Steel slag stress absorption layer material and preparation method thereof

A stress-absorbing layer and steel slag technology is applied in the field of asphalt pavement material preparation, which can solve the problems of limited resource reserves, weakening the strength and stiffness of the roadbed, and affecting the performance of the pavement, and achieves a simple preparation method process, excellent fatigue crack resistance, and stress The ability to enhance the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

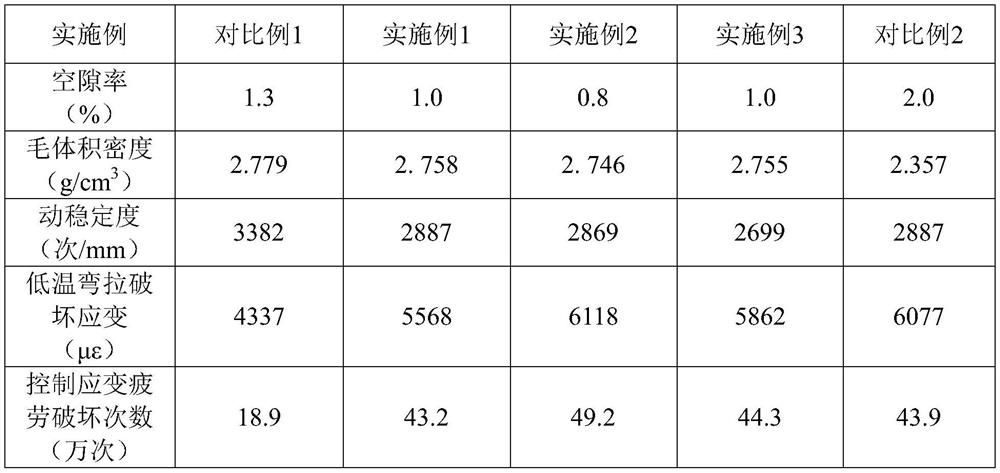

Embodiment 1

[0040] The preparation of the steel slag stress absorbing layer material comprises the following steps:

[0041] Step 1, weighing 7 parts of mineral powder, 100 parts of steel slag aggregate, 9 parts of SBS modified pitch and 0.2 part of brucite mineral fiber by weight;

[0042] Step 2, heating the aggregate and mineral powder at a constant temperature of 170-180°C for 5 hours, and set aside;

[0043] Step 3, heating the SBS modified asphalt to 170-180°C, fully stirring evenly, and setting aside;

[0044] Step 4, dry mix the steel slag aggregate heated at constant temperature for 30 seconds, then add brucite mineral fiber, dry mix for 10 seconds, then add heated SBS modified asphalt, wet mix for 90 seconds, and finally add mineral powder and mix for 20 seconds.

Embodiment 2

[0046] The preparation of the steel slag stress absorbing layer material comprises the following steps:

[0047] Step 1, taking by weight 14 parts of mineral powder, 200 parts of steel slag aggregate, 19 parts of SBS modified pitch and 0.4 part of brucite mineral fiber;

[0048] Step 2, heating the aggregate and mineral powder at a constant temperature of 170-180°C for 5 hours, and set aside;

[0049] Step 3, heating the SBS modified asphalt to 170-180°C, fully stirring evenly, and setting aside;

[0050] Step 4, dry mix the steel slag aggregate heated at constant temperature for 30 seconds, then add brucite mineral fiber, dry mix for 10 seconds, then add heated SBS modified asphalt, wet mix for 90 seconds, and finally add mineral powder and mix for 20 seconds.

Embodiment 3

[0052] The preparation of the steel slag stress absorbing layer material comprises the following steps:

[0053] Step 1, weighing 7 parts of mineral powder, 100 parts of steel slag aggregate, 9 parts of SBS modified pitch and 0.3 part of brucite mineral fiber by weight;

[0054] Step 2, heating the aggregate and mineral powder at a constant temperature of 170-180°C for 5 hours, and set aside;

[0055] Step 3, heating the SBS modified asphalt to 170-180°C, fully stirring evenly, and setting aside;

[0056] Step 4, dry mix the steel slag aggregate heated at constant temperature for 30 seconds, then add brucite mineral fiber, dry mix for 10 seconds, then add heated SBS modified asphalt, wet mix for 90 seconds, and finally add mineral powder and mix for 20 seconds.

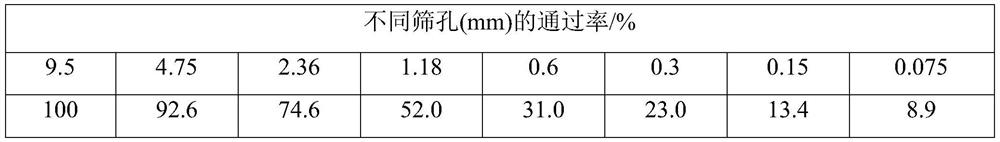

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com