Patents

Literature

118results about How to "Delayed expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

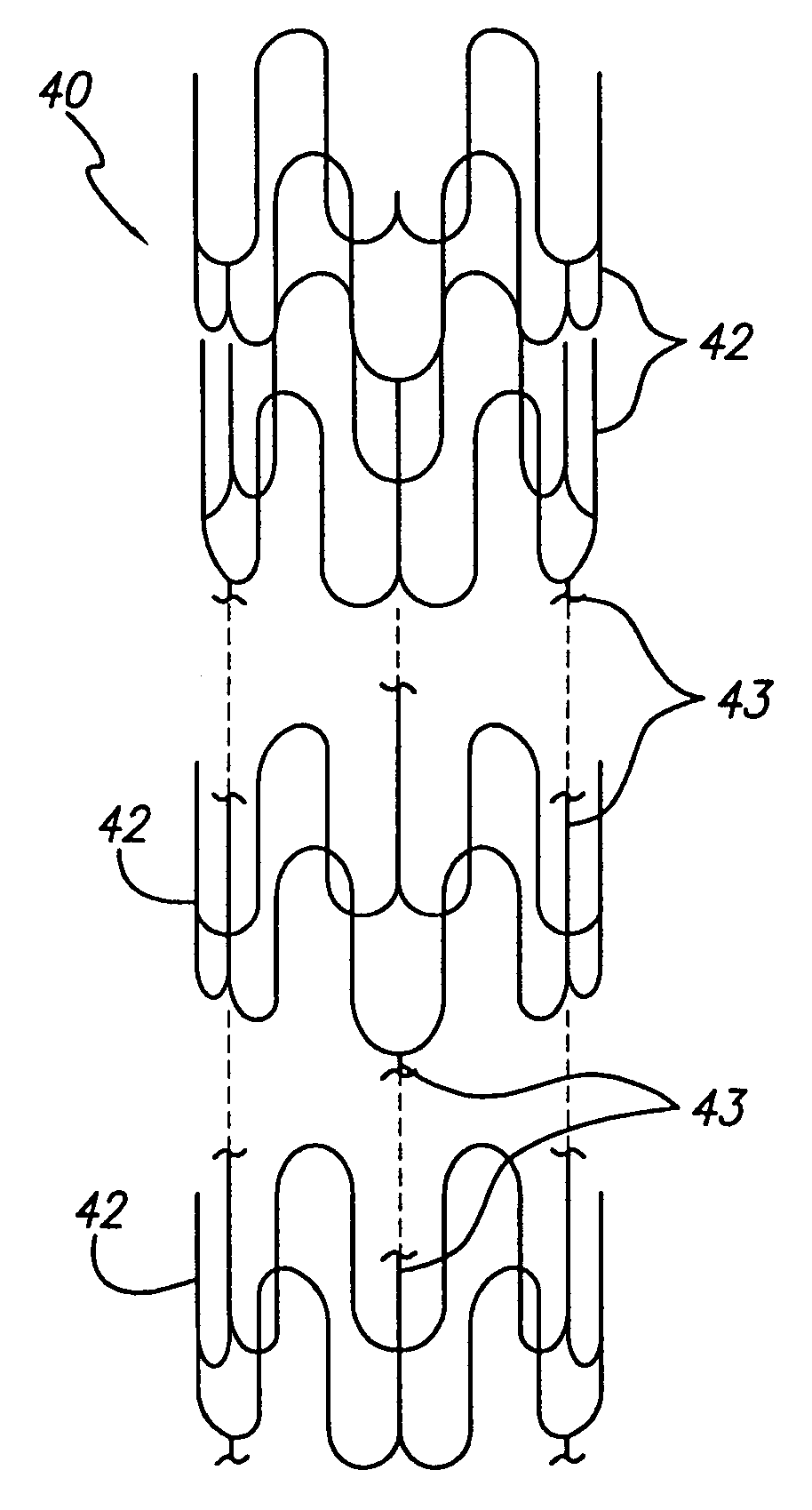

Polymer-based stent assembly

Methods for preparing a polymer-based stent assembly comprising an inflatable balloon catheter and a polymer-based stent resistant to relaxation-related negative recoil are provided. The methods comprise heating a polymeric cylindrical device which is at a final predetermined shape and diameter to a temperature sufficiently above the glass transition temperature (Tg) of the polymer and for a time sufficient to erase any memory of previous processing of the polymeric cylindrical device and then quenching the polymeric cylindrical device to provide an educated polymeric cylindrical device having a memory of the final predetermined diameter and shape, mounting the educated cylindrical device on an inflatable balloon catheter, reducing the diameter of the educated cylindrical device by heating to a temperature at or slightly above the Tg of the polymer while evenly applying pressure on the exterior surface of the wall of the cylindrical device, and then cooling the cylindrical device below the Tg of the polymer to provide a stent assembly comprising an inflatable balloon catheter and an expandable, educated, polymeric stent snugly and stably disposed thereon. Assemblies comprising an inflatable balloon and a polymer based stent that is substantially resistant to relaxation related recoil mounted snugly on the balloon are also provided.

Owner:SAHAJANAND TECHNOLOGIES PRIVATE LTD

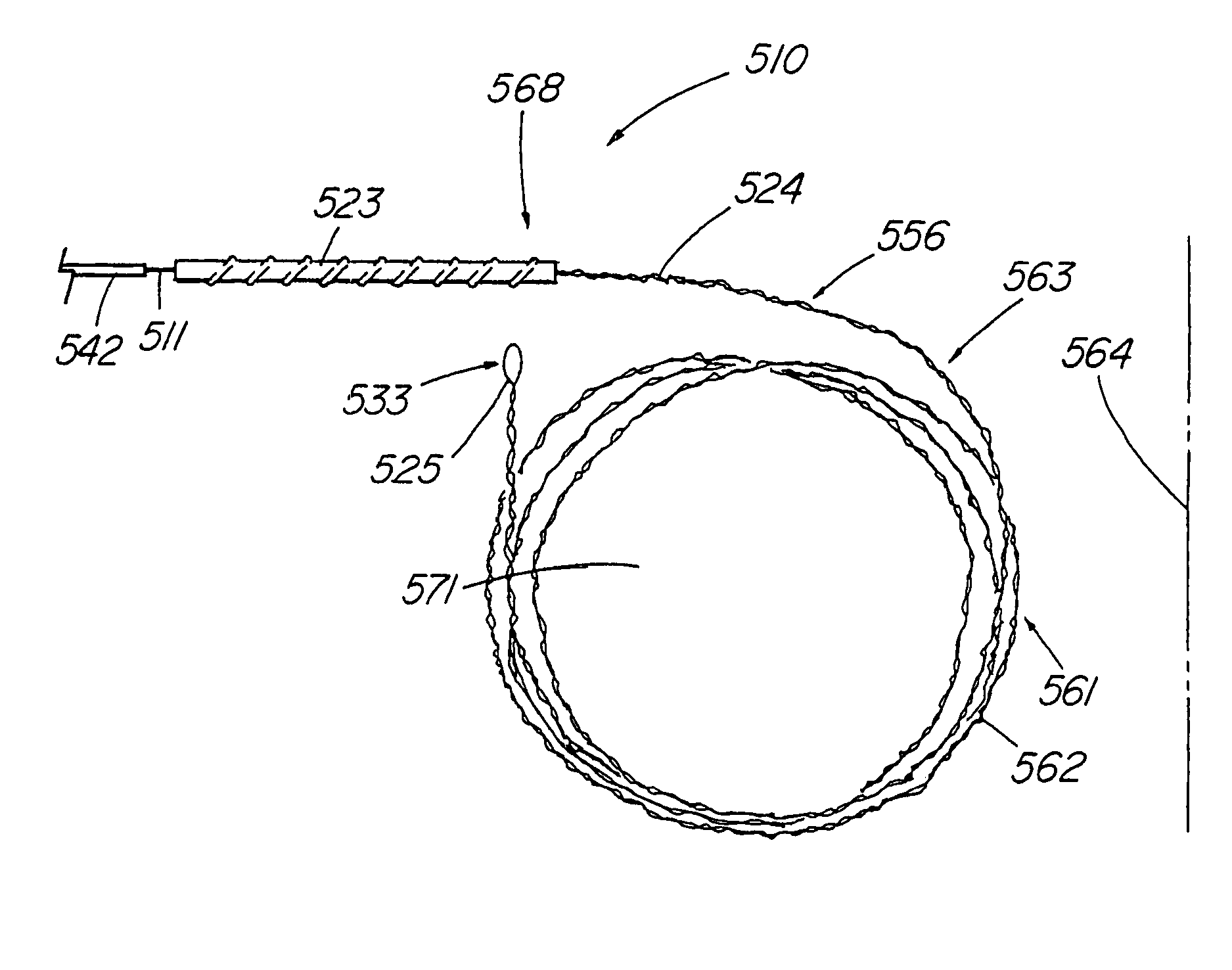

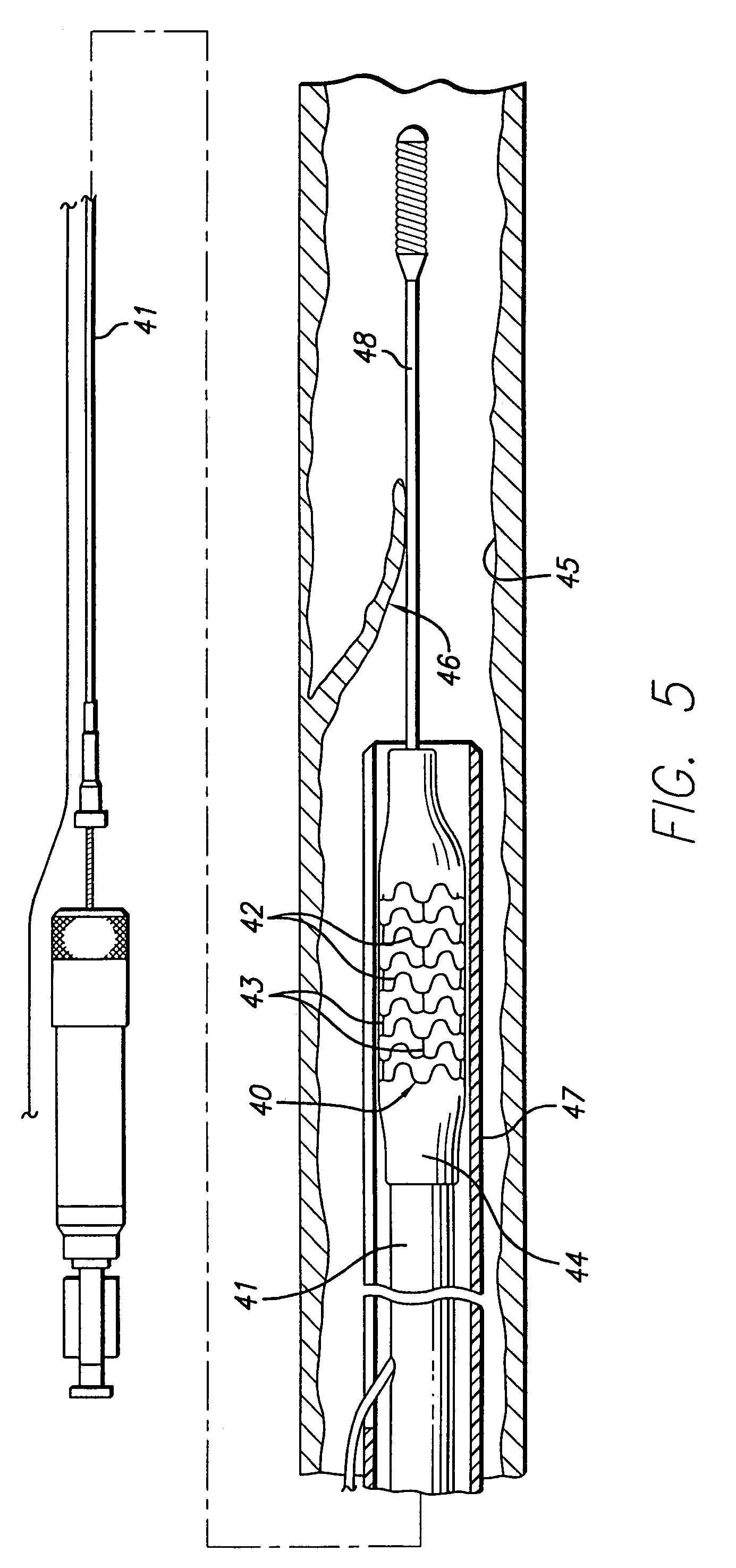

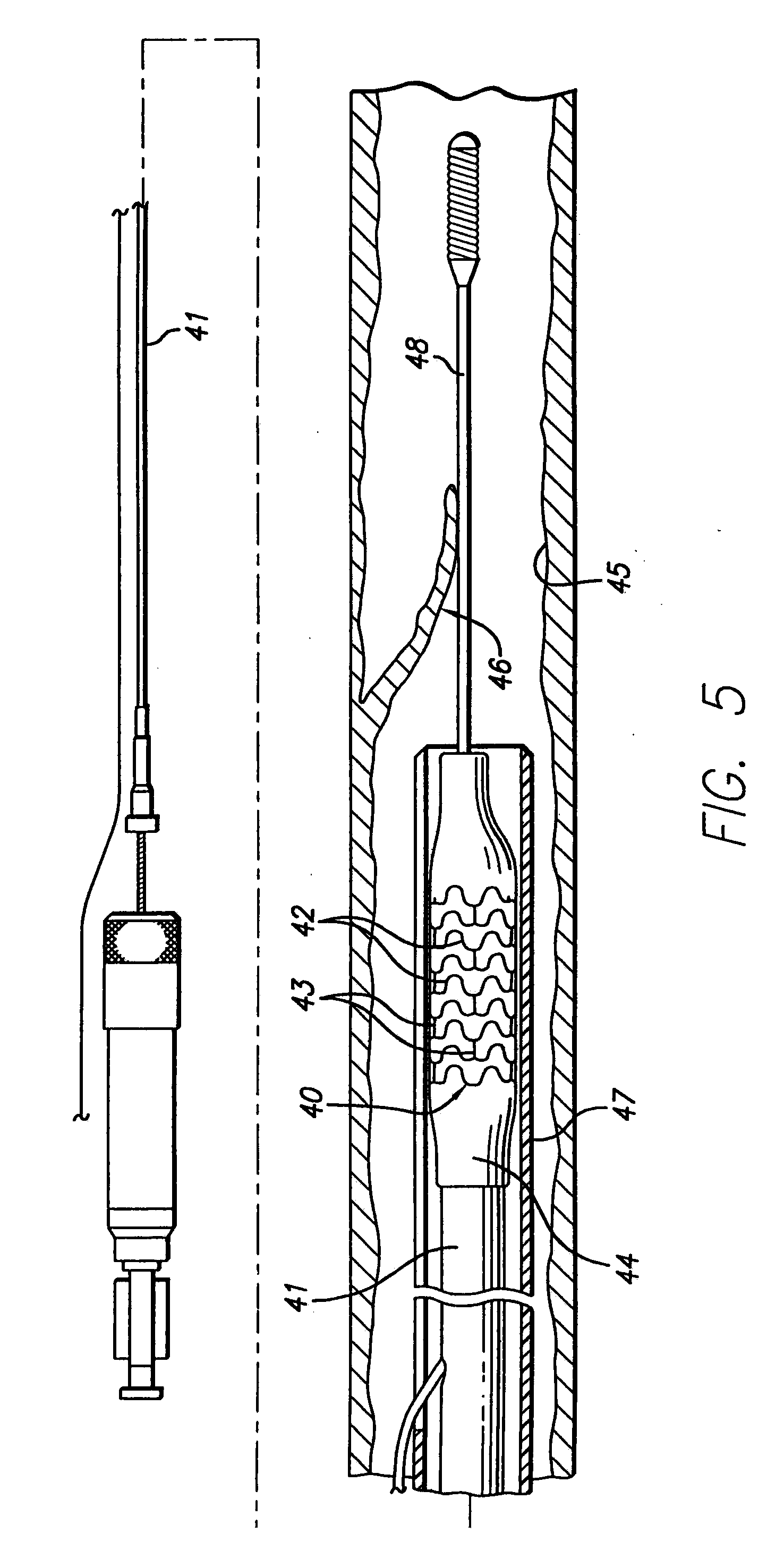

Method of removing an elongated structure implanted in biological tissue

ActiveUS7359756B2Great abilityDelayed expansionEar treatmentTransvascular endocardial electrodesBiological tissueEngineering

Disclosed is a lead removal apparatus for removing an implanted pacemaker or defibrillator lead from the heart. The lead removal apparatus includes a proximal handle that further includes a proximal portion, such as an elongate section of intertwined wire, having a compact, pre-formed first configuration, such as one or more coiled loops. The compact shape permits the operator to utilize the proximal portion without requiring the assistance of a second person to help keep it within the sterile field during a procedure. The operator is thus able to constrain or uncoil the proximal portion into a second configuration that is sufficiently straight such that a medical device, such as a dilator sheath, can be advanced thereover to help separate the lead from scar tissue along the vein path. The proximal portion may include sufficient resiliency to substantially return to the first configuration once the sheath has been advanced.

Owner:COOK MEDICAL TECH LLC

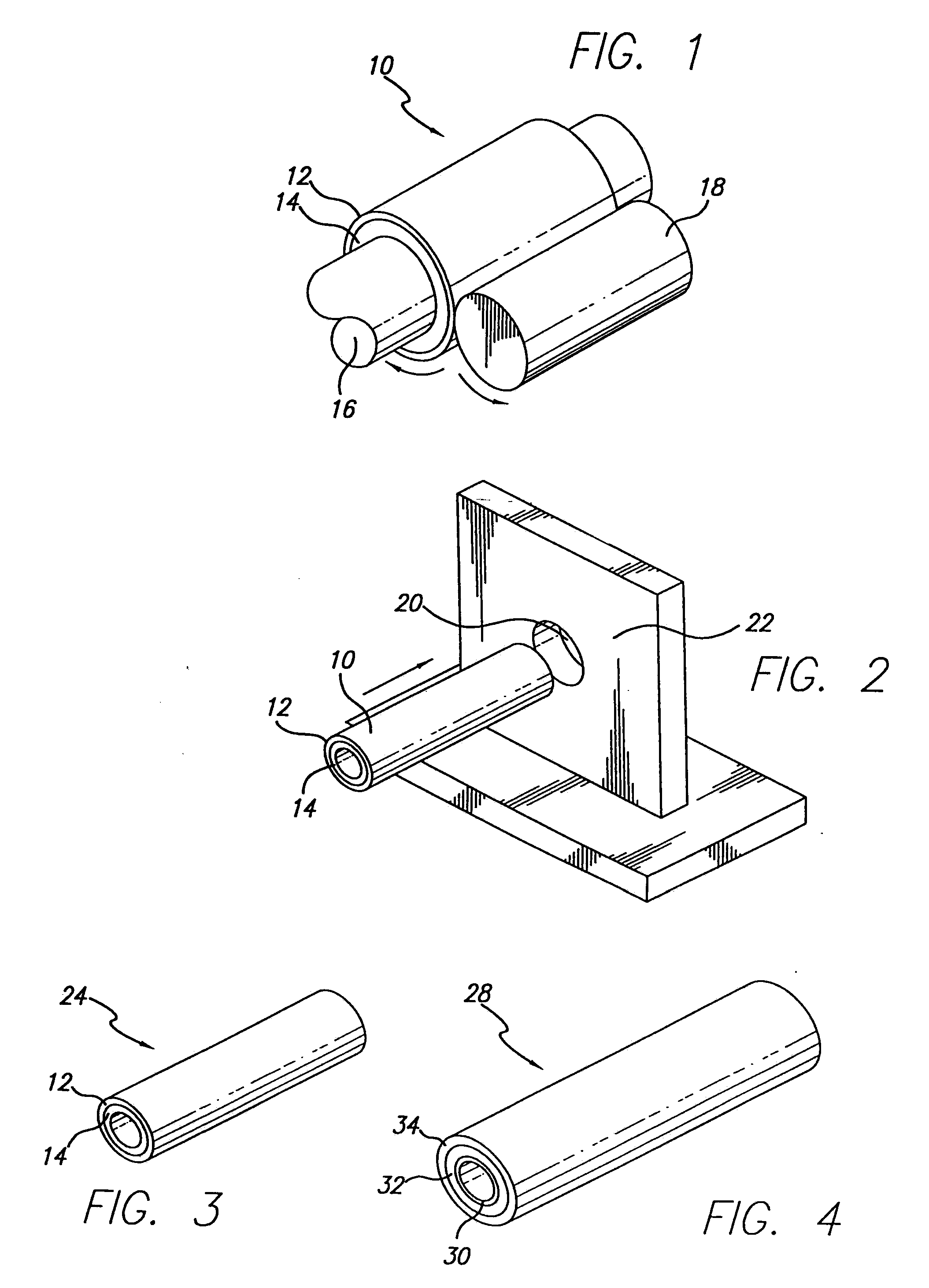

Polymer-based stent assembly

InactiveUS20060058863A1Reduce the overall diameterStablyStentsSurgeryPolymer scienceBalloon catheter

Methods for preparing a polymer-based stent assembly comprising an inflatable balloon catheter and a polymer-based stent resistant to relaxation-related negative recoil are provided. The methods comprise heating a polymeric cylindrical device which is at a final predetermined shape and diameter to a temperature sufficiently above the glass transition temperature (Tg) of the polymer and for a time sufficient to erase any memory of previous processing of the polymeric cylindrical device and then quenching the polymeric cylindrical device to provide an educated polymeric cylindrical device having a memory of the final predetermined diameter and shape, mounting the educated cylindrical device on an inflatable balloon catheter, reducing the diameter of the educated cylindrical device by heating to a temperature at or slightly above the Tg of the polymer while evenly applying pressure on the exterior surface of the wall of the cylindrical device, and then cooling the cylindrical device below the Tg of the polymer to provide a stent assembly comprising an inflatable balloon catheter and an expandable, educated, polymeric stent snugly and stably disposed thereon. Assemblies comprising an inflatable balloon and a polymer based stent that is substantially resistant to relaxation related recoil mounted snugly on the balloon are also provided.

Owner:SAHAJANAND TECHNOLOGIES PRIVATE LTD

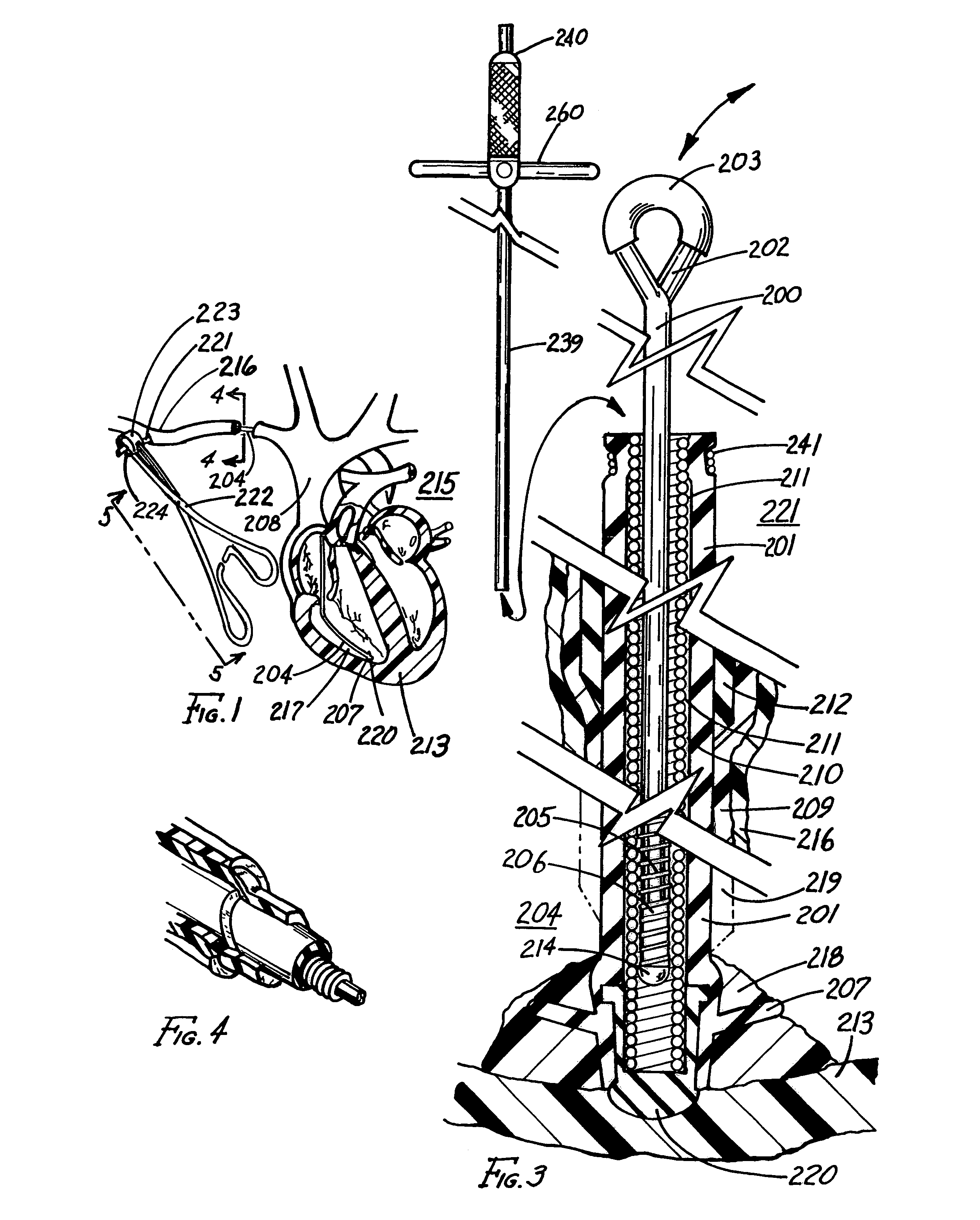

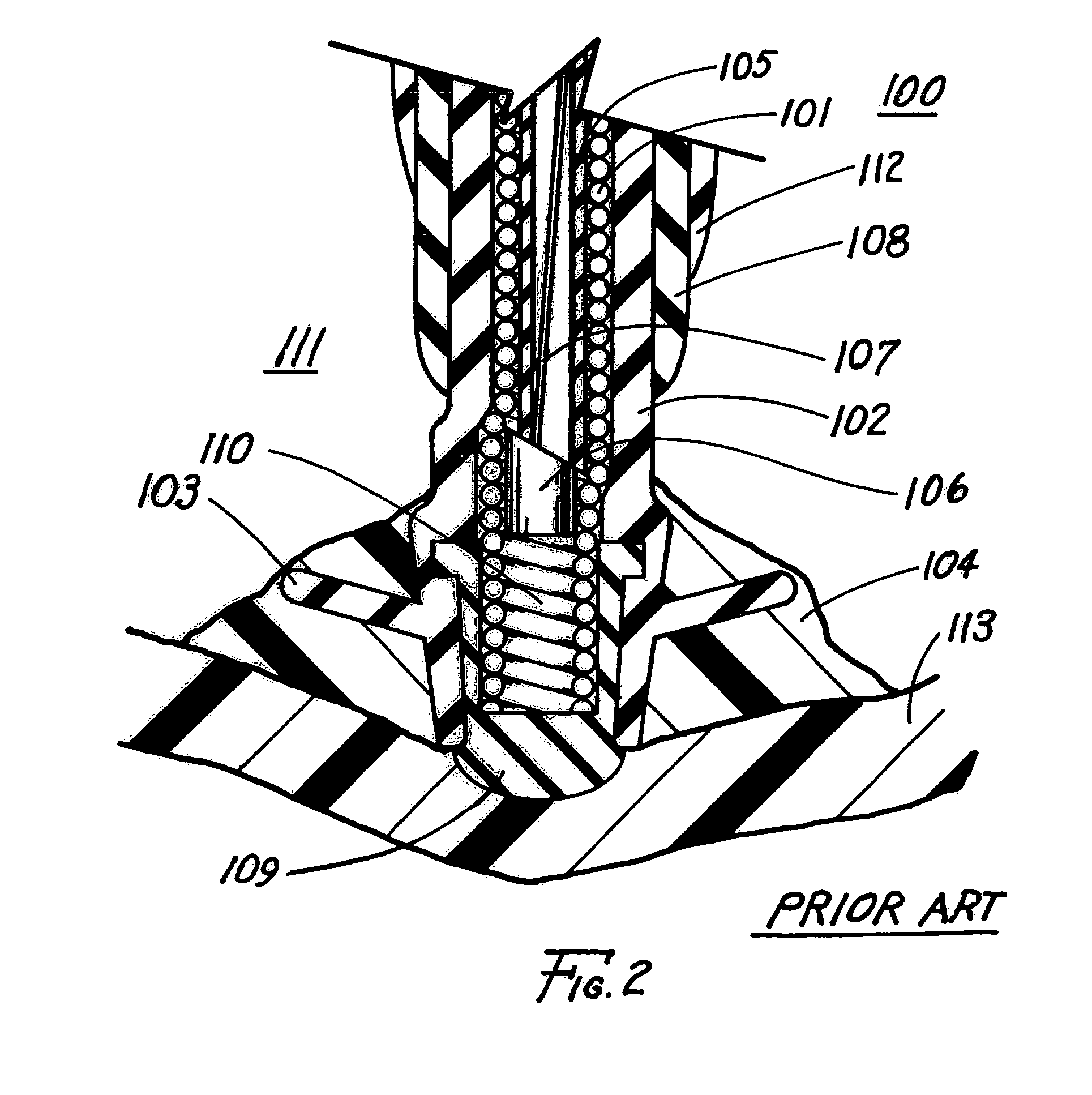

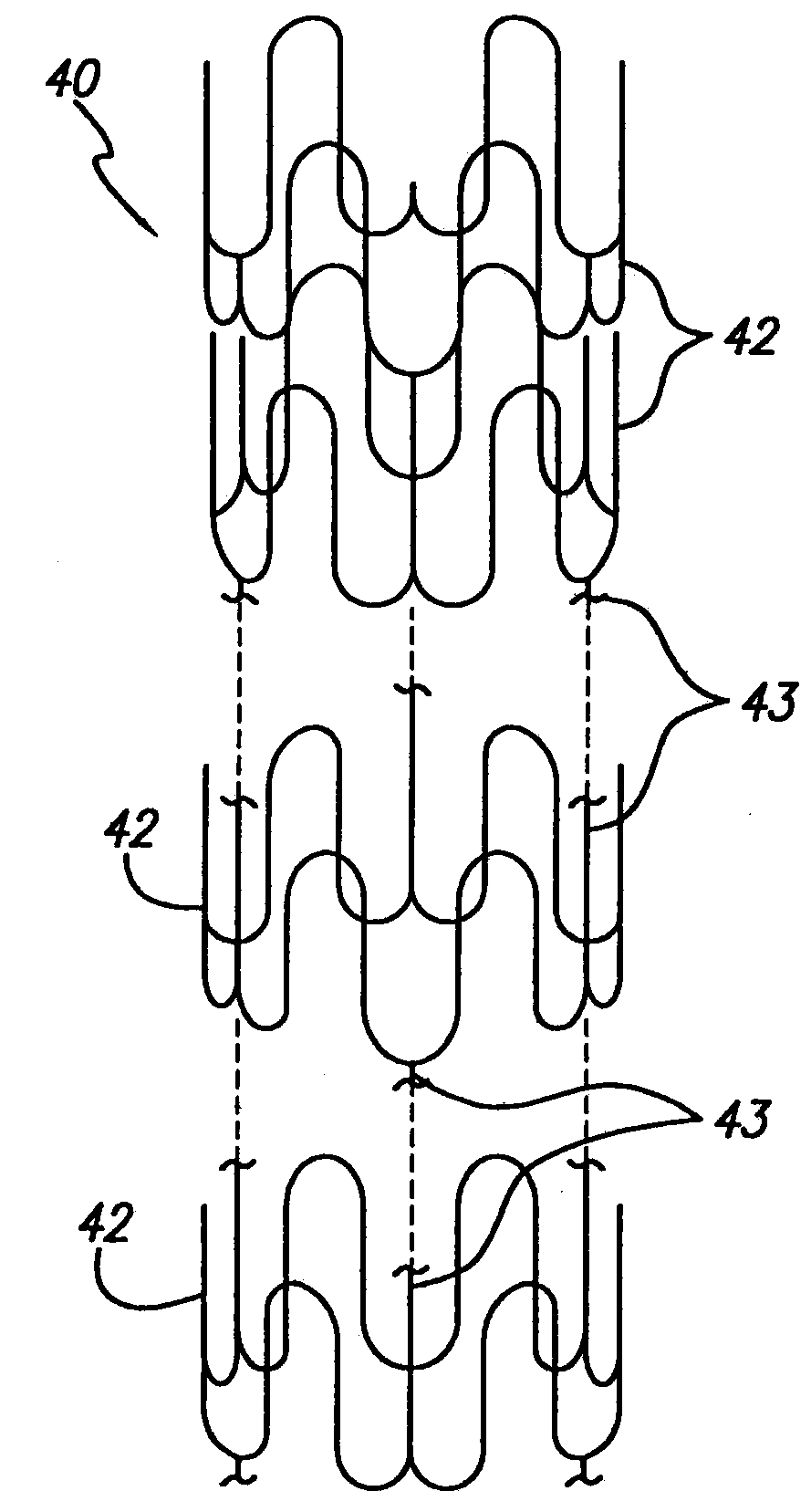

Multilayer stent

A composite stent having a substrate tube made of stainless steel, a nickel-cobalt-chromium-molybdenum alloy, or chonichrome with at least one metal cladding tube is disclosed. Specifically, the substrate tube is placed within a metal cladding tube made of platinum, gold, tantalum, tungsten, platinum-iridium, palladium, or nickel-titanium, preferably with an interference fit therebetween. The composite, laminate tube then undergoes a series of rolling or cold drawing processes interspersed with heat treating to release built up stresses. When the final diameter of the laminate tube is reached, the cladding has been laminated to the exterior of the substrate tube by a bond generated from the rolling and / or cold drawing operations. The finished laminate tube is then cut by laser cutting or chemical etching to form a suitable stent pattern.

Owner:ABBOTT CARDIOVASCULAR

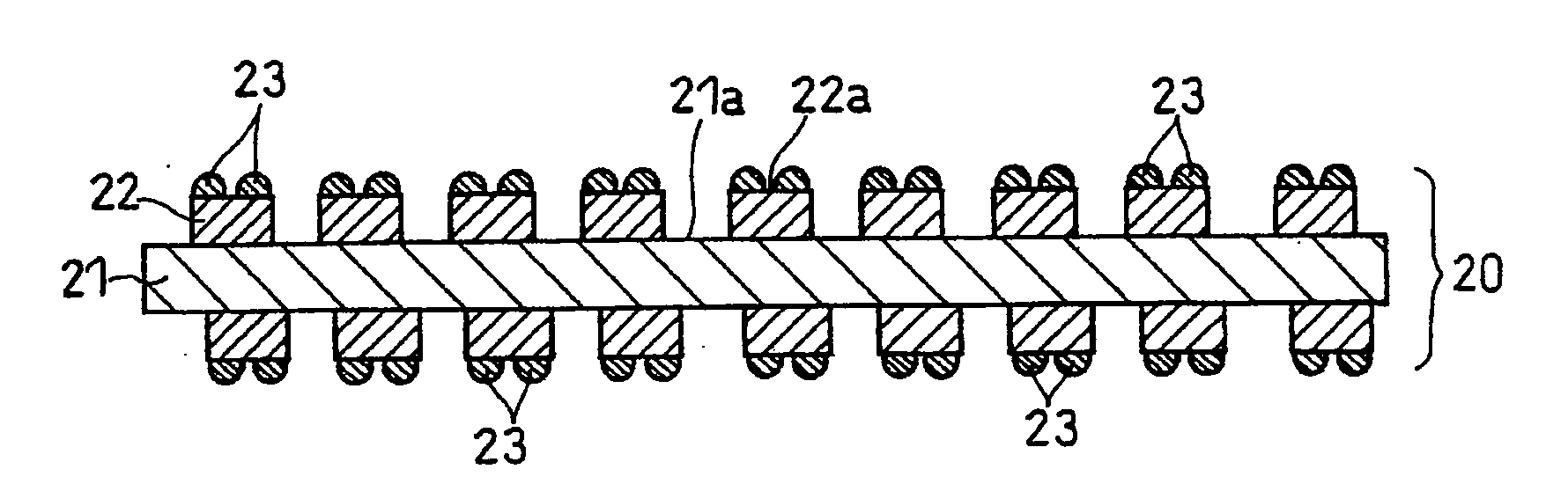

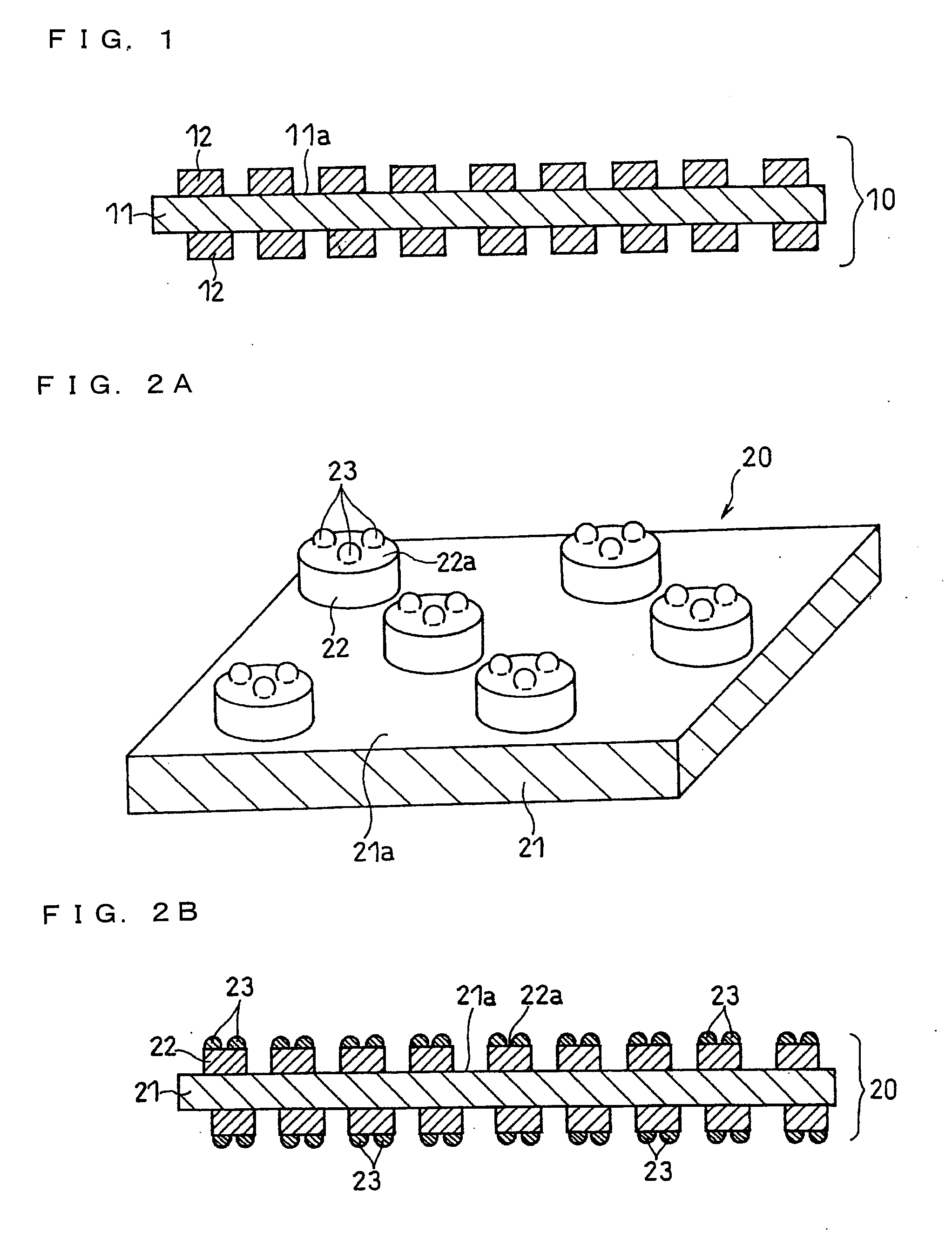

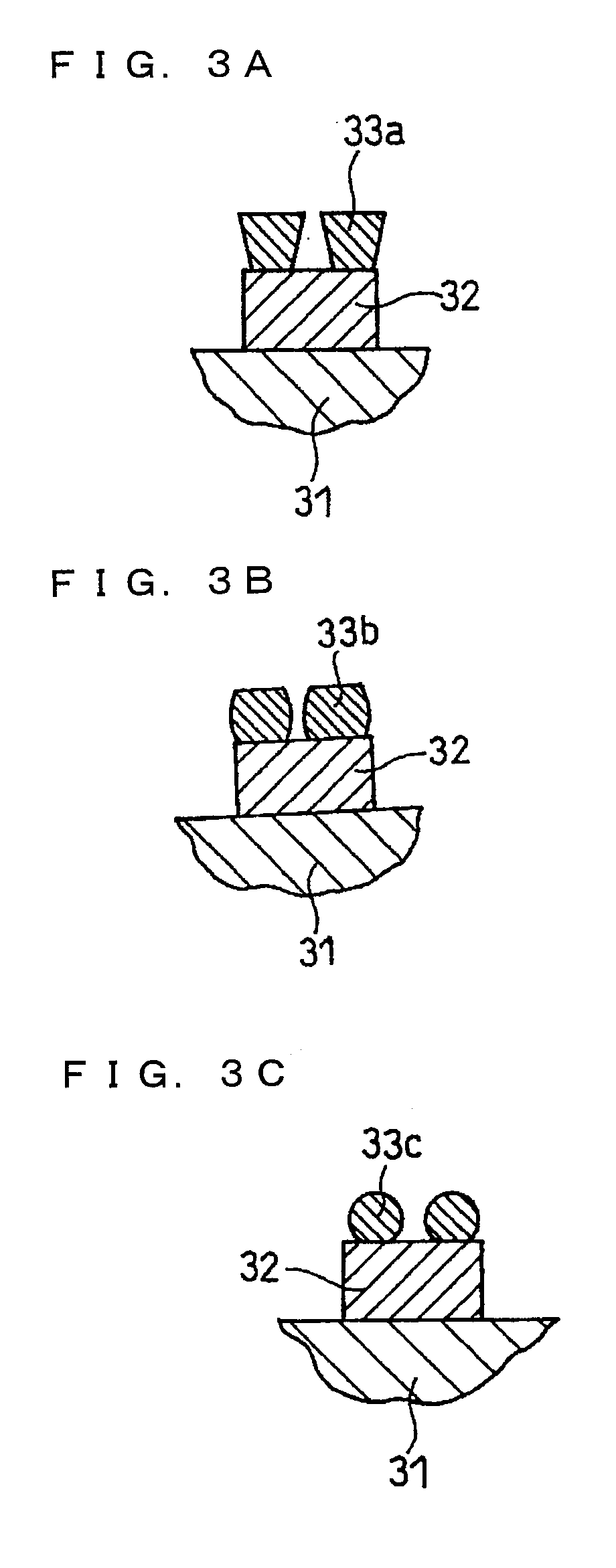

Battery, electrode, and current collector used therefor

InactiveUS20090280407A1Improve reliabilityImprove cycle performanceElectrode manufacturing processesFinal product manufactureLithiumEngineering

The present invention relates to a current collector including a base portion with a flat face, primary projections projecting from the flat face, and secondary projections projecting from the top of the primary projections. The present invention also relates to a current collector including a base portion with a flat face and primary projections projecting from the flat face, wherein the roughening rate of the top of the primary projections is 3 to 20. By using such a current collector, separation of the active material from the current collector can be inhibited when using an active material that has a high capacity but undergoes a large expansion at the time of lithium ion absorption.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

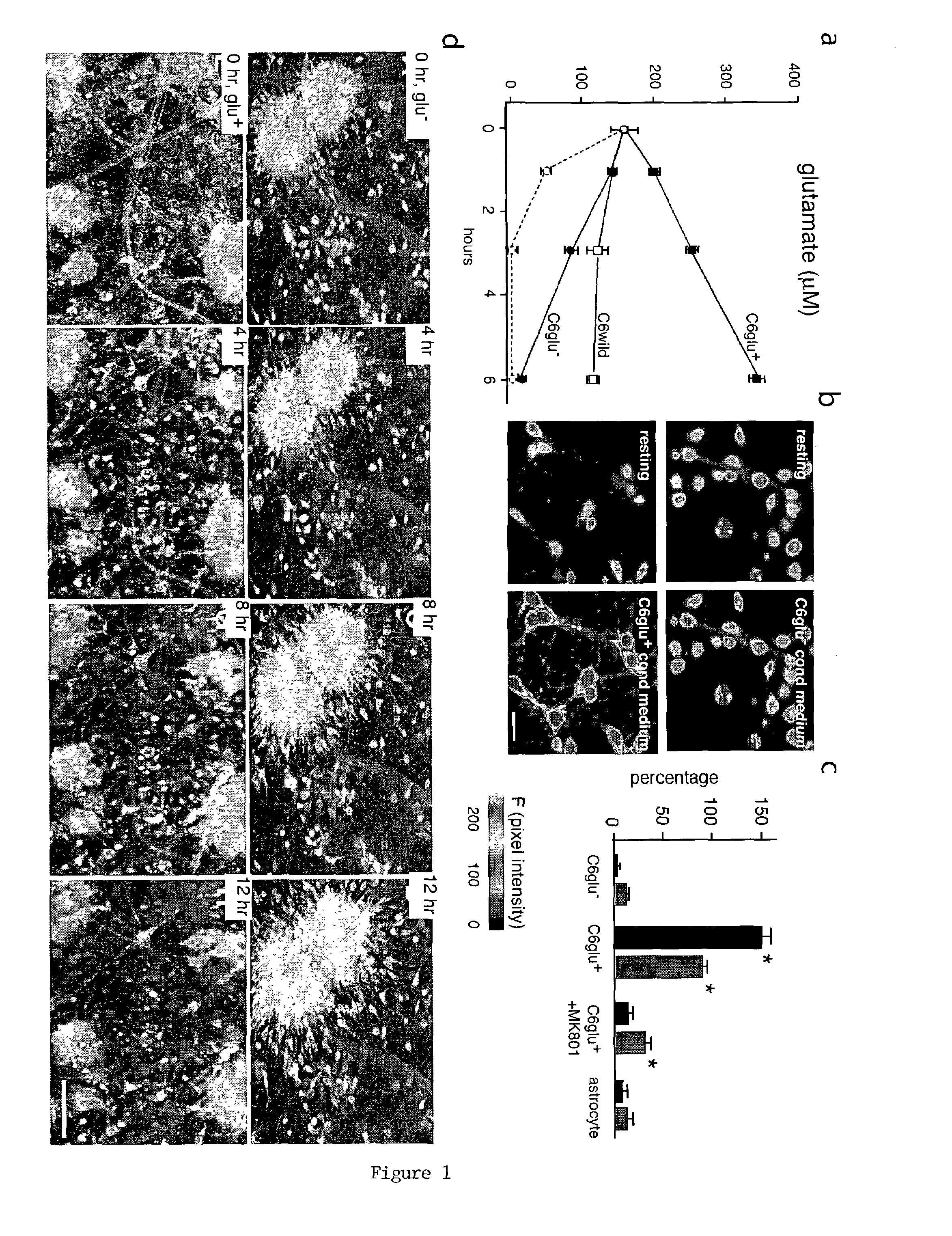

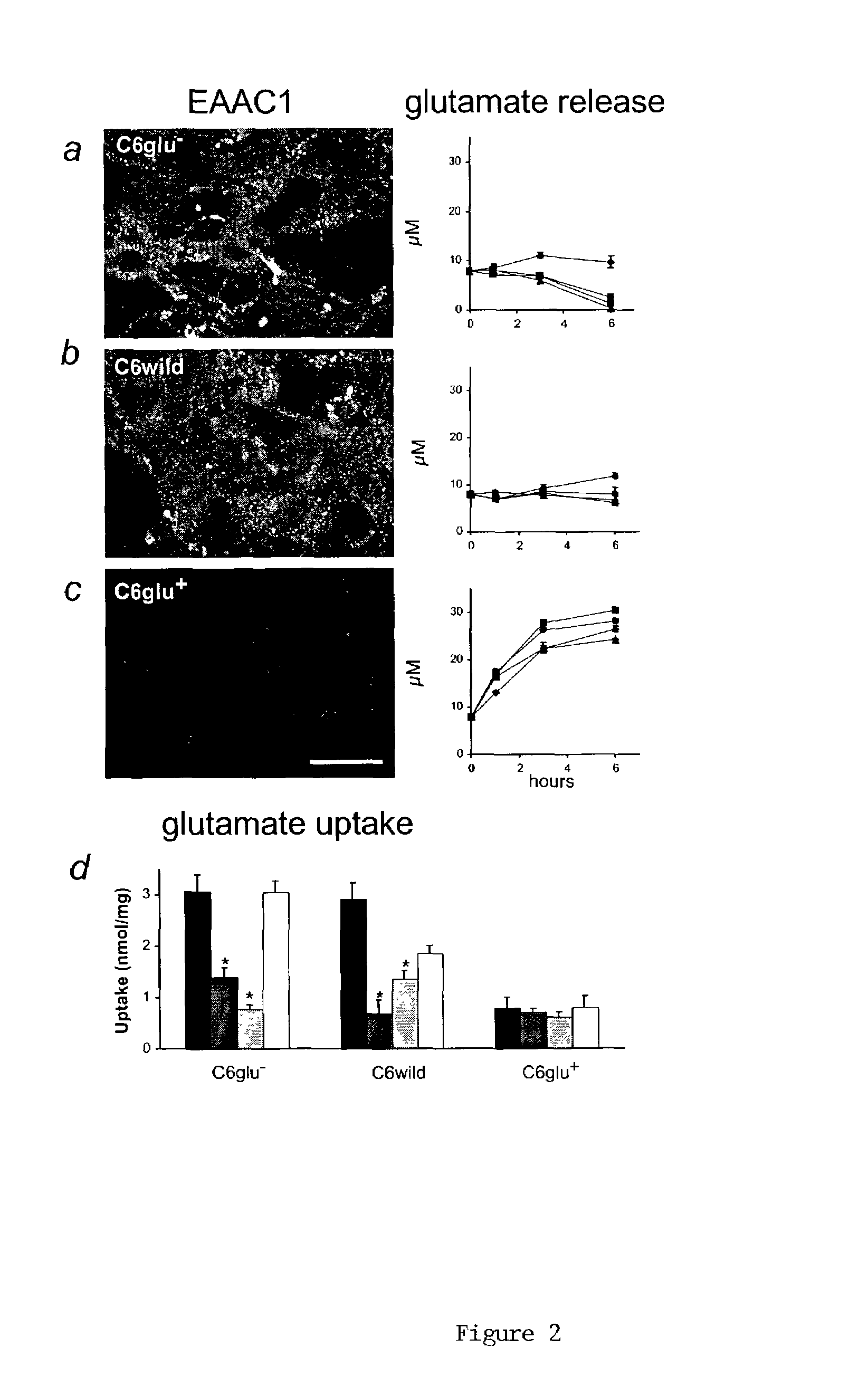

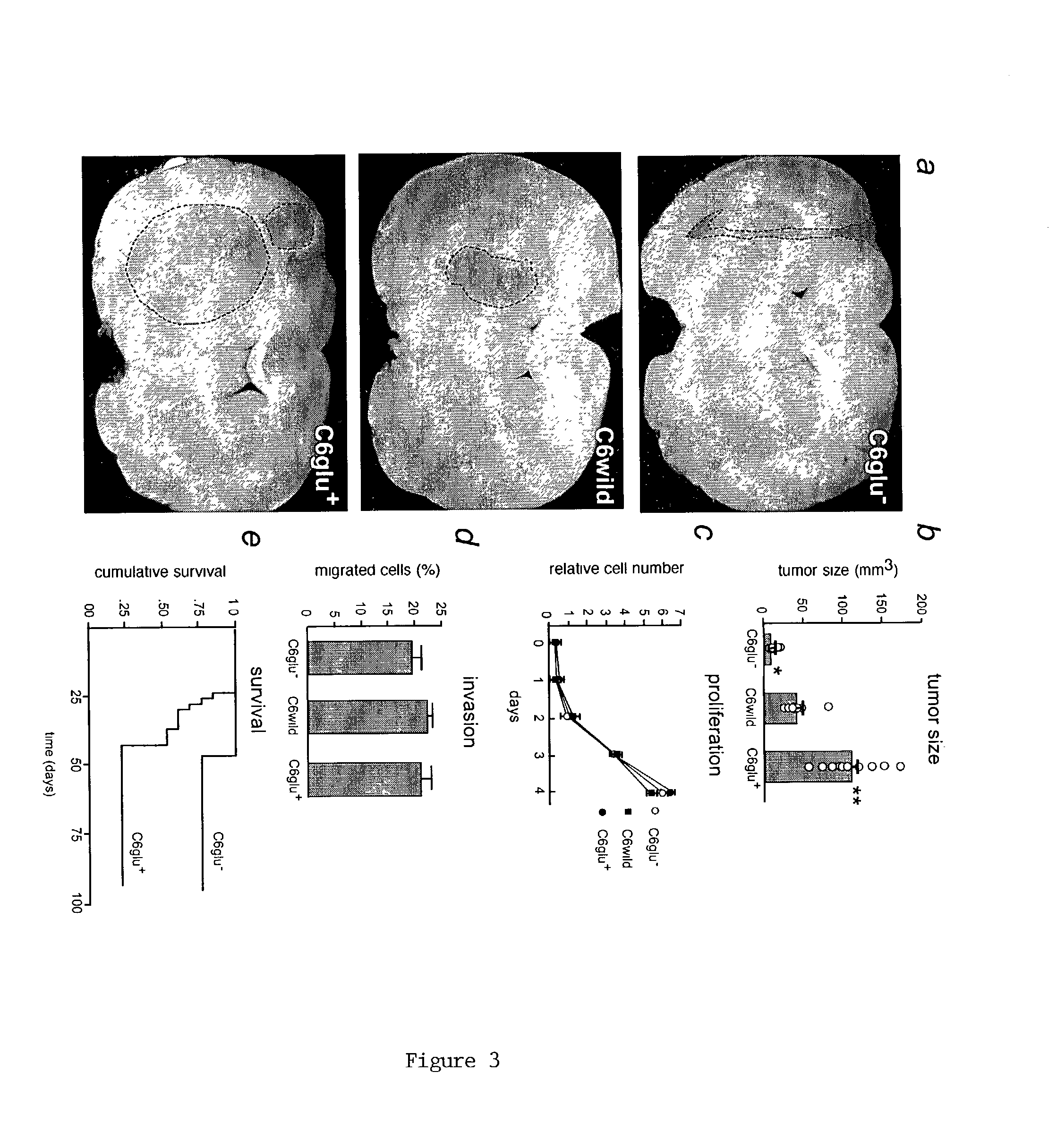

Treatment of glial tumors with glutamate antagonists

InactiveUS7250394B2Increase heightInhibitory activityBiocideOrganic active ingredientsNR1 NMDA receptorGlial tumor

Owner:NEDERGAARD MAIKEN

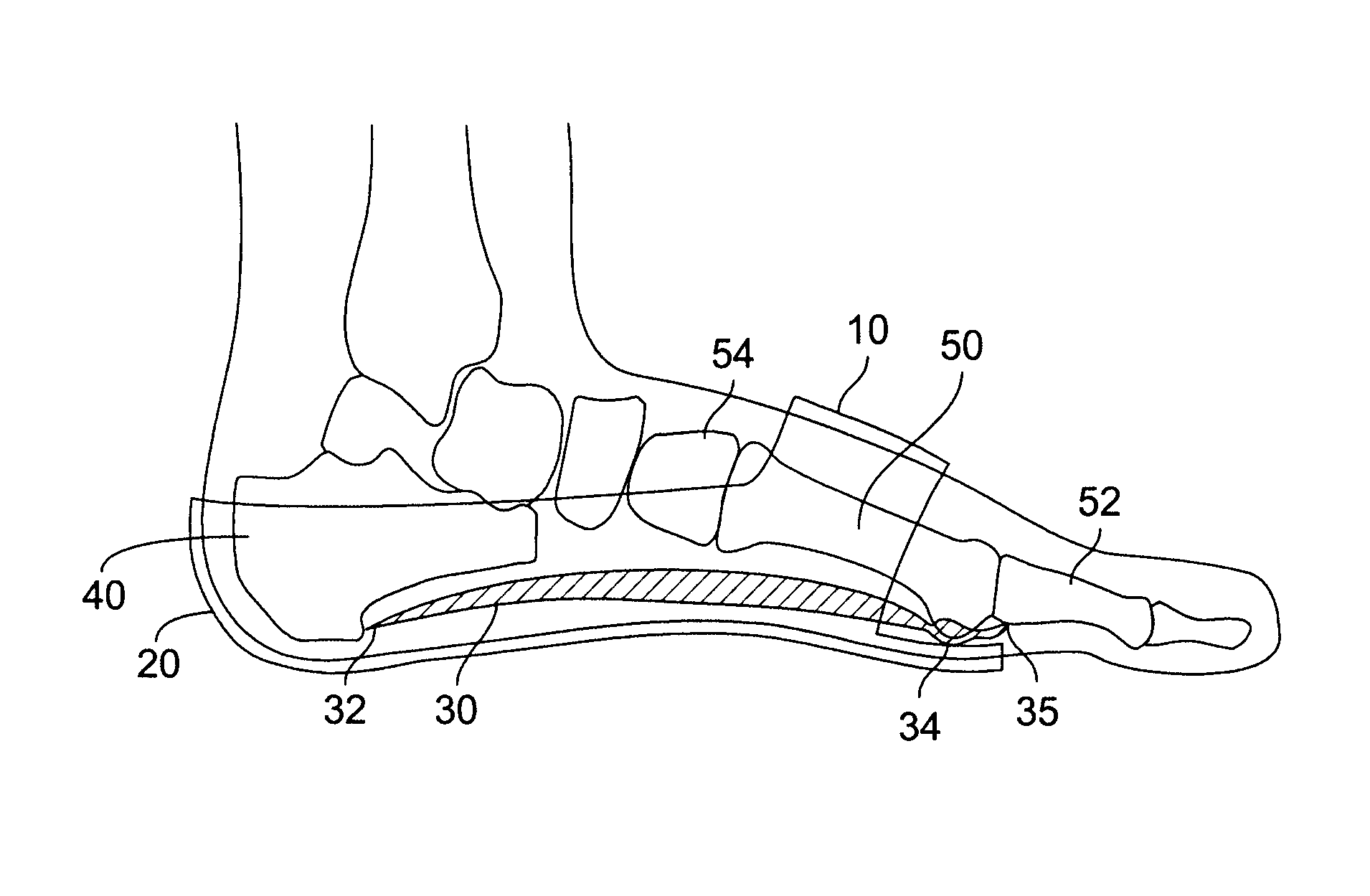

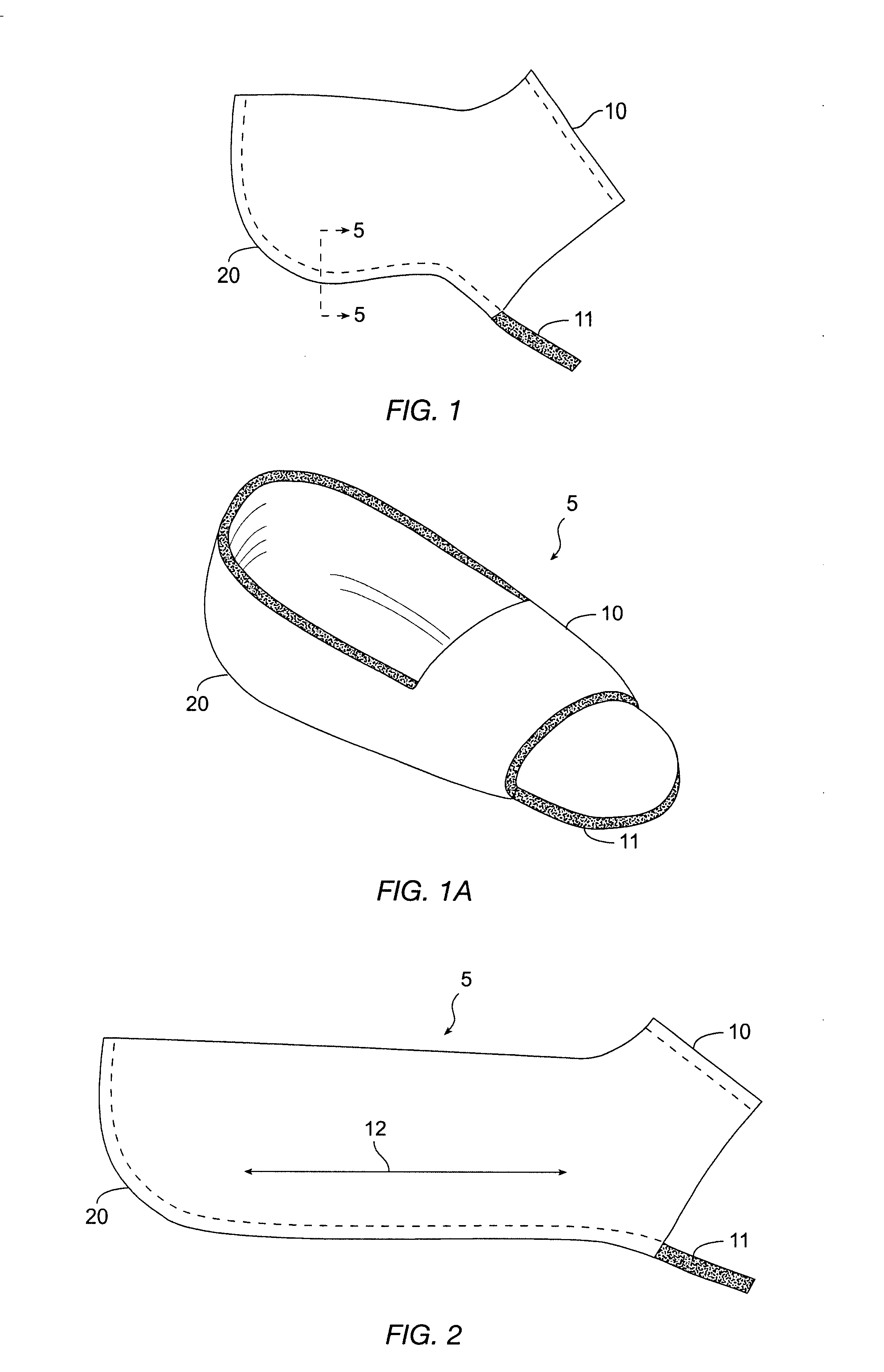

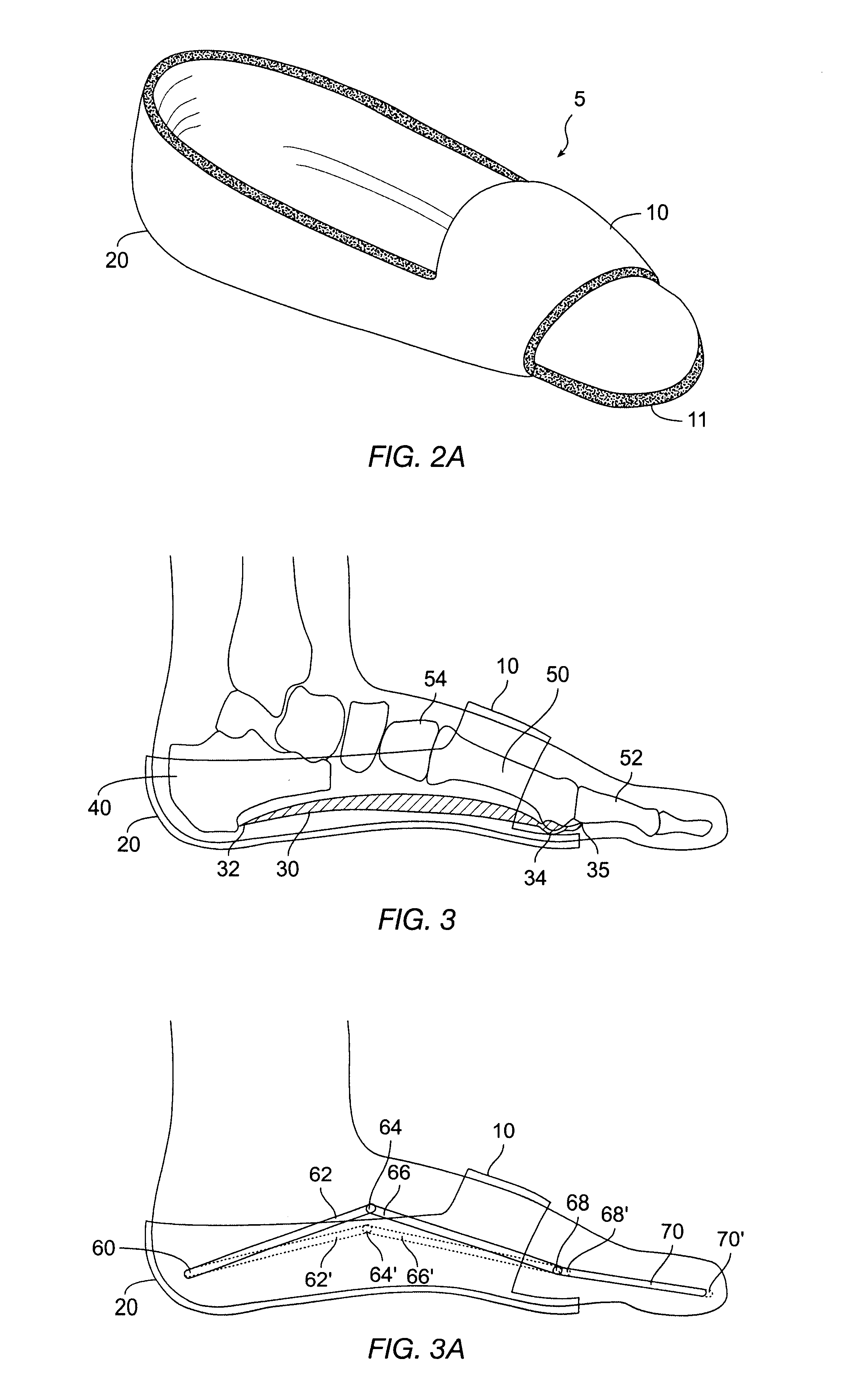

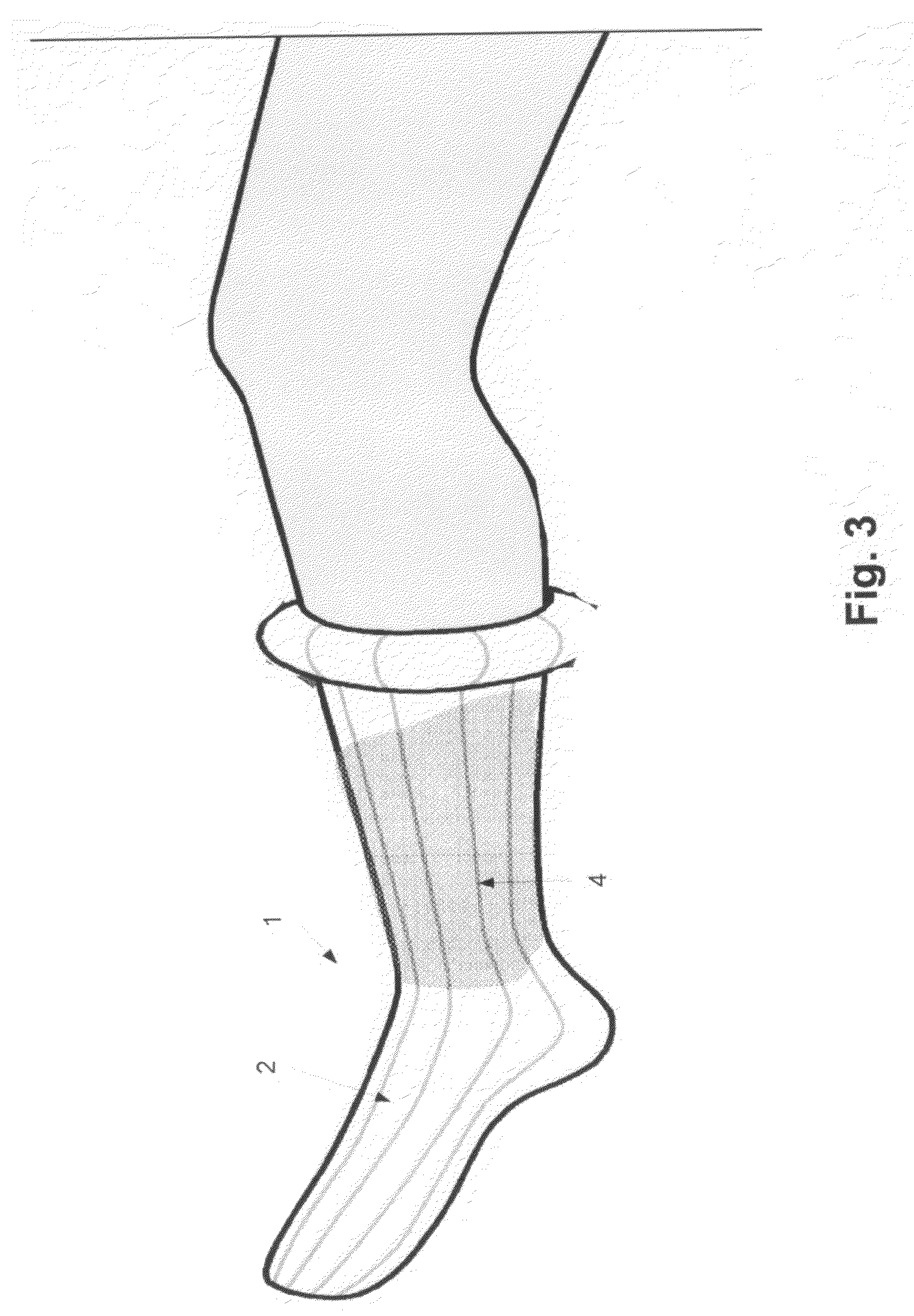

Plantar fascia support apparatus

InactiveUS6886276B2Dissipate shockDelayed expansionInsolesFeet bandagesPhysical medicine and rehabilitationHeel strike

A support apparatus for supporting the plantar fascia of a foot. The support apparatus is made of an elastic material expandable in the width and longitudinal axis of the foot. When in operative position on the foot, the apparatus frictionally remains in place mid the first metatarsal bone and extends behind the heel of the foot above its os calcis bone such that when the foot is caused to bear weight, the apparatus expands along the longitudinal axis of the foot to its limit of expandability such that the arch of the foot is maintained substantially unchanged as the foot alternates between load bearing and non-load bearing orientations.

Owner:HLAVAC HARRY H

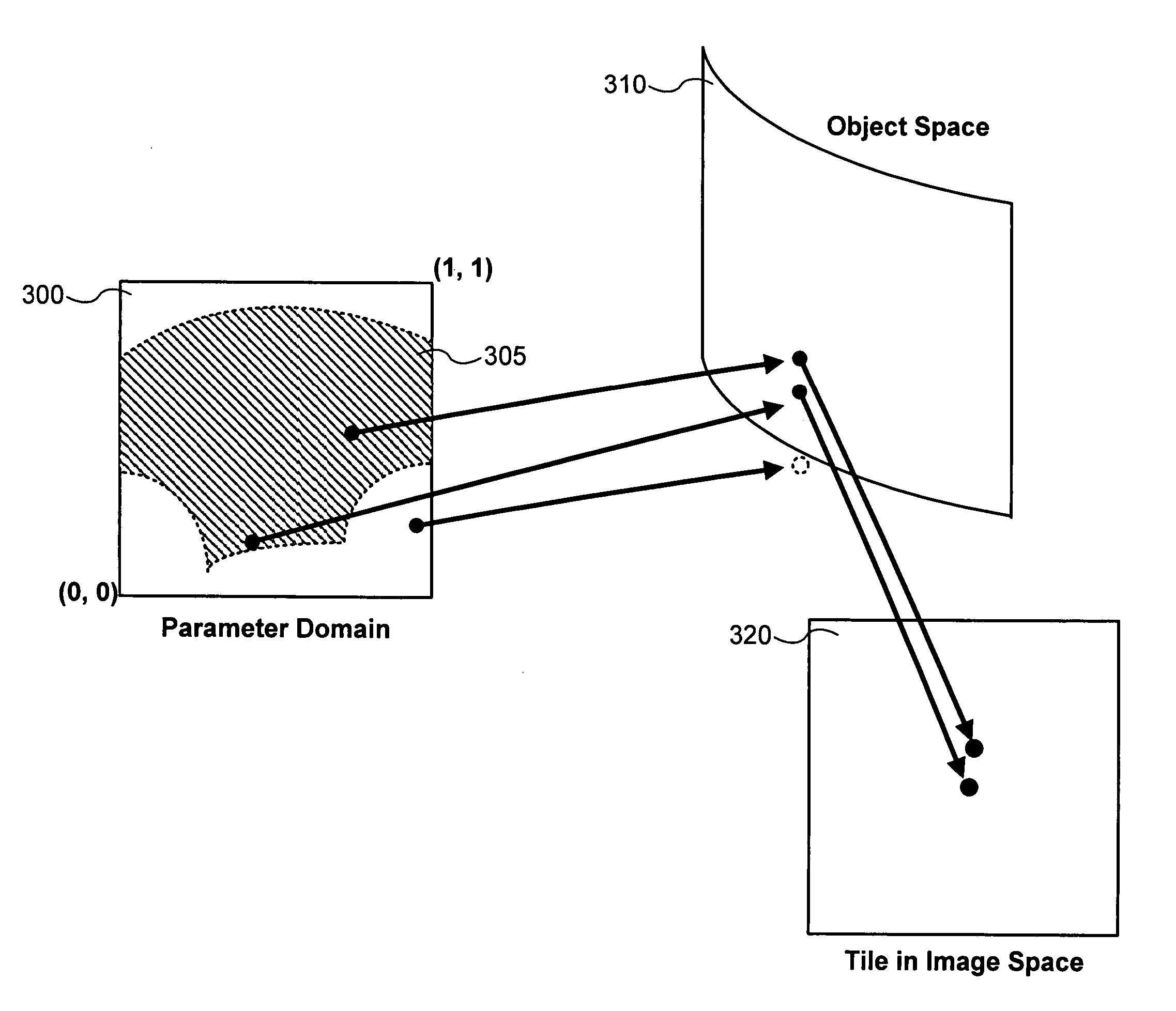

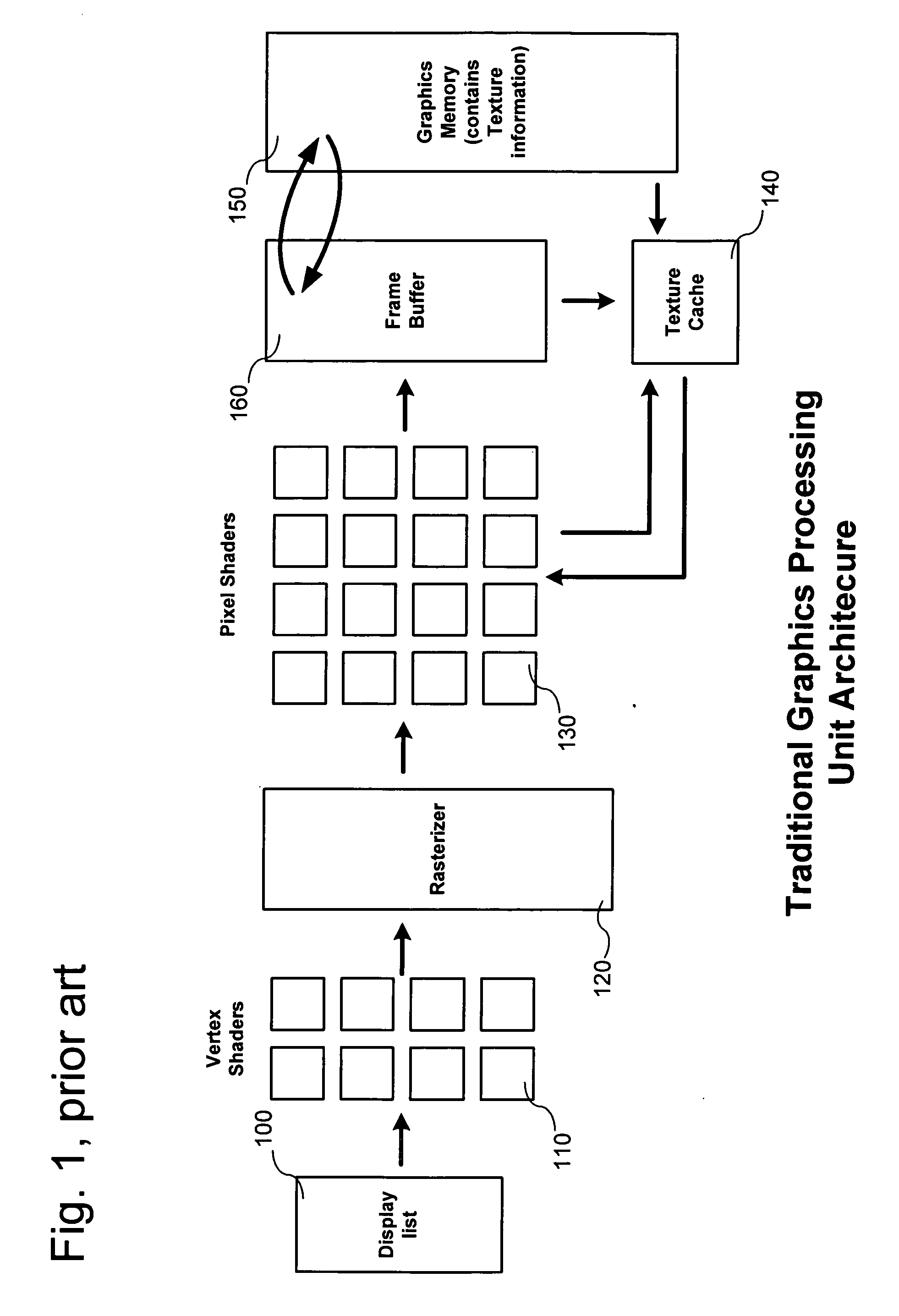

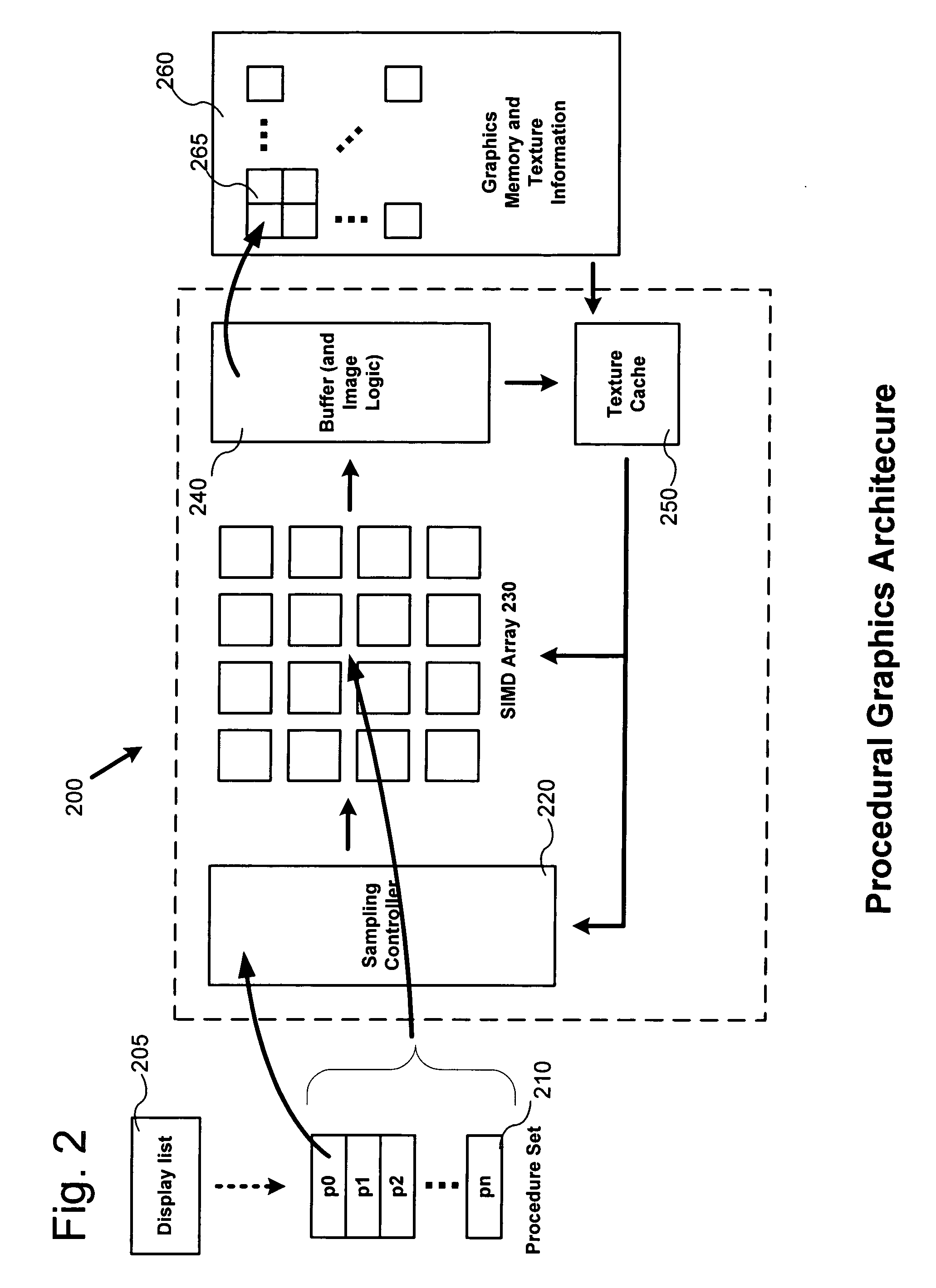

Procedural graphics architectures and techniques

InactiveUS20070002066A1Prevent needless proliferationReduce data transfer bandwidthCathode-ray tube indicatorsDetails involving image processing hardwareComputational scienceGraphics

Techniques and tools for rendering procedural graphics are described. For example, an architecture is provided which allows evaluation of geometric, transform, texture, and shading procedures locally for a given set of procedure parameter values. This evaluation is performed in parallel for different parameter values on a single-instruction, multiple-data array to allow parallel processing of a procedure set. In another example, a sampling controller is described which selects sets of parameter points for evaluation based on information in tag maps, rate maps, and parameter maps.

Owner:MICROSOFT TECH LICENSING LLC

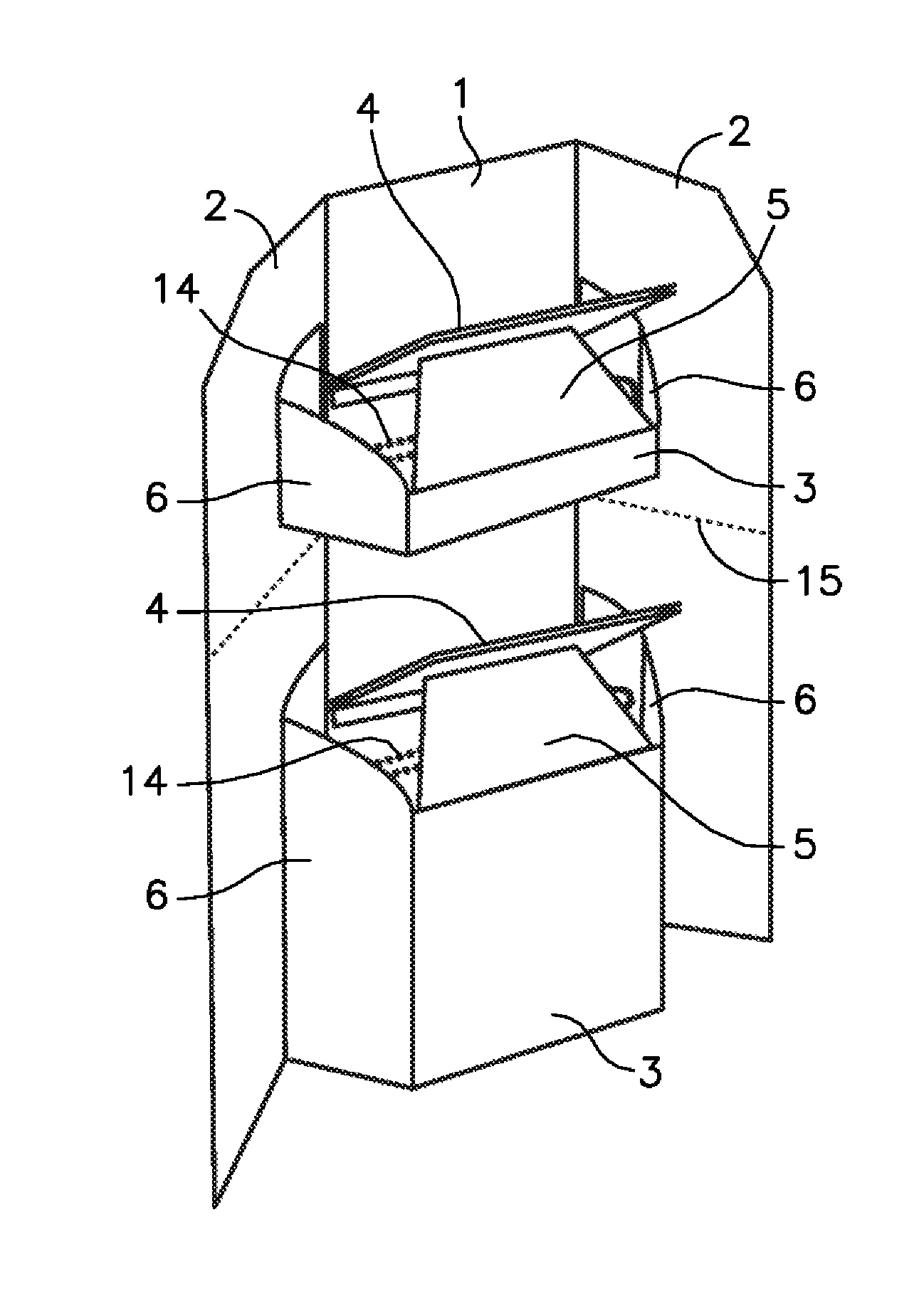

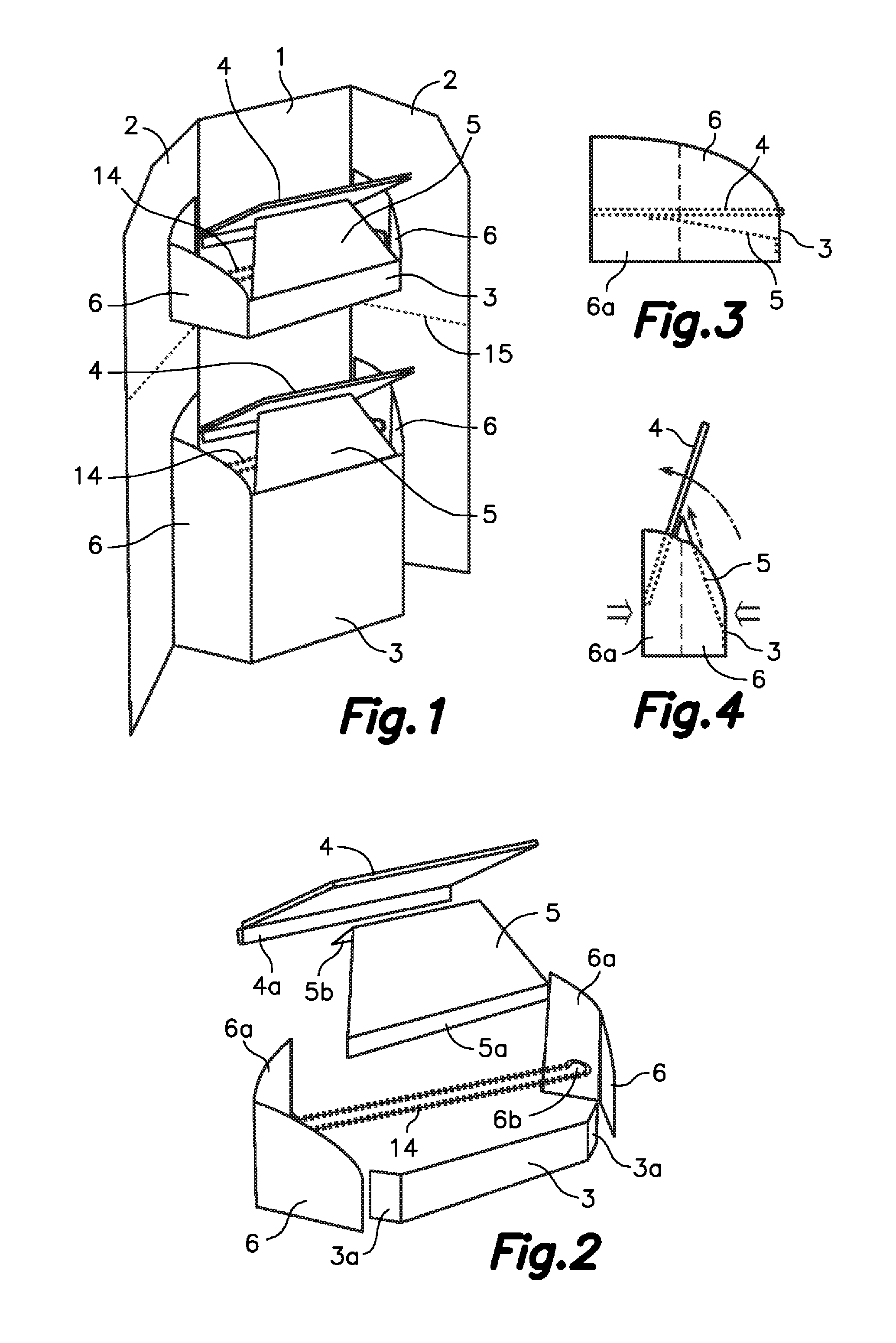

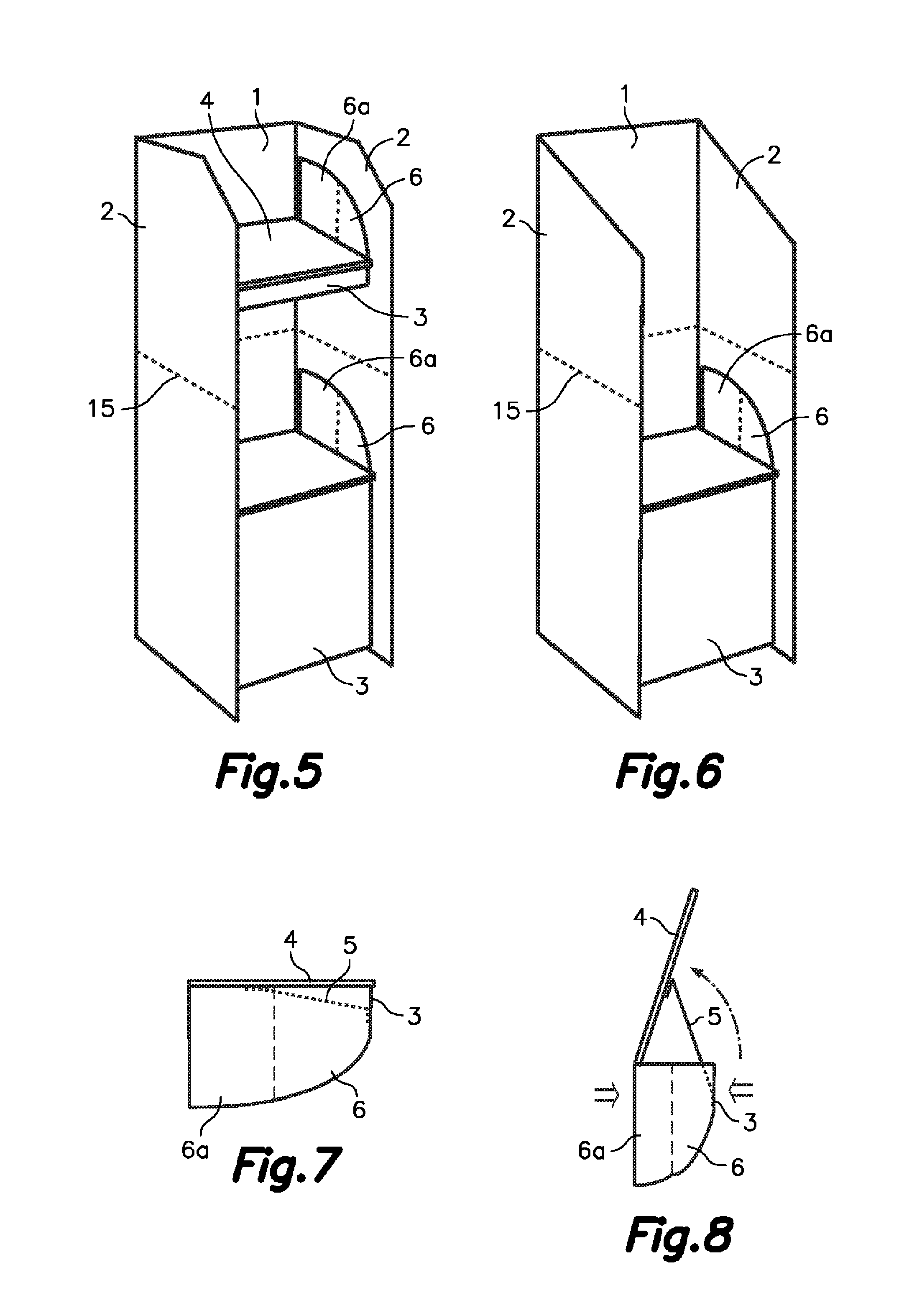

Fold-out shelving unit made of cardboard or a similar material

Owner:MESTRES ARMENGOL FERRAN

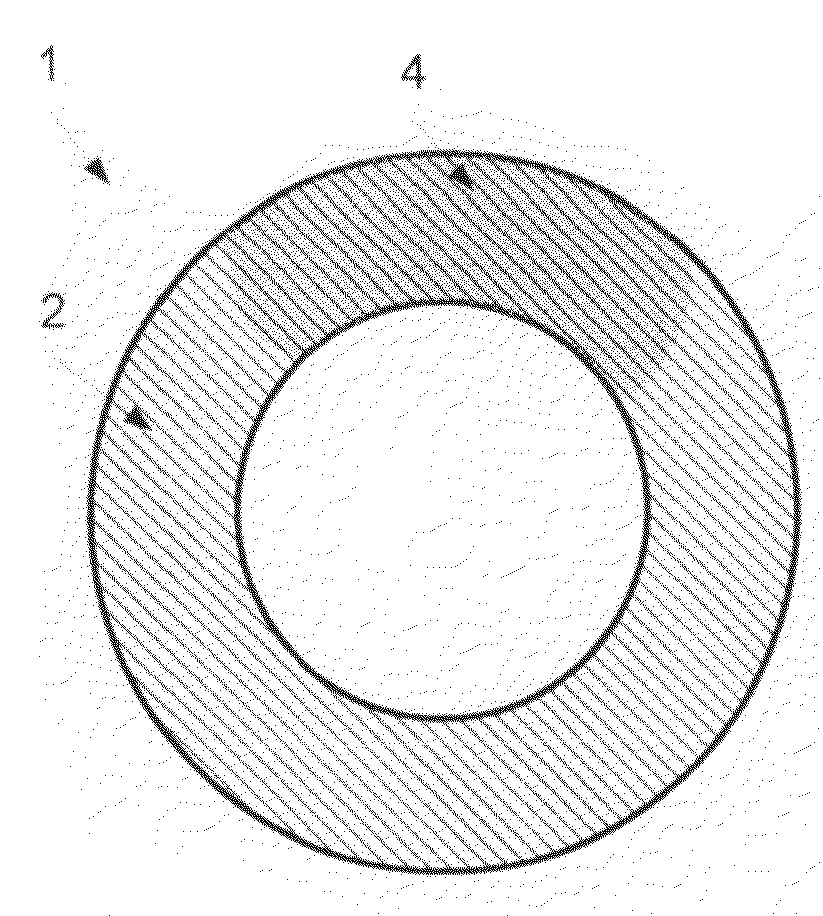

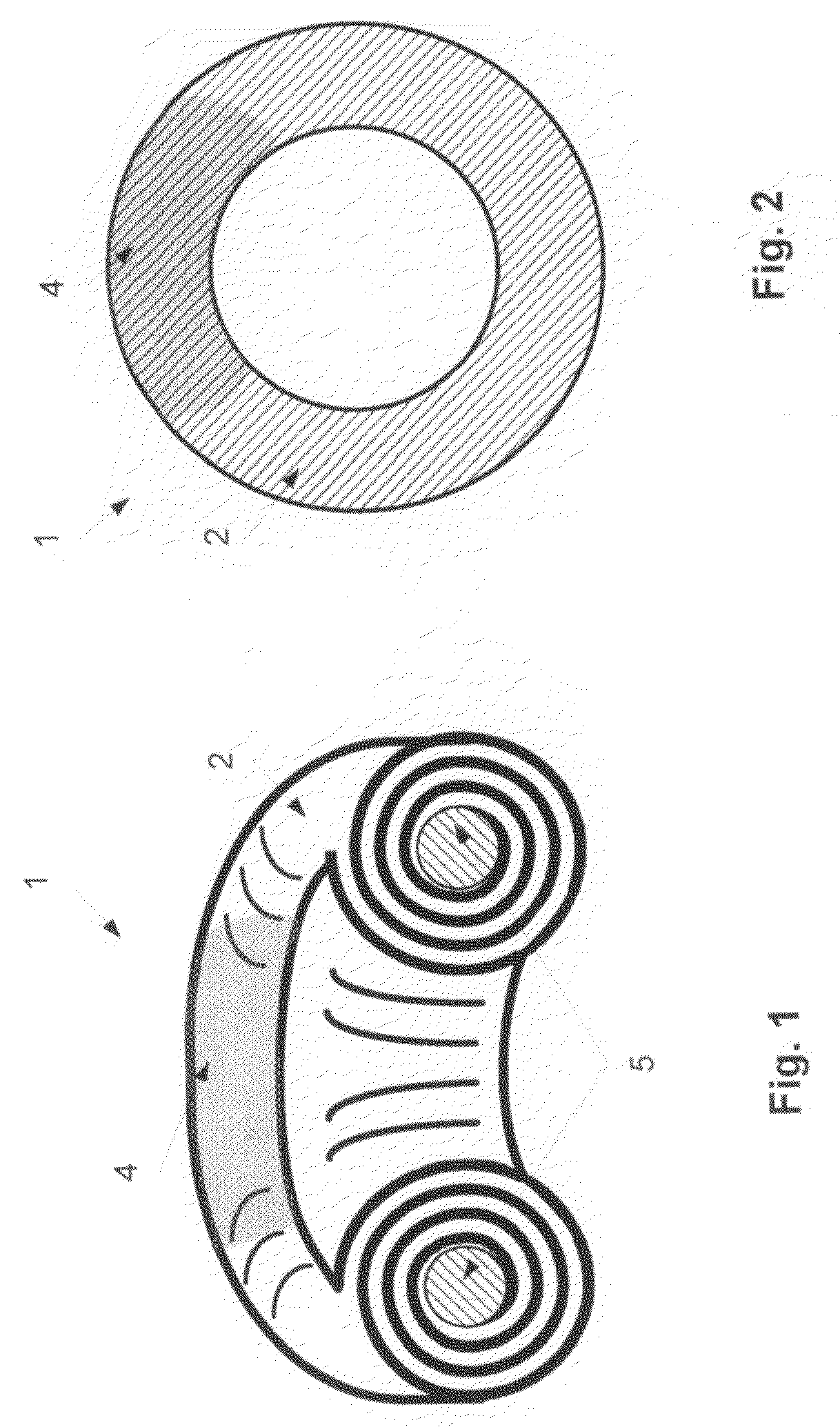

Medical device and a method for applying a biochemically active material on one or more body parts

A medical device having a sleeve-shaped elastic body which is rolled up to form an annular structure and may be rolled down to annularly contacting one or more body parts, such as limbs, a biochemically active material, such as a disinfecting material, added substantially to a portion of the sleeve-shaped elastic body, and a pressure-exerting element for rolling down the sleeve-shaped elastic body while applying an external pressure on a contact point between the portion and the one or more body parts.

Owner:OHK MEDICAL DEVICES

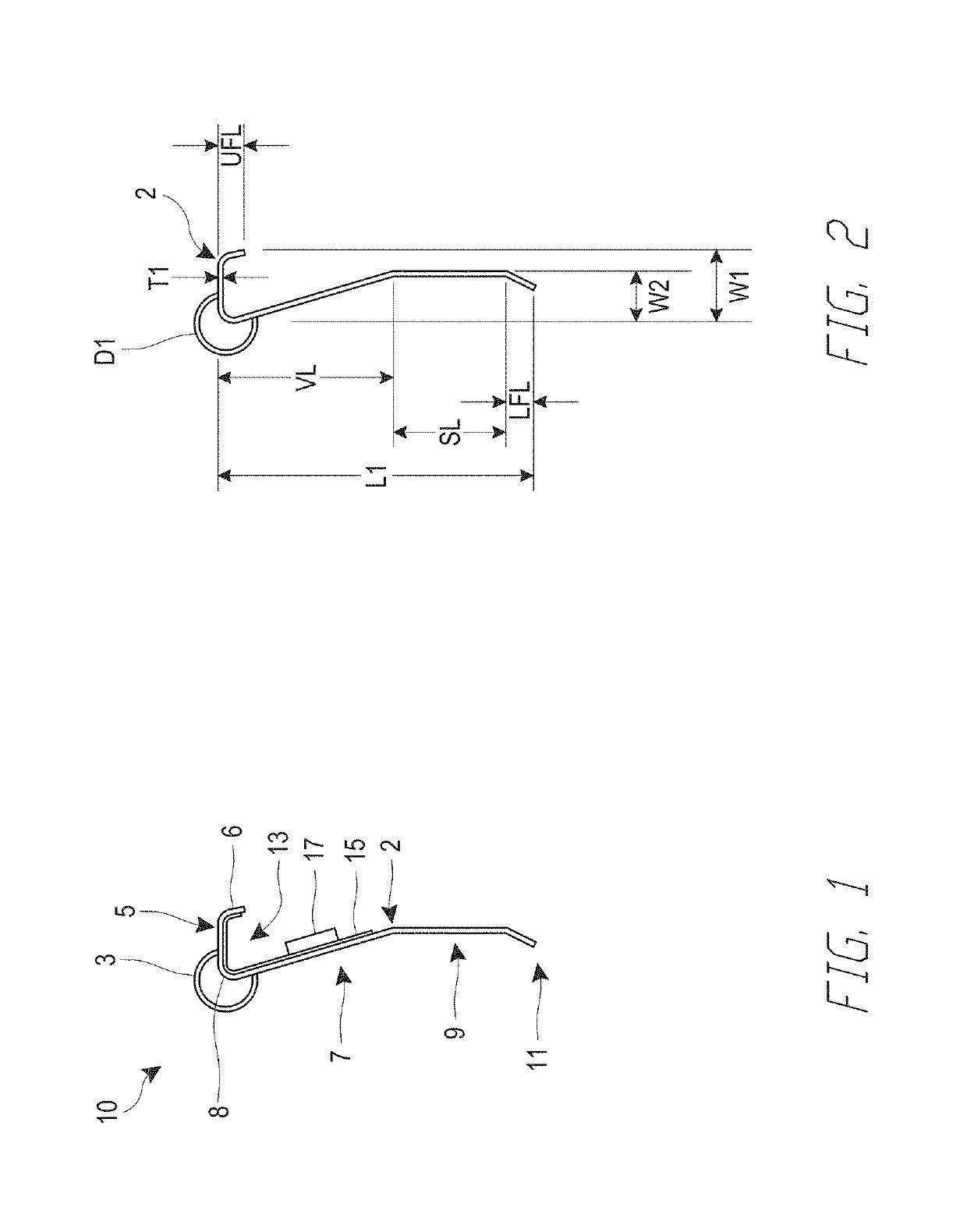

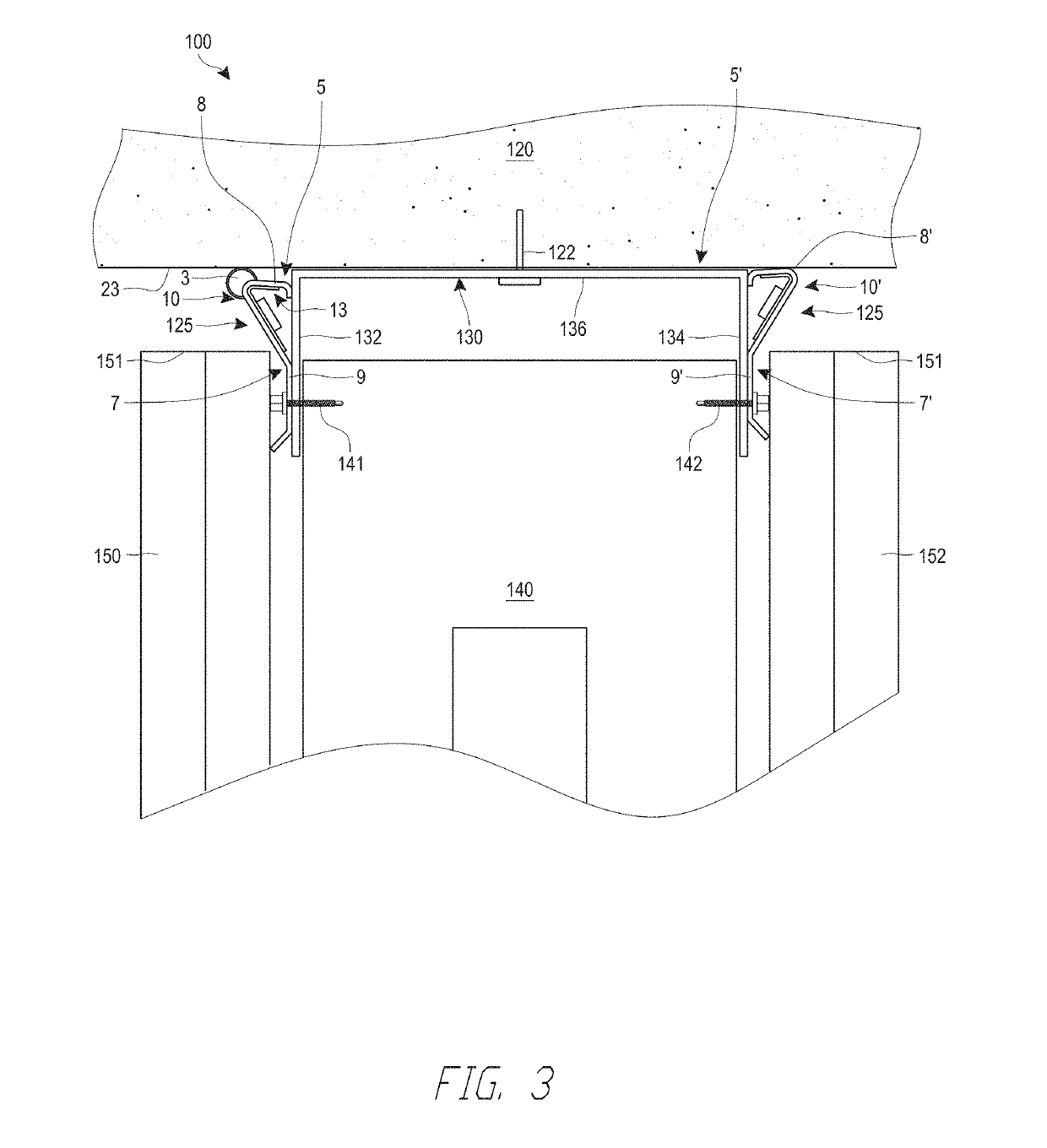

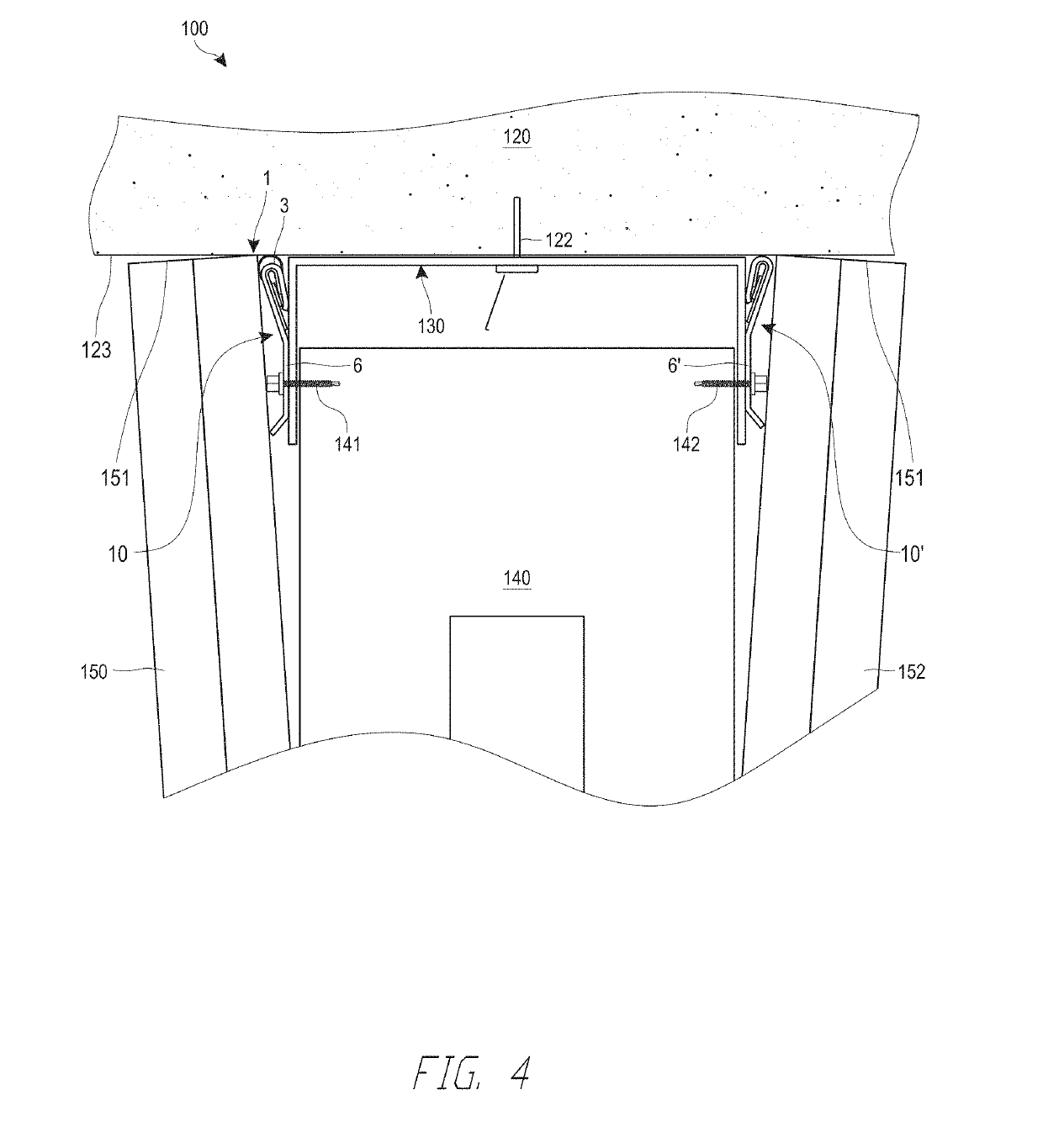

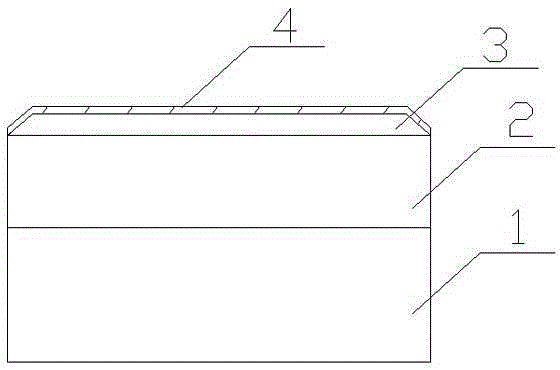

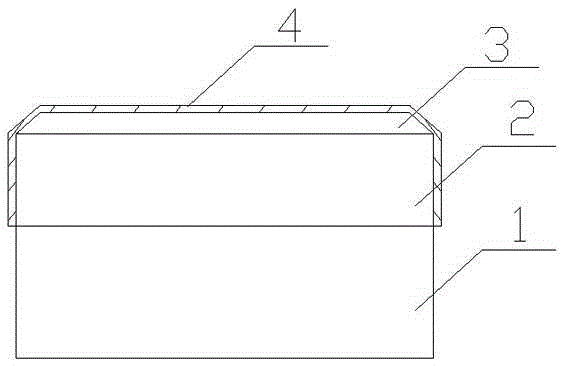

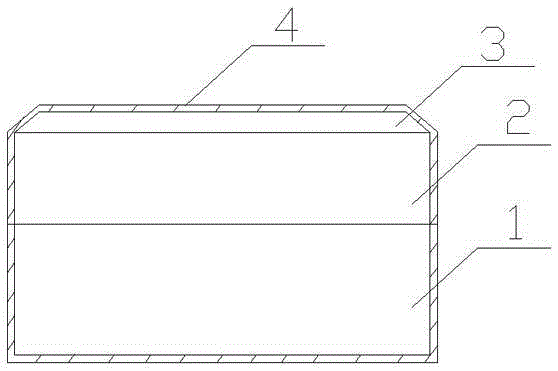

Multi-layer fire-rated joint component

ActiveUS20190284797A1Delayed expansionOpen the deflection gapWallsSynthetic resin layered productsJoint componentEngineering

An improved fire-blocking gasket profile for a fire-rated joint, such as a head-of-wall assembly. Fire-rated joints are aimed at inhibiting or preventing fire, heat, or smoke from leaving one portion of a building and entering another portion of a building. Fire-rated joints can also accommodate movement between adjacent building structures, such as between a ceiling and the top of a wall. The improved fire-blocking gasket profile includes a first layer formed of an intumescent material, a second layer formed of a foil lining and a third layer formed of the vinyl profile. The vinyl profile includes an air gap with the intumescent material positioned therein. A vertical portion of the vinyl profile is positioned between a header track and a wallboard in the fire-rated joint. A horizontal portion of the vinyl profile is positioned at least partially within a deflection gap and sealingly engages with the ceiling.

Owner:CEMCO LLC

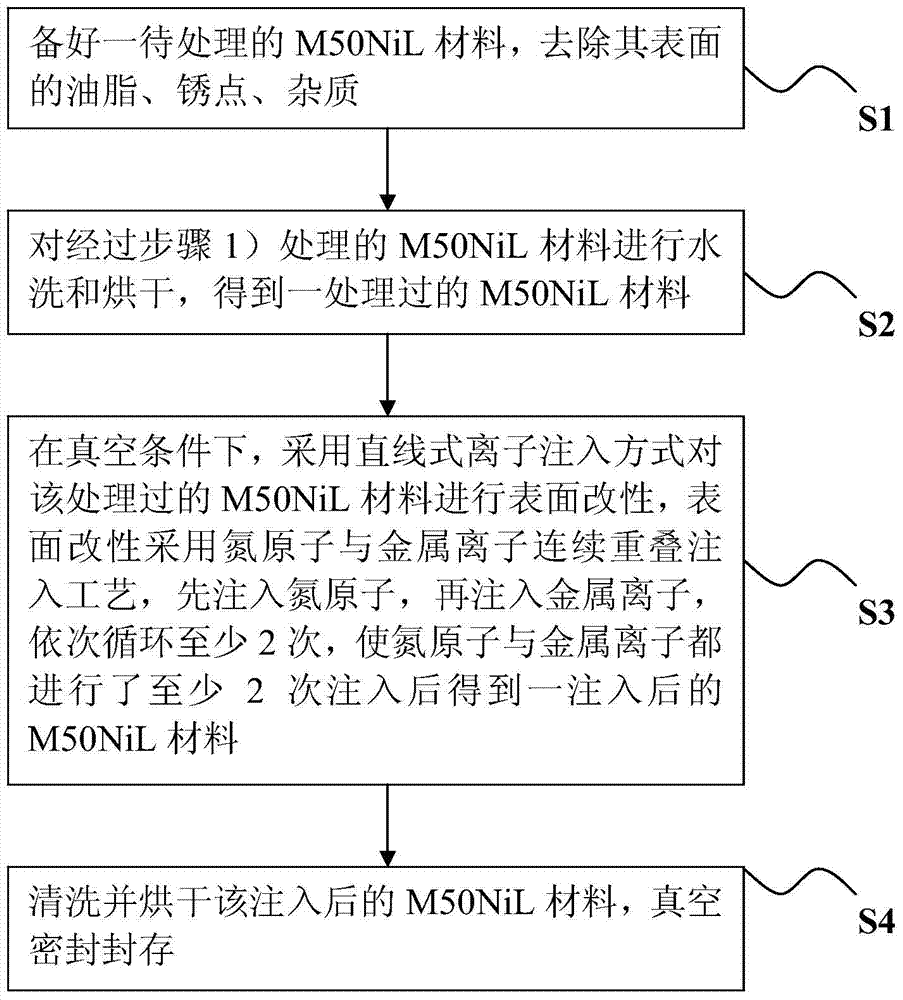

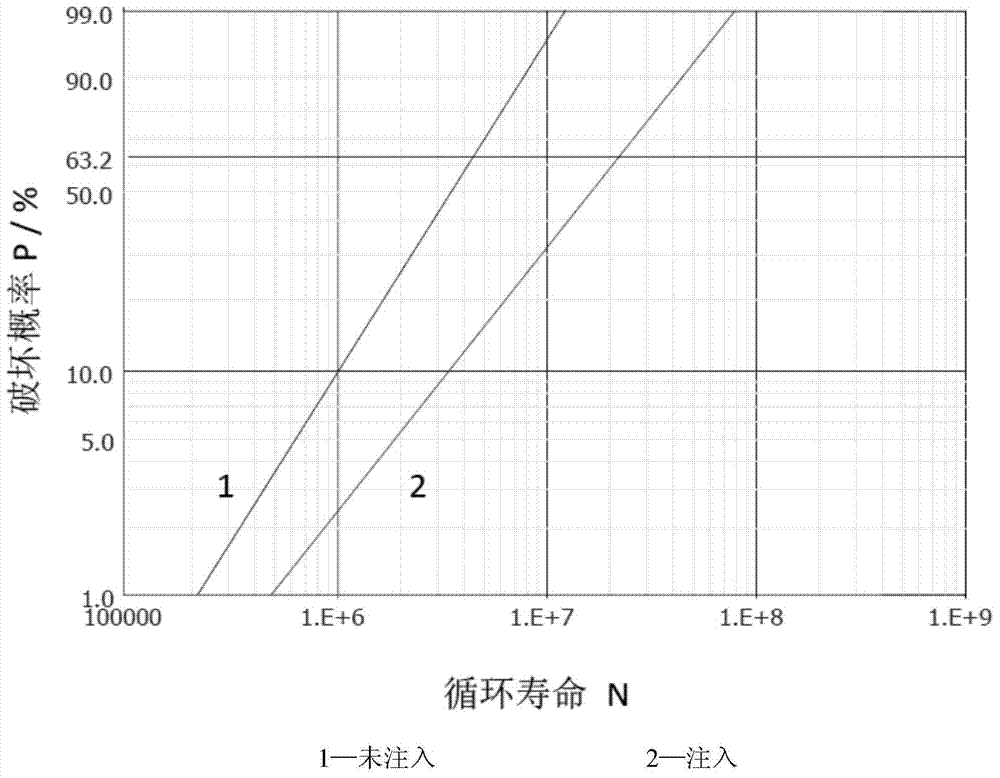

Linear ion implantation surface modification method of M50NiL material

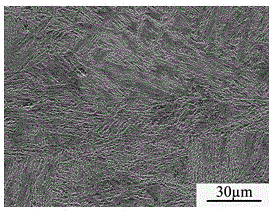

ActiveCN103757598AImprove surface conditionImproved slip characteristicsVacuum evaporation coatingSputtering coatingNitrogenIon implantation

The invention discloses a linear ion implantation surface modification method of an M50NiL material. The method comprises the following steps: carrying out surface modification on M50NiL material by adopting a linear ion implantation mode, carrying out continuous overlapping injection by adopting nitrogen ions and metal ions for surface modification; firstly, injecting the nitrogen ions, then injecting the metal ions, and orderly circulating at least twice, so that the nitrogen ions and the metal ions are injected at least twice. By adopting the linear ion implantation surface modification method of the M50NiL material and the surface-modified M50NiL material disclosed by the invention, the surface of the modified M50NiL material has good contact fatigue resistance.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

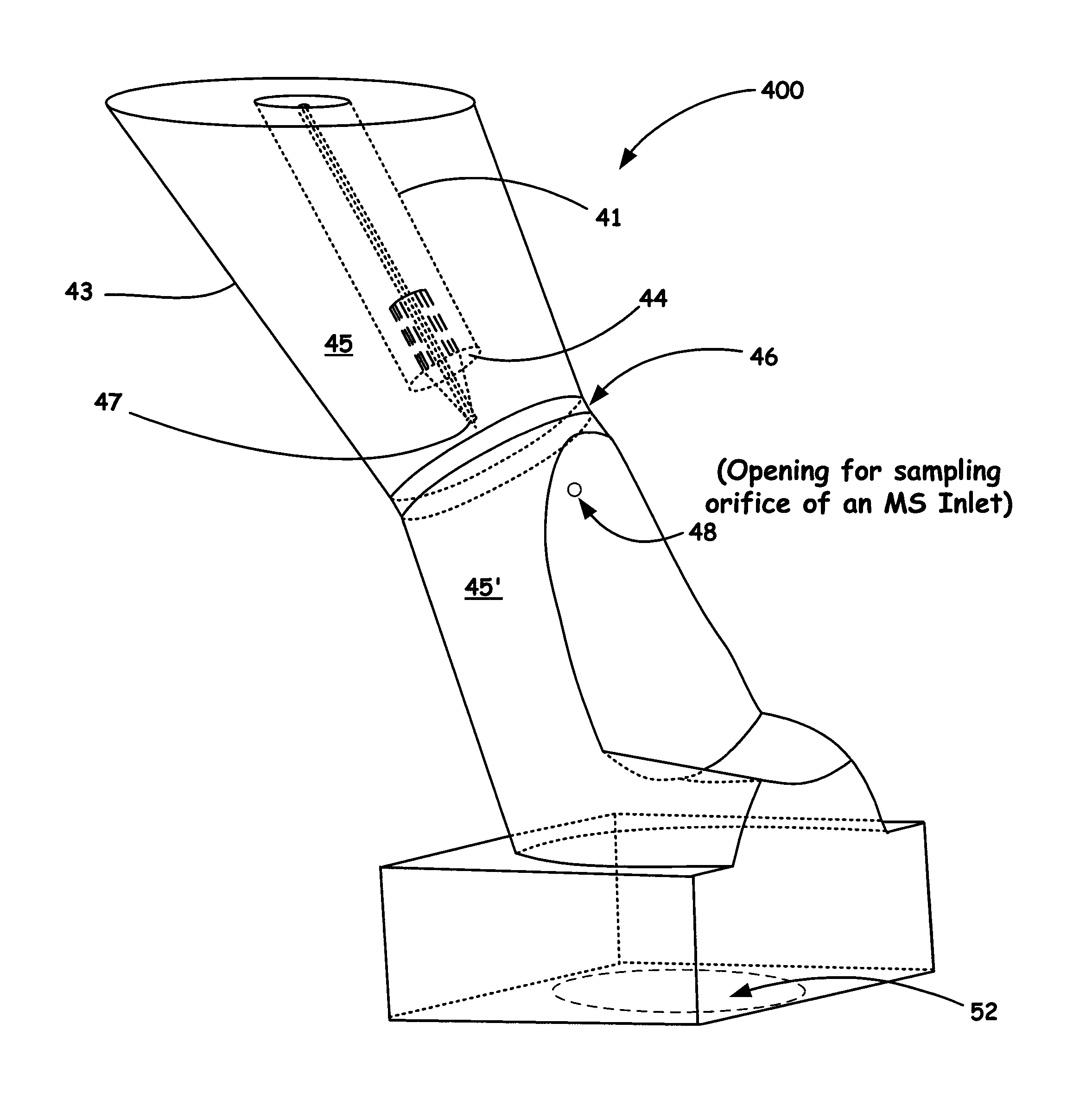

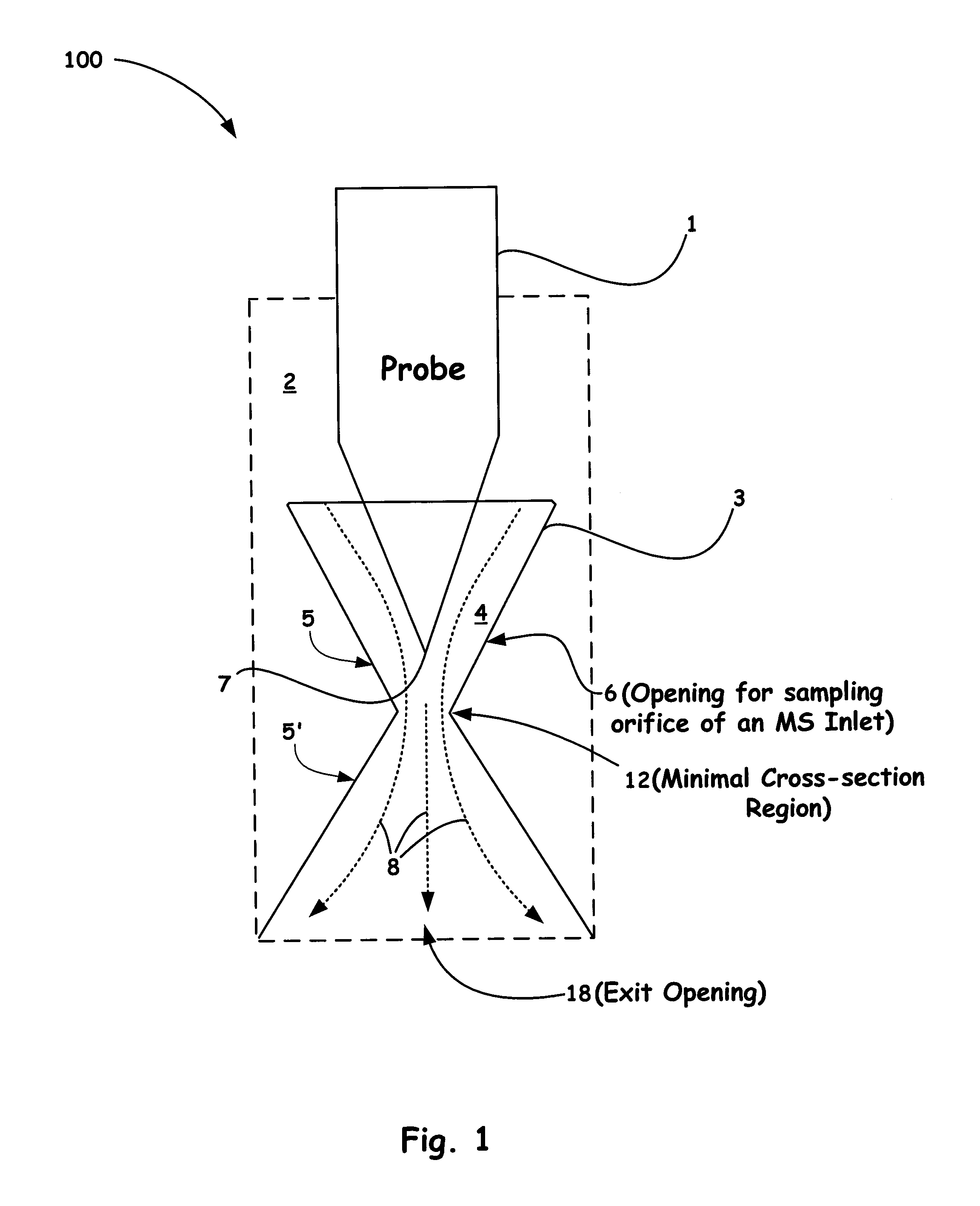

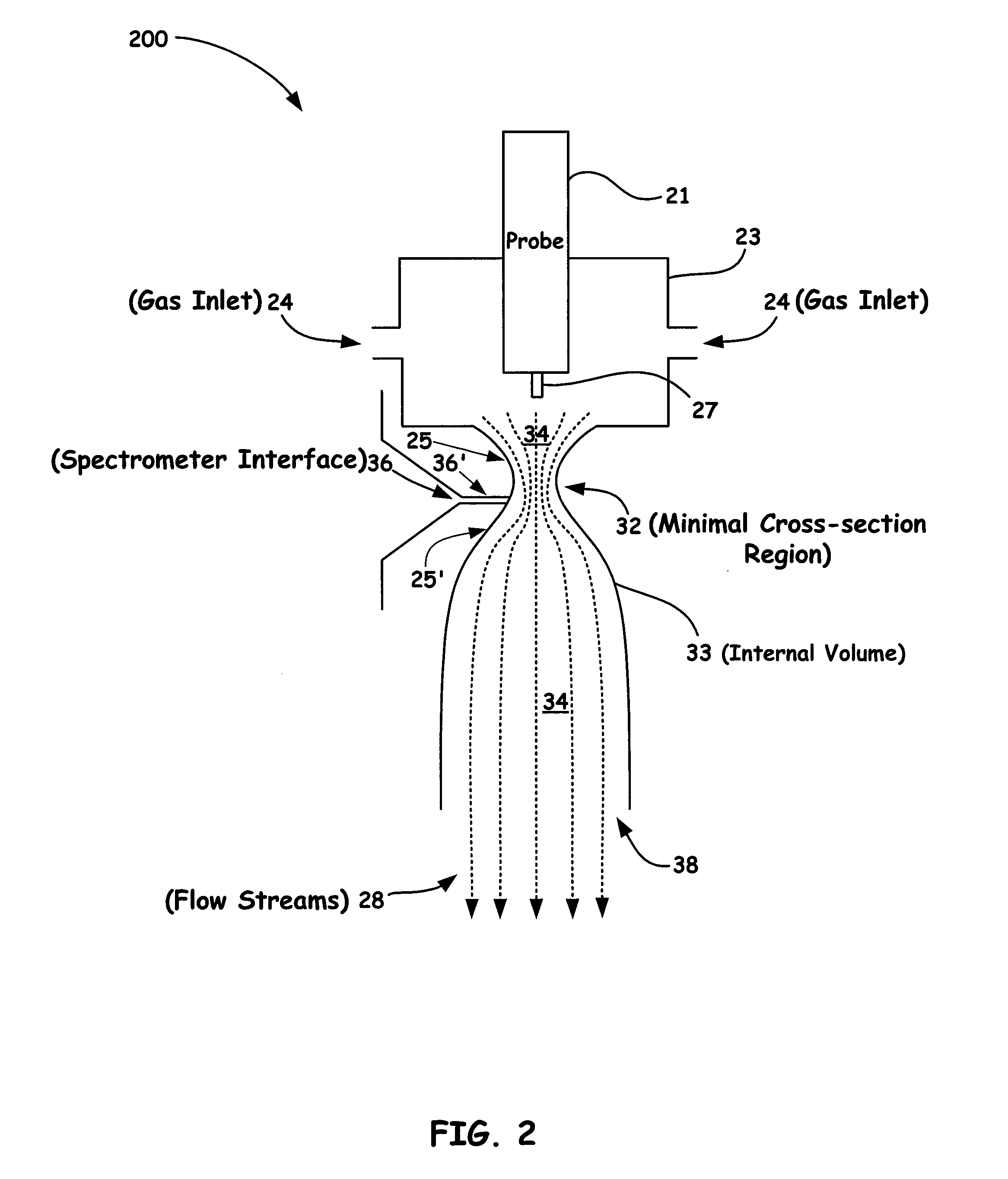

System for Preventing Backflow in an Ion Source

ActiveUS20110068263A1Prevent backflowMinimize carryoverIsotope separationMass spectrometersEngineeringContinuous flow

A system for preventing backflow as part of an ion source arrangement is introduced. Such a system incorporates a novel continuous flow guide within a source, such as an API ion source. In the spray direction, the cross-sectional area that defines the first portion of the internal volume initially decreases in a convergent-like manner and thereafter increases in a divergent-like manner towards the exit opening of the source housing. Such a flow guide has been designed as an integral part of an ion source housing to provide for an optimal unidirectional flow past a sampling orifice of a mass spectrometer inlet. Accordingly, the novel design of the present invention prevents recirculation and thus minimizes carryover, chemical noise, and source turbulence and as an added benefit, enables a user to easily clean such a system during maintenance.

Owner:THERMO FINNIGAN

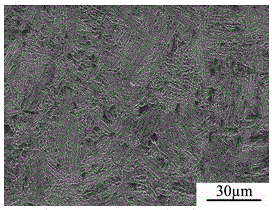

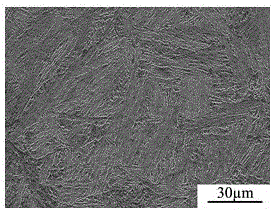

Ultrahigh-strength high-toughness multistep isothermal bainite steel and preparation method thereof

The invention relates to an ultrahigh-strength high-toughness multistep isothermal bainite steel and a preparation method thereof. The technical scheme of the invention is as follows: a hot-rolled steel billet is austenitized 0.2-5.0 hours at a temperature of 850-1100 DEG C firstly, and then the steel billet is subjected to bainite multistep isothermal transformation, so that an ultrahigh-strength high-toughness multistep isothermal bainite steel is obtained. The multistep isothermal transformation is implemented through the following steps: 1, carrying out heat preservation 0.2-3.0 hours in an isothermal medium at a temperature of 250-450 DEG C; 2, carrying out heat preservation 2-50 hours in the isothermal medium at a temperature of 220-350 DEG C; 3, carrying out heat preservation 24-240 hours in the isothermal medium at a temperature of 180-250 DEG C; and 4, carrying out heat preservation 50-360 hours in the isothermal medium at a temperature of 150-220 DEG C, and cooling the obtained product to room temperature, wherein the multistep refers to step 1 to step 2, or step 1 to step 3, or step 1 to step 4. The bainite steel prepared by using the method disclosed by the invention has the characteristics of high hardness, high strength, high toughness, good volume stability and fine microstructure.

Owner:WUHAN UNIV OF SCI & TECH

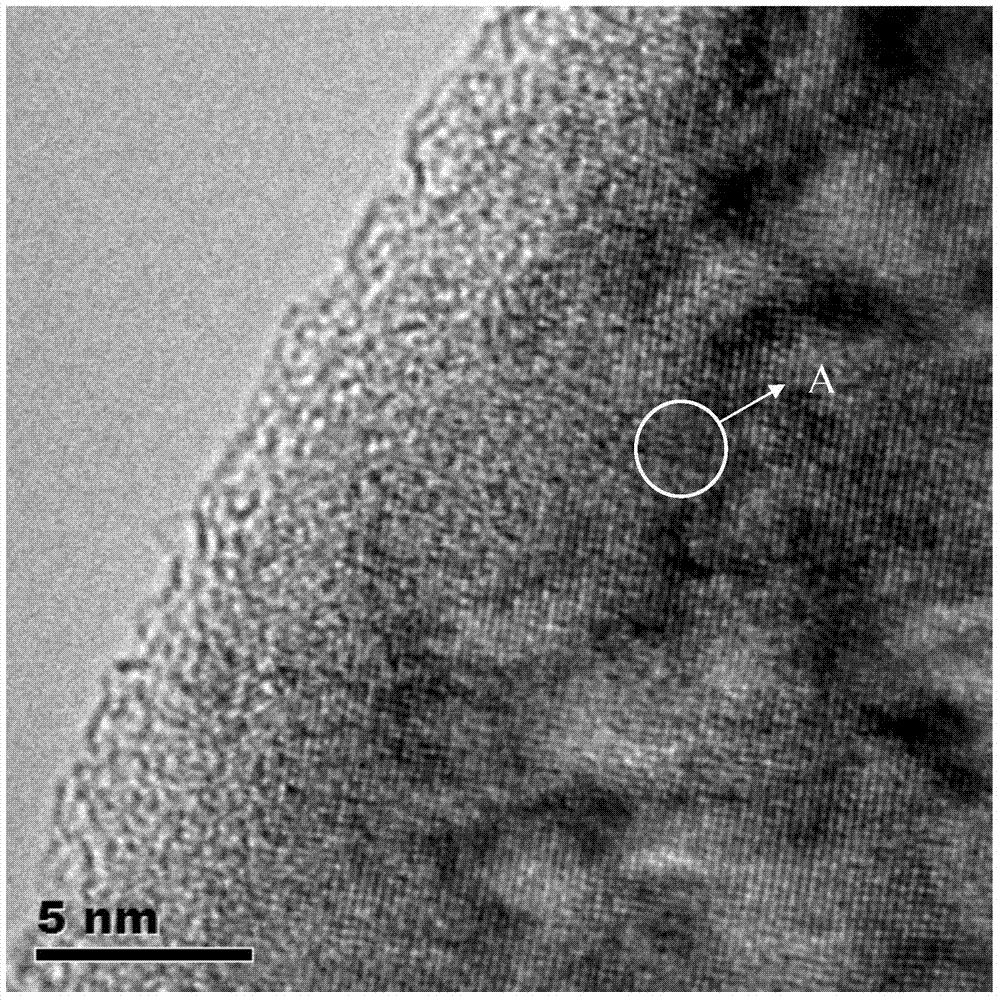

Polycrystalline diamond compact and manufacturing method thereof

ActiveCN105349965AImprove wear resistanceExtended service lifeChemical vapor deposition coatingPolycrystalline diamondFilm coating

The invention provides a polycrystalline diamond compact and a manufacturing method thereof. The polycrystalline diamond compact comprises a cylindrical compact base body and a working end face. The compact base body comprises a hard alloy base layer and a polycrystalline diamond layer covering the upper surface of the hard alloy base layer. The working end face is located on the upper end face of the polycrystalline diamond layer and provided with multiple nanodiamond layers. Each nanodiamond layer comprises two nanocrystalline layers of different average grain sizes. The manufacturing method of the polycrystalline diamond compact includes the steps of firstly, compact base body manufacturing, secondly pretreatment, thirdly CVD film coating and fourthly nanodiamond layer surface polishing after which the compact is obtained. The outer layer of the compact is coated with the nanodiamond layers, the abrasion resistance, impact resistance and toughness of the polycrystalline diamond compact are improved, and the service life of the compact is prolonged; and the polycrystalline diamond compact manufactured through the method is good in abrasion resistance, high-temperature resistance and impact resistance.

Owner:FUNIK ULTRAHARD MATERIAL

Multilayer stent

A composite stent having a substrate tube made of stainless steel, a nickel-cobalt-chromium-molybdenum alloy, or chonichrome with at least one metal cladding tube is disclosed. Specifically, the substrate tube is placed within a metal cladding tube made of platinum, gold, tantalum, tungsten, platinum-iridium, palladium, or nickel-titanium, preferably with an interference fit therebetween. The composite, laminate tube then undergoes a series of rolling or cold drawing processes interspersed with heat treating to release built up stresses. When the final diameter of the laminate tube is reached, the cladding has been laminated to the exterior of the substrate tube by a bond generated from the rolling and / or cold drawing operations. The finished laminate tube is then cut by laser cutting or chemical etching to form a suitable stent pattern.

Owner:JALISI MARC M

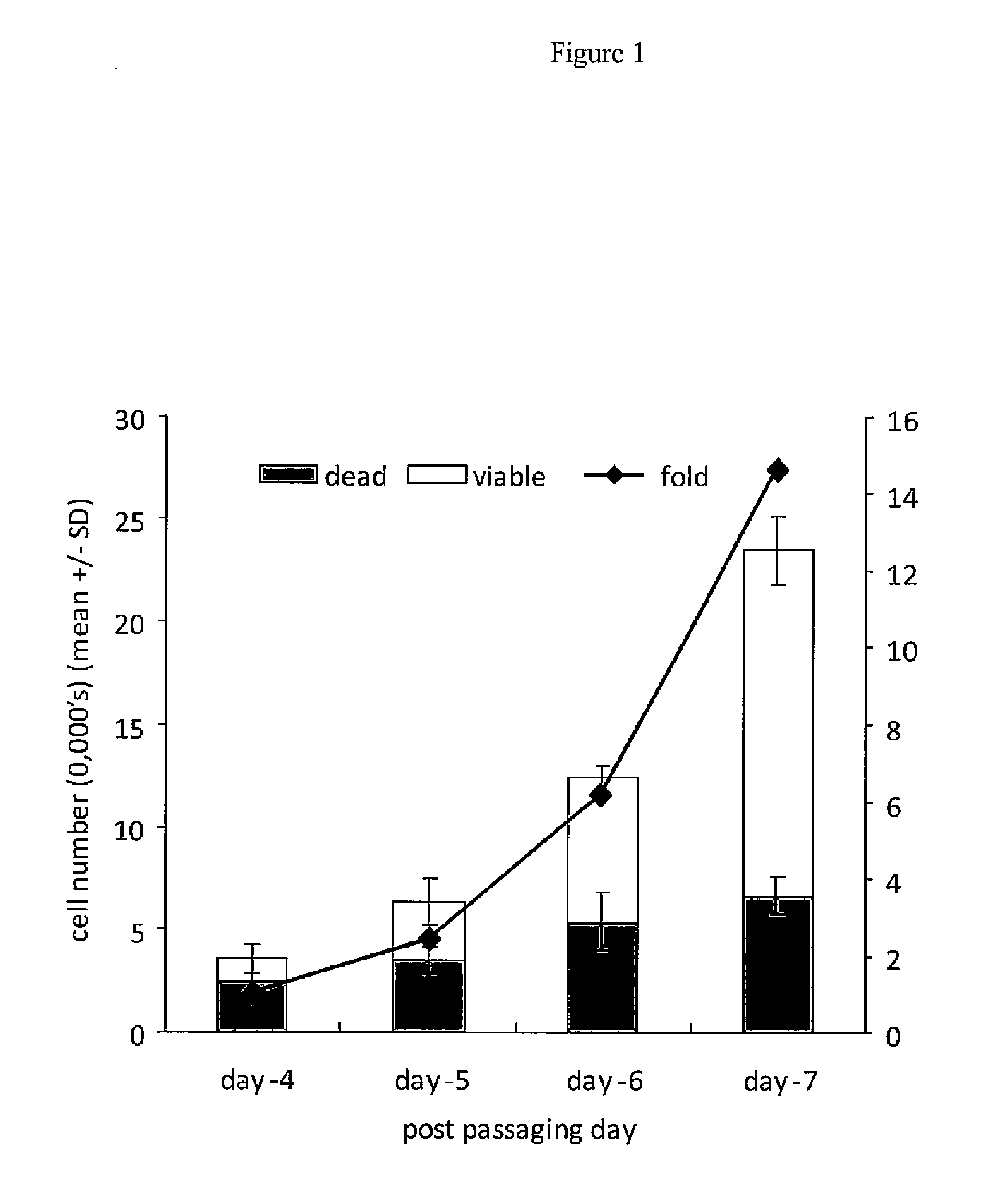

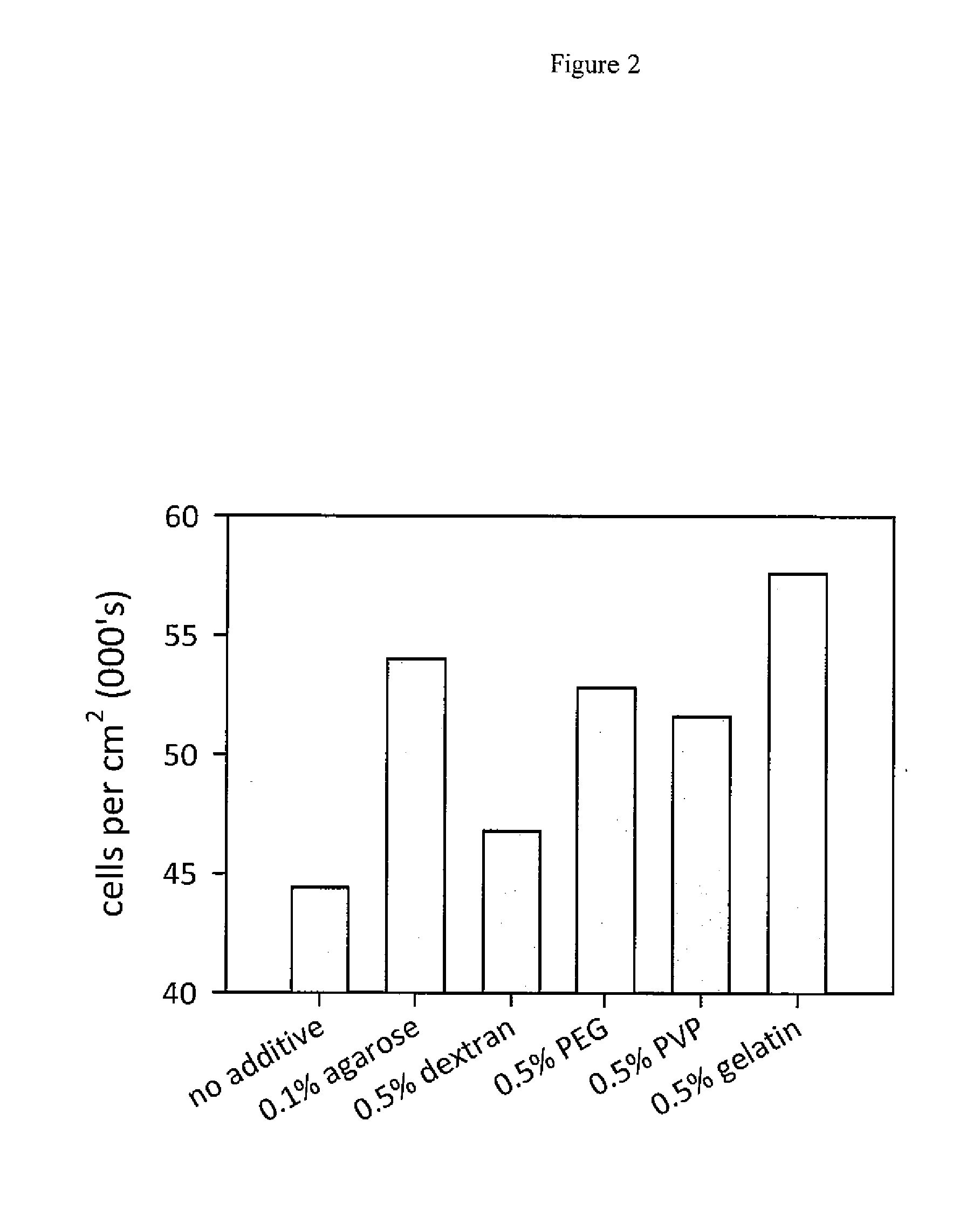

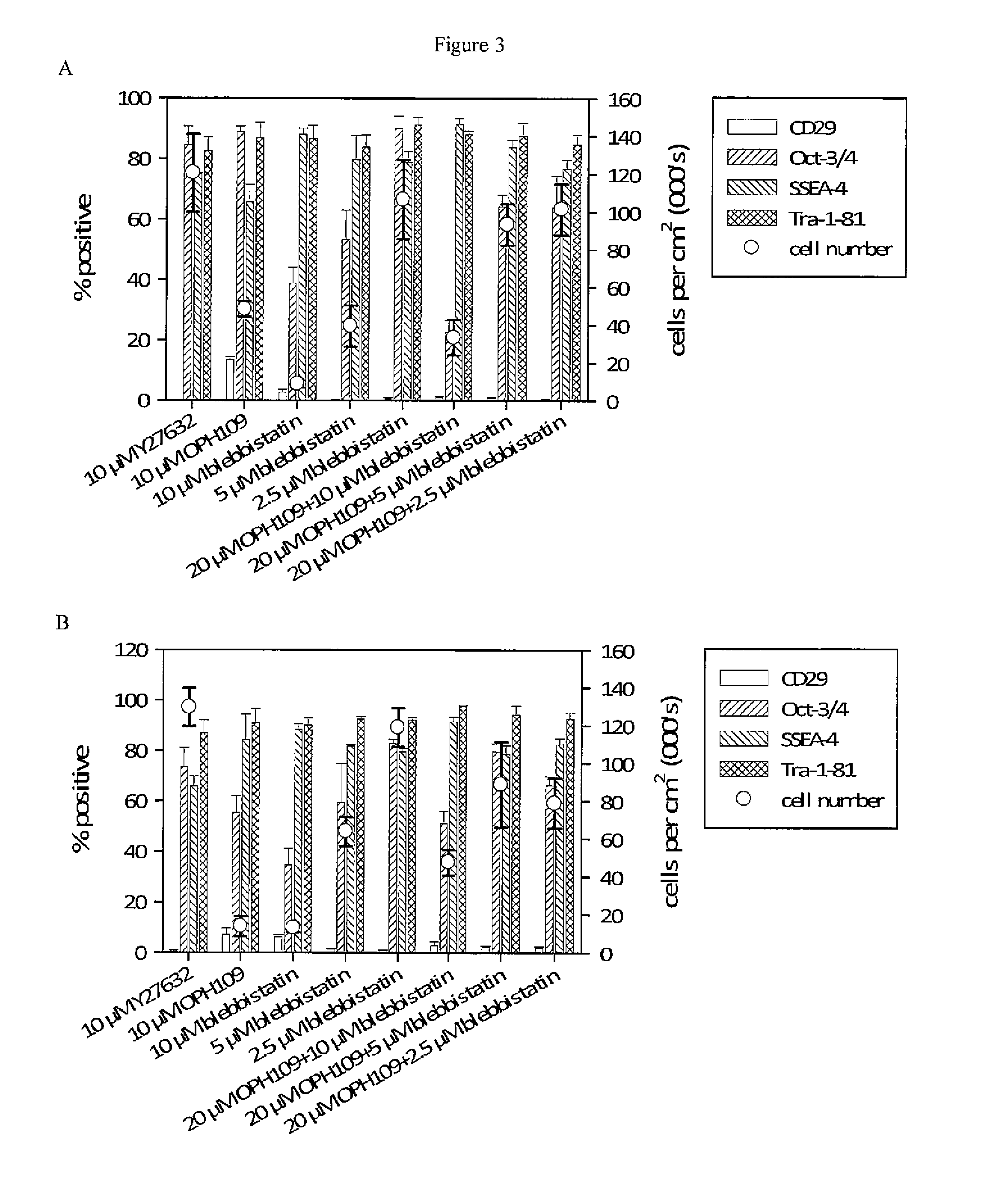

Media and methods for cell culture

InactiveUS20130071927A1Reduce the numberDelayed expansionOrganic chemistryCulture processCell culture mediaMicrobiology

The present invention provides a cell passaging medium comprising at least one agent capable of detaching from a surface a cell that is culture in vitro on said surface, and a water-soluble polymer capable of protecting the detached cell. The present invention also provides a cell culturing medium comprising one or more cell culture protectants capable of protecting cells in culture. The present invention further relates to the use of said media in methods for culturing cells in vitro or for deriving monolayer cell cultures of mammalian stem cells.

Owner:GENEA

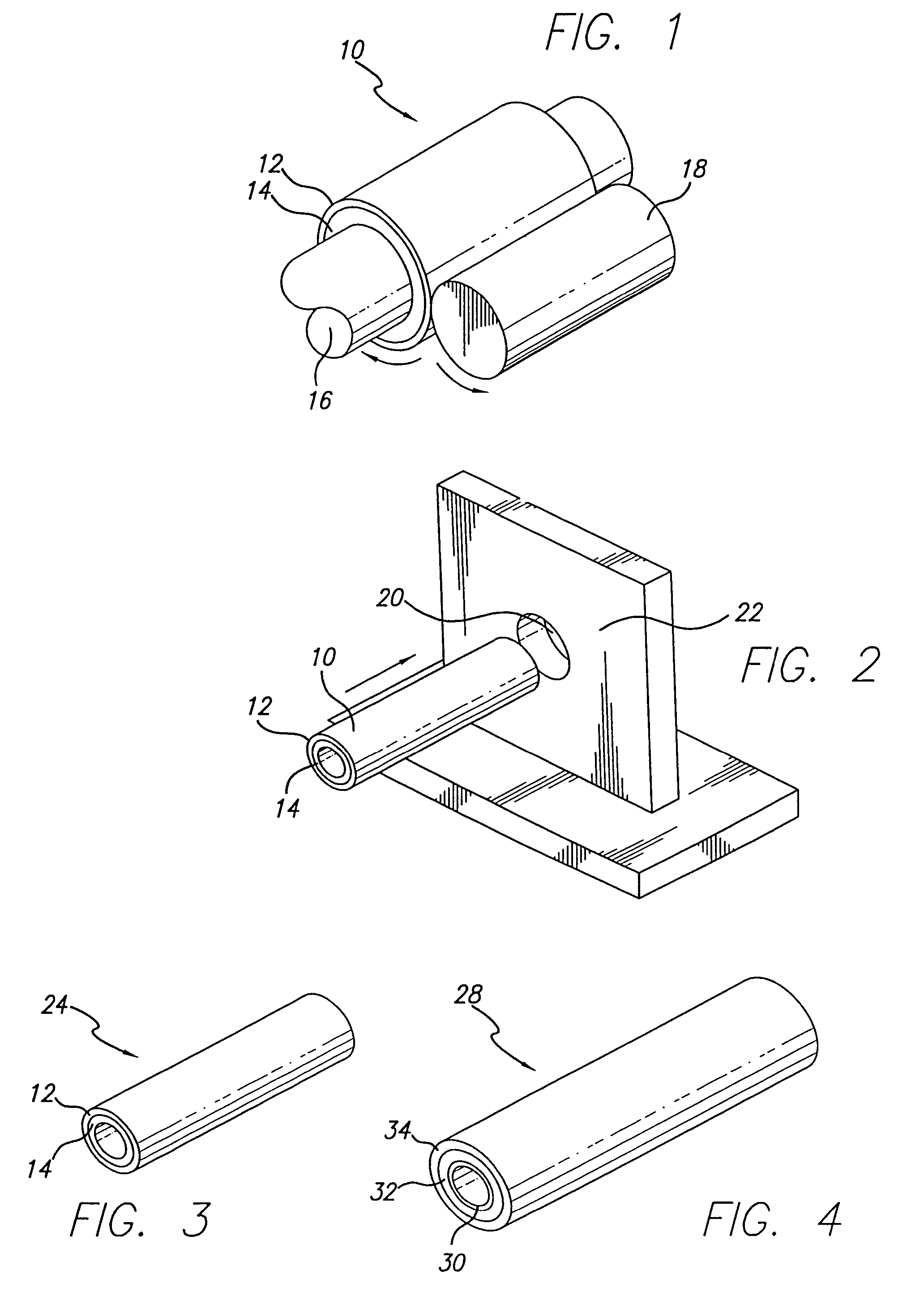

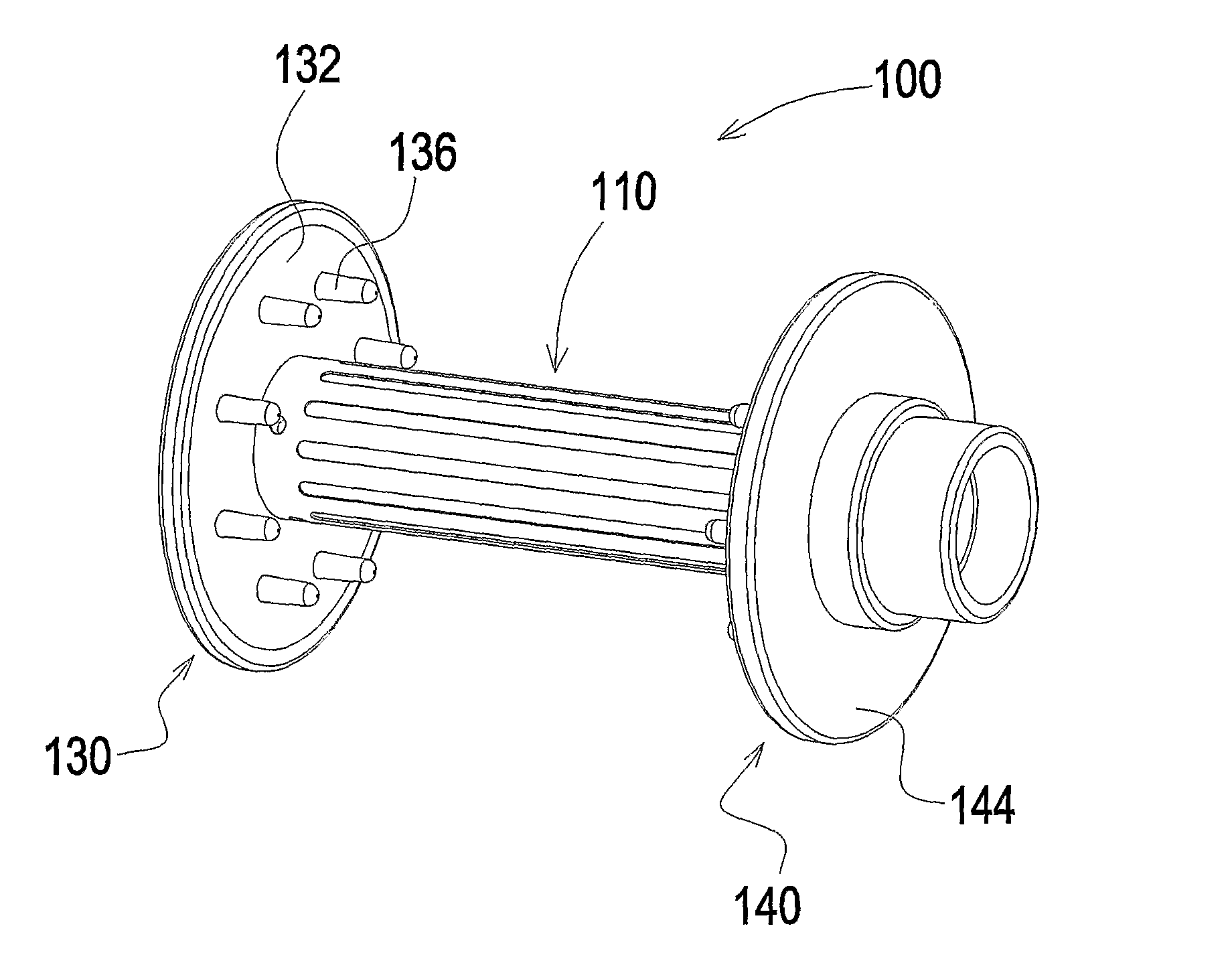

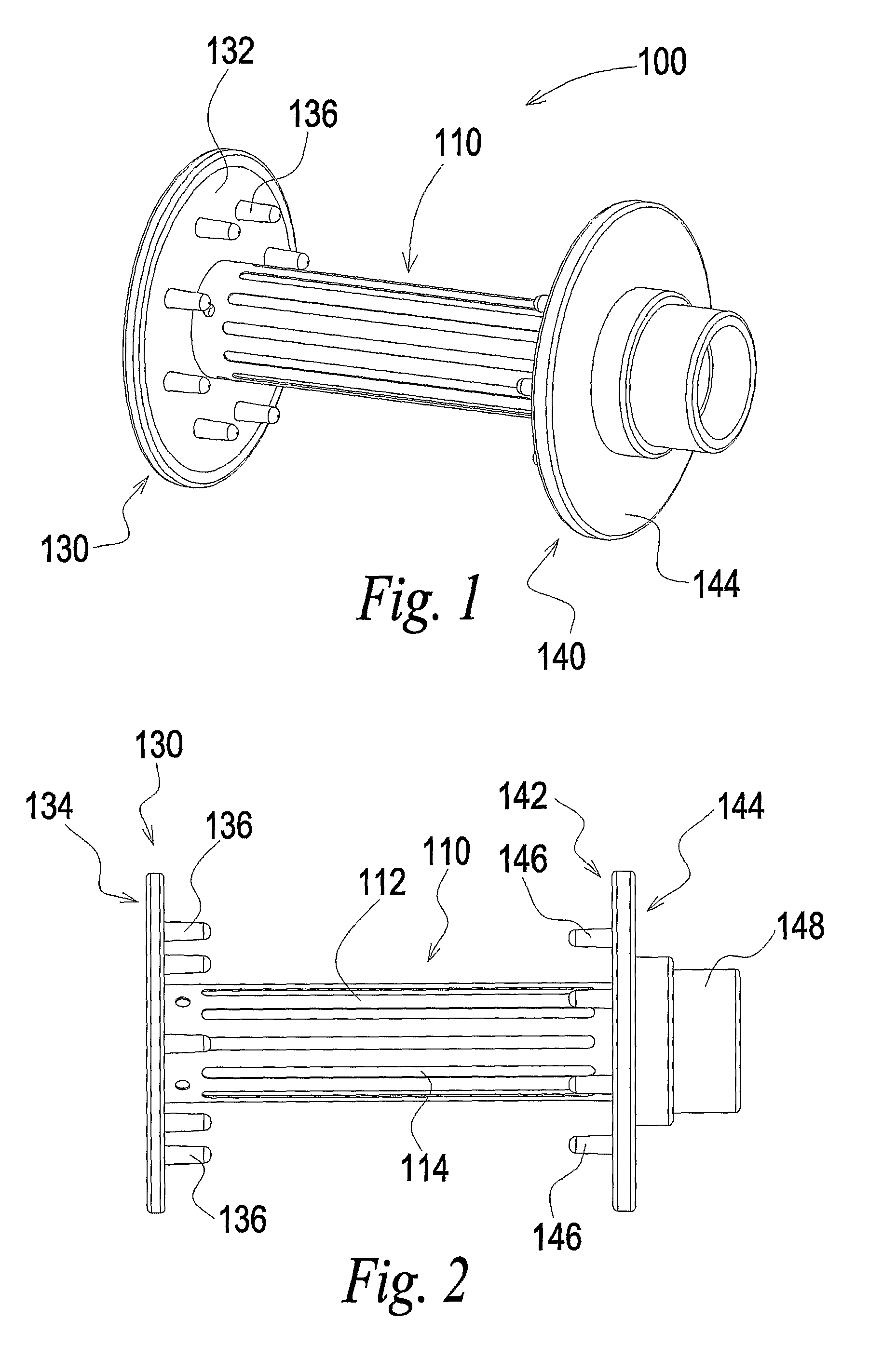

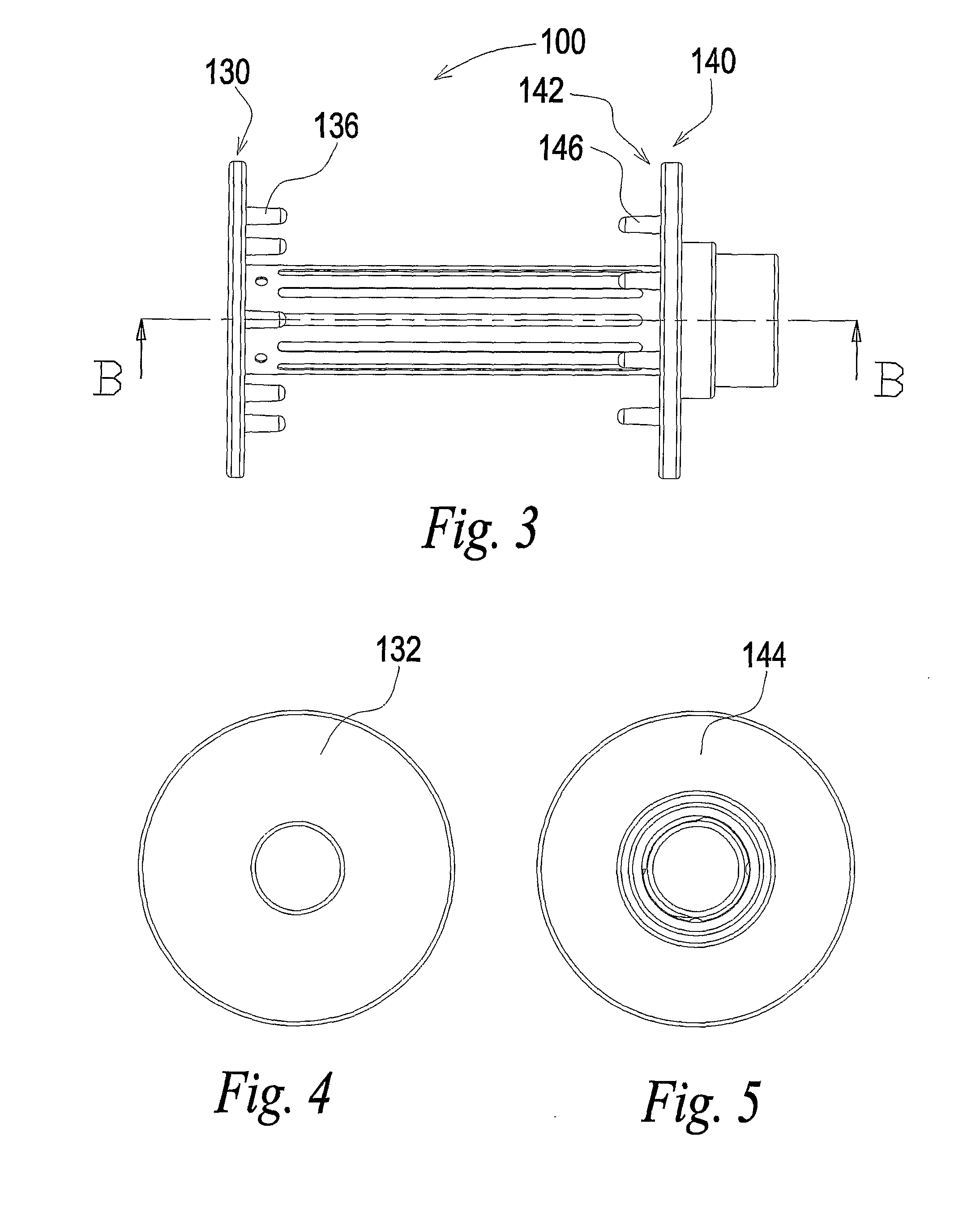

Expandable Roller

A hair roller includes a longitudinally extending hair curling portion defined between a pair of opposed end members. The hair curling portion is expandable and retractable in a radial direction with respect to the longitudinal axis of the hair curling portion, in response to relative movement of the end members with respect to each other.

Owner:DICKSON IND CO LTD

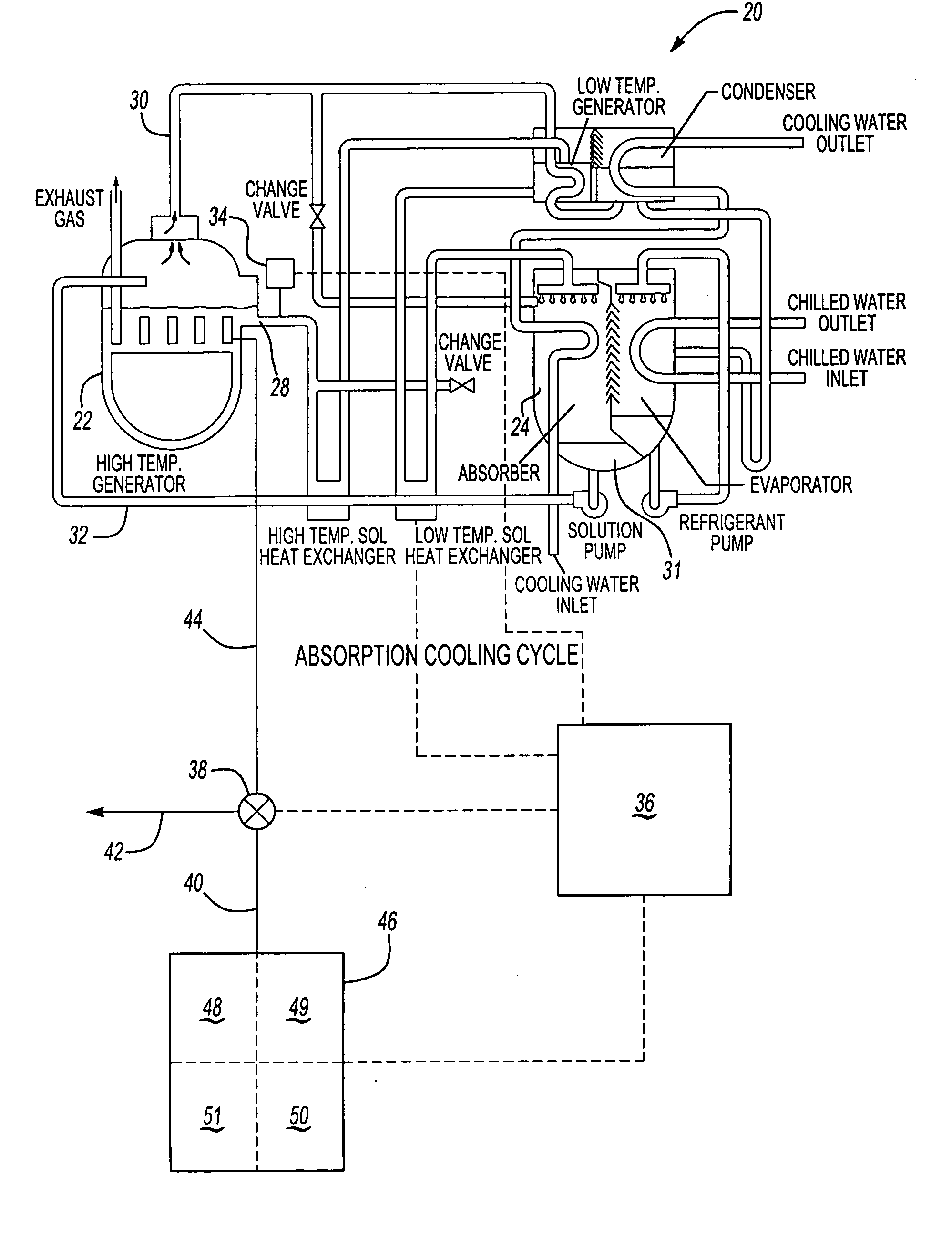

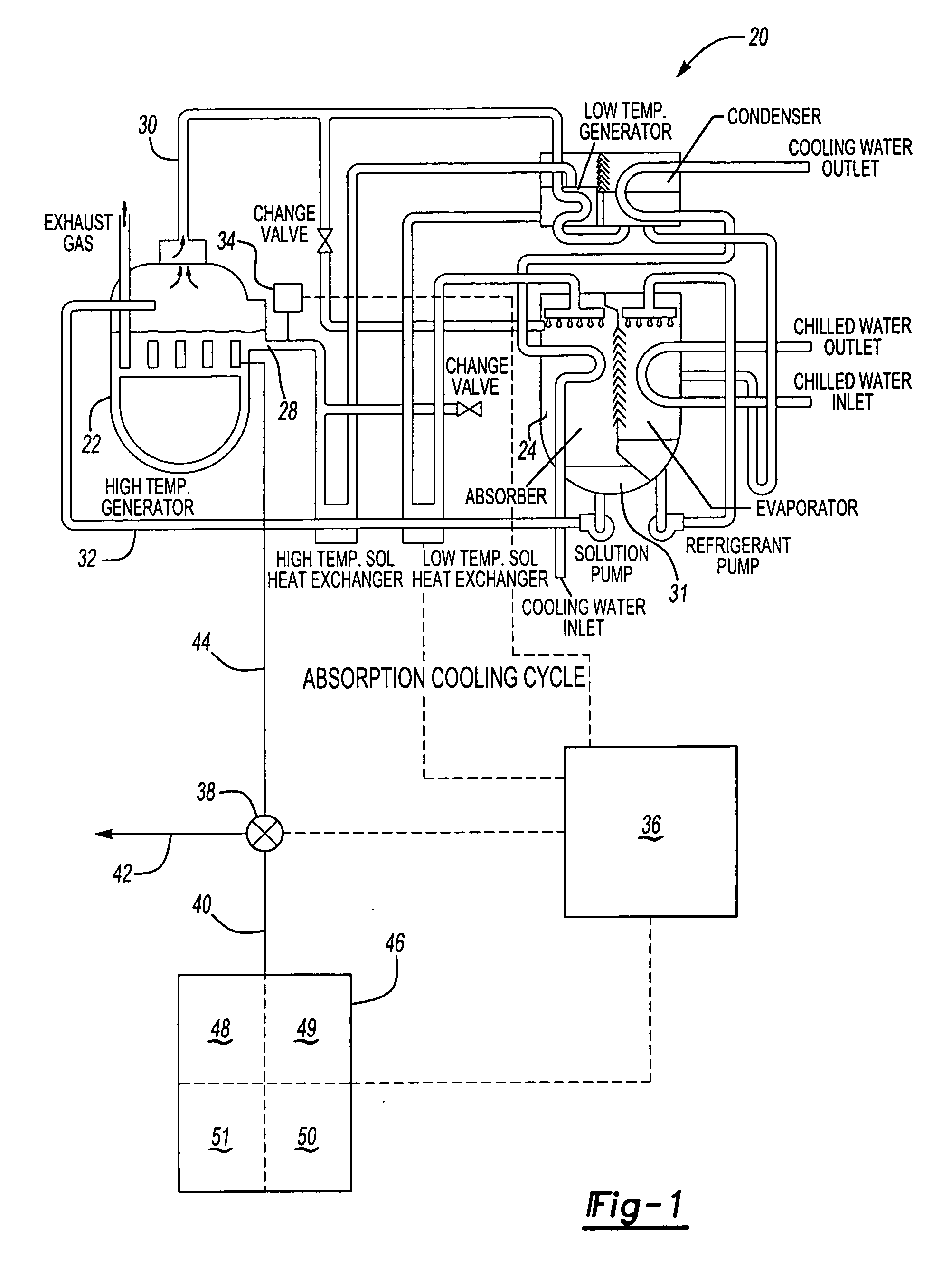

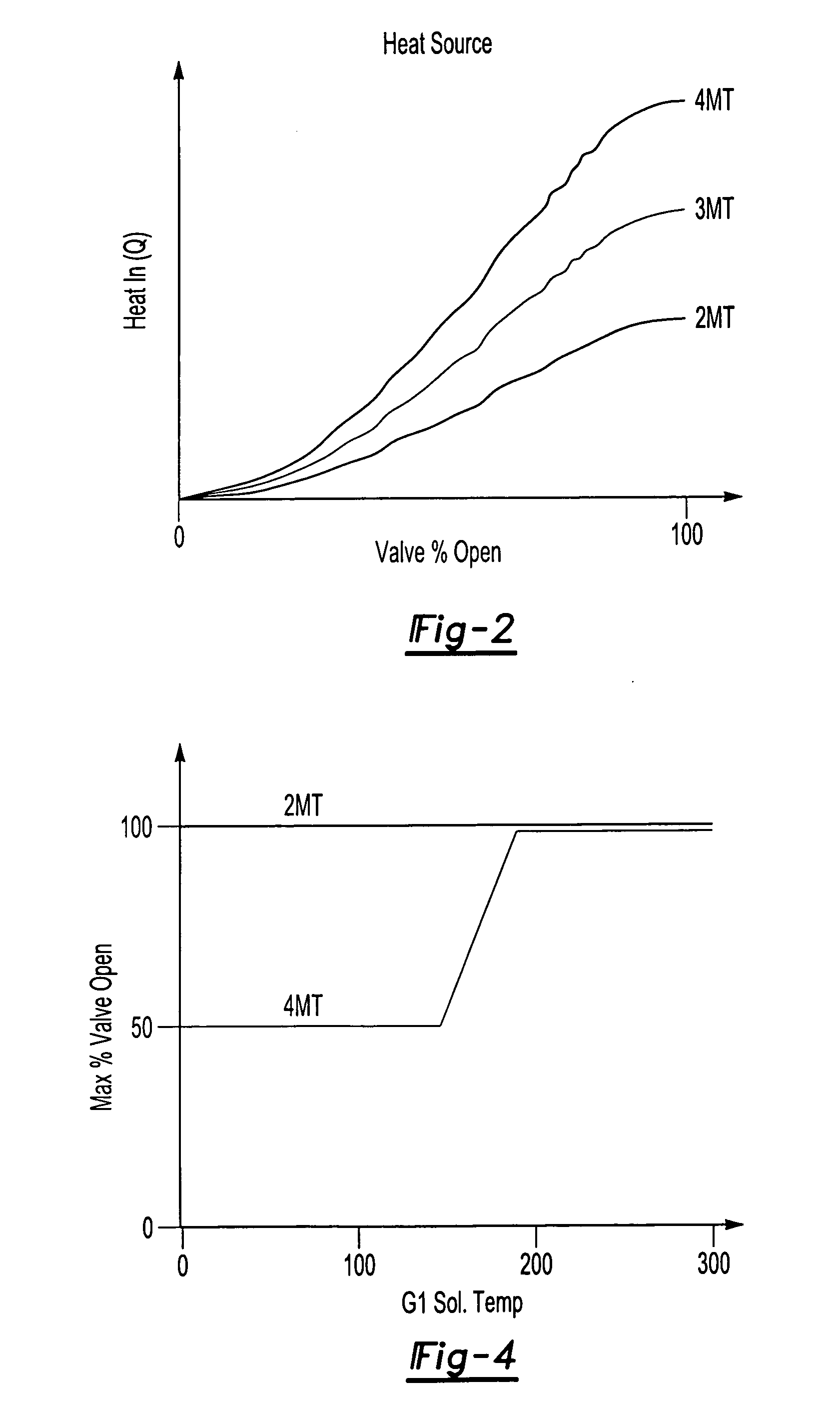

Efficient control for smoothly and rapidly starting up an absorption solution system

InactiveUS20050138938A1Delayed expansionRapid resultsBoilers/analysersClimate change adaptationSolution systemProcess engineering

An absorption chiller system has an efficient start-up control that monitors system condition, and in particular the absorption solution temperature. The system limits the amount of heat delivered into the absorption chiller generator, to provide a gradual rise in the absorption solution temperature at start-up. In this manner, undesirable noise vibration and rapid thermal expansion, which may have occurred in the past is reduced or eliminated.

Owner:CARRIER CORP

Preparation method of painted real-wood furniture crack repairing paste and crack repairing method

The invention discloses a preparation method of a painted real-wood furniture crack repairing paste and a crack repairing method, belonging to the field of painted wood component repairing. The preparation method comprises the following steps of: 1) grinding saw powder obtained by machining ailanthus into ailanthus debris of 50-150 meshes; 2) taking 200-300 parts by mass of sticky rice, adding into 800-1000 parts of water to boil, adding the ailanthus debris in the step 1) after the water is boiled, stirring while the ailanthus debris is added so as to obtain a mixed solution of the sticky rice and the ailanthus debris; and 3) boiling the mixted solution of the sticky rice and the ailanthus debris in the step 2) for 30-60 minutes so as to obtain a paste mixture, adding 100-130 parts of epoxy resin, 45-75 parts of polyacrylamide and 5-35 parts of hydroxypropyl guar gum, uniformly stirring, and putting out the fire so as to obtain the painted real-wood furniture crack repairing paste. By utilizing the painted real-wood furniture crack repairing paste, the cracks of real-wood furniture can be effectively filled, and the paste can be solidly bonded with the wood, so that the expansion of the cracks is effectively prevented.

Owner:FUJIAN OUPINXUAN BAMBOO & WOOD FURNITURE CO LTD

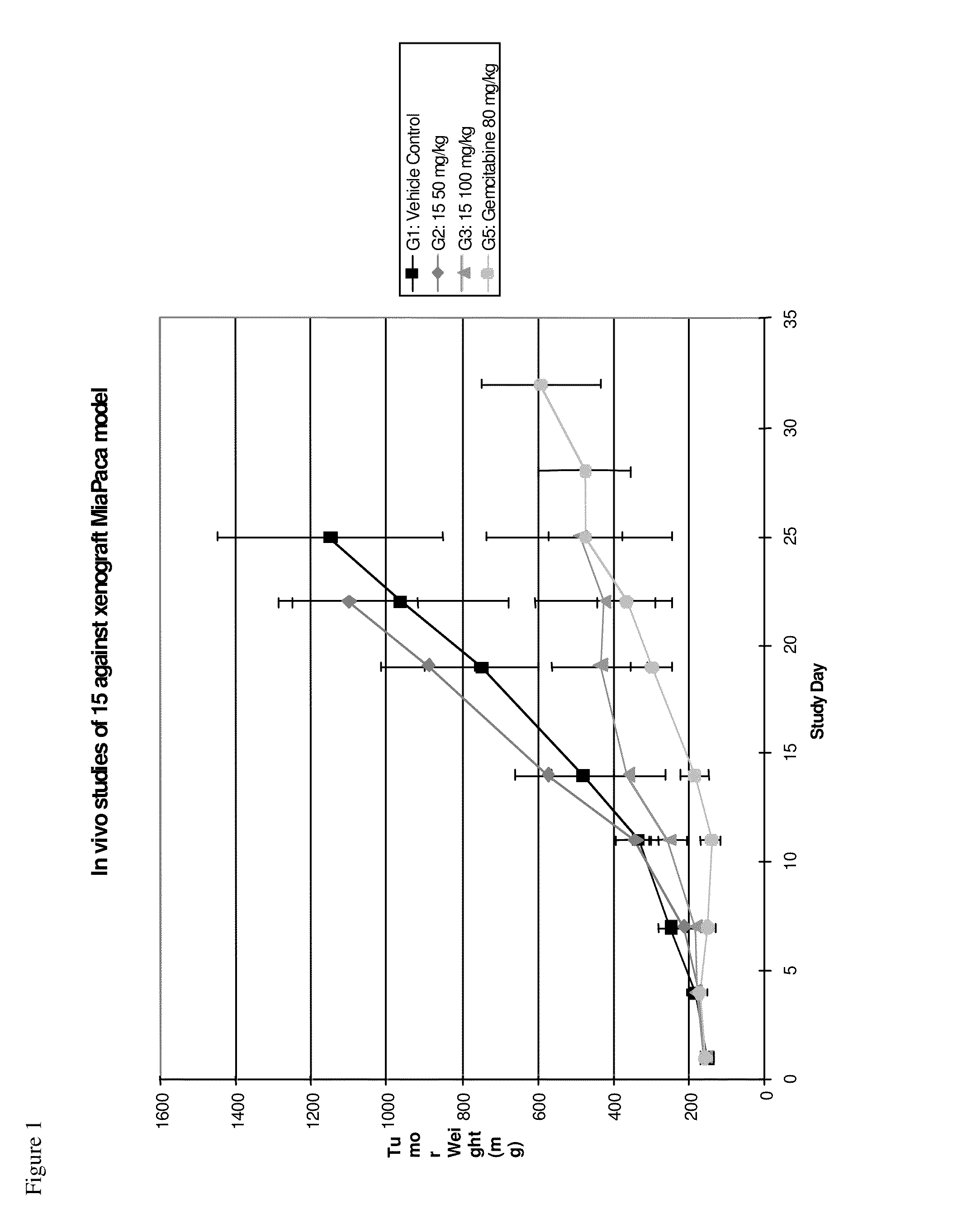

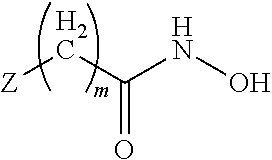

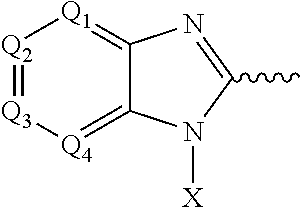

Compounds, pharmaceutical compositions and methods of use of hydroxamic acid derivatives

The invention encompasses a compound derived from hydroxamic acid that may be used to slow the expansion of cancer cells and thus is effective in the treatment of cancer. Generally, the disclosed compound includes a benzimidazole group coupled to a hydroxyamide of five or more unsubstituted carbon atoms and any pharmaceutically acceptable salts, solvates and chemically protected forms thereof. Also disclosed are pharmacological compositions including the compound and methods of using the compound to slow the expansion of cancer cells as well as methods of using the compound to treat cancer.

Owner:TRANSLATIONAL DRUG DEV LLC

Room-temperature high-plasticity wrought magnesium alloy and preparation method thereof

ActiveCN103866169AMeet the needs of plastic processingIncrease productivitySmelting processGrain structure

The invention provides room-temperature high-plasticity wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components by weight percent: 5.5wt%-7.3wt% of Al, 0.40wt%-1.50wt% of Zn, 0.15wt%-0.50wt% of Mn, 0.05wt%-1.0wt% of P and the balance being Mg and inevitable impurities, wherein the inevitable impurities comprise the following components: not more than 0.05wt% of Si, not more than 0.004wt% of Fe, not more than 0.004wt% of Cu and not more than 0.002wt% of Ni. According to the magnesium alloy, a nonmetal element P is added in an existing magnesium alloy smelting process, a stable small grain structure is obtained under the action of the nonmetal element P, the room-temperature plasticity is improved, and the room-temperature processing and using requirements of finished products or semi-finished products can be met.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

Zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material and preparation method thereof

InactiveCN102179977AImprove fracture toughnessImprove mechanical propertiesCeramic layered productsIron borideUltrahigh temperature ceramics

The invention discloses a zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material and a preparation method thereof, relating to a ultrahigh-temperature ceramic material and a preparation method thereof, wherein the material can be used for solving the problem that the existing boride ultrahigh-temperature ceramic matrix composite material has poor toughness. The zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material is prepared by laminating residual compressive stress layers and residual tensile stress layers alternatively. The preparation method comprises the following steps: 1. weighing raw materials; 2. preparing residual compressive stress layer powder and residual tensile stress layer powder; 3. preparing a laminated mixture; 4. carrying out sintering and heat insulation on the laminated mixture to obtain the zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material. The fracture toughness value of the zirconium boride-silicon carbide laminated composite ultrahigh-temperature ceramic material can reach up to 10.4MPaml / 2. In the invention, the preparation process is simple, the cost is low, and the fracture toughness is improved without influencing the strength of the material.

Owner:HARBIN INST OF TECH

A kind of ultra-high strength and high toughness multi-step isothermal bainitic steel and its preparation method

The invention relates to an ultra-high-strength, high-toughness multi-step isothermal bainite steel and a preparation method thereof. The technical solution is: first austenitize the hot-rolled billet at 850-1100°C for 0.2-5.0 hours, and then perform bainite multi-step isothermal transformation to obtain ultra-high strength and high toughness multi-step isothermal bainite steel . The multi-step isothermal transformation is as follows: the first step is to incubate in an isothermal medium for 0.2 to 3.0 hours at 250 to 450°C, the second step is to incubate in an isothermal medium for 2 to 50 hours at 220 to 350°C, and the third The first step is to keep warm in isothermal medium at 180-250°C for 24-240 hours, and the fourth step is to keep warm in isothermal medium at 150-220°C for 50-360 hours, and then cool to room temperature. The multiple steps are the first step to the second step, or the first step to the third step, or the first step to the fourth step. The bainite steel prepared by the invention has the characteristics of high hardness, high strength, high toughness, good volume stability and fine microstructure.

Owner:WUHAN UNIV OF SCI & TECH

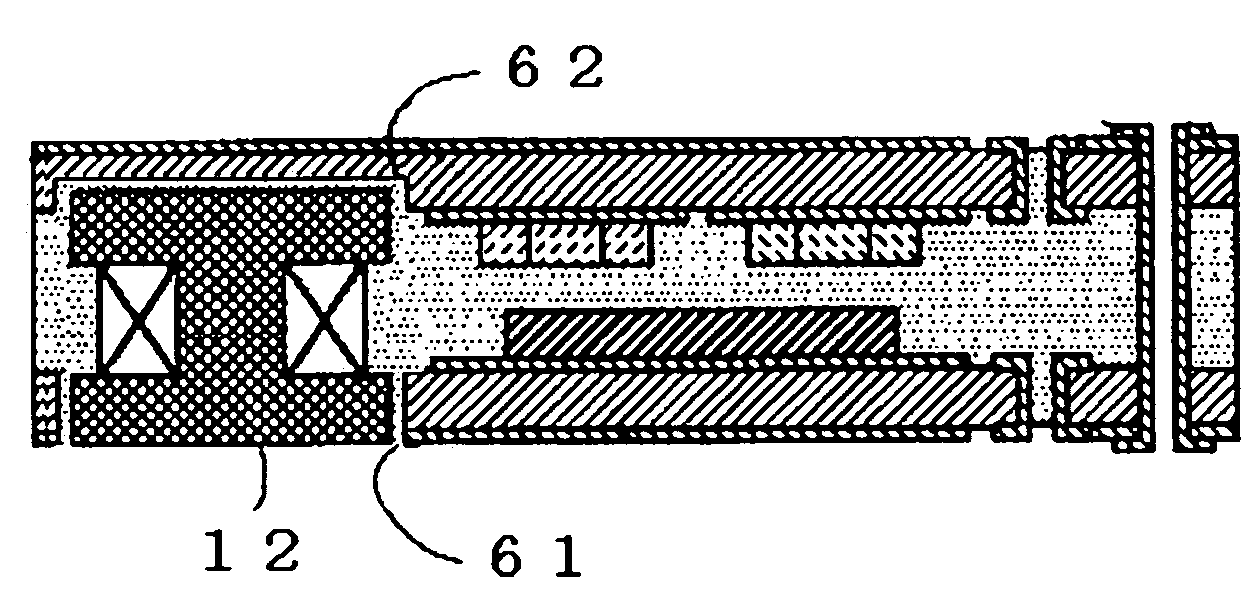

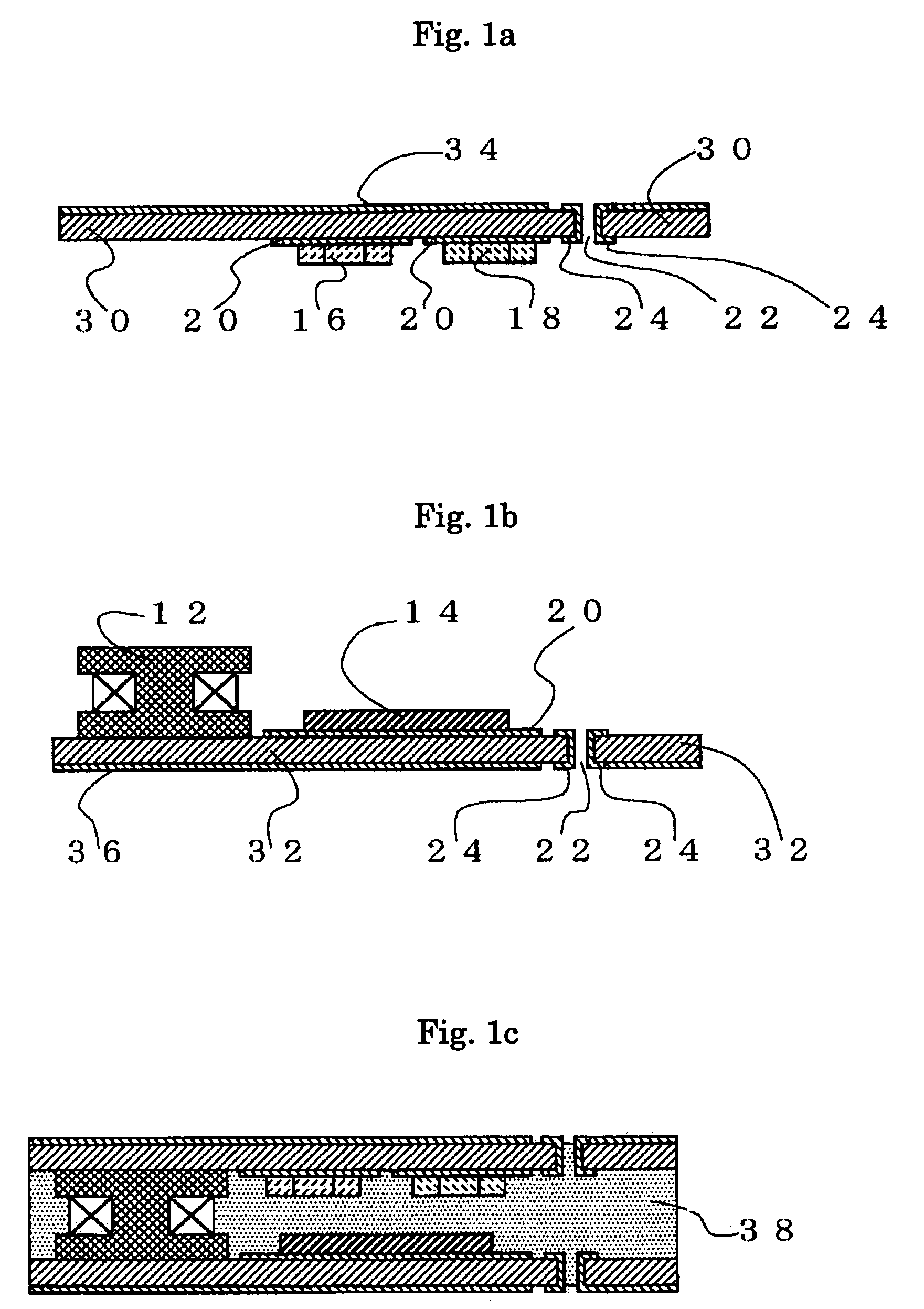

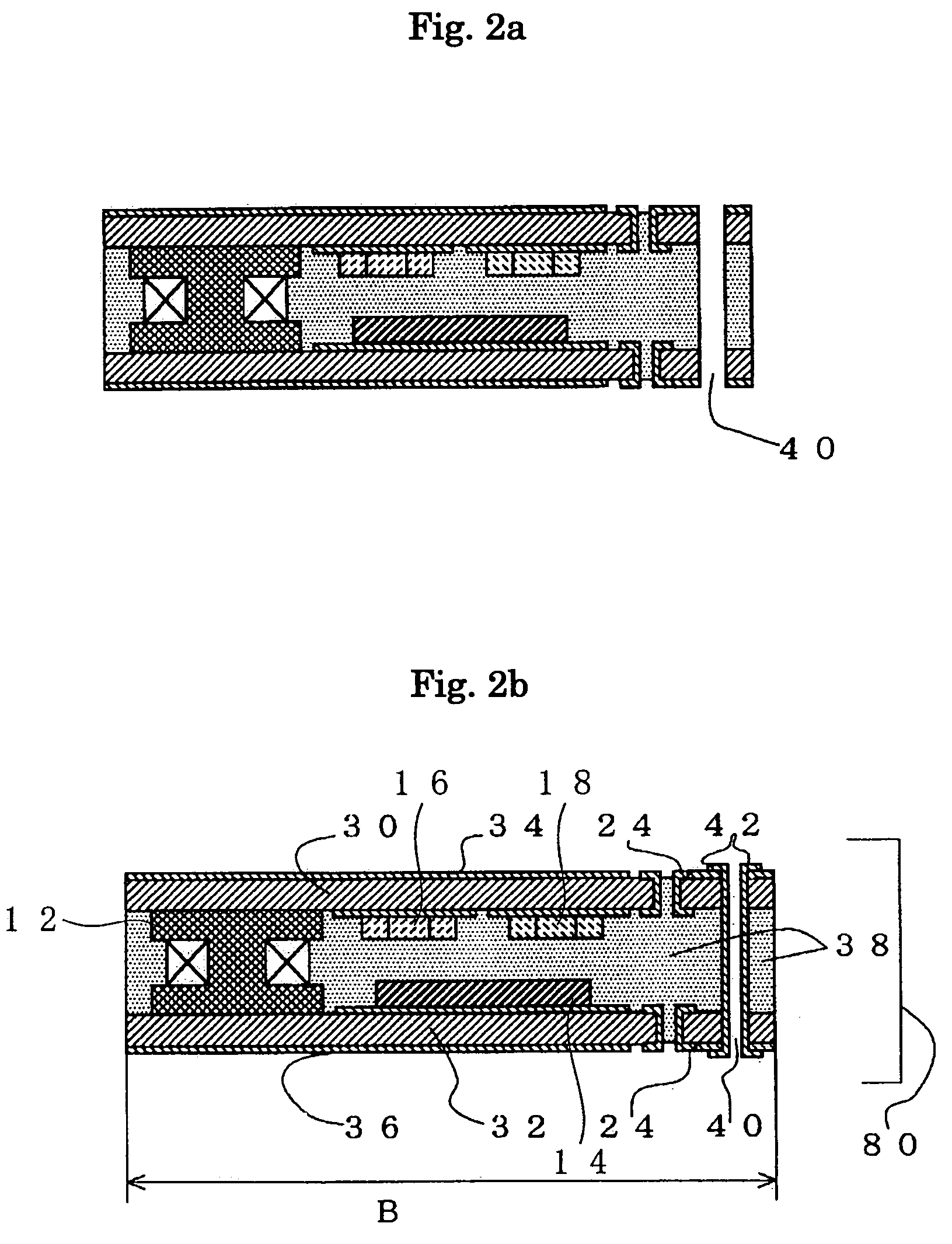

Electronic package and packaging method

InactiveUS7288728B2Small sizeRelieve pressureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringCapacitor

A first substrate includes a coil assembly and an integrated circuit mounted thereon. A second substrate includes capacitors 16 and resistors mounted thereon. The first substrate and the second substrate are interconnected by an encapsulating medium. A conductive via is provided to electrically connect the first substrate and the second substrate together

Owner:CITIZEN ELECTRONICS CO LTD

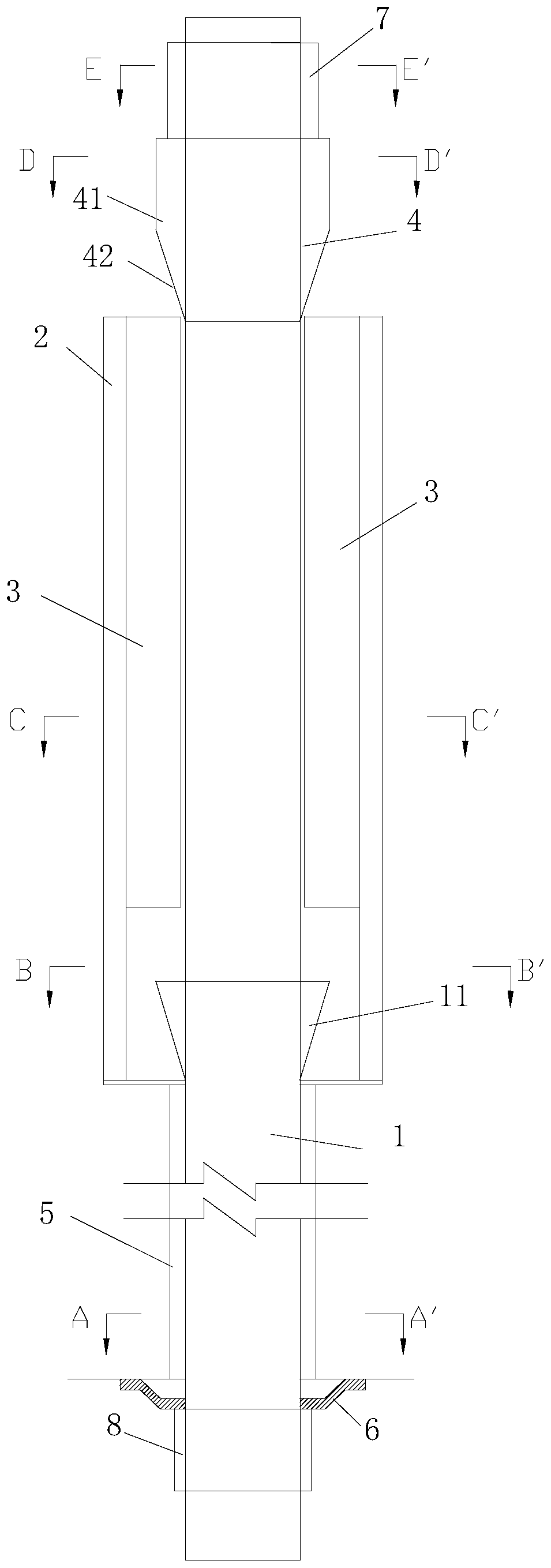

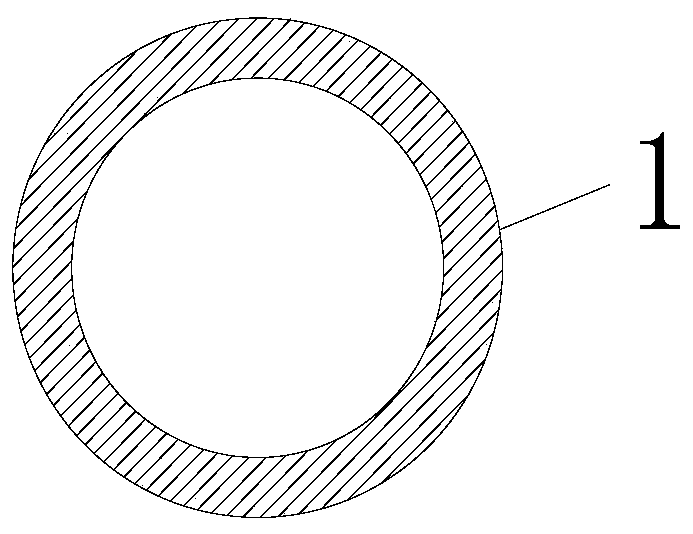

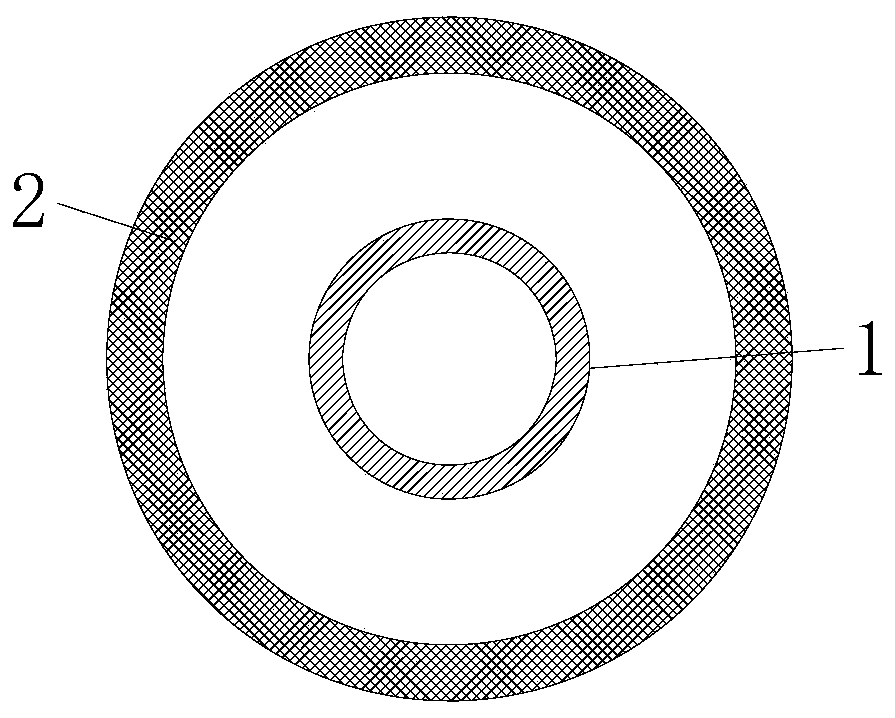

Pressure tube friction type extendable anchor rod

The invention belongs to the technical field of road tunnel support, and discloses a pressure tube friction type extendable anchor rod which comprises an anchor rod and a sleeve, wherein the anchor rod is sleeved with the sleeve; damping tubes are disposed between the side wall of the sleeve and the side wall of the anchor rod; a damping block is disposed at the upper end of the anchor rod; a straight section is arranged at the upper part of the damping block; a tapered section is disposed at the lower part of the damping block; the cross-sectional area of the upper part of the tapered sectionis greater than the cross-sectional area of the lower part of the tapered section; and the damping tubes are deformable in the radial direction. The extendable anchor rod has the advantages that by arranging the damping block and the damping tubes, the damping block continuously squeezes the damping tubes on both sides when entering the sleeve, so that a certain frictional force is generated between the damping block and the damping tubes, and when the surrounding rock deformation in a tunnel occurs, the constant resistance of large deformation is continuously provided by the frictional forceso as to delay the expansion of a plastic zone to accommodate the large deformation.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +2

JPEG image bit stream encryption method based on alternating current statistical characteristic change

ActiveCN109889687AImprove securityIncrease aggressivenessDigital video signal modificationComputer hardwareBitstream encryption

The invention discloses a JPEG image bit stream encryption method based on alternating current statistical characteristic change. The method comprises: in a JPEG bit stream, a user selects the last non-zero communication coefficient entropy code in a part of image blocks by using a user key to encrypt; hiding the secret information into a part of image block entropy codes through a histogram translation method; statistical characteristics are obtained through a user secret key and an alternating current coefficient, a direct current coefficient encryption secret key and an alternating currentcoefficient encryption secret key are generated in a self-adaptive mode, inter-group scrambling and differential coding iteration scrambling are carried out on the direct current coefficient, and intra-block scrambling and inter-block scrambling are carried out on the alternating current coefficient; and the receiver extracts secret information from the encrypted bit stream and decrypts the secretinformation, recovers the direct current coefficient and the alternating current coefficient encryption key according to the user key and the alternating current coefficient statistical characteristics in the encrypted bit stream, decrypts the alternating current coefficient and the direct current coefficient, recovers the alternating current coefficient entropy code in each image block entropy code, and obtains the original bit stream. The method is high in security and small in encrypted file expansion.

Owner:SOUTHWEST JIAOTONG UNIV

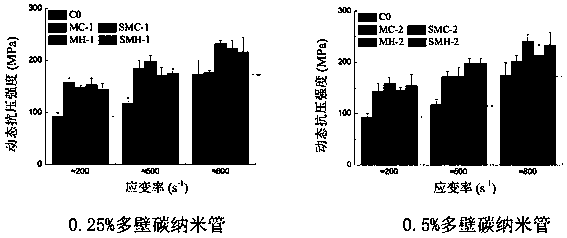

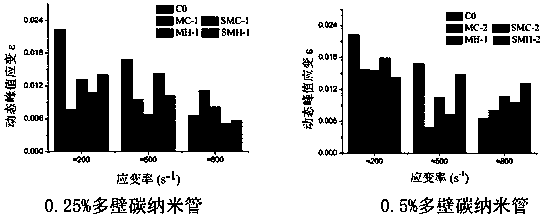

High-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete

The invention discloses a high-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete. The high-impact resistance surface functional group treated carbonnanotube modified reactive powder concrete is characterized in that the raw materials of the high-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete comprise cement, functionalized multi-walled carbon nanotubes, silica fume, fly ash, sands, a water reducer and water; and the functionalized multi-walled carbon nanotubes are carboxylated multi-walledcarbon nanotubes or hydroxylated multi-walled carbon nanotubes. The functionalized multi-walled carbon nanotubes can significantly enhance the dynamic compressive strength, dynamic peak strain and impact toughness of the reactive powder concrete. When the strain rate is in a range of 200-800 / s and the dosage of the multi-wall carbon nanotubes is 0.25-0.5%, the dynamic compressive strength of concrete can be increased by 71.3%, the dynamic peak strain can be increased by 101. 1%, and the impact toughness can be increased by 100.8%.

Owner:DALIAN UNIV OF TECH

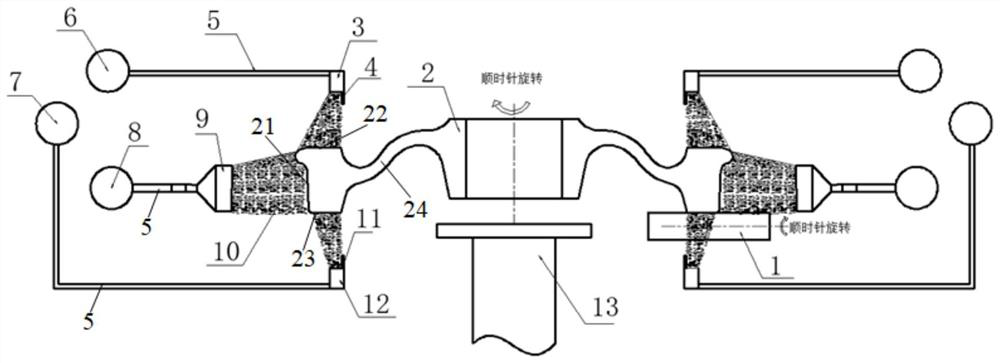

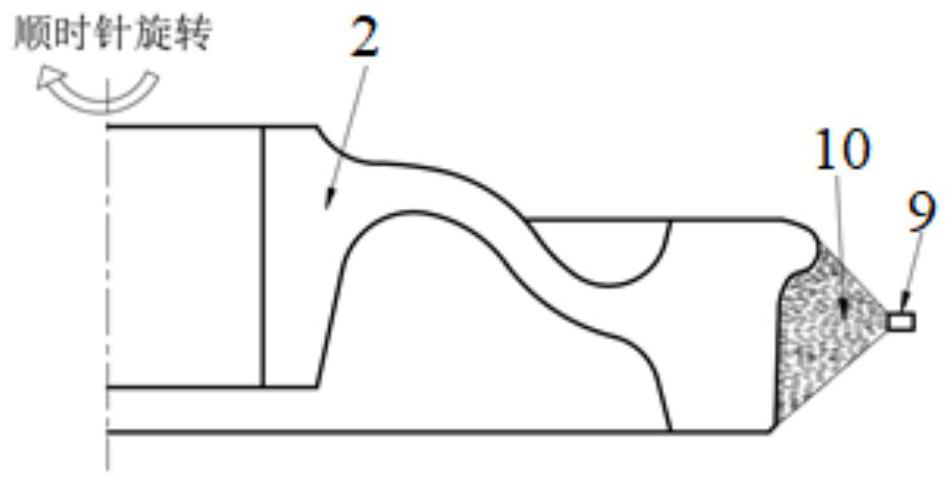

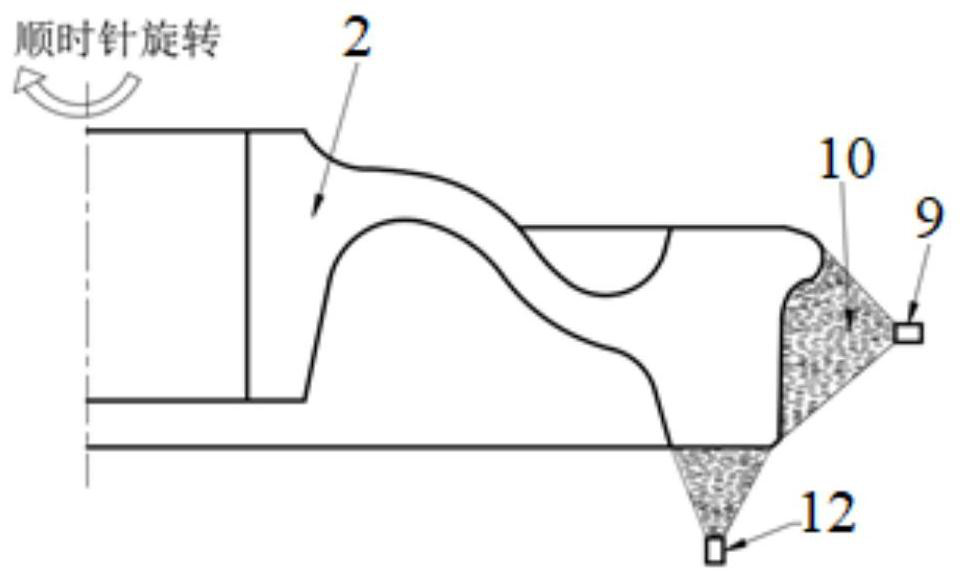

Heat treatment process for wheel

ActiveCN113046540AHigh hardnessImprove toughnessFurnace typesHeat treatment process controlTemperingPearlite

The invention discloses a heat treatment process for a heavy-load wheel. The heat treatment process comprises the steps of: a, heating a rolled wheel; b, quenching the wheel; and c, tempering and cooling the wheel. In the heat treatment process for the heavy-load wheel, a quench cooling device used for quench cooling of the wheel is included, the quench cooling device comprises a carrier roller platform for supporting the wheel, nozzles for carrying out quench cooling on a wheel tread and a wheel rim surface, and a cooling mechanism for quench cooling of the nozzles; the wheel is placed on the carrier roller platform; the nozzles are evenly distributed in the circumferential direction of the carrier roller platform and connected with the cooling mechanism; carrier rollers rotate to drive the wheel to rotate; and quench cooling liquid is evenly sprayed on the wheel tread and the wheel rim surface. According to the quench cooling mode and the heat treatment process for the wheel, on the premise that the microstructure of conventional high-carbon steel AAR-C is still kept to be fine pearlite and a small amount of ferrite, the wheel has high hardness, high toughness and high plasticity at the same time, and the wear resistance and safety of the heavy-load wheel with the axle load of 40 tons are met.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com