A kind of ultra-high strength and high toughness multi-step isothermal bainitic steel and its preparation method

An ultra-high-strength, bainite steel technology, applied in the field of ultra-high-strength steel, can solve the problems of insufficient plasticity and toughness, insufficient tensile strength, high alloying elements, etc., and achieve improved toughness and plasticity, increased strength, and volume stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

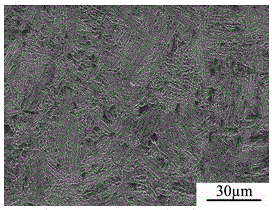

Embodiment 1

[0030] An ultra-high-strength, high-toughness multi-step isothermal bainite steel and a preparation method thereof. After molten iron is made and refined, die casting or continuous casting is carried out, followed by hot rolling. First austenitize the hot-rolled steel slab at 850-1000°C for 0.5-5.0 hours, and then perform bainitic multi-step isothermal transformation to obtain ultra-high strength and high toughness multi-step isothermal bainitic steel.

[0031] The multi-step isothermal transformation of the bainite is transformed into a two-step isothermal transformation: the first step is kept at 350-450°C in a salt bath for 0.2-1.0 hours, and the second step is kept at 250-350°C in a salt bath for 2-30 hours .

[0032] The ultra-high strength and high toughness multi-step isothermal bainite steel prepared in this example: the tensile strength is 1500~1800MPa; the hardness is 450~550HV; the elongation is 15~25%; the impact toughness is 45~60J / cm 2 .

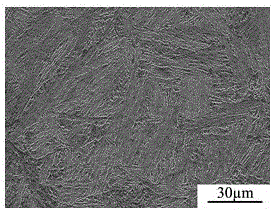

Embodiment 2

[0034] An ultra-high-strength, high-toughness multi-step isothermal bainite steel and a preparation method thereof. After steelmaking and refining, the scrap steel will be die-cast or continuous-cast and hot-rolled. First austenitize the hot-rolled billet at 950-1100°C for 0.2-4.0 hours, and then perform bainitic multi-step isothermal transformation to obtain ultra-high strength and high toughness multi-step isothermal bainitic steel.

[0035] The multi-step isothermal transformation of the bainite is transformed into a two-step isothermal transformation: the first step is kept at 250-350°C in an inert atmosphere for 1.0-3.0 hours, and the second step is kept at 220-300°C in an inert atmosphere 10~50 hours.

[0036] The ultra-high strength and high toughness multi-step isothermal bainitic steel prepared in this example: the tensile strength is 1500~1800MPa; the hardness is 450~550HV; the elongation is 15~25%; the impact toughness is 45~55J / cm 2 .

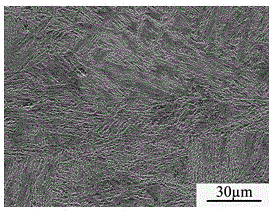

Embodiment 3

[0038] An ultra-high-strength, high-toughness multi-step isothermal bainite steel and a preparation method thereof. After the scrap steel is made and refined, die casting or continuous casting is carried out, and hot rolling is carried out. First austenitize the hot-rolled steel slab at 850-1000°C for 0.5-5.0 hours, and then perform bainitic multi-step isothermal transformation to obtain ultra-high strength and high toughness multi-step isothermal bainitic steel.

[0039] The multi-step isothermal transformation of the bainite is transformed into a three-step isothermal transformation: the first step is kept at 350-450°C in a salt bath for 0.2-1.0 hours, and the second step is kept at 250-350°C in a salt bath for 2-30 hours , the third step is to keep warm in an inert atmosphere at 220~250°C for 24~120 hours, and then cool to room temperature.

[0040] The ultra-high strength and high toughness multi-step isothermal bainite steel prepared in this example: the tensile strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com