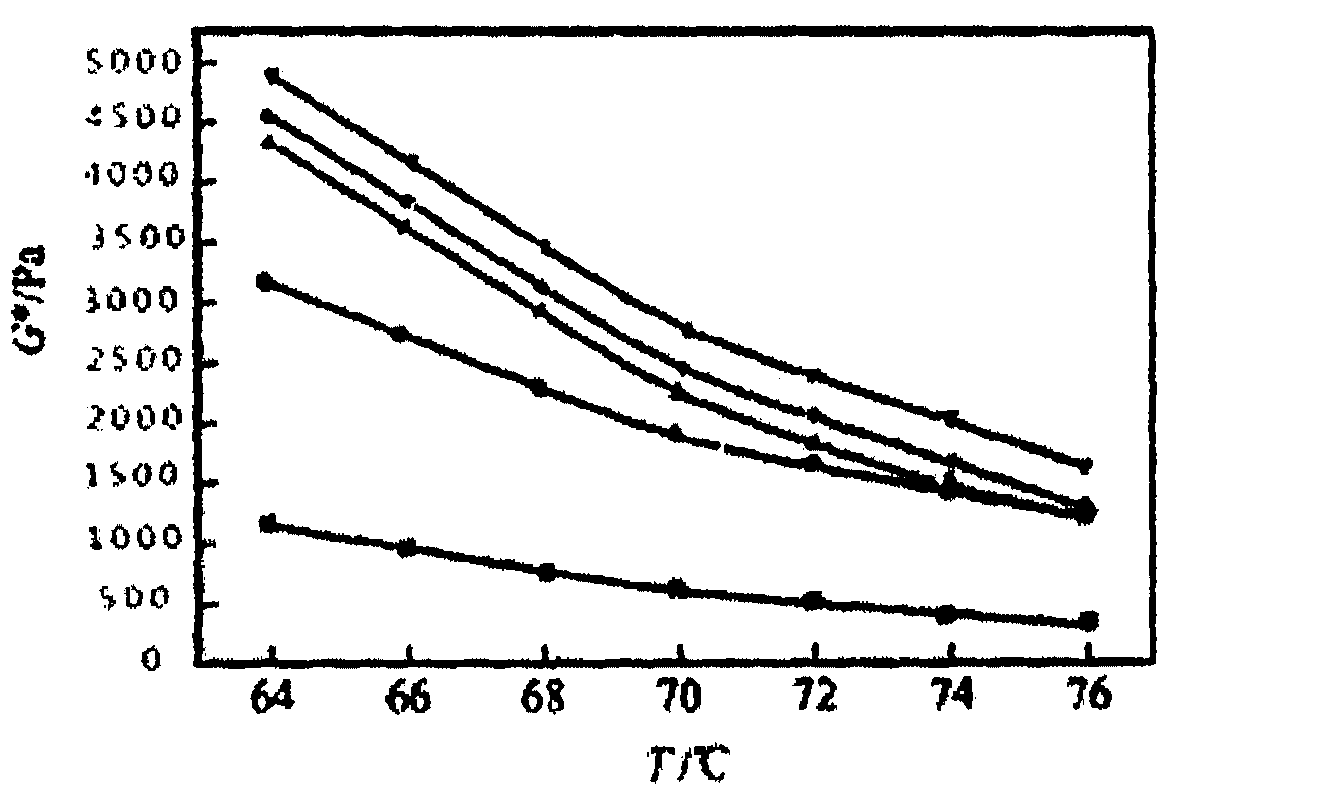

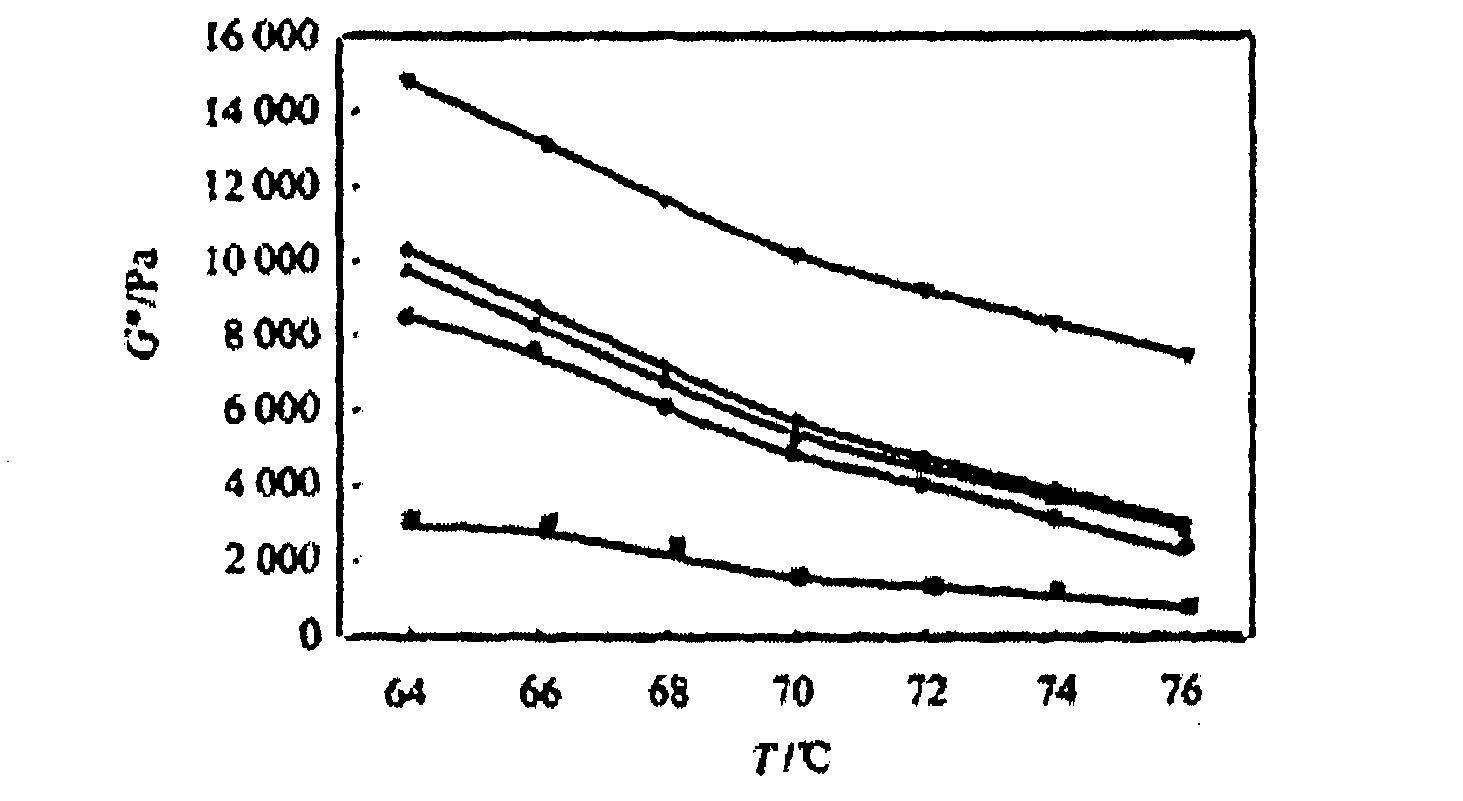

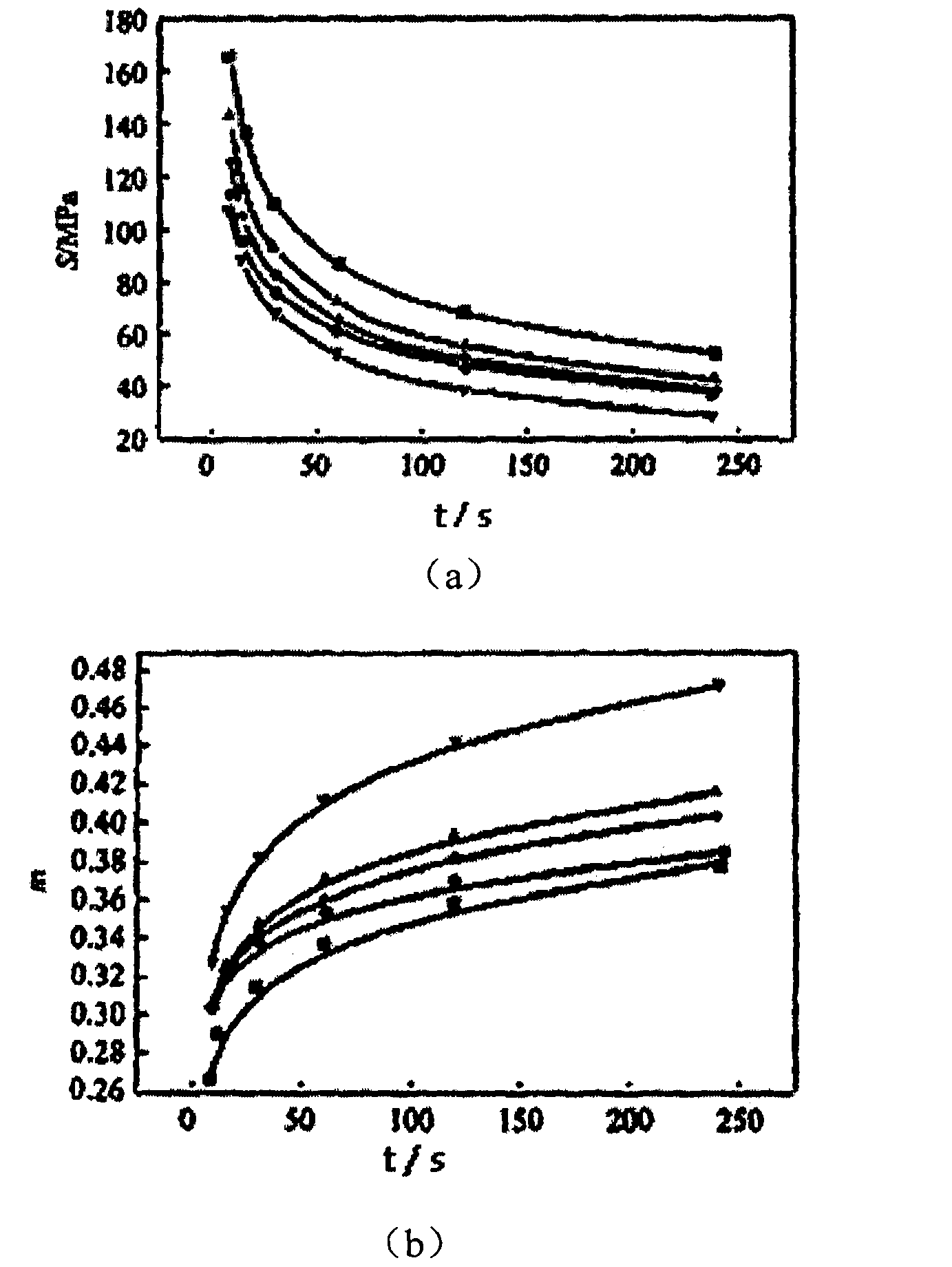

[0015] 1 experiment

[0016] 1.1 Raw material

[0017] SBS, a public product of Beijing Yanshan Petrochemical Co., Ltd., the brand is 4303, star-shaped, the relative molecular mass is about 350,000, and the mass fraction of styrene block is 30%. Asphalt, heavy traffic asphalt AH-90, product of Lanzhou Oil Refinery General Plant, penetration 90 (0.1mm), softening point 45°C, ductility greater than 150cm. Organic bentonite, 325 mesh, product of Tianjin Hualian Organic Chemical Factory. Silane coupling agent, product of Nanjing Shuguang Chemical Factory.

[0018] 1.2 Sample preparation

[0019] After heating the asphalt to 170°C, add a certain amount of SBS, and shear it for 0.5-1h under the conditions of 170-190°C and 3000-5000r / min to obtain a sample without adding organic bentonite. Add organic bentonite and coupling agent to this sample, continue to shear 0.5-1.sh under the original conditions, and then get a modified asphalt sample with organic bentonite and coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com