Linear ion implantation surface modification method of M50NiL material

A technology of surface modification and ion implantation, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of material mechanical properties, bombardment damage, etc., to meet performance requirements, improve surface state, Effect of Excellent Contact Fatigue Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

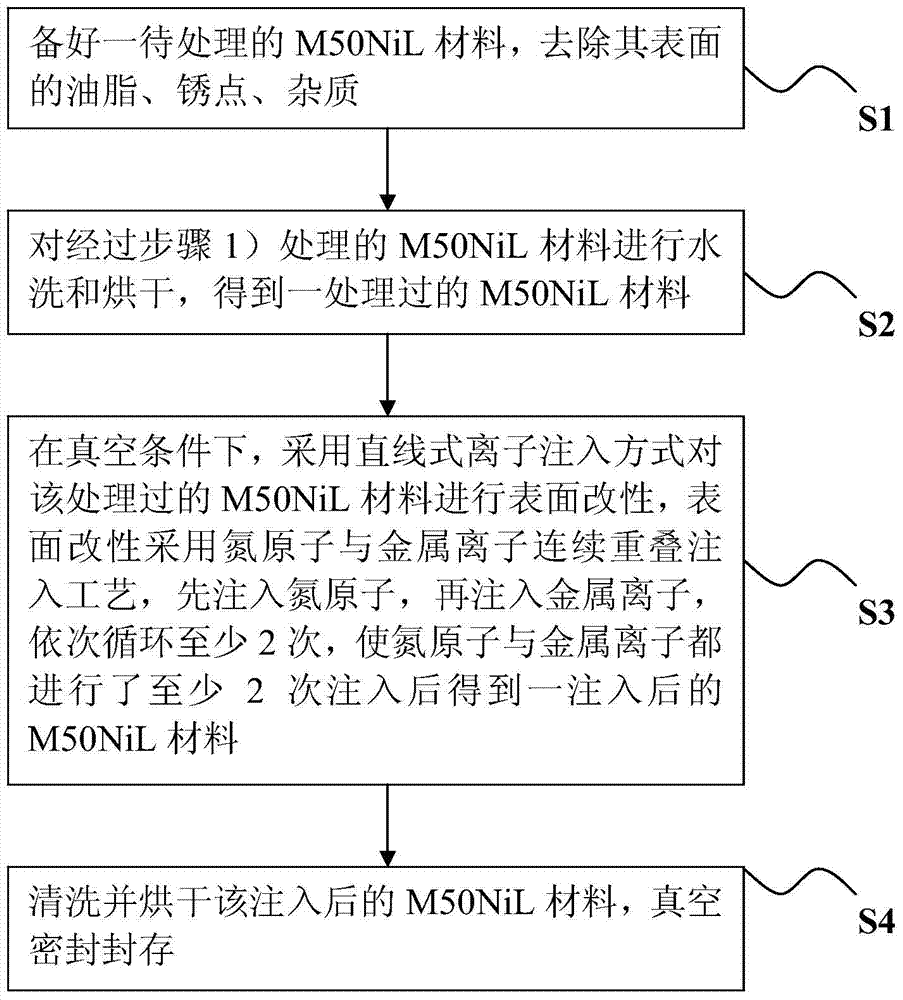

[0042] Step 1) Prepare a M50NiL material to be processed,

[0043] Remove the grease on its surface: first remove the grease on the surface of the M50NiL material to be treated with a metal degreasing solvent, then soak it in non-polluting tetrachlorethylene for 20 to 30 minutes, take it out, and use rice paper to absorb the residual solvent. Then wipe the surface of the material with absorbent cotton, and finally wipe it with a clean silk cloth; the metal degreasing solvent is a commercially available common metal degreasing solvent, and its ingredients include sodium hydroxide, sodium carbonate, sodium phosphate decahydrate, sodium silicate, washing Agents, corrosion inhibitors, solvent water, etc.; tetrachlorethylene for cleaning can also be replaced by other organic solvents.

[0044] Remove the rust spots on the surface of the M50NiL material: soak and clean the M50NiL material with a metal cleaning agent (metal rust remover) with rust removal function for 10-20 minutes, ...

Embodiment 1

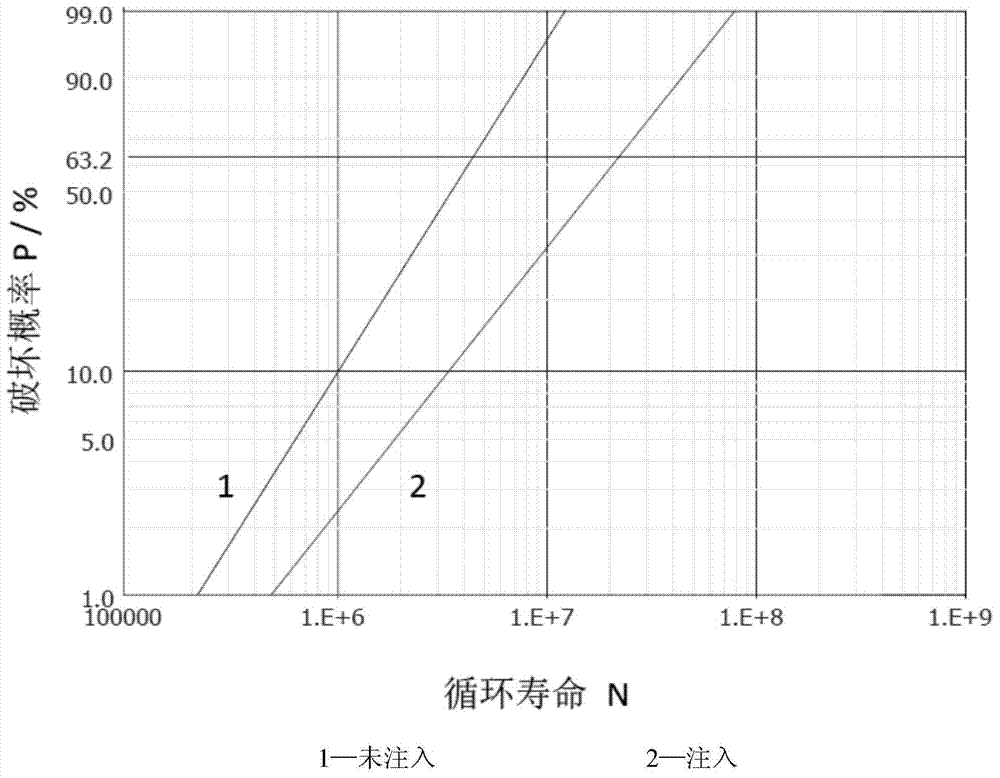

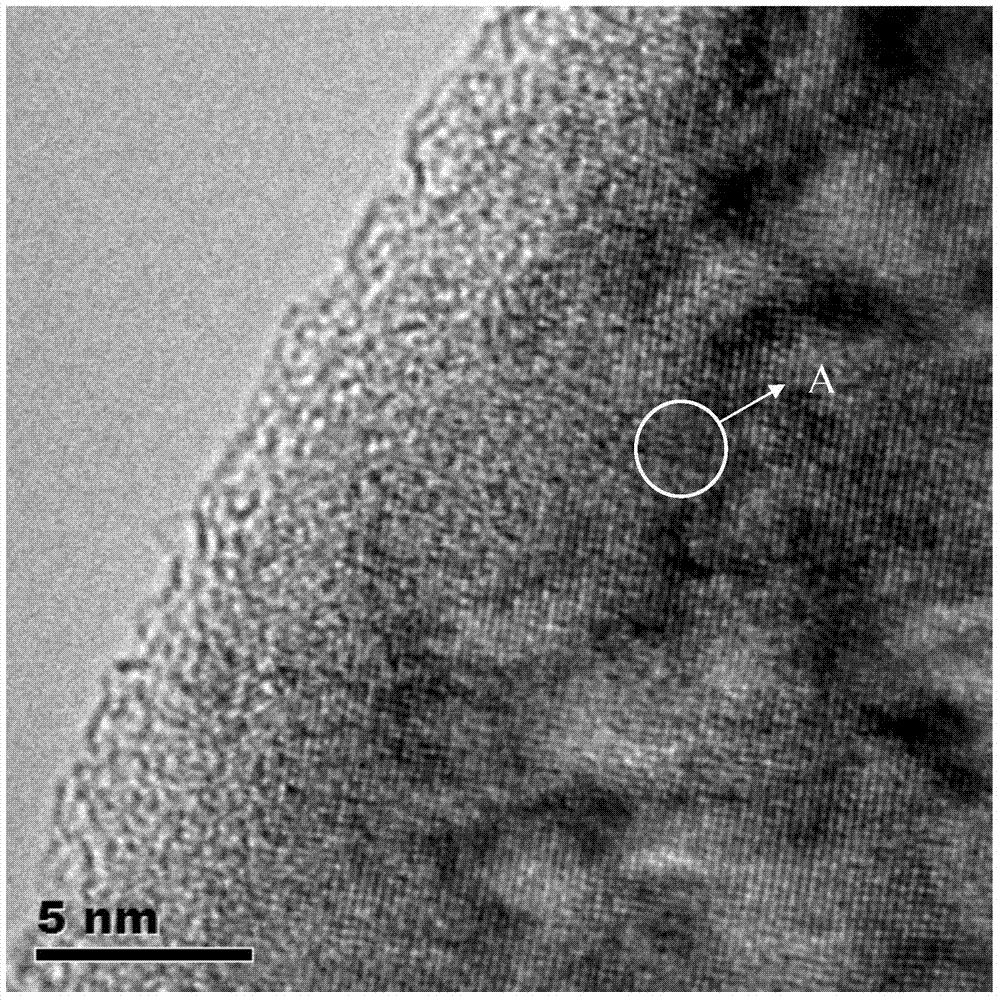

[0052] In this embodiment, nitrogen ions and zirconium ions are used to modify the surface of the M50NiL material, and three implants are performed. The zirconium ions can be equally replaced by titanium ions, molybdenum ions, and chromium ions, and various parameters (such as implantation energy, implantation dose, etc.) remain unchanged.

[0053] Step 1) Prepare a M50NiL material to be treated, first remove the grease on the surface of the M50NiL material to be treated with a metal degreasing solvent, then put it in non-polluting tetrachlorethylene for 20 minutes, take it out, and absorb it with rice paper If the solvent remains, wipe the surface of the material with absorbent cotton, and finally wipe it with a clean silk cloth; soak and clean the M50NiL material with a metal cleaner with rust removal function for 10 minutes, so that there are no micro rust spots on the surface; put the M50NiL material in acetone , take it out after ultrasonic cleaning for 20 minutes, and dr...

Embodiment 2

[0058] In this embodiment, nitrogen ions and zirconium ions were used to modify the surface of the M50NiL material, and four implants were performed. The zirconium ions can be equally replaced by titanium ions, molybdenum ions, and chromium ions, and various parameters (such as implantation energy, implantation dose, etc.) remain unchanged.

[0059] Step 1) Prepare a M50NiL material to be treated, first remove the grease on the surface of the M50NiL material to be treated with a metal degreasing solvent, then put it in non-polluting tetrachlorethylene for 30 minutes, take it out, and absorb it with rice paper If the solvent remains, wipe the surface of the material with absorbent cotton, and finally wipe it with a clean silk cloth; soak and clean the M50NiL material with a metal cleaner with rust removal function for 20 minutes to make the surface free of micro rust spots; put the M50NiL material in acetone , take it out after ultrasonic cleaning for 40 minutes, and dry it wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com