Rare-earth sol modified composite zinc-aluminum low-temperature sintered coating slurry

A rare earth sol, low-temperature sintering technology, used in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc. problems, to achieve good protection effect, low curing and sintering temperature, and good comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

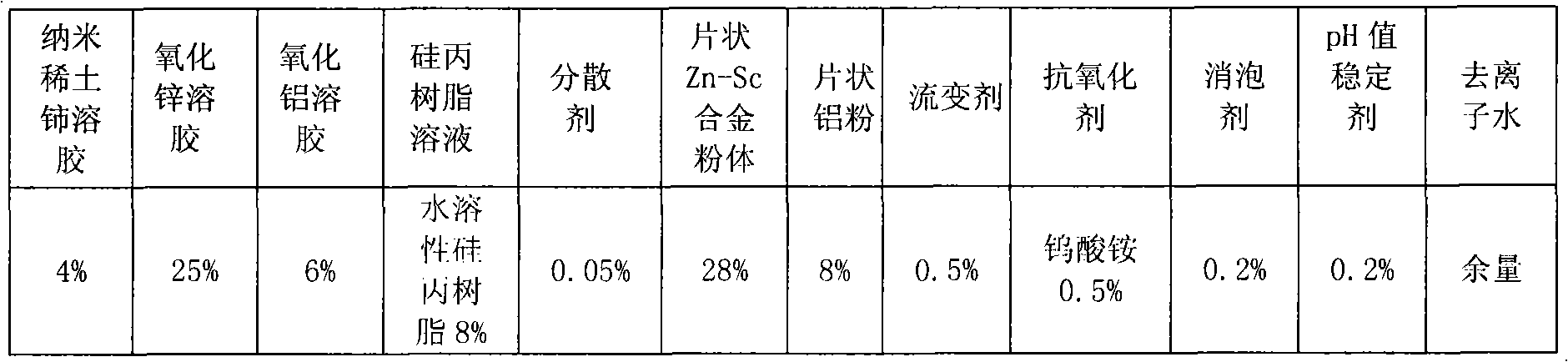

[0023] A rare earth sol modified inorganic-organic composite material system is the zinc-aluminum low-temperature sintering coating slurry of the bonding material, and its raw materials and their weight percentages are shown in Table 1;

[0024] Table 1

[0025]

[0026] The manufacturing method of the coating slurry is as follows: firstly prepare the nano-rare earth cerium-zinc oxide-alumina ternary sol slurry; Each sol is prepared by hydrolysis, followed by mixing and dispersing in proportion; then adding silicone acrylic resin solution to continue dispersing and mixing, and then adding dispersant, zinc-aluminum flake powder, F-111 defoamer, product The coating rheology agent of model XY-501, antioxidant ammonium tungstate or metatungstic acid is added to deionized water and mixed, and dispersed at a speed of 300-500 rpm.

Embodiment 2~10

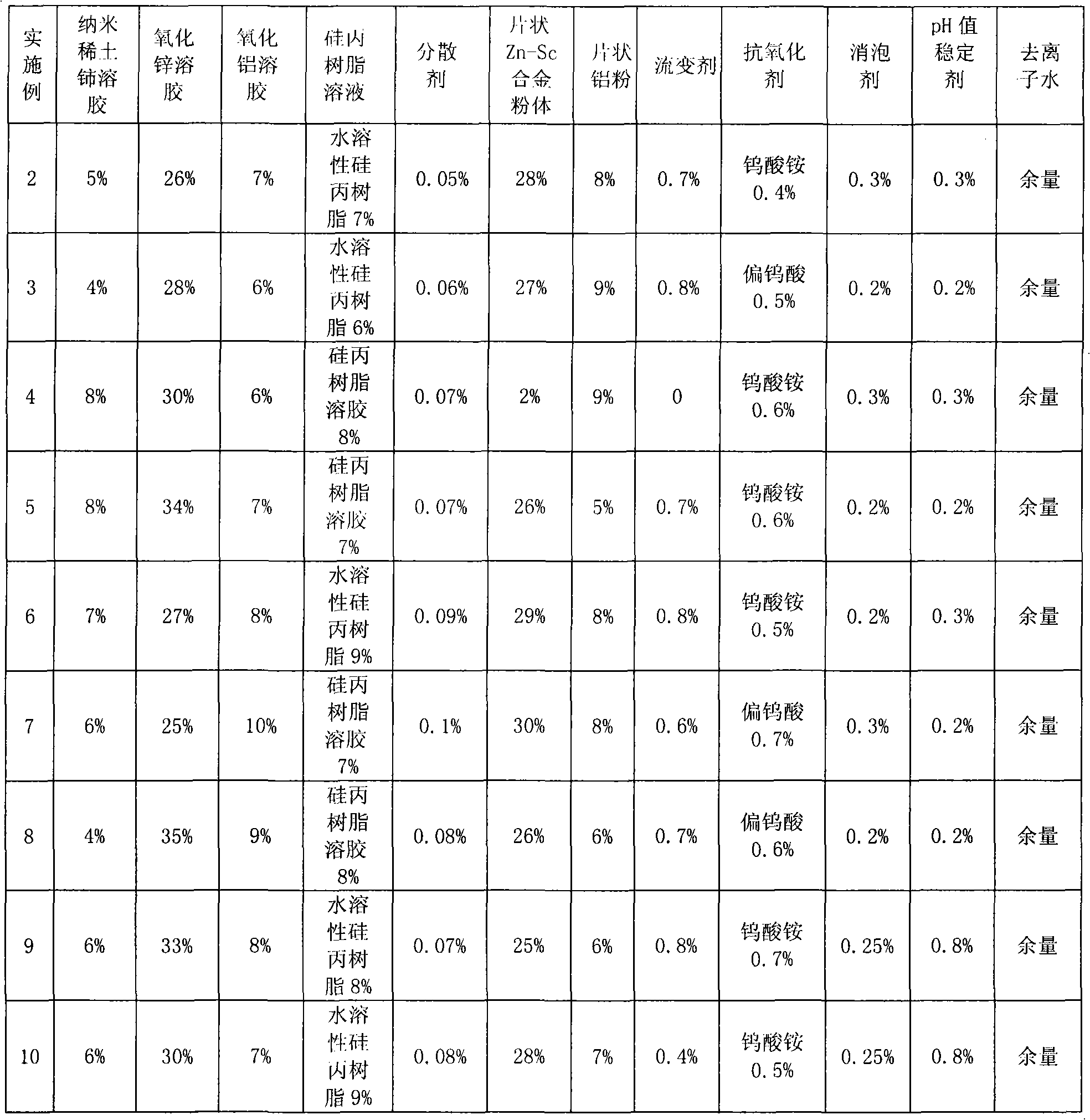

[0028] Adopt each raw material and its weight ratio relationship as described in Table 2, and adopt the preparation method identical with embodiment 1, prepare coating of the present invention; Wherein, auxiliary agent all selects other general commercially available products for use; Water can preferably adopt deionized water.

[0029] Table 2

[0030]

[0031] The invention uses rare earth cerium (Ce) sol to modify zinc oxide-alumina sol and silicone acrylic resin solution to form an inorganic-organic composite bonding material system. The three kinds of sols are obtained by hydrolysis; the silicone acrylic resin solution is water-soluble silicone acrylic resin or silicone acrylic resin emulsion, and fluoropropylene emulsion can also be used instead of silicone acrylic resin solution, water-soluble silicone acrylic resin, silicone acrylic resin emulsion or Fluorine-acrylic emulsions can be purchased in the market, such as HL-T15 water-soluble silicone acrylic resin, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com