Orthotropic steel bridge deck structure with transverse straining beam

An orthotropic, steel bridge deck technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of reducing the strength of transverse stiffeners, reducing the service life of bridges, weakening cross-sections, etc. Service life, the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

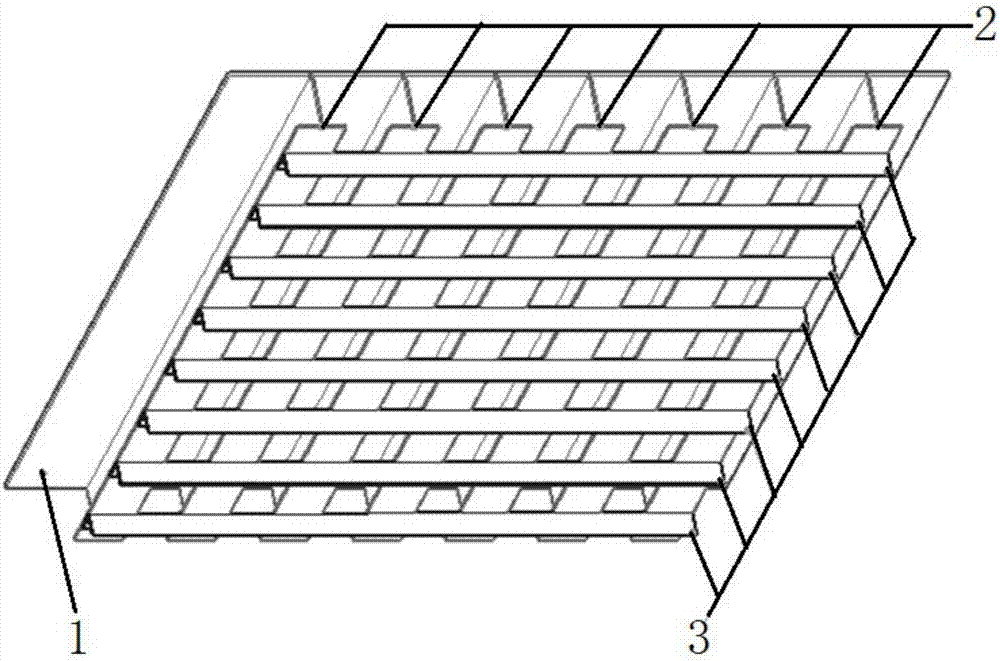

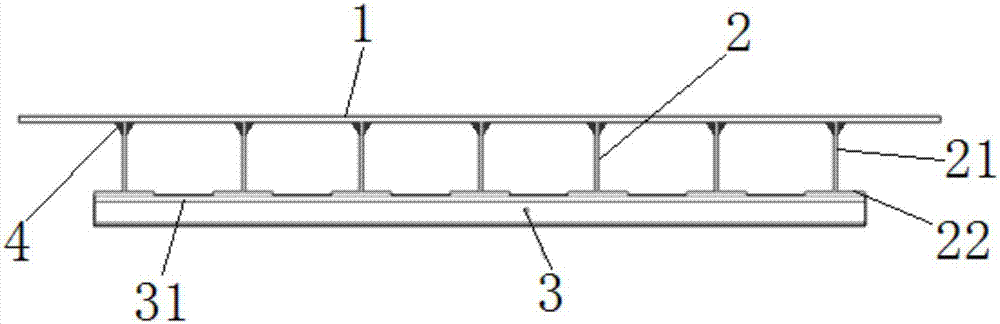

[0025] like figure 1 , figure 2 An orthotropic steel bridge deck structure with transverse tie beams is shown, which includes a cover plate 1, a plurality of longitudinal stiffeners 2 arranged side by side on the lower surface of the cover plate 1, and a plurality of longitudinal stiffeners arranged side by side on the lower surface of the cover plate 1 The transverse tie beam 3 on the lower surface of the rib 2 and perpendicular to the longitudinal stiffener 2, the longitudinal stiffener 2 is an open stiffener, and the open stiffener includes a longitudinal stiffener arranged on the lower surface of the cover plate 1 and perpendicular to the cover plate 1 The rib vertical part 21 and the longitudinal stiffener horizontal part 22 arranged at the bottom of the longitudinal stiffener vertical part 21 and perpendicular to the longitudinal stiffener vertical part 21 pass between the top of the longitudinal stiffener vertical part 21 and the cover plate 1 The double-sided weld se...

Embodiment 2

[0028] In this embodiment, the open stiffeners are L-shaped stiffeners, the transverse tie beam 3 is I-shaped steel, the double-sided weld 4 is a partially penetrated double-sided weld, and the rest are the same as in Embodiment 1.

Embodiment 3

[0030] In this embodiment, the transverse tie beam 3 is H-shaped steel, the double-sided weld 4 is a double-sided fillet weld, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com