Manufacturing method for copper-based friction plate provided with core plate with overall hardness and high spline precision

A manufacturing method and friction plate technology, applied in the field of copper-based friction plate manufacturing, can solve the problems of poor high temperature resistance, reduced precision of core plate splines, unsuitable for use, etc., so as to improve the ability to resist fatigue fracture and the time to resist fatigue fracture The effect of improving and reducing the dimensional accuracy of the spline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

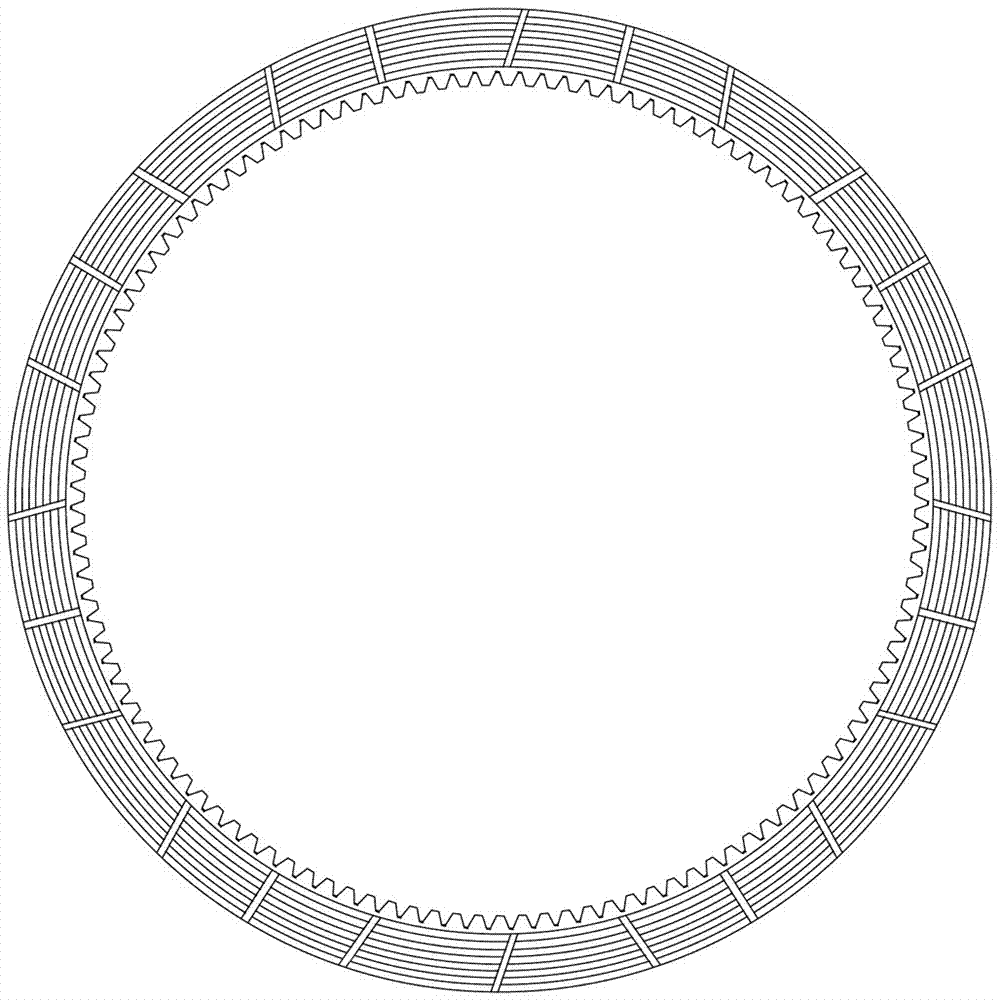

[0039] A copper-based friction plate is integrated by high-temperature sintering of a steel core plate and two friction layers. The material formula is made according to the conventional copper-based friction material mixing method and the friction layer blank is pressed. The friction layer and the steel core plate are processed in a bell furnace The connection is realized by high temperature alloying at 750-820°C. The difference between the present invention and the existing technology is:

[0040] 1. The core plate of the friction plate does not process splines when firing the friction layer;

[0041]2. Carry out overall heat treatment on the sintered friction plate. Due to the high overall heat treatment temperature, the friction material layer formula adopts the high-carbon formula copper-based friction material formula with better temperature resistance, so that the friction material components will not be affected by the subsequent overall heat treatment. Precipitation o...

Embodiment 1

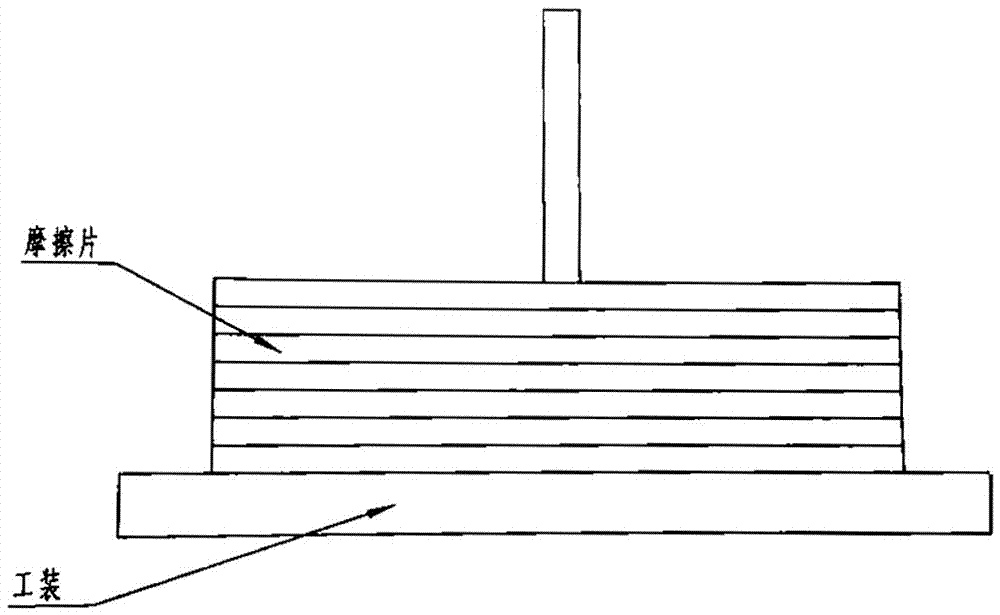

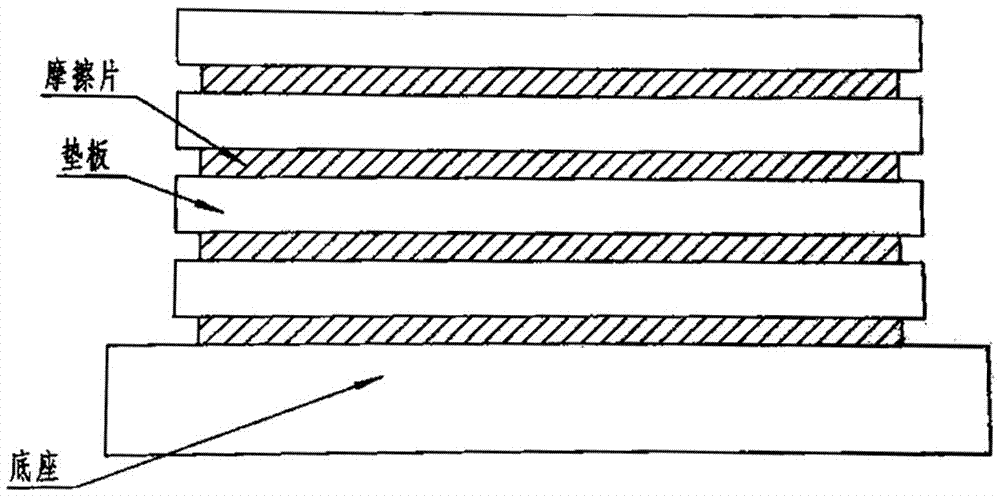

[0049] According to Cu 63%, Sn 6%, Pb 2%, Zn 6%, C 18%, quartz powder 5%, copper-based friction material high-carbon formula is mixed in a V-shaped mixer, and pressed into the blank required for the friction plate , the density is controlled at 4.6~4.8g / cm 3 , the core plate of the friction plate is processed to the required size (without splines), the material of the core plate is 30CrMnSiA, and it is nickel-plated and copper-plated. The friction layer blank and the core plate are fixed and placed in a bell furnace for pressure sintering to make the core plate The plate and the friction layer are alloyed and bonded firmly to obtain the required friction plate blank, and the surface of the friction plate blank is machined to control the thickness of the friction plate within 0.05mm. Stack the friction discs (eg figure 2 ), the overall heat treatment is carried out in a well-type furnace, the heating temperature is 850-860 °C, the holding time is 40 minutes, and the methane a...

Embodiment 2

[0051] According to Cu 69%, Sn 4%, Zn 7%, C 16%, quartz powder 4%, the copper-based friction material high-carbon formula is mixed in a V-shaped mixer, and pressed into the blank required for the friction plate, and the density is controlled at 4.7~4.9g / cm 3 , the core plate of the friction plate is processed to the required size, the material of the core plate is 30CrMnSiA, nickel-plated and copper-plated, the friction layer blank and the core plate are fixed and placed in a bell furnace for pressure sintering, so that the core plate and the friction layer are alloyed The bonding is firm, and the required friction plate blank is obtained. The surface of the friction plate blank is machined, and the thickness of the friction plate is controlled within 0.05mm. Put the friction plate flat on the heat treatment stick furnace for overall heat treatment, heating temperature 860-870°C, pass time 25 minutes, methane atmosphere protection, after the friction plate comes out of the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com