A micro-repair type release agent for asphalt mixture rolling and preparation method thereof

An asphalt mixture and micro-repair technology, which is applied in the field of road engineering, can solve the problems of flammability increasing fire hazards, affecting the compactness of rolling, and reducing the rolling temperature of asphalt mixture, so as to ensure the degree of compaction and water seepage coefficient. , Good anti-stick isolation effect, realize the effect of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

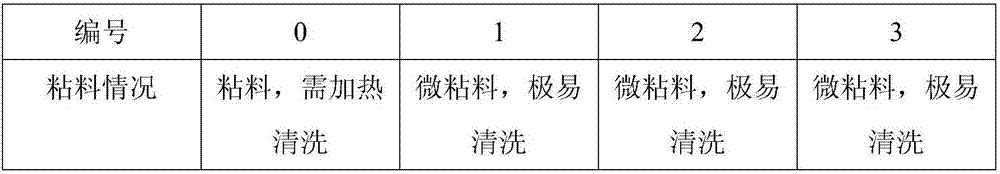

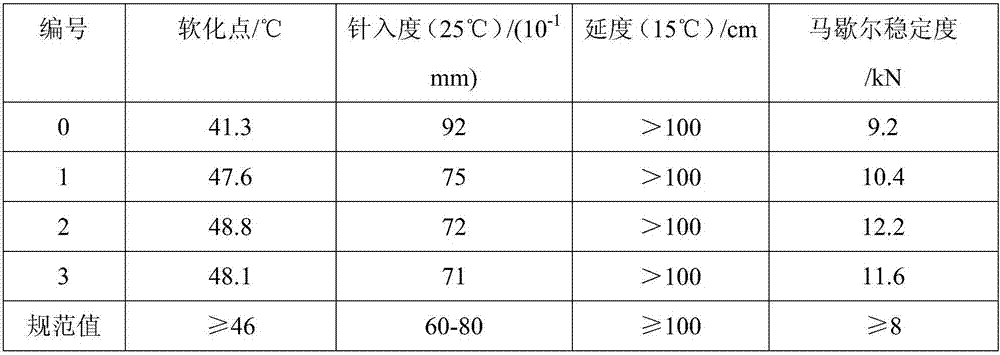

Embodiment 1

[0028] This example provides a micro-repair type release agent for asphalt mixture rolling, which consists of the following raw materials in terms of mass fraction: 10% waste cooking oil, 8% carbon black, 15% emulsified silicone oil, 10% ten Sodium dialkylbenzene sulfonate, 5% organic acid, 4% polyethylene glycol, 4% mica powder, the balance is 44% water, wherein: the organic acid is a mixture of benzoic acid and polycarboxylic acid, pKa is 4.8 In terms of mass percentage, benzoic acid accounts for 70%, polycarboxylic acid accounts for 30%, and in polycarboxylic acid, citric acid accounts for 55%, butane tetracarboxylic acid accounts for 45%.

[0029] Waste edible oil is frying waste oil after standing and purifying, with a relative molecular mass of 200-400, which is commonly known as gutter oil. The fresh crude oil corresponding to the frying waste oil is edible oil such as soybean vegetable oil.

[0030] Waste cooking oil can be replaced by cooking oil of equal quality.

...

Embodiment 2

[0044] This example provides a micro-repair type release agent for asphalt mixture rolling, which consists of the following raw materials in terms of mass fraction: 12% waste cooking oil, 7% carbon black, 18% emulsified silicone oil, 8% ten Sodium dialkylbenzene sulfonate, 4% organic acid, 6% polyethylene glycol, 3% mica powder, the balance is 42% water, wherein: organic acid is a mixture of benzoic acid and polycarboxylic acid, pKa is 4.8 In terms of mass percentage, benzoic acid accounts for 60%, polycarboxylic acid accounts for 40%, and in polycarboxylic acid, citric acid accounts for 65%, butane tetracarboxylic acid accounts for 35%.

[0045] The requirements for each raw material are the same as in Example 1 in this example.

[0046] The preparation method of the release agent in this example is the same as that in Example 1, and finally a micro-restoration release agent for asphalt mixture rolling is prepared, number 2#.

Embodiment 3

[0048] This example provides a micro-repair type release agent for asphalt mixture rolling, which consists of the following raw materials in terms of mass fraction: 15% waste cooking oil, 6% carbon black, 20% emulsified silicone oil, 6% ten Sodium dialkylbenzene sulfonate, 3% organic acid, 7% polyethylene glycol, 2% mica powder, the balance is 41% water, wherein: the organic acid is a mixture of benzoic acid and polycarboxylic acid, pKa is 4.8 In terms of mass percentage, benzoic acid accounts for 65%, polycarboxylic acid accounts for 35%, and in polycarboxylic acid, citric acid accounts for 60%, butane tetracarboxylic acid accounts for 40%.

[0049] The requirements for each raw material are the same as in Example 1 in this example.

[0050] The preparation method of the release agent in this example is the same as that in Example 1, and finally a micro-restoration release agent for asphalt mixture rolling is prepared, number 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com