Modified emulsified asphalt and preparation method thereof

A technology for emulsified asphalt and modification, applied in building components, building insulation materials, buildings, etc., can solve the problems that the temperature of the mixture cannot be too high, the storage time cannot be too long, and the human body is injured, so as to improve the softening point and avoid Physical injury, effect of improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

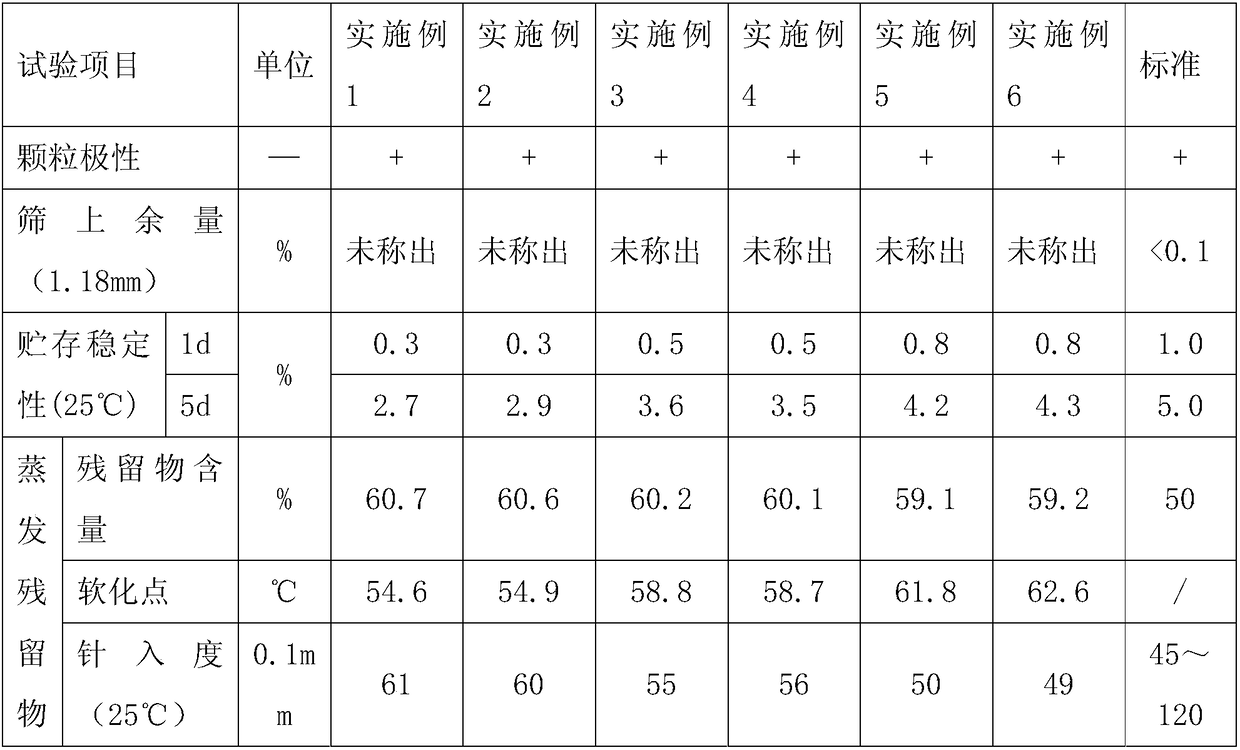

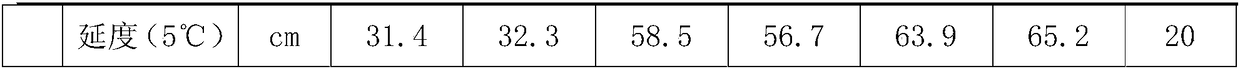

Examples

Embodiment 1

[0028] The modified emulsified asphalt of the present invention consists of the following raw materials in parts by mass:

[0029] 55 parts of 110# heavy traffic asphalt, 6 parts of liquid sulfur, 2 parts of styrene-butadiene latex, 1 part of alkylpropylenediamine, 1 part of octadecyltrimethylammonium chloride, 0.1 part of polyacrylamide, 1.0 part of potassium chloride Parts, 0.5 parts of hydrochloric acid, 40 parts of water.

[0030] The preparation method of modified emulsified asphalt of the present invention is:

[0031] (1) Add 6 parts of liquid sulfur and 55 parts of asphalt into the reaction kettle, react at 180°C for 1.5h, and cool down to 150°C.

[0032] (2) Weigh 1 part of cationic emulsifier alkylpropylenediamine, add 1 part of octadecyltrimethylammonium chloride into 40 parts of water, then add 0.1 part of polyacrylamide and 1.0 part of potassium chloride, and stir While adding 0.5 parts of acid, adjust the pH value to 3-5, prepare an emulsifier aqueous solution ...

Embodiment 2

[0035] The modified emulsified asphalt of the present invention is composed of the following raw materials in parts by mass: 50 parts of 110# heavy traffic asphalt, 6 parts of liquid sulfur, 2 parts of styrene-butadiene latex, 1 part of alkylpropylenediamine, octadecyl trimethyl chloride 1 part of ammonium, 0.1 part of polyacrylamide, 1.5 parts of potassium chloride, 0.5 part of hydrochloric acid, 40 parts of water.

Embodiment 3

[0037] The modified emulsified asphalt of the present invention is composed of the following raw materials in parts by mass: 50 parts of 90# heavy traffic asphalt, 11 parts of liquid sulfur, 6 parts of styrene-butadiene latex, 1 part of alkylpropylene triamine, octadecyl trimethyl chloride 2 parts of ammonium, 0.3 parts of polyacrylamide, 1.5 parts of potassium chloride, 1 part of hydrochloric acid, 40 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com