Silicone rubber composite material for fused deposition 3D printing and preparation method thereof

A composite material and 3D printing technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of poor thermal conductivity, shrinkage cavity of printing wire, and psychological pressure of patients, so as to improve bonding performance and anti-corrosion Fatigue cracking performance, ensuring molding dimensional accuracy and appearance, and the effect of excellent high and low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

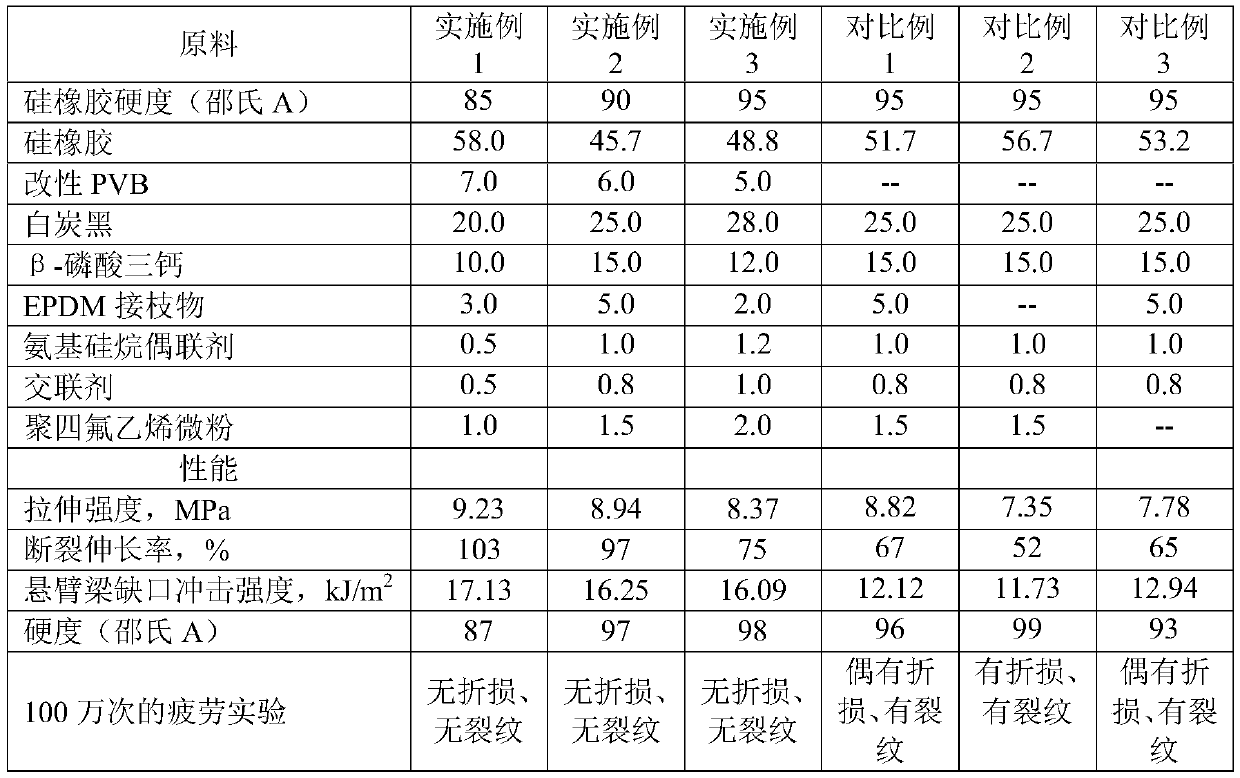

Embodiment 1

[0058] Take by weighing each raw material according to the following proportioning: silicone rubber (Shore A hardness 85) mass fraction is 58.0 parts, modified PVB mass fraction is 7.0 mass fraction, white carbon black mass fraction is 20.0 mass fraction, tricalcium phosphate mass fraction The parts are 10.0 parts, the EPDM grafted substance is 3.0 parts, the aminosilane coupling agent KH550 is 0.5 parts, the crosslinking agent is 0.5 parts, and the lubricant is 1.0 parts.

[0059] Add silicone rubber, modified PVB, white carbon black, tricalcium phosphate, EPDM graft, aminosilane coupling agent, crosslinking agent and lubricant to the mixer in sequence for pre-mixing. The mixing temperature is 20-25°C. The rotation speed was 300 rpm and the mixing time was 2 minutes.

[0060] The pre-mixed material is fed into the extensional rheological extruder from the feeder, melted and extruded to granulate, the screw speed is 250 rpm, and the main feeder speed is 50 rpm. The temperatur...

Embodiment 2

[0063] Take by weighing each raw material according to the following proportioning: silicone rubber (Shore A hardness 90) mass fraction is 45.7 mass fractions, PVB mass fraction is 6.0 mass fractions, silica mass fraction is 25.0 mass fractions, tricalcium phosphate mass fractions 15.0 parts, 5.0 parts by mass of EPDM grafted substance, 1.0 parts by mass of aminosilane coupling agent KH550, 0.8 parts by mass of crosslinking agent, and 1.5 parts by mass of lubricant.

[0064] Add silicone rubber, modified PVB, white carbon black, tricalcium phosphate, EPDM graft, aminosilane coupling agent, crosslinking agent and lubricant to the mixer in sequence for pre-mixing. The mixing temperature is 25-30°C. The rotational speed was 250 rpm and the mixing time was 3 minutes.

[0065] The pre-mixed material is fed into the extensional rheological extruder from the feeder, melted and extruded to granulate, the screw speed is 300 rpm, and the main feeder speed is 60 rpm. The temperature of ...

Embodiment 3

[0068] Take by weighing each raw material according to the following ratio: silicone rubber (Shore A hardness 95) mass fraction is 48.8 parts, modified PVB mass fraction is 5.0 mass fraction, white carbon black mass fraction is 28.0 mass fraction, tricalcium phosphate mass fraction The parts are 12.0 parts, the EPDM grafted substance is 2.0 parts, the aminosilane coupling agent KH550 is 1.2 parts, the crosslinking agent is 1.0 parts, and the lubricant is 2.0 parts.

[0069] Add silicone rubber, modified PVB, white carbon black, tricalcium phosphate, EPDM graft, aminosilane coupling agent, crosslinking agent and lubricant into the mixer in sequence for pre-mixing. The mixing temperature is 22-26°C. The rotational speed was 280 rpm and the mixing time was 1.5 minutes. The pre-mixed material is fed into the extensional rheological extruder from the feeder, melted and extruded to granulate, the screw speed is 150 rpm, and the main feeder speed is 55 rpm. The temperature of each s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com