Drainability bituminous pavement

A technology of drainage asphalt and modified asphalt, which is applied to the coagulation pavement, roads, roads and other directions laid on site, can solve the problems of poor fatigue resistance, poor stability and short service life of drainage asphalt pavement. Achieve the effect of improving fatigue crack resistance, improving road performance, and overcoming bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

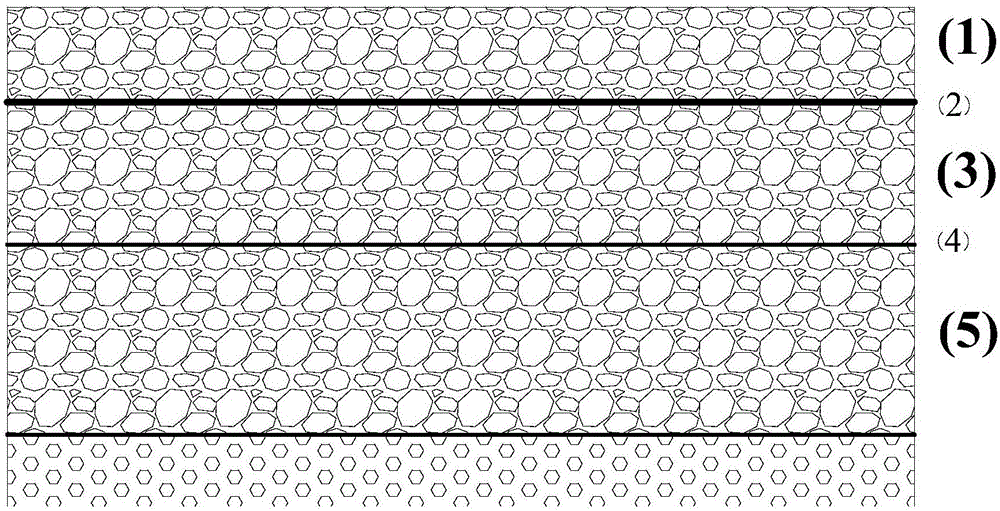

[0050] like figure 1 The new durable drainage asphalt pavement structure shown, the pavement structure consists of permeable asphalt mixture PAC-13 upper layer, seal layer, asphalt mixture Superpave-20 middle surface layer, adhesive layer and asphalt mixture arranged in sequence from top to bottom The lower layer of Superpave-25.

[0051] Wherein, the thickness of the upper layer of the permeable asphalt mixture PAC-13 is 40.0mm; the thickness of the middle layer of the asphalt mixture Superpave-20 is 60.0mm; the thickness of the lower layer of the asphalt mixture Superpave-25 is 80.0mm.

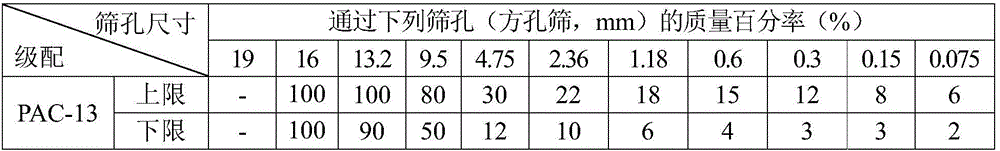

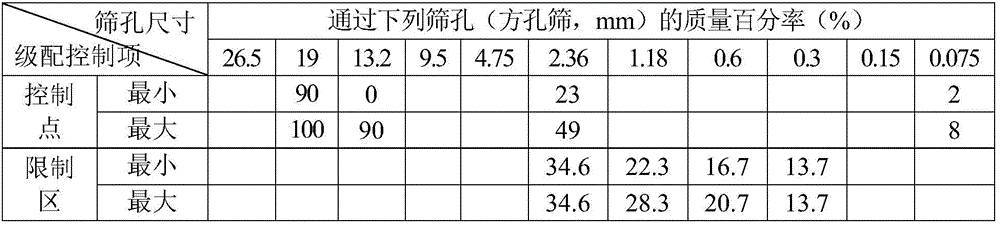

[0052] Among them, the upper layer of the permeable asphalt mixture PAC-13 is paved by mixing high-viscosity modified asphalt, basalt fiber and the first mineral material with a mass ratio of 4.6:0.3:100. The void ratio of the mixture is The nominal maximum particle size of the aggregate is 13.2mm, and the basalt fiber used is chopped basalt fiber with a length of 6.0mm; Agent TPS and SBS ...

Embodiment 2

[0061] Such as figure 1 The new durable drainage asphalt pavement structure shown, the pavement structure consists of permeable asphalt mixture PAC-13 upper layer, seal layer, asphalt mixture Superpave-20 middle surface layer, adhesive layer and asphalt mixture arranged in sequence from top to bottom The lower layer of Superpave-25.

[0062] Wherein, the thickness of the upper layer of the permeable asphalt mixture PAC-13 is 40.0mm; the thickness of the middle layer of the asphalt mixture Superpave-20 is 60.0mm; the thickness of the lower layer of the asphalt mixture Superpave-25 is 80.0mm.

[0063] Among them, the upper layer of the permeable asphalt mixture PAC-13 is paved by mixing high-viscosity modified asphalt, basalt fiber and the first mineral material with a mass ratio of 4.7:0.32:100. The void ratio of the mixture is The nominal maximum particle size of the aggregate is 13.2mm, and the basalt fiber used is chopped basalt fiber with a length of 6.0mm; Agent TPS and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com