Fold-out shelving unit made of cardboard or a similar material

a shelving unit and cardboard technology, applied in the direction of show shelves, show hangers, show stands, etc., can solve the problems of self-expansion of the fold-out shelving unit, the risk of shelf panels sagging or failing, and the inability or fairly complex to incorporate elastic members arranged to push the shelving unit towards the expanded position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

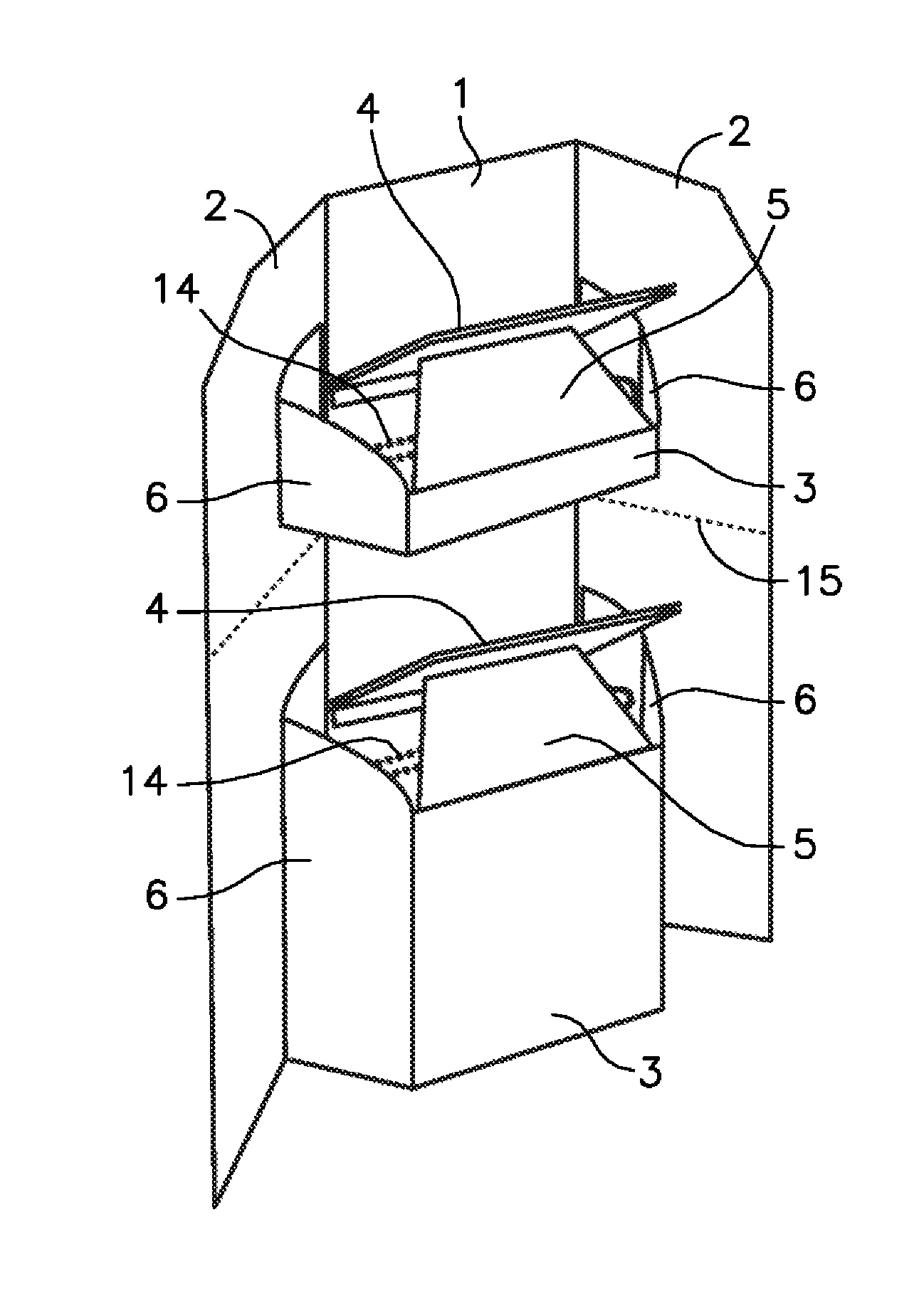

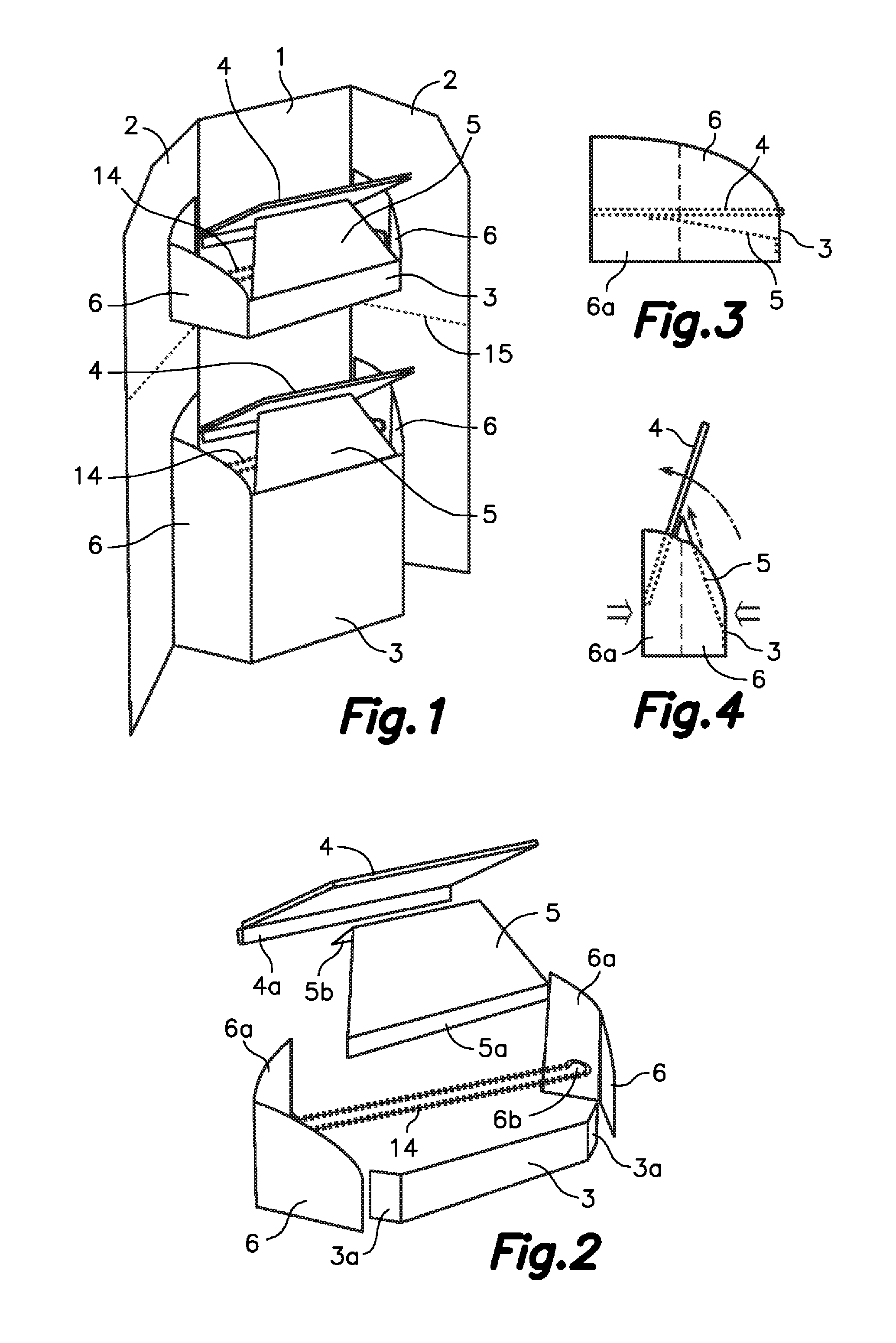

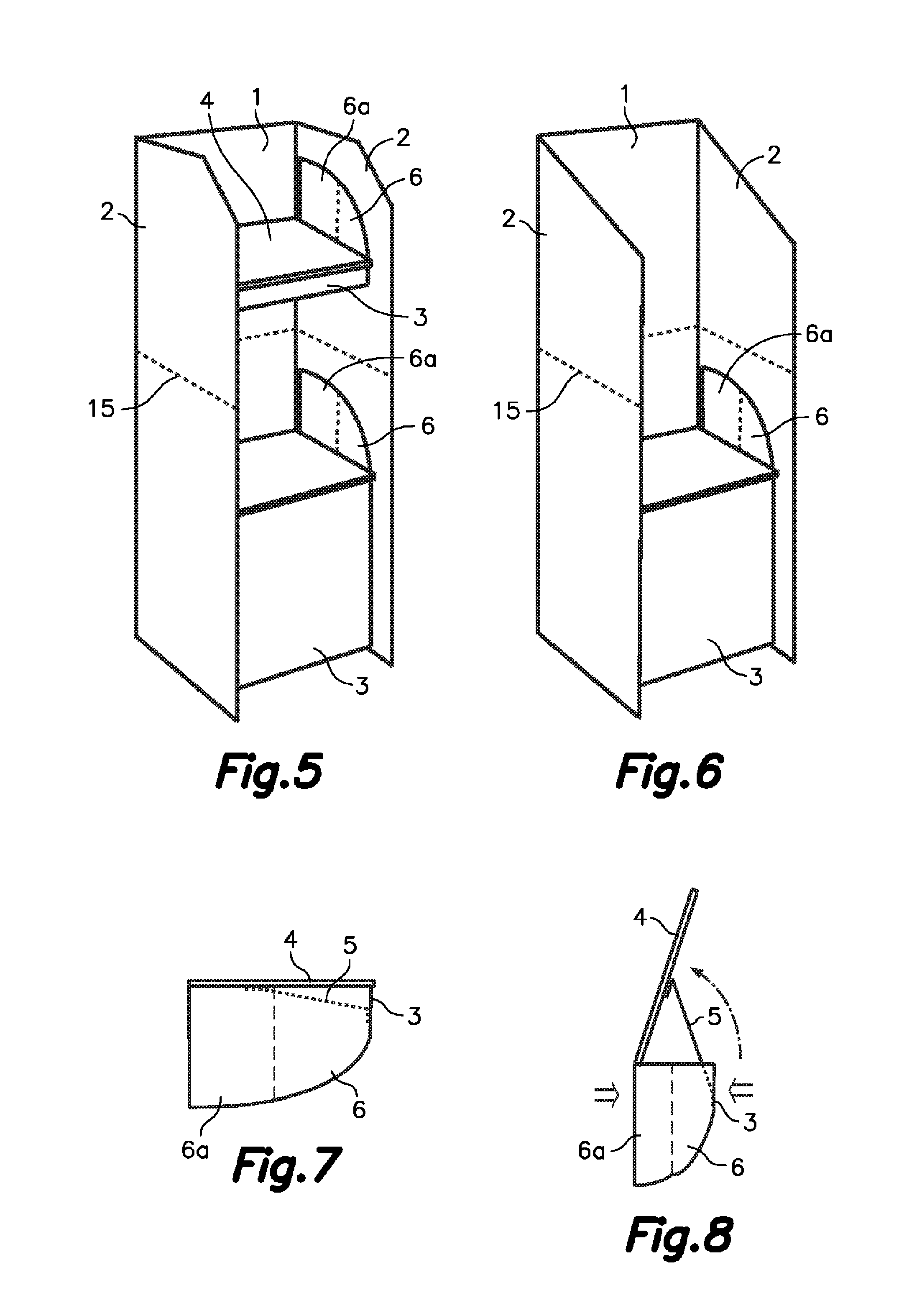

[0064]With reference, firstly, to FIGS. 1 to 5, the fold-out shelving unit made of cardboard or a similar material according to one embodiment of the present invention comprises a rear panel 1 having opposite side edges and side panels 2 hingedly attached to said opposite side edges of the rear panel 1 so that they can be moved between a folded position (not shown), wherein said side panels 2 and the rear panel 1 are substantially parallel or coplanar, and an expanded position (shown in FIG. 5), wherein the side panels 2 are substantially perpendicular to the rear panel 1.

[0065]Although it is not imperative, the rear and side panels 1, 2 are preferably made of one single piece, the hinged attachment therebetween comprising folding lines including split lines, partial cut-off lines or combinations of both. In addition, the rear and side panels 1, 2 preferably comprise a transversal folding line 15 substantially perpendicular to the side edges of the rear panel 1 that allows folding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com