Pressure tube friction type extendable anchor rod

A bolt and tube type technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of complex bolt structure, unfavorable market promotion, rare road tunnels, etc., and achieves easy popularization and application and long service life , the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The purpose of this embodiment is to provide a tube-type friction-type extensible anchor rod.

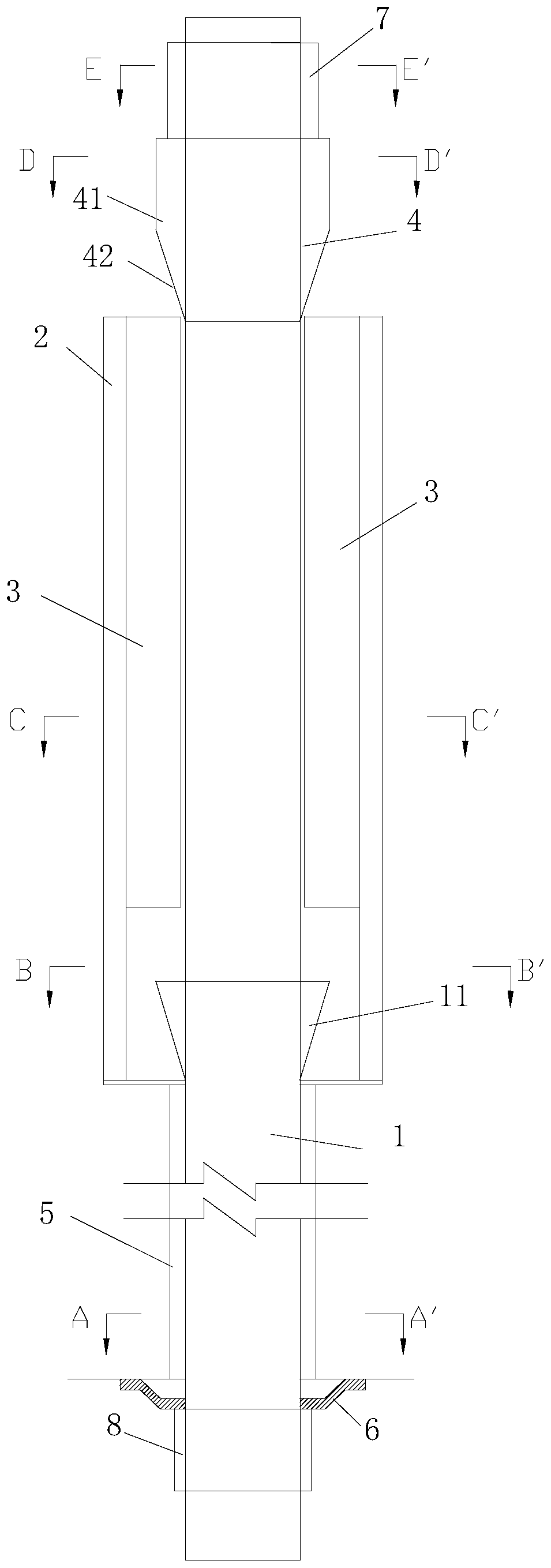

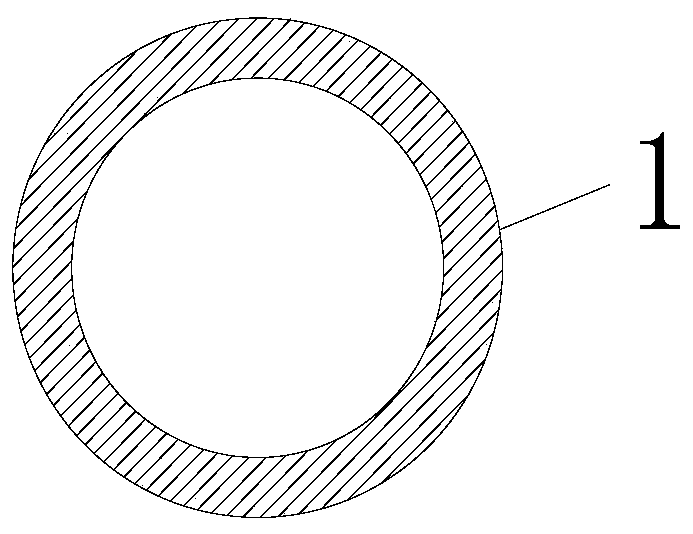

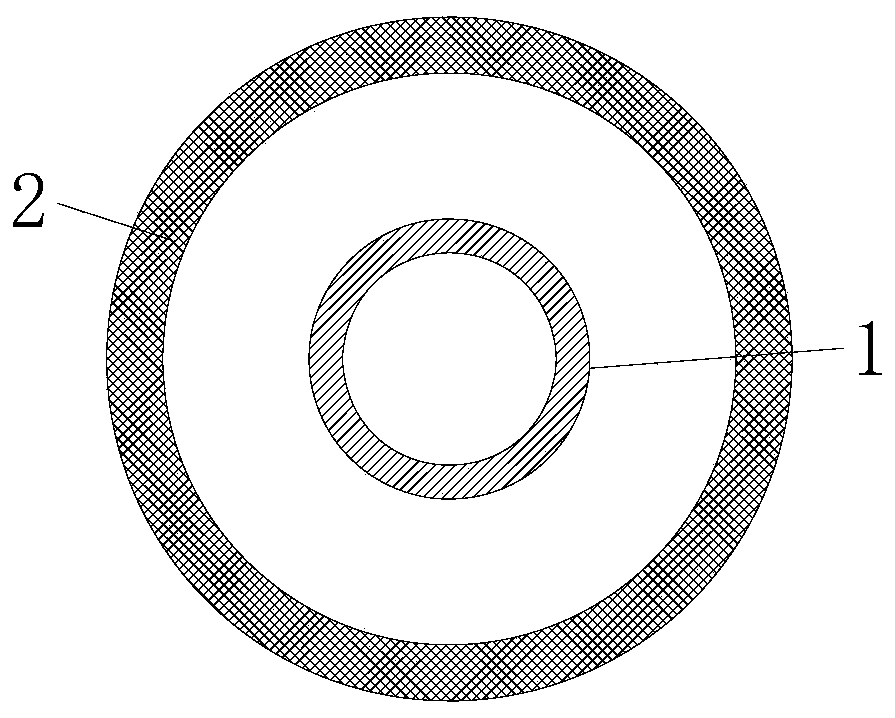

[0037] Such as figure 1 As shown, the tube-type friction-type extensible anchor includes an anchor 1 and a sleeve 2, the sleeve 2 is sleeved on the anchor 1, and the side wall of the sleeve 2 and the side wall of the anchor 1 A damping tube 3 is provided, and the damping tube 3 is welded on the side wall of the anchor rod 1. The upper end of the anchor rod 1 is fixed with a damping block 4. The upper part of the damping block 4 is a straight line segment 41, which is cylindrical, and the lower part of the damping block 4 Be the taper section 42, be conical frustum shape, the cross-sectional area of the top of the taper section 42 is greater than the cross-sectional area of the bottom of the taper section 42, namely the cross-section of the taper section 42 gradually becomes smaller from top to bottom, and the damping tube 3 can be deform in its radial direction.

[0038...

Embodiment 2

[0041] The purpose of this embodiment is to provide a tube-type friction-type extensible anchor rod.

[0042] Such as Figure 1-6 As shown, the tube-type friction-type extensible anchor includes an anchor 1 and a sleeve 2, the sleeve 2 is sleeved on the anchor 1, and the side wall of the sleeve 2 and the side wall of the anchor 1 A damping tube 3 is provided, and two slender damping tubes 3 are symmetrically welded on both sides of the anchor rod 1 respectively. The upper end of the anchor rod 1 is fixedly provided with a damping block 4, the upper part of the damping block 4 is a straight section 41, which is cylindrical, and the lower part of the damping block 4 is a tapered section 42, which is in the shape of a truncated cone, and the cross-sectional area of the upper part of the tapered section 42 is larger than The cross-sectional area of the lower part of the tapered section 42 , that is, the cross-section of the tapered section 42 gradually decreases from top to b...

Embodiment 3

[0047] The purpose of this embodiment is to provide a tube-type friction-type extensible anchor rod.

[0048] Such as Figure 1-6 As shown, the tube-type friction-type extensible anchor includes an anchor 1 and a sleeve 2, the sleeve 2 is sleeved on the anchor 1, and the side wall of the sleeve 2 and the side wall of the anchor 1 A damping tube 3 is provided, and two slender damping tubes 3 are symmetrically welded on both sides of the anchor rod 1 respectively. The upper end of the anchor rod 1 is fixedly provided with a damping block 4, the upper part of the damping block 4 is a straight section 41, which is cylindrical, and the lower part of the damping block 4 is a tapered section 42, which is in the shape of a truncated cone, and the cross-sectional area of the upper part of the tapered section 42 is larger than The cross-sectional area of the lower part of the tapered section 42 , that is, the cross-section of the tapered section 42 gradually decreases from top to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com