Multilayer stent

a multi-layer, stent technology, applied in the field of expandable intraluminal vascular devices, can solve the problems of lack of localized therapeutic pharmacological delivery, lack of stents with metallic claddings, and lack of stents with expansion characteristics,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

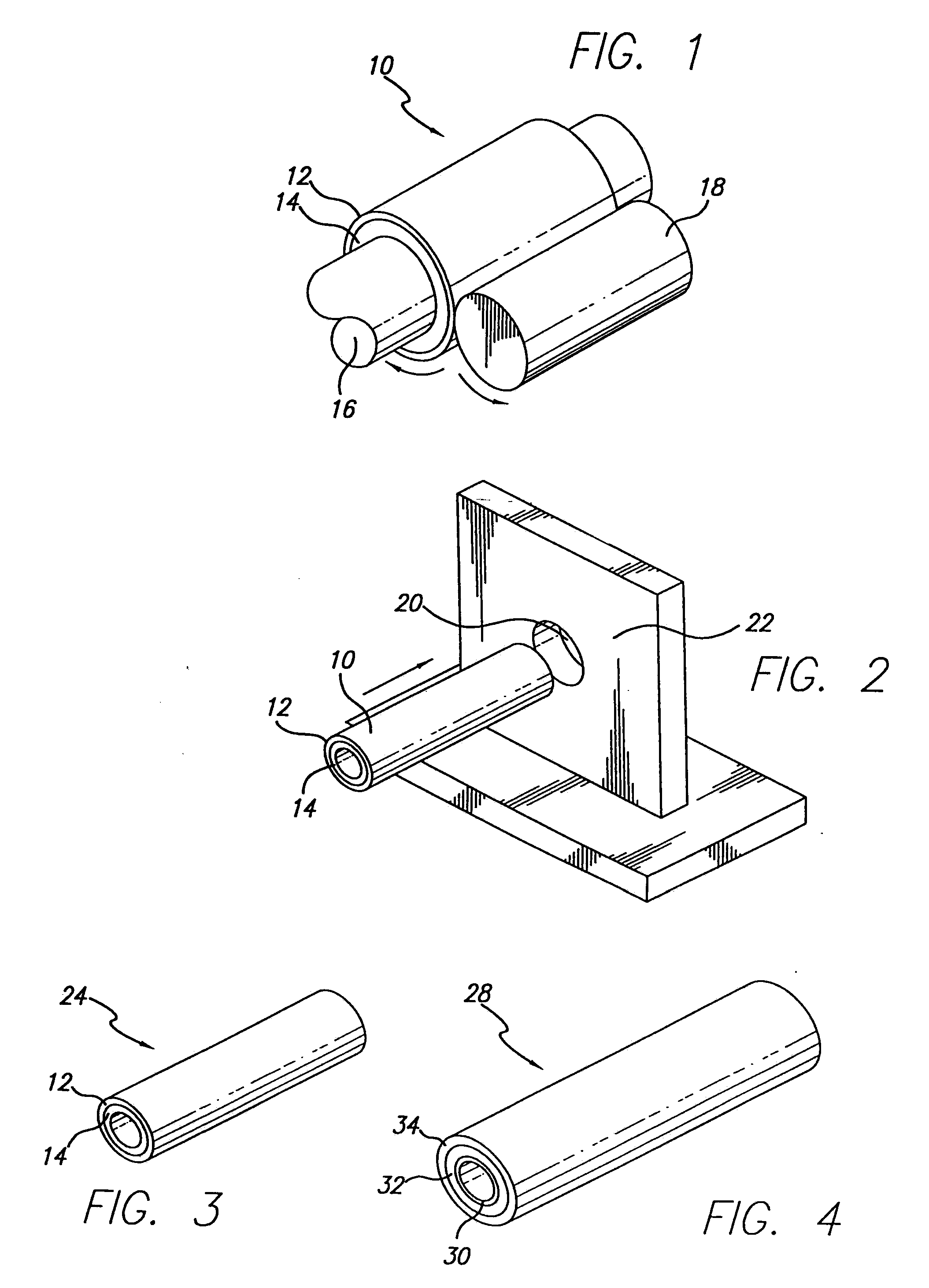

[0023]FIG. 1 is a perspective view of a preferred embodiment of a laminate tube having features of the present invention. As seen in this simplified view, the present invention contemplates creation of laminate tube 10 by joining metal cladding tube 12 to an exterior surface of substrate tube 14. Fundamental to this joining process is first defining the initial diameters of metal cladding tube 12, which should already be in a tubular configuration as seen in FIG. 1, and of substrate tube 14. Tubes 12, 14 can be made by conventional fabrication processes, such as drawing, rolling sheet stock and welding the seam, etc. During these preliminary steps, the diameters and wall thickness of tubes 12 and 14 are selected and set.

[0024]In the preferred embodiment of the present invention, there should be an interference fit between the outside diameter of substrate tube 14 and the inside diameter of metal cladding tube 12. The interference fit prevents unwanted, relative shifting between subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com