One-time molding asphalt concrete speed bump and its construction technology

A technology of asphalt concrete and construction technology, which is applied to roads, buildings, road signs, etc., and can solve problems such as increased road maintenance costs, small width of speed bumps, and insufficient service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

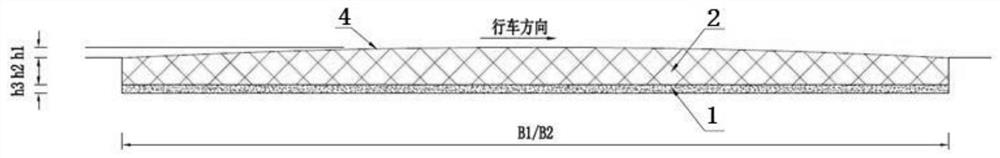

[0037] This embodiment provides an asphalt concrete deceleration belt with one-time molding properties, including a high-viscosity emulsified asphalt macadam seal layer 1 laid on the ground base, and a deceleration belt surface laid on the high-viscosity emulsified asphalt macadam seal layer 1 Layer 2, the material of the deceleration strip surface layer 1 is poured asphalt concrete; the two ends of the deceleration strip surface layer 1 are buried under the road surface, and the surface of the deceleration strip surface layer 1 has a hump-shaped protrusion 4 higher than the road surface , the upper surface of the hump-shaped protrusion 4 is provided with deceleration markings 3 . The paving thickness of the high-viscosity emulsified asphalt gravel seal layer 1 is 1-2 cm, and the paving thickness of the speed bump surface layer 2 is 2-4 cm.

[0038] The technical requirements of the materials used in the one-shot asphalt concrete speed bump provided in this example are as foll...

Embodiment 2

[0067] This embodiment provides a once-formed asphalt concrete speed bump and its construction technology, which is basically the same as that of Embodiment 1, except that:

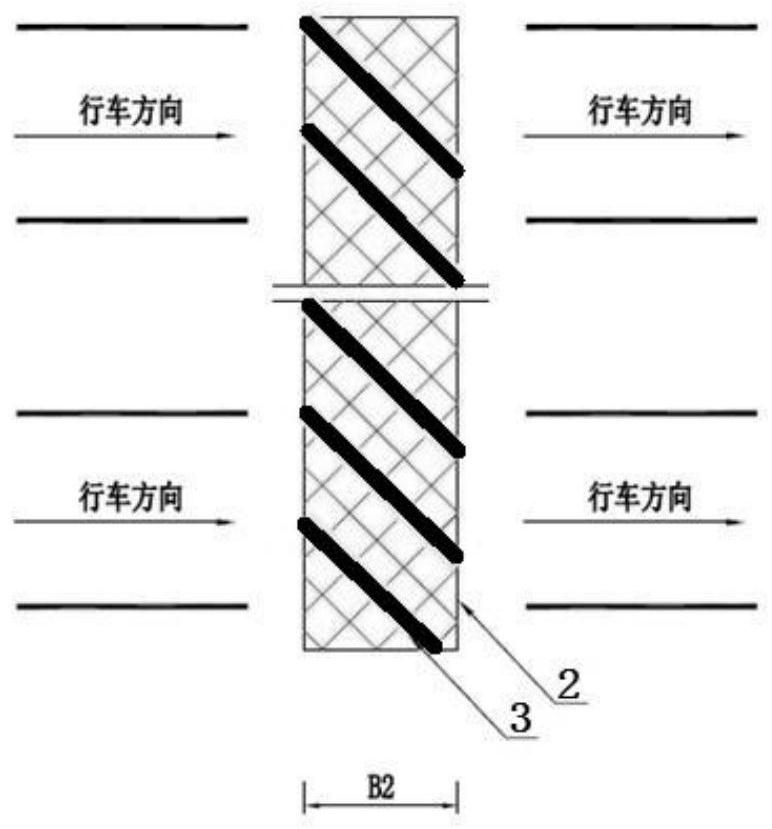

[0068] The deceleration belt provided in this embodiment is suitable for roads with relatively low driving speeds. It is installed at the gates of enterprises, schools, etc., where vehicles need to slow down and easily cause traffic accidents. In order to reduce the driving speed in advance, the deceleration belt is 20 meters away previous setting.

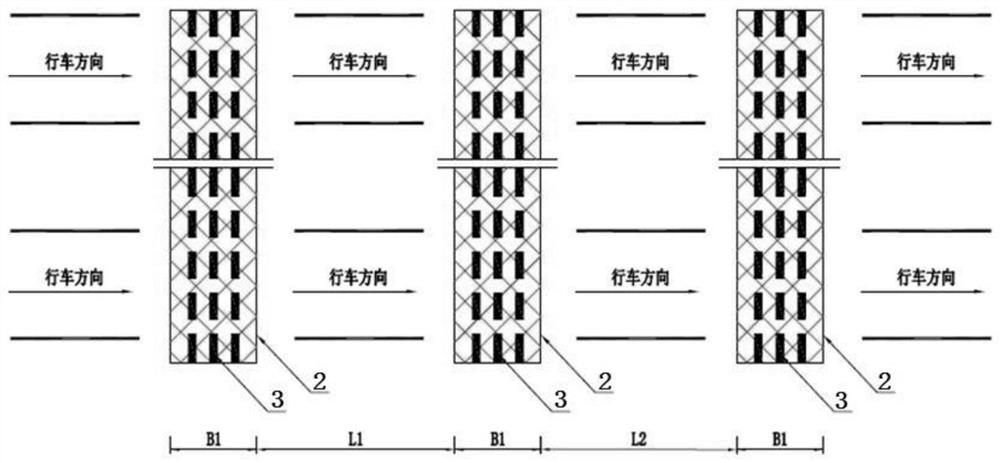

[0069] Specifically, as attached figure 2 As shown, the deceleration belt applied to high-grade roads consists of a hump-shaped asphalt concrete deceleration belt perpendicular to the driving direction. Hump-type asphalt concrete deceleration strip surface layer 2 (for specific materials, please refer to "Table 1 Grading Composition and Technical Requirements of Poured Asphalt Concrete": According to the specification ZTVAsphalt-StB, the maximum diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com