Patents

Literature

110results about How to "Good high and low temperature stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

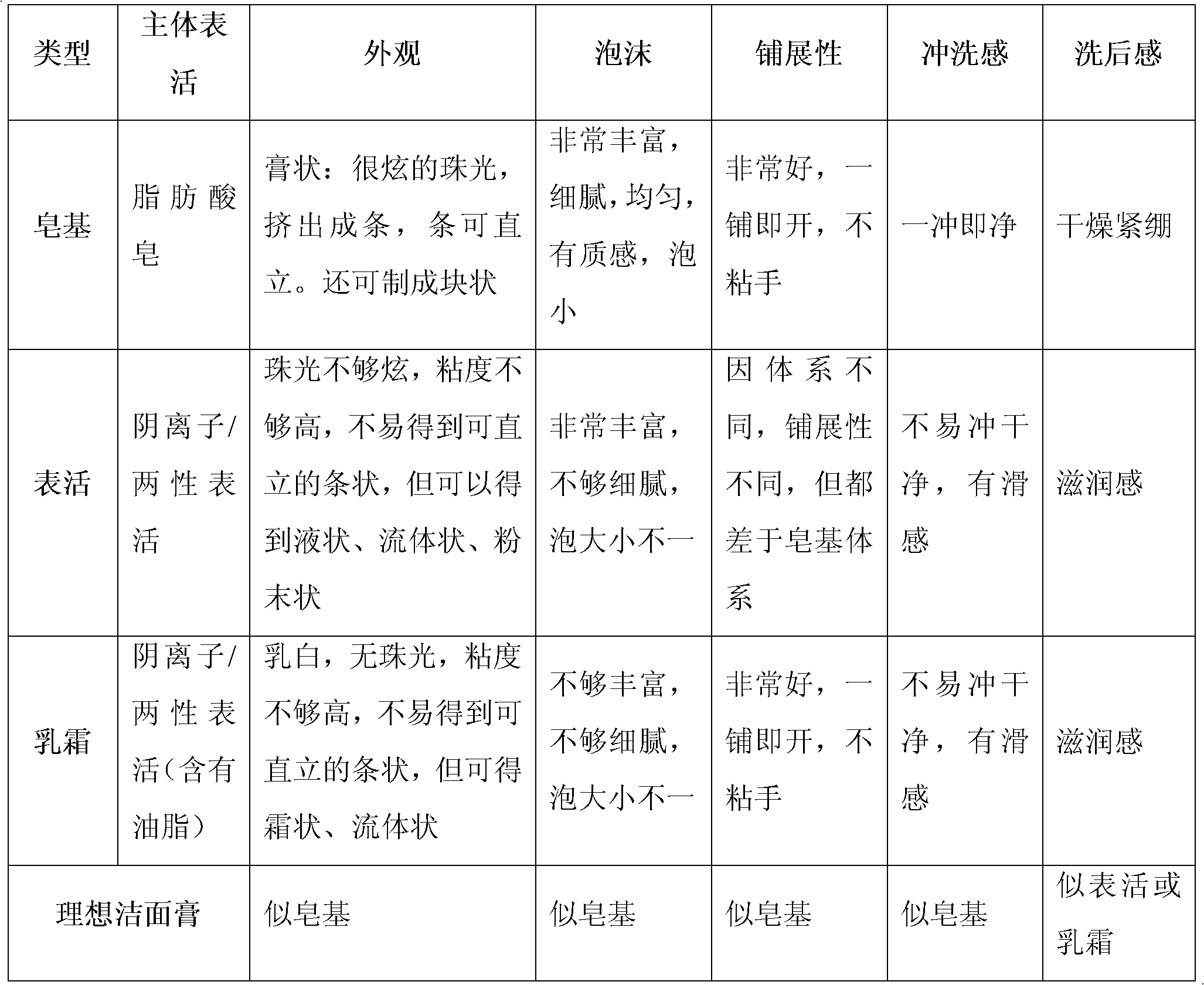

Mild soap base cleansing cream composition and production process thereof

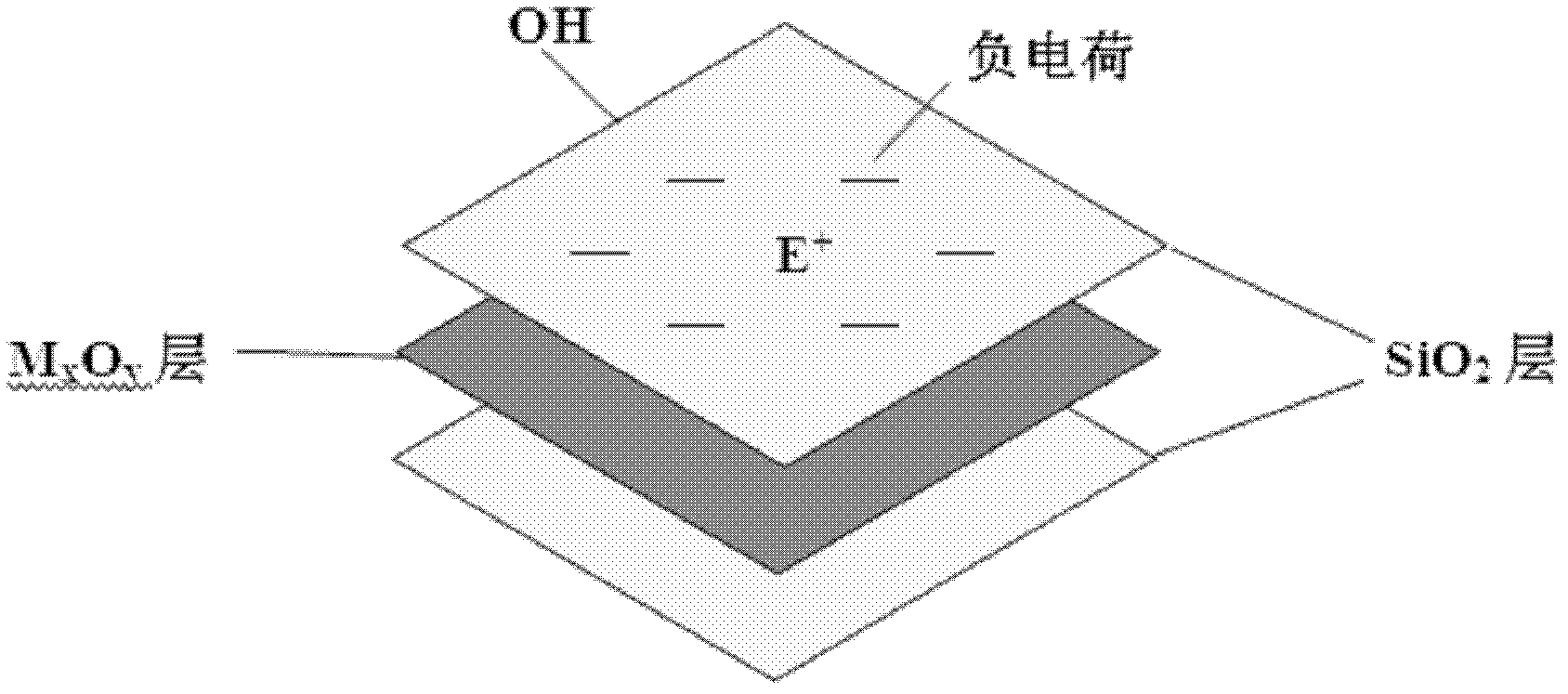

ActiveCN103126911AReduce contentDoes not affect viscosityCosmetic preparationsToilet preparationsSurface-active agentsFatty acid

The invention discloses a mild soap base cleansing cream composition and a production process thereof. The composition comprises, by weight, 2.0% to 50.0% of soap base, 2.0% to 30.0% of negative ion surface active agents, 0.5% to 20.0% of rheolobic modifiers and the balance water. The production process of the mild soap base cleansing cream comprises the following steps: firstly diluting fatty acid with other constituents, compatible with the fatty acid, in the formula and enabling the diluted fatty acid to disperse into fatty acid oil drips through blending; then adding in alkali liquor, so that tiny soap particles are generated after the alkali liquor contacts with the fatty acid oil drips; and finally adding in the constituents which can be added at a low temperature and blending evenly so that materials can be discharged directly. The mild soap base cleansing cream composition has a mild and moistening function, so that a skin can be neither dry nor tight and touches well after being washed. The mild soap base cleansing cream composition also has good high low temperature stability. The production process of the mild soap base cleansing cream is simple and easy to operate, has good repeatability, and can avoid quality problems frequently occurring in the production of a soap base cleansing cream.

Owner:浙江萃芙化妆品有限公司

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

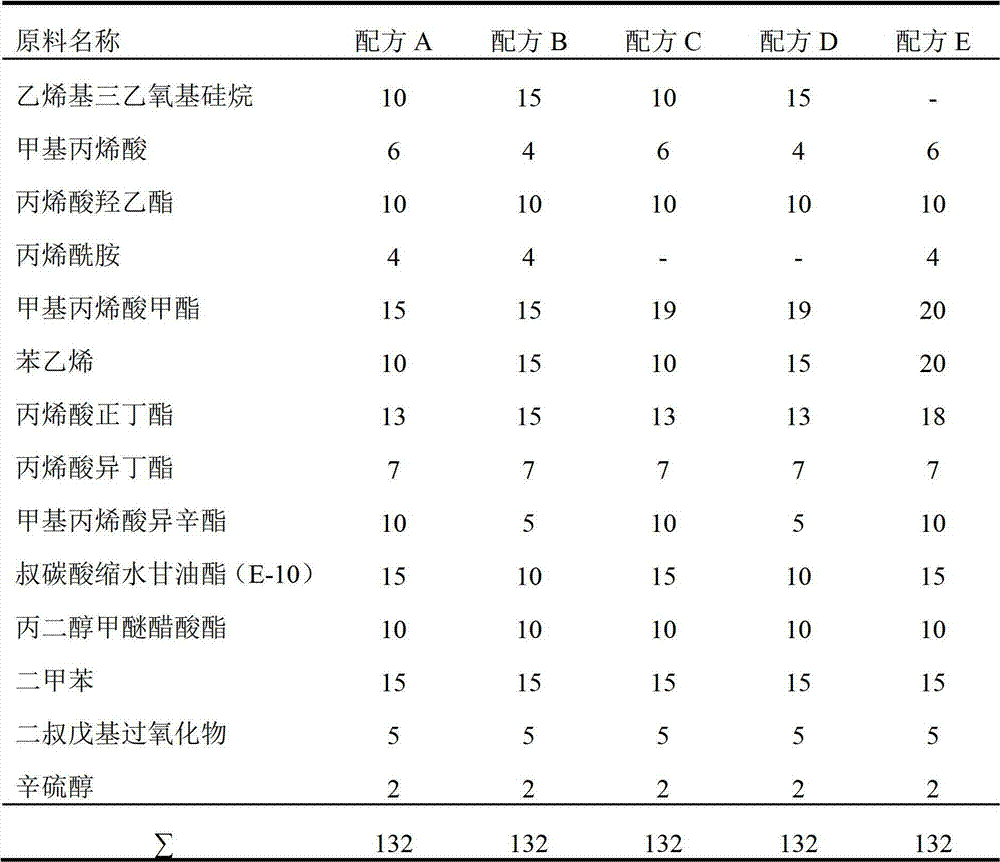

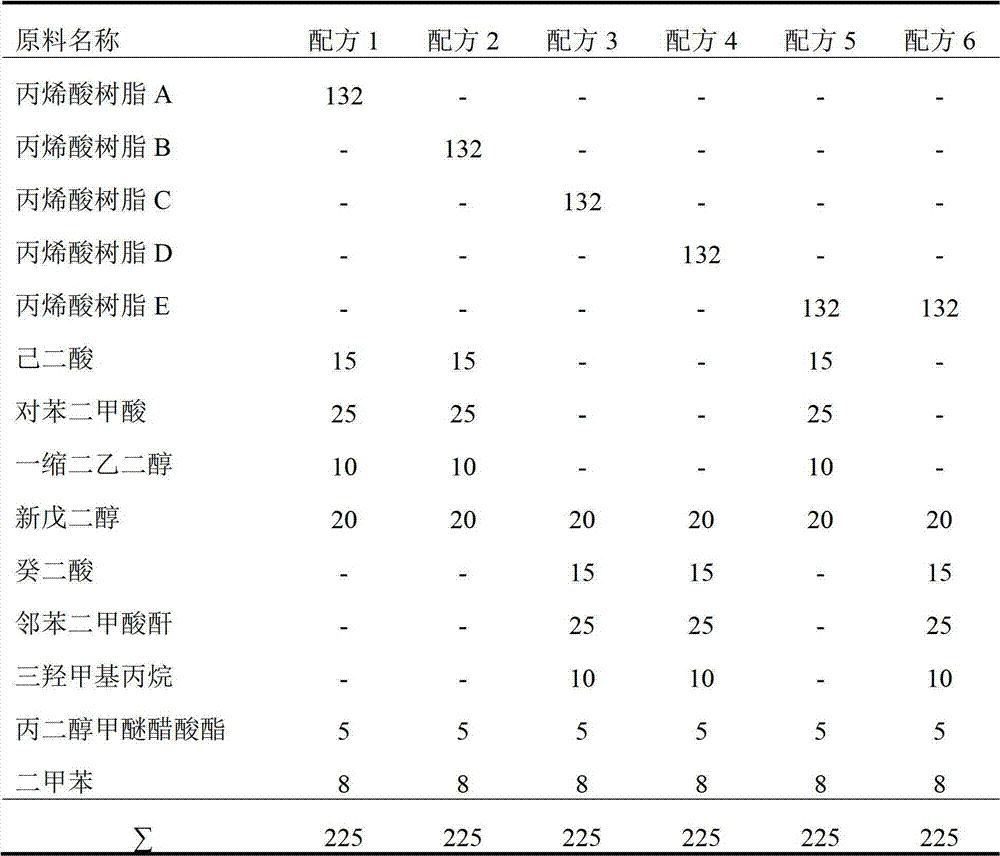

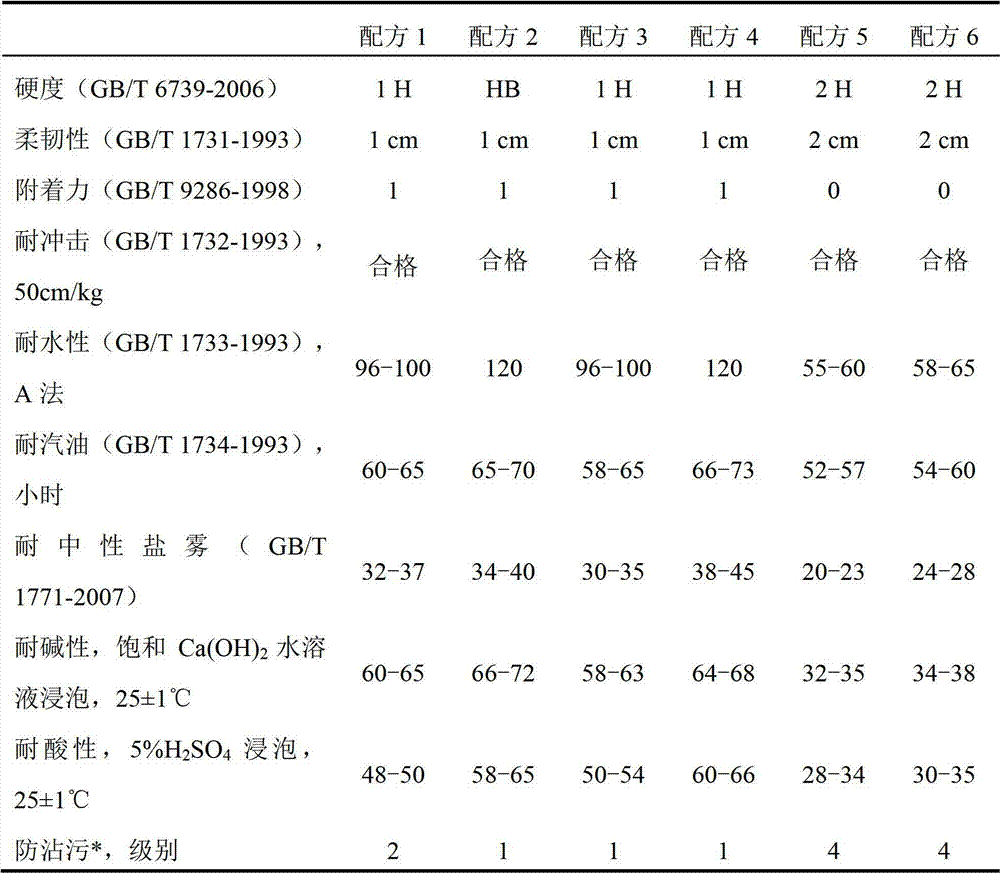

Silicon-containing acrylate-polyester resin, and finish coat and application thereof

InactiveCN102850536AImprove stain resistanceImprove self-cleaning functionPolyurea/polyurethane coatingsFunctional monomerCarboxylic acid

The invention relates to a silicon-containing acrylate-polyester resin which is prepared by carrying out free-radical polymerization and polycondensation on functional monomers composed of organic silison monomer (especially vinyl siloxane monomer) and multiple (methyl) acrylic acid (acrylate) monomers, polybasic carboxylic acids and polybasic alcohols. By increasing the quantity and varieties of the polymerization monomers, the prepared resin effectively combines the advantages of the organic silicon resin, acrylate resin and polyester resin, so that the coat prepared by using the resin as the base material not only has excellent functions of pollution resistance and self-cleaning, but also has the advantages of excellent corrosion resistance, high / low temperature stability, weather resistance, wear resistance, shock resistance, chemical medium resistance, corrosion resistance and solvent resistance as well as sufficient hardness, flexibility, brightness, fullness and the like.

Owner:常州市弘可利办公用品有限公司 +1

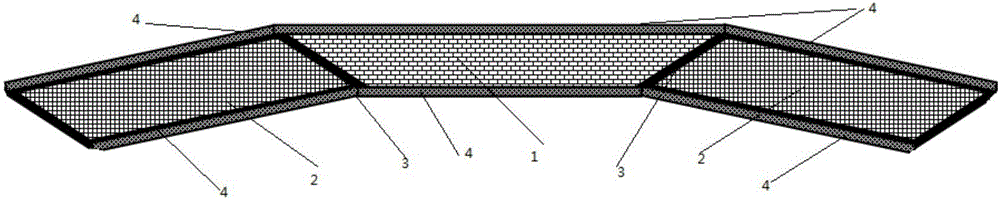

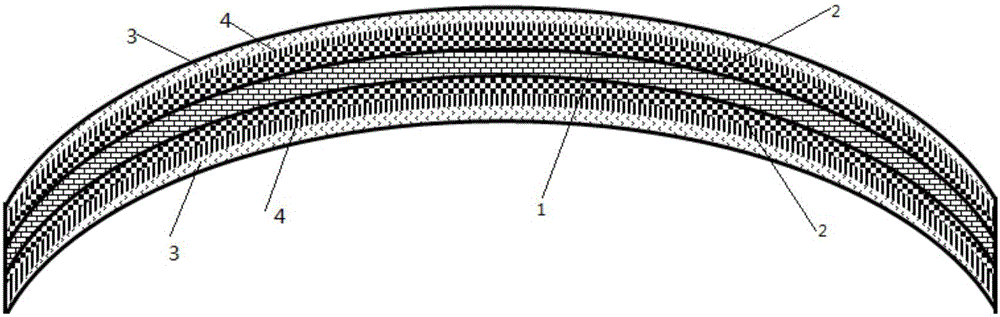

Automobile plate spring of three-dimensional braided composite material and preparation method thereof

The invention discloses an automobile plate spring of three-dimensional braided composite material and a preparation method thereof. The plate spring is of a three-dimensional fabric structure which is formed by combining and waving hybrid fibers, the material of fibers, the amount of tows and the structure of the fabric are adjusted to make the important part of the plate spring higher in strength and fatigue rigidity and longer in use durability, and simultaneously a resin vacuum transfer moulding technology is cooperated to uniformly soak, cure and shape the special composite resin, so as to obtain the heavy truck plate spring of three-dimensional braided composite material, the heavy truck plate spring is light in weight, strong in fatigue resistance, high in strength, rigidity and dimensional stability and relatively long in service life, and the problems of the common plate spring of two-dimensional laminated structure composite material such as interlayer fracture under fatigue loading condition are conquered.

Owner:山东宽原新材料科技有限公司

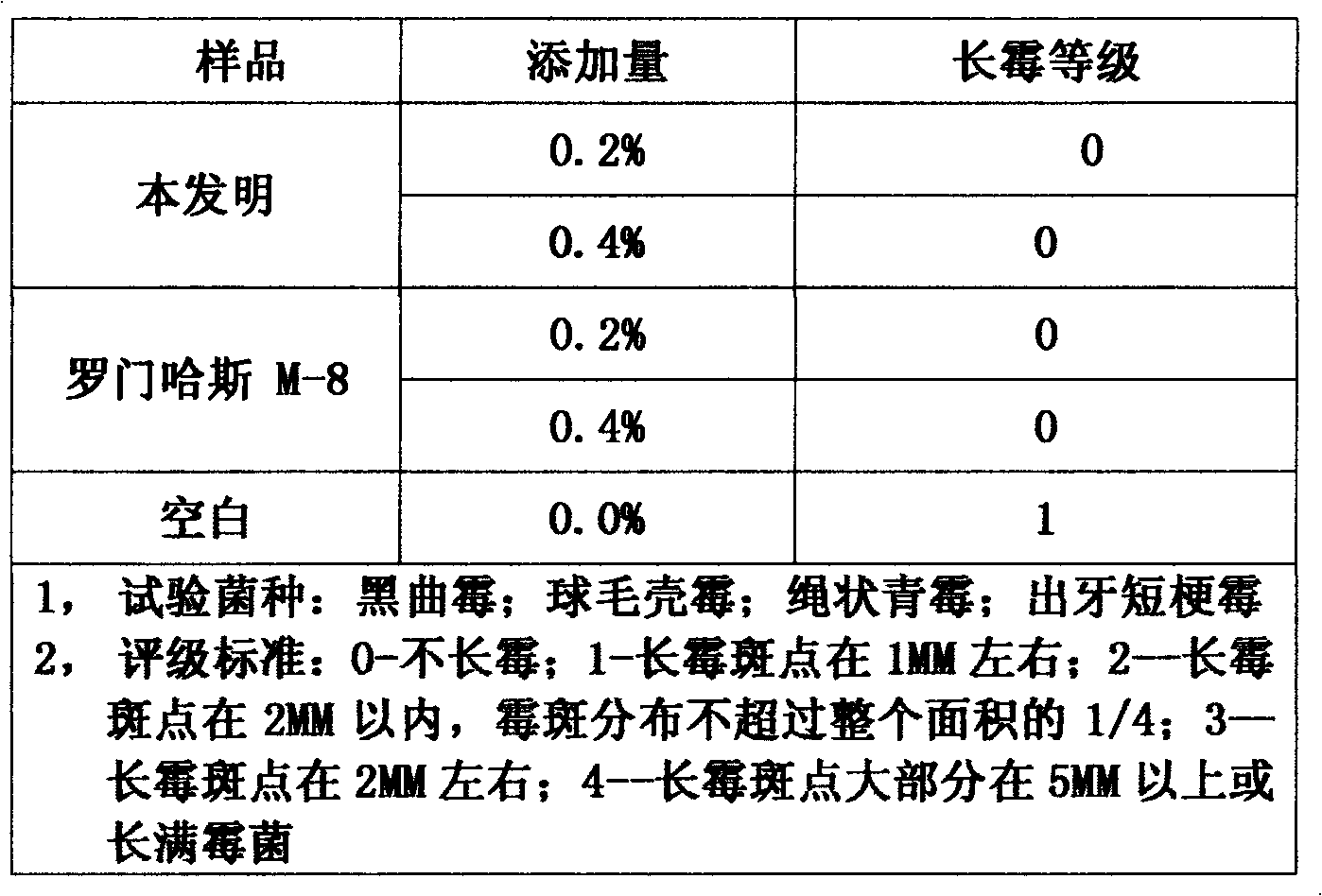

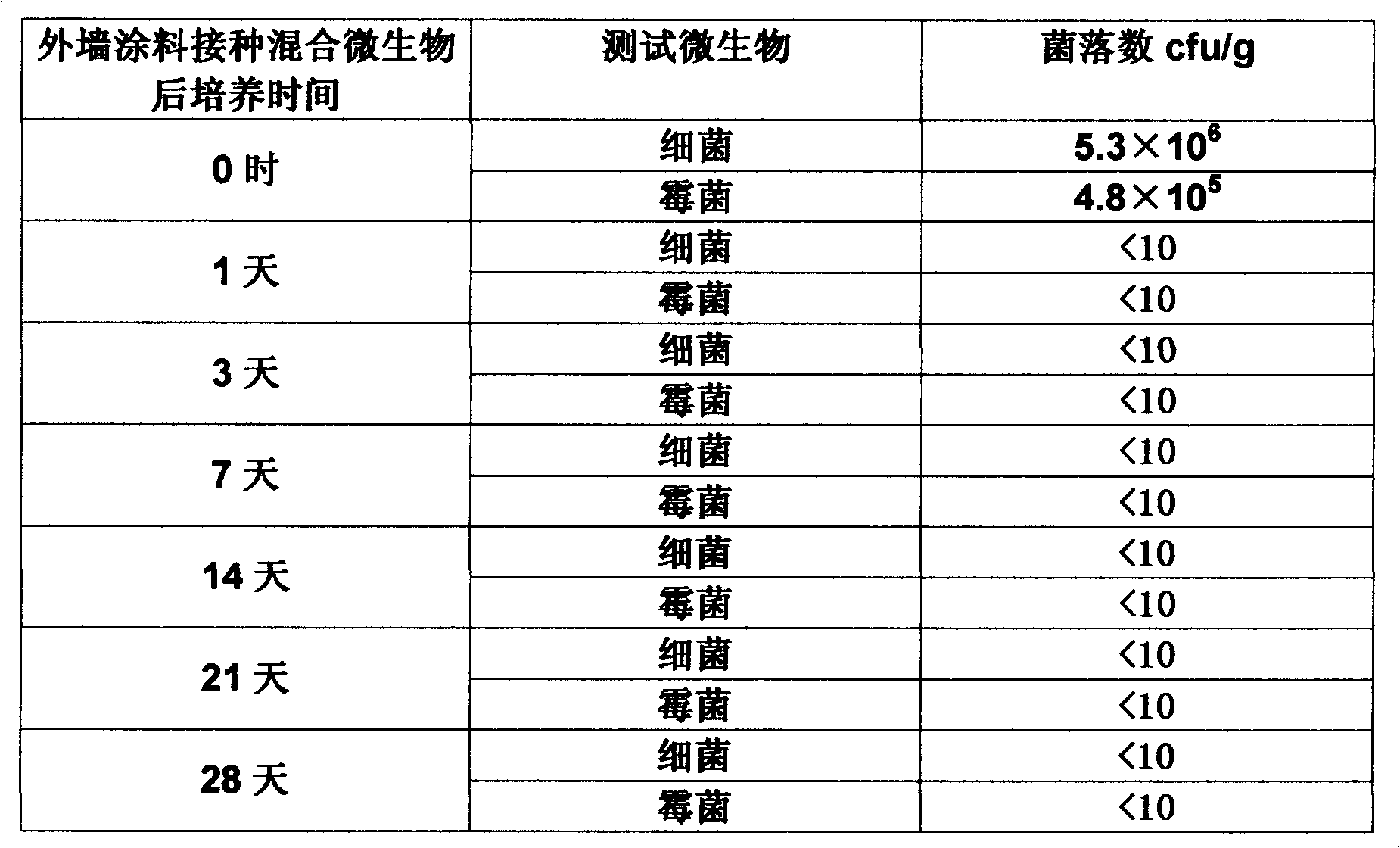

In-tank antiseptic antimildew agent composition integrated with dry film for paint

ActiveCN102702839AReduce dosageLow toxicityBiocidePaints with biocidesWater basedMicrobial challenge

The invention relates to an in-tank antiseptic antimildew agent composition integrated with a dry film for paint. The composition is prepared from a water-based paint in-tank antiseptic bactericide, a dry film antimildew agent, a solvent, an aid, a stabilizing agent and water. The in-tank antiseptic antimildew agent composition integrated with a dry film for paint has the advantages of reasonable formula, advanced process, good corrosion and mildew prevention effects, good stability, and the like. When the in-tank antiseptic antimildew agent composition integrated with a dry film for paint is used for paint, salt cluster phenomena can be avoided, an in-tank antiseptic effect can pass a microorganism challenge test, and the dry film mildew-growing grade is a zero grade.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Production method of quartz composite ceramic radome with polytetrafluoroethylene damp-proof coating

ActiveCN107253853AExcellent high and low temperature stabilityReduce dosageRadiating element housingsLow-k dielectricVapor barrier

The invention relates to a production method of a quartz composite ceramic radome with polytetrafluoroethylene damp-proof coating; the production method comprises the steps of pretreating quartz fiber profiled fabric; impregnating the quartz fiber profiled fabric, combining, and drying; subjecting the quartz fiber profiled fabric base to vacuum impregnating, concentrating, performing integrated compositing, and drying; subjecting the base to high-temperature thermal treatment, and performing machining. A polytetrafluoroethylene coating layer is formed on the surface of the radome. The PTFE (polytetrafluoroethylene) film formed on the surface of the quartz ceramic, bringing good low dielectric constant, continuous high vapor barrier performance, excellent high and low temperature stability, and high weatherability, can provide ultralow damp-proof performance for the storage of radomes and antenna windows for missile weapon systems in severe environments.

Owner:湖北三江航天江北机械工程有限公司

Plate spring of interlayer reinforced two-dimensional/three-dimensional braided composite material and preparation method thereof

InactiveCN105128357AHigh strengthReduce weightLeaf springsResilient suspensionsWhole bodyTransfer molding

The invention discloses a plate spring of interlayer reinforced two-dimensional / three-dimensional braided composite material and a preparation method thereof. A monolayer fabric of different fiber materials is formed by three-dimensional stereo braiding, the monolayer of the special fiber material and in the three-dimensional braided structure is designed on the special part in relatively high rigid or strength requirements, and finally the layers are vertically seamed to make the laminated monolayer structure form a whole body. Finally, the fabric of the two-dimensional / three-dimensional composite structure and resin are repeatedly soaked and composited through a resin vacuum transfer moulding technology, and the novel automobile plate spring of composite material which is high in strength and rigidity, small in deformation amount, large in fatigues resistance, long in service life and high in high-low temperature environment adaptability is prepared through gradient heating and curing. The plate spring uses the novel structure and the structure form to satisfy the use requirements of different loading capacities especially automobiles with heavy loads, and the problems such as interlayer fracture caused by relatively low fatigue load strength of the common plate spring of two-dimensional laminated structure composite material are conquered.

Owner:SHANDONG UNIV

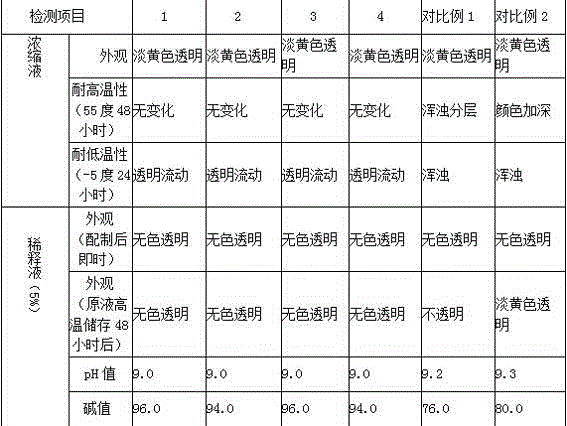

High-efficiency safe environment-friendly all-synthetic cutting fluid and preparation method thereof

InactiveCN104479833AImprove the lubrication effectExcellent rust and corrosion inhibition performanceLubricant compositionEnvironmental resistanceWork in process

The invention discloses a high-efficiency safe environment-friendly all-synthetic cutting fluid and a preparation method thereof. The cutting fluid consists of the following components in percentage by weight: 20-30% of synthetic ester, 4-8% of surfactant, 5-15% of antirust agent, 2-10% of pH regulator, 0-3% of corrosion inhibitor and the balance of deionized water. The preparation method comprises the following specific steps: adding the pH regulator into part of the deionized water and stirring uniformly; adding the corrosion inhibitor and the antirust agent in turn and stirring until solid powder is completely dissolved; after uniformly mixing and stirring the synthetic ester, adding the surfactant of the proportion and stirring for 15 minutes till uniformity; pouring a semi-finished product into the reaction system and stirring uniformly; repeatedly flushing the preparation container with the rest deionized water, and completely beating the flushing liquid back into the reaction system; and continuously stirring the reaction system until the solution is uniform and transparent to obtain a finished product. In the invention, the prepared all-synthetic cutting fluid has excellent lubricating and antirust and corrosion inhibition properties as well as good stability at high and low temperature to avoid color change, and avoids stimulation to the skin of a human body; and moreover, the all-synthetic cutting fluid has good biological stability and is safe, environment-friendly and non-irritant.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

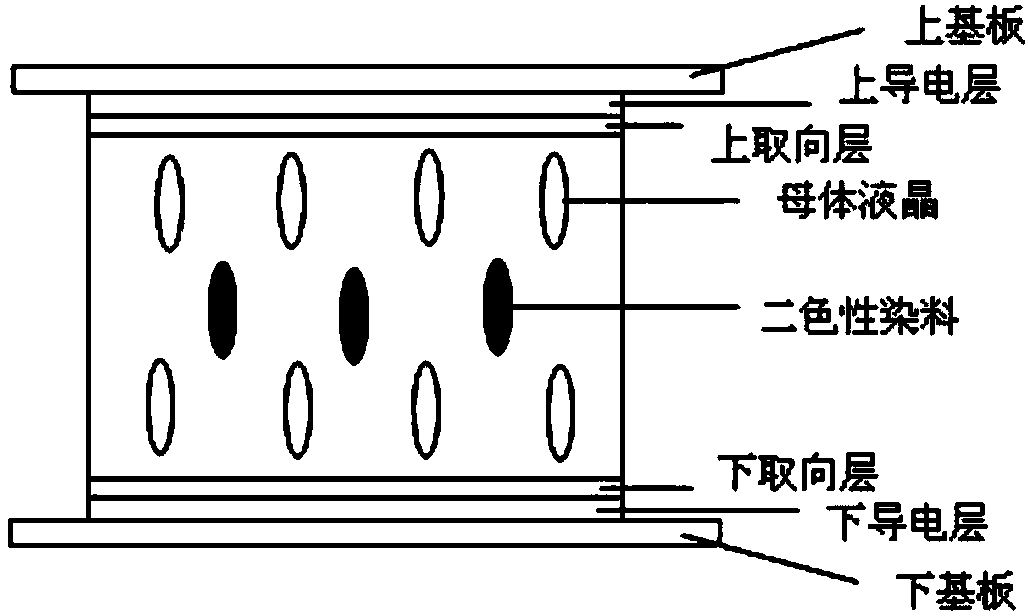

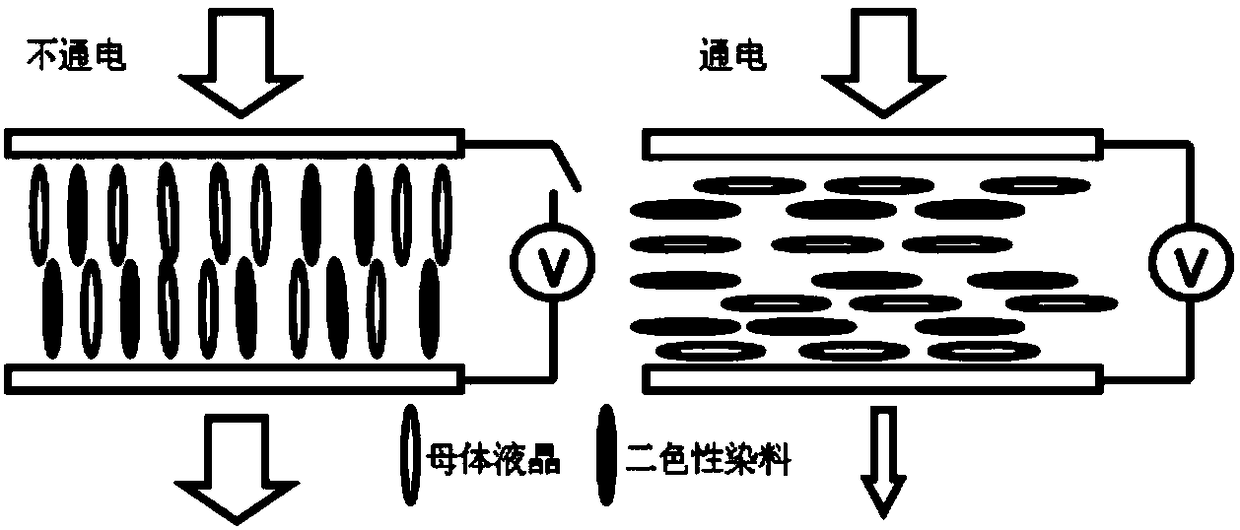

Dimming device containing guest-host liquid crystal composition

ActiveCN108663866AGood high and low temperature stabilityGood anti-UV weather resistanceLiquid crystal compositionsNon-linear opticsDichroic dyeChemistry

The invention provides a dimming device containing a guest-host liquid crystal composition. The dimming device comprises an upper substrate, a lower substrate, an upper electric conduction layer, a lower electric conduction layer, an upper aligning layer, a lower aligning layer and the guest-host liquid crystal composition which is sandwiched between the upper aligning layer and the lower aligninglayer, wherein the guest-host liquid crystal composition comprises a dichroic dye and mother liquid crystals. As the guest-host liquid crystal composition is used for dimming, a polarizer is omitted,and the cost is greatly reduced.

Owner:JIANGSU HECHENG DISPLAY TECHCO

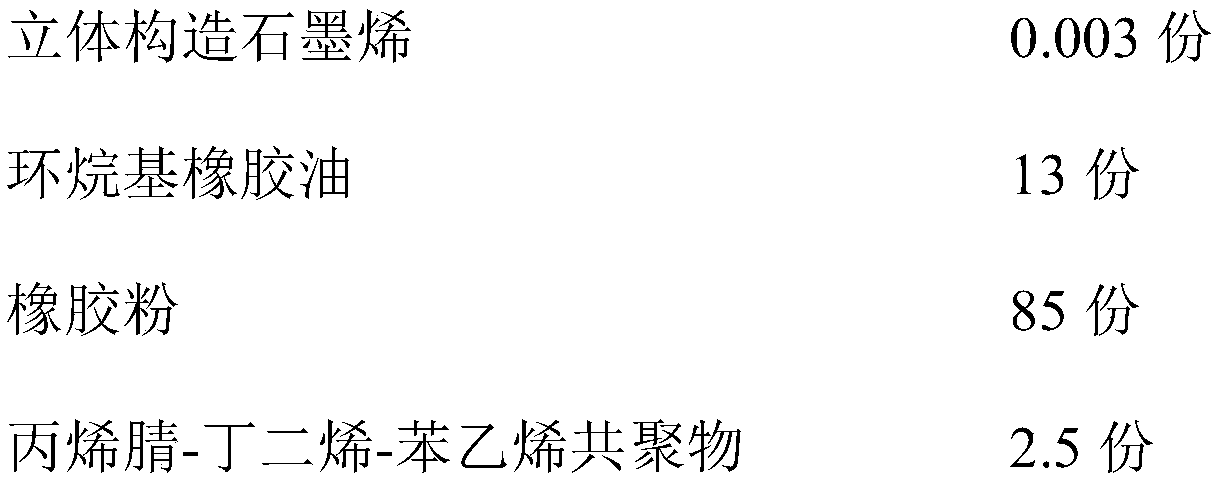

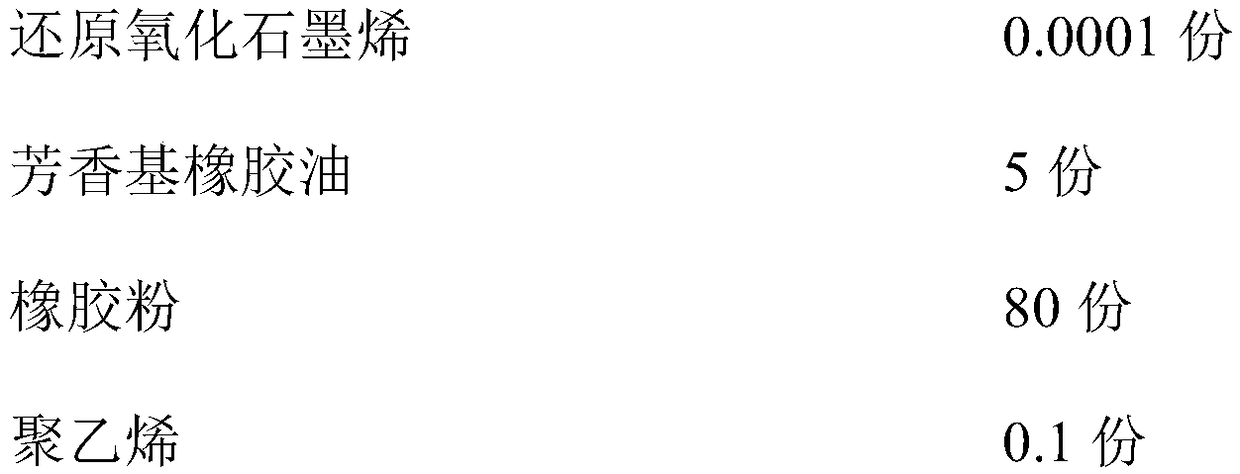

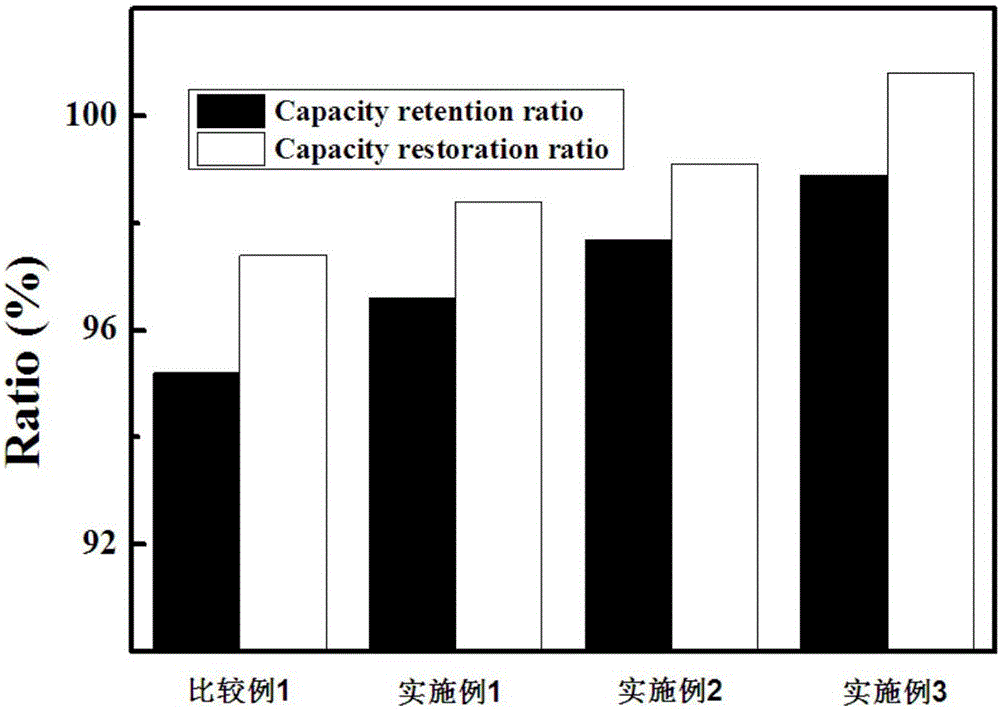

Graphene composite rubber asphalt modifier as well as preparation method and application thereof

ActiveCN108690360AGood dispersionGood modification effectBuilding insulationsPolymer scienceRoad surface

The invention discloses a graphene composite rubber asphalt modifier as well as a preparation method and application thereof. The graphene composite rubber asphalt modifier is prepared from the following components in parts by weight: 0.00005 to 0.01 part of graphene powder, 3 to 23 parts of dispersion medium, 78 to 92 parts of rubber powder and 0.05 to 6 parts of additive. The preparation methodof the graphene composite rubber asphalt modifier comprises the following steps: (1) mixing the graphene powder with the dispersion medium, mechanically stirring the graphene powder and the dispersionmedium so as to obtain a graphene dispersion solution through high-speed dispersion; (2) carrying out banburying on the graphene dispersion solution, the rubber powder and the additive to prepare thegraphene composite rubber asphalt modifier. The graphene composite rubber asphalt modifier or the preparation method can be applied to the asphalt modifier, so that the compatibility and the stability of the rubber powder in the asphalt can be greatly improved, the binding performance of the graphene composite rubber modified asphalt and sand stones and high-low temperature stabilizing performance can be improved, and meanwhile, the temperature of a road surface is reduced and the service life of the road surface is prolonged.

Owner:GUANGXI UNIV +1

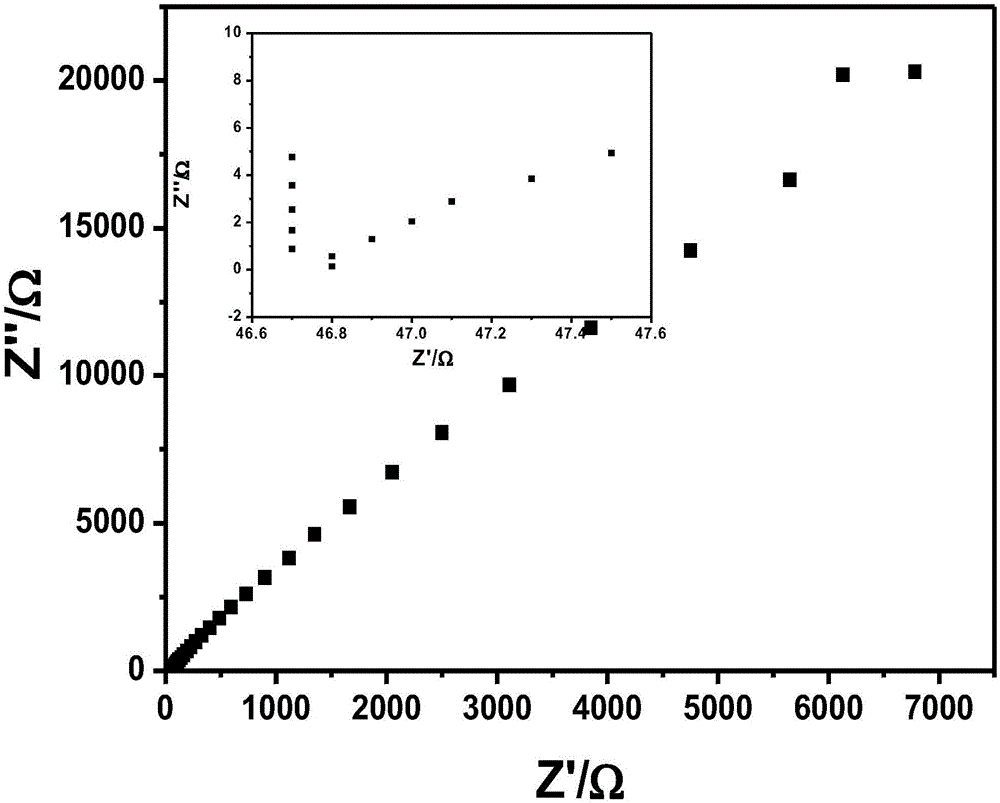

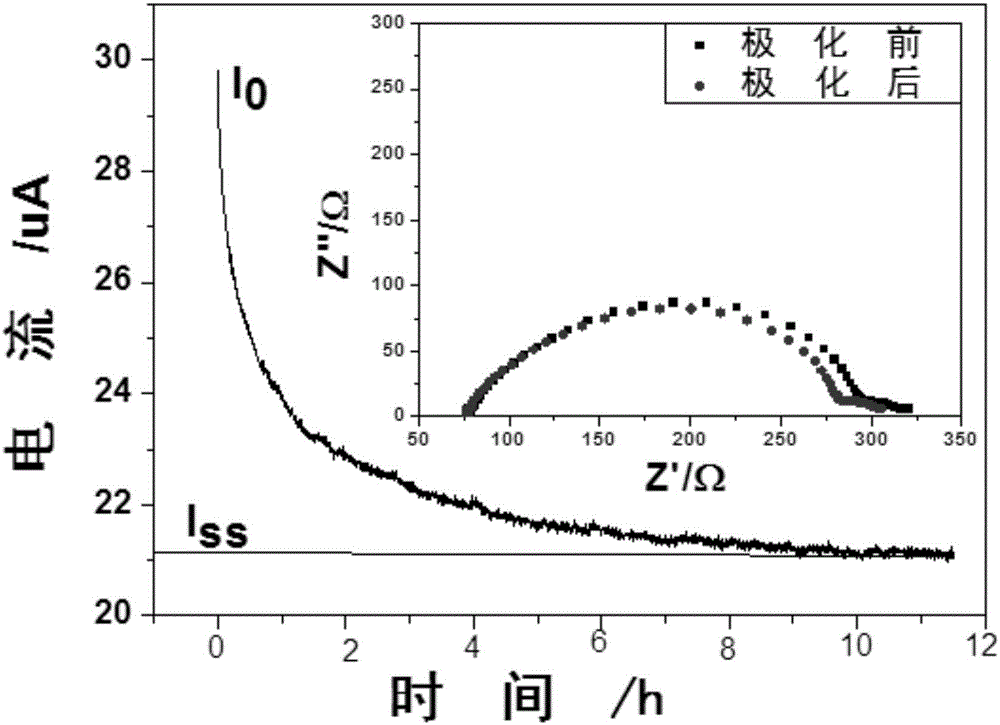

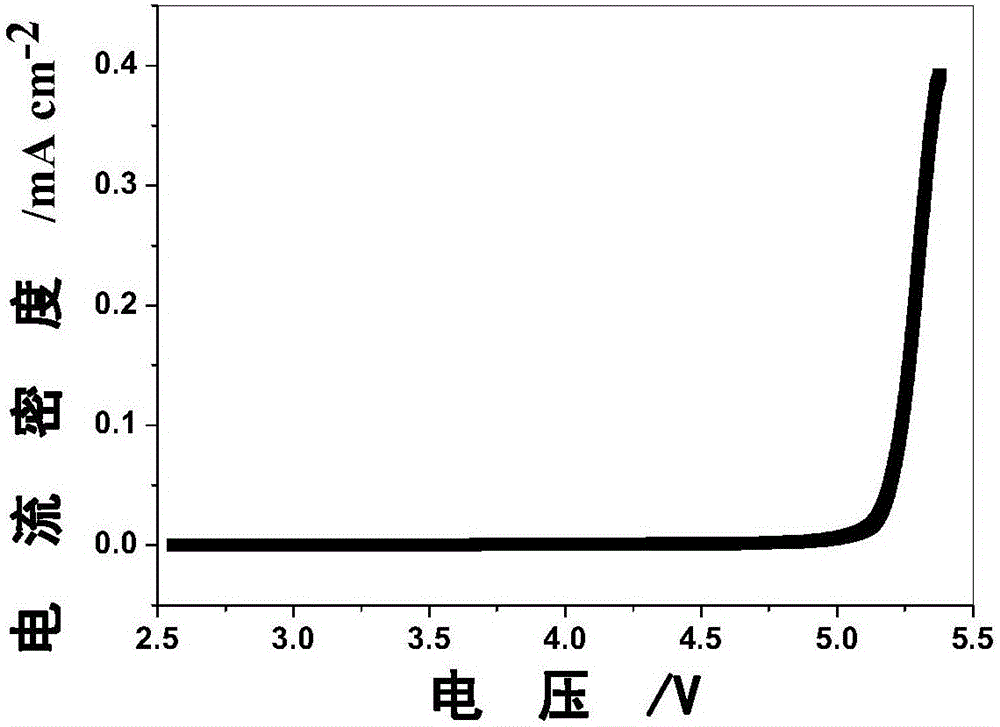

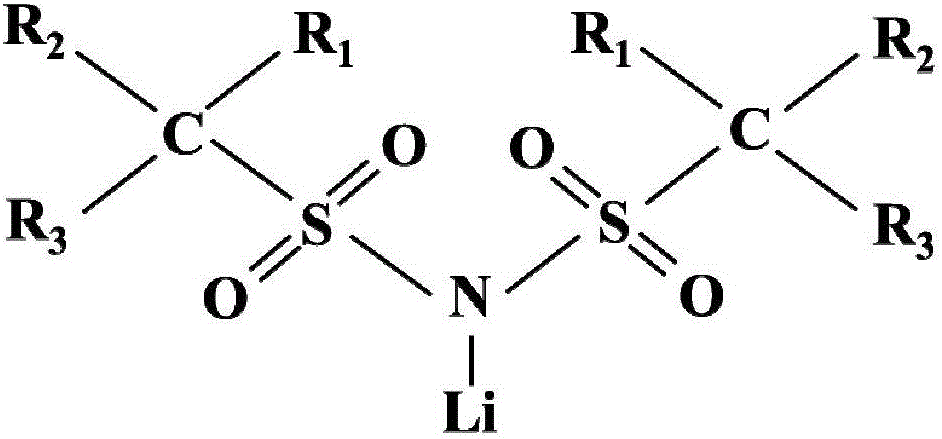

Polymer electrolyte for lithium ion battery and preparation method

ActiveCN106785032AImprove Interface StabilityGrowth inhibitionSolid electrolytesSecondary cellsCross-linkPolymer science

The invention provides a polymer electrolyte for a lithium ion battery and a preparation method, relating to the field of the electrolyte for the lithium ion battery. Specifically, the invention relates to the polymer electrolyte which is prepared by cross-linking and curing a silane terminal blocked polyether oligomer as a prepolymer, a conductive lithium salt as a lithium source, an organic solvent as a plasticizer and tin salt as a catalyst and application of the polymer electrolyte in the lithium ion polymer battery. The polymer electrolyte has the characteristics of polypropylene oxide (PEO) and silicone rubber and has excellent mechanical property, high / low temperature resistance stability, electrochemical stability, window stability and high ionic conductivity; the lithium ion battery still can work at 80 DEG C; the preparation condition and the process are simple and easy to control; the polymer electrolyte has excellent flexibility; the growth of cathode lithium dendrites can be effectively restrained; the interface stability of the lithium ion polymer battery is promoted; the polymer electrolyte is suitable for the flexible lithium ion polymer battery.

Owner:BEIJING UNIV OF TECH

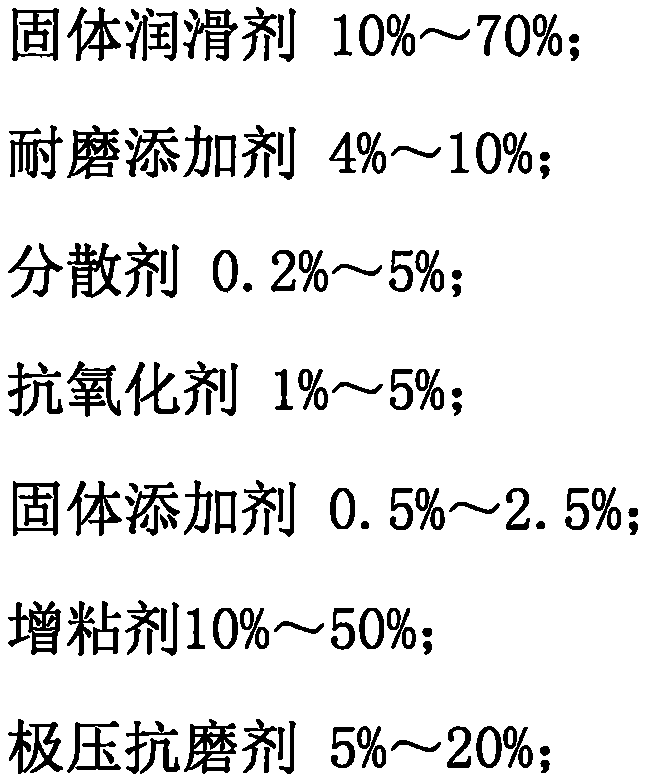

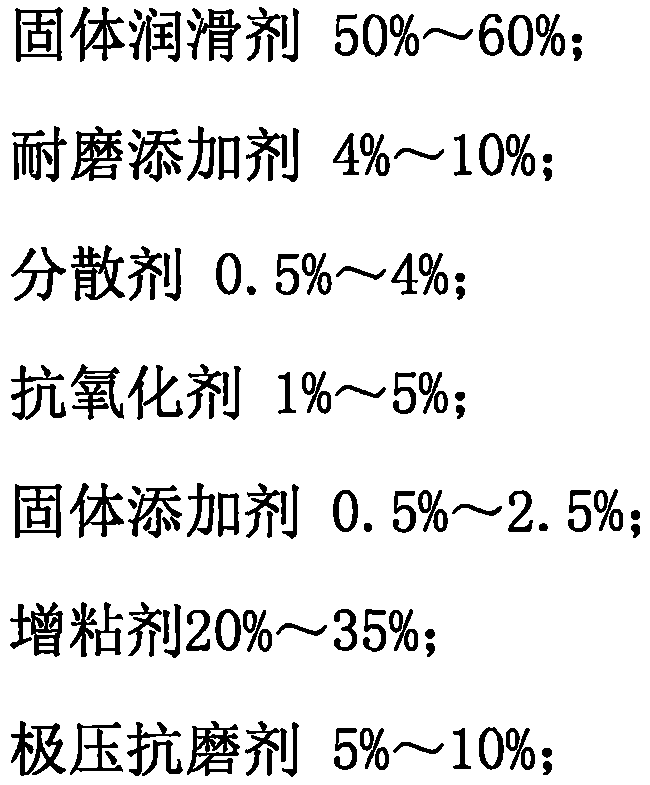

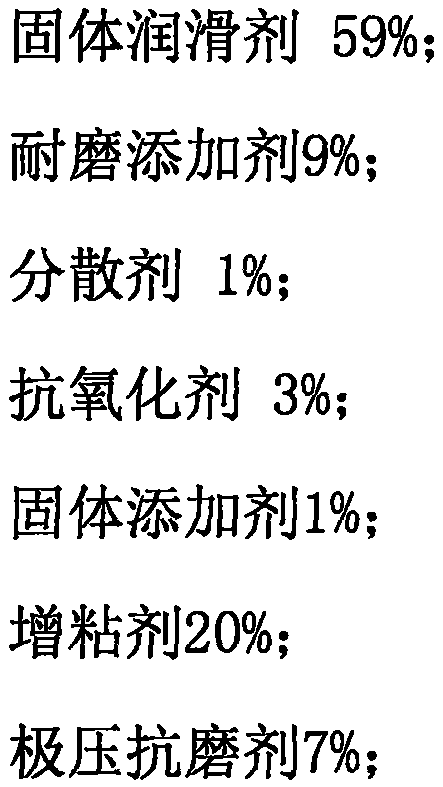

Quick-dry type dry film lubricating agent and preparation method thereof

PendingCN106566605AUniform film coverageGood insulationLubricant compositionUltrasonic oscillationWear resistant

The invention belongs to the technical field of preparation of lubricating agents for lubricating solid, and particularly relates to a quick-dry type dry film lubricating agent and a preparation method thereof. The quick-dry type dry film lubricating agent consists of the following raw materials in percentages by weight: 10-70% of a solid lubricating agent, 4-10% of a wear-resistant additive, 0.2-5% of a dispersing agent, 1-5% of an antioxidant, 0.5-2.5% of a solid additive, 10-50% of a tackifier and 5-20% of an anti-wear reagent at extreme pressure. The preparation method comprises the following steps: evenly mixing and stirring the various weighed components; carrying out ultrasonic oscillation on the components for 30-60 minutes in a stirring process; drying the components at the temperature of 80-100 DEG C until the weight percentage of water in the components is 20-30%; and grinding the dried components to obtain the lubricating agent. The film forming speed is high, the film forming time is about 15-30 seconds at normal temperature, and a film covers evenly.

Owner:东莞市颖兴金属表面处理材料有限公司

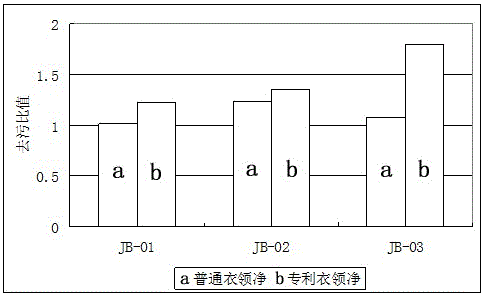

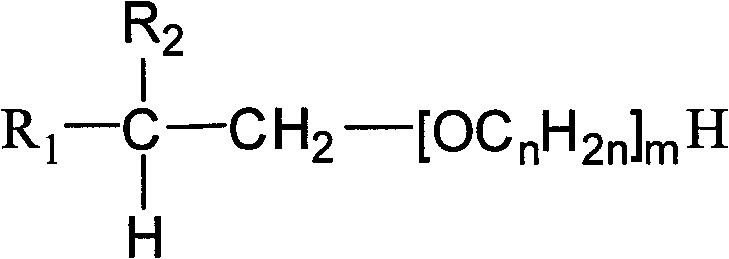

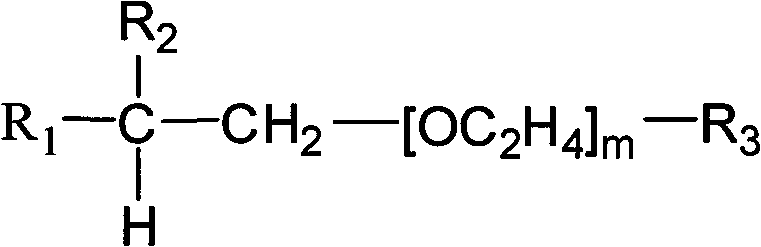

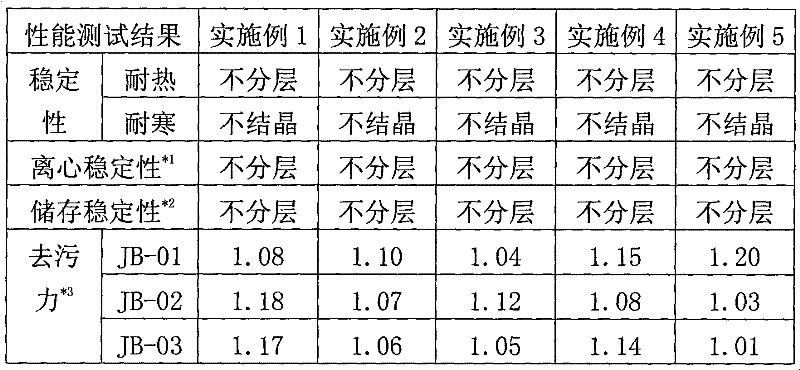

Total-effect clothing pre-washing agent free from organic solvent

InactiveCN105754745AExcellent physical and chemical propertiesGood high and low temperature stabilityNon-ionic surface-active compoundsOrganic detergent compounding agentsProtein stainingHydrotrope

The invention relates to a total-effect clothing pre-washing agent free from an organic solvent. The organic solvent has different degrees of toxic actions to the human body, is combustible and easy to explode, pollutes the environment and has obvious limitation. The total-effect clothing pre-washing agent disclosed by the invention is prepared from an anionic surfactant, a nonionic surfactant, an emulsifier with an HLB value of 5-13, aids, a short chain surfactant, a pH value regulator, a hydrotropic agent, a preservative, essence and water, wherein the emulsifier with the HLB value of 5-13 replaces a common organic solvent and is scientifically compatible with detergents and other aids, oily dirt is removed in emulsifying and dispersing modes, the ratio of the emulsifier to the detergent is between 1:10 and 2:1, an effect of removing multiple stains is achieved, and the stain removal ratios of standard carbon black stained cloth, protein stained cloth and sebum stained cloth are all over 1.0.

Owner:于文 +1

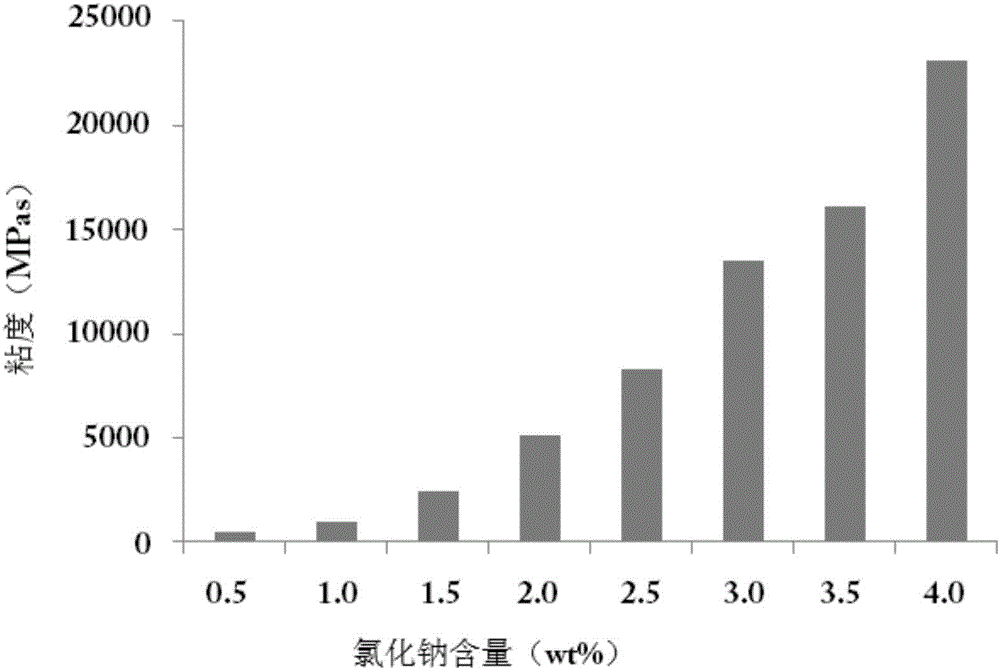

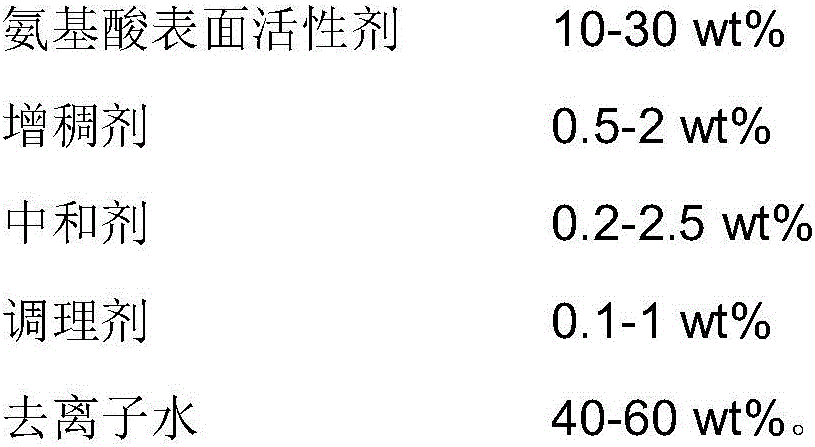

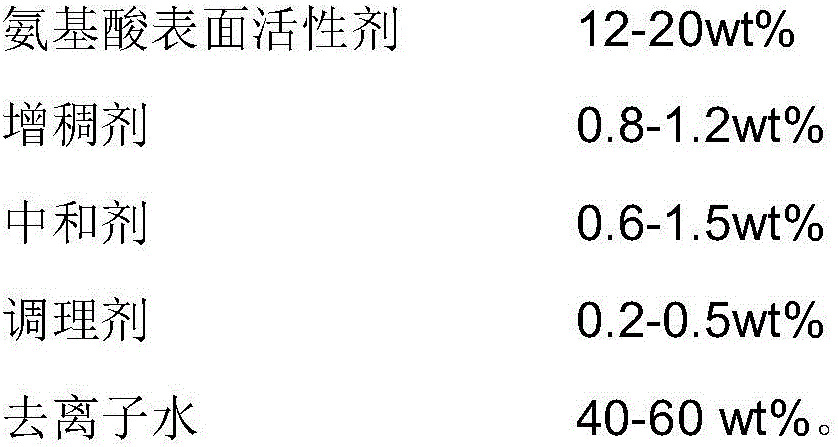

Amino acid type facial cleanser and preparation method thereof

ActiveCN106726698AHigh and low temperature stabilityAppropriate consistencyCosmetic preparationsToilet preparationsCleansers skinEmulsion

The invention provides an amino acid type facial cleanser which is prepared from the following raw materials in percentage by weight: 10 to 30 percent of amino acid surfactant, 0.5 to 2 percent of thickener, 0.2 to 2.5 percent of neutralizer, 0.1 to 1 percent of conditioner and deionized water. The invention also provides a preparation method of the amino acid type facial cleanser. The preparation method comprises the steps of firstly, thinning the thickener, adding the amino acid surfactant, stirring, dissolving, adding the conditioner and the like, and standing for one night, so as to obtain the amino acid type facial cleanser. The amino acid type facial cleanser provided by the invention is neutral, mild and skin-friendly, safe and non-irritant without adding burden to skin, capable of deeply cleaning the skin, and suitable for any skin and can be used for a long term, and after the skin is cleaned by using the cleanser, the skin can quickly return to oil-water balance and acid-base balance; the texture of the cleanser is emulsion appearance, and the cleanser has excellent appearance and moisture retention, excellent in high and low temperature stability, has a certain thickness and can provide good user using experience.

Owner:SHANGHAI INOHERB COSMETIC

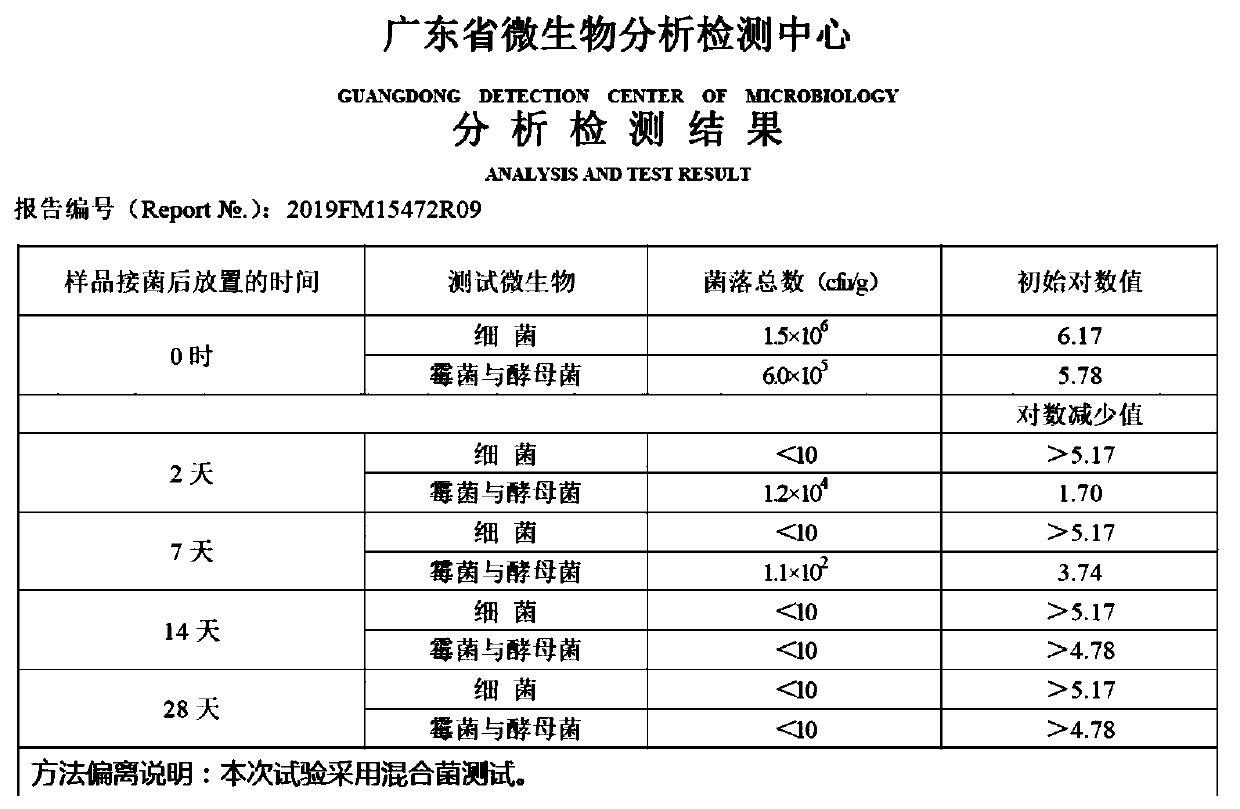

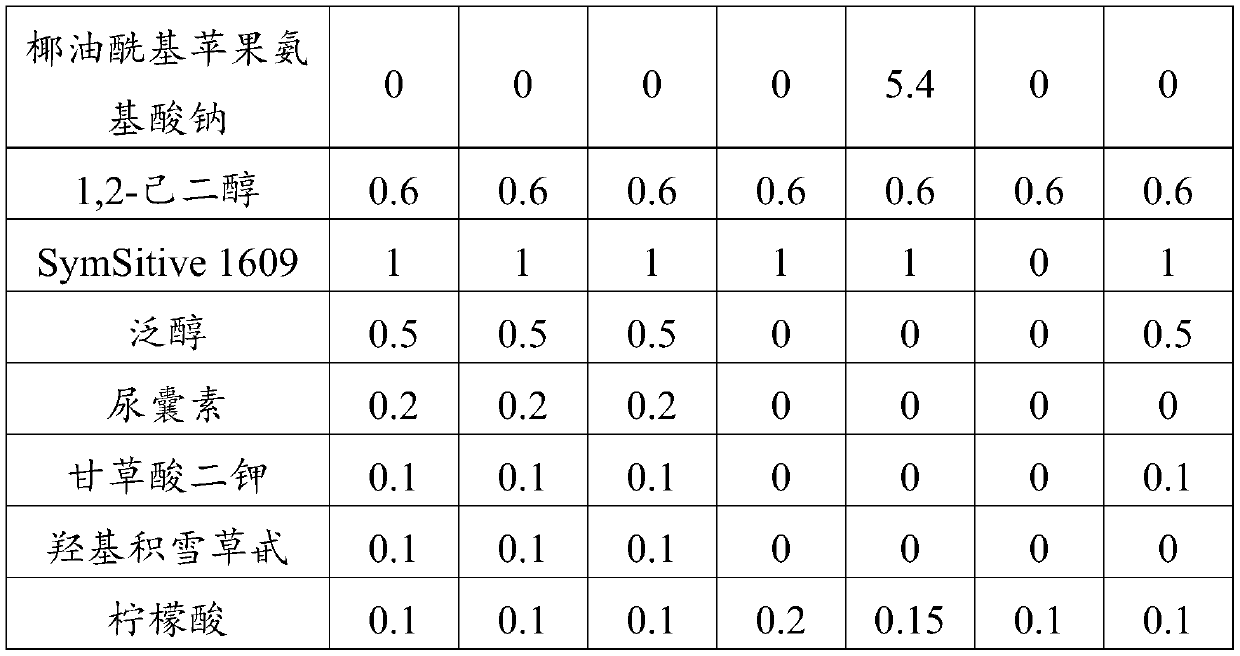

Mild face-cleaning active cleansing foam suitable for sensitive skin

InactiveCN111529420AImprove air tightnessGood air tightnessCosmetic preparationsMake-upCocoyl glutamateActive agent

The invention provides mild face-cleaning active cleansing foam suitable for sensitive skin. The mild face-cleaning active cleansing foam comprises moisturizing and conditioning components, surfactantcomponents, allergy-resisting relaxing components and pH regulating components, wherein the surfactant components comprise the following components in percentage by weight of 3%-6% of cocoyl glutamate acid TEA salts, 1.5%-3% of disodium cocoyl glutamate, 0.6%-3% of lauryl hydroxysultaine and 0.3%-1.8% of sodium taurine cocoyl methyltaurate; the allergy-resisting relaxing components comprise the following components in percentage by weight of 0.5%-1.0% of panthenol, 0.1%-0.2% of allantoin, 0.1%-0.2% of dipotassium glycyrrhizinate and 0.1%-0.2% of madecassoside. The moisturizing and conditioning components in the face-cleaning active cleansing foam achieve the effects of immediate relaxing sensitive skin, resisting inflammation, moisturizing, conditioning and repairing. The face-cleaning active cleansing foam is low in stimulability, has good tenderness, is good in capacity for removing makeup, can easily remove base makeup and eye and lip makeup, and is non-irritating when entering eyes.

Owner:泉后(广州)生物科技研究院有限公司

Powder metallurgy high-strength bearing material and preparation method thereof

The invention discloses a powder metallurgy high-strength bearing material and a preparation method thereof. The powder metallurgy high-strength bearing material is prepared from the following raw materials of, by weight, 85-90 parts of aluminum, 5-8 parts of iron, 3-4 parts of copper, 1-2 parts of silicon, 0.5-1 parts of magnesium, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methyl cellulose, 1-1.5 parts of graphite, 1-2 parts of pine sawdust, 0.3-0.4 part of yttrium oxide, 0.8-1.5 parts of carbon microspheres and an appropriate amount of oleic acid. The bearing material prepared through the preparation method has the characteristics such as smaller particle size, uniform distribution, high hardness, high flexure strength, high fracture toughness and good high-low-temperature stability, and is worth popularizing.

Owner:HEFEI ZHENGHAO MECHANICAL TECH

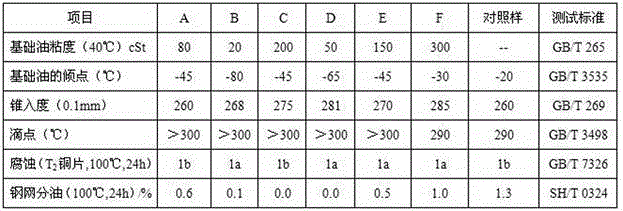

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724AImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed onthe bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolongedat a maximum level.

Owner:KINGDREAM PLC CO +2

Chemical detergent for clearing hard scales from air pre-heater and preparation method thereof

InactiveCN107674778AEasy to cleanNo corrosionInorganic/elemental detergent compounding agentsCationic surface-active compoundsPentaerythritolPhosphate

The invention discloses a chemical detergent for clearing hard scales from an air pre-heater, and belongs to the technical field of detergents. The chemical detergent is prepared from the following ingredients in parts by weight: 22-25.5 parts of 3-methoxy propylamine, 8.3-9.7 parts of pentaerythritol phosphate, 11.2-12.9 parts of N,N-dimethylacetamide, 1.4-2.6 parts of sodium hydroxide, 18.8-20 parts of trisodium phosphate, 7.3-8.8 parts of corrosion inhibitor, 5.6-6.4 parts of stripper, 3.2-4.1 parts of penetrant, 2.5-3.3 parts of surfactant, 8.7-9.6 parts of scale inhibitor, 3.5-4.4 parts of dispersant and 45-58 parts of water. The detergent provided by the invention has the advantages of good comprehensive performance, remarkable cleaning effect and stable performance, and can form a protective layer on the surface of the air pre-heater to play roles in inhibiting scales and preventing rust, and thus, the service life of the air pre-heater is prolonged.

Owner:NANYANG INST OF TECH

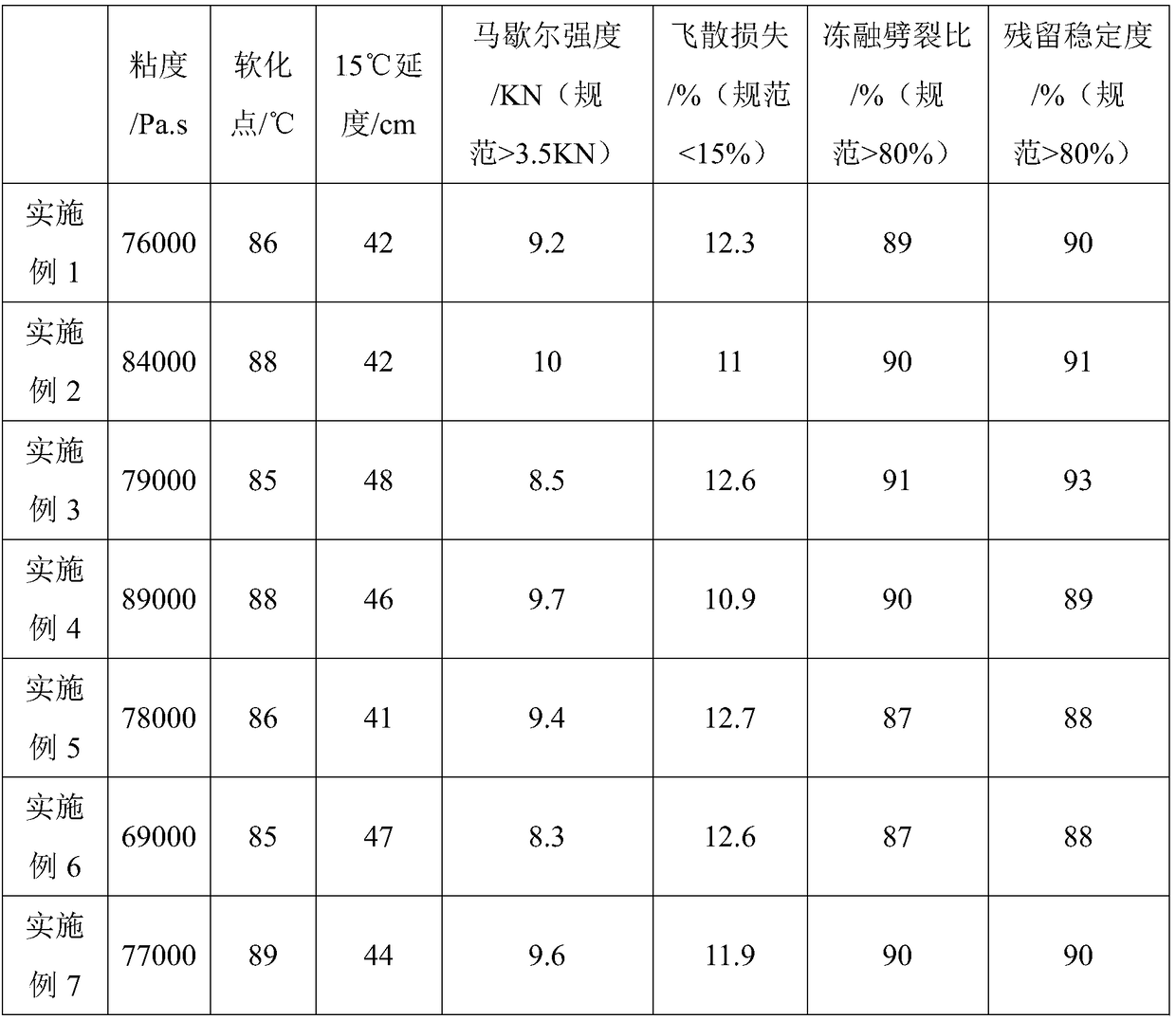

Preparation method for compound modified emulsified asphalt material and application thereof in porous pavements

InactiveCN109233311AImprove viscosity and penetrationReduce sensitivityBuilding insulationsBituminous materialsButadiene-styrene rubber

The invention discloses a preparation method for a compound modified emulsified asphalt material and an application thereof in porous pavements and belongs to the technical field of road materials. The compound modified emulsified asphalt material is acquired by mixing 50-59 parts of porous pavement, 5-45 parts of emulsified asphalt modified additive, 1-4.5 parts of styrene-butadiene latex and 0.1-1 part of dispersing agent and then stirring for 30min at 300r / min. The emulsified asphalt modified additive contains the following components: 5-10 parts of polyphosphoric acid, 15-30 parts of thermoplastic polyurethane elastomer, 10-20 parts of styrene-butadiene segmented copolymer, 10-15 parts of nonionic asphalt emulsifier and 45-80 parts of deionized water. According to the invention, viscosity, softening point and 15 DEG C ductility of evaporated residue of modified emulsified asphalt can be effectively promoted; strength, abrasive resistance and low-temperature toughness of asphalt canbe promoted; brittle rupture can be prevented; after the compound modified emulsified asphalt is paved on a porous pavement, the porous pavement has the characteristics of high bonding strength and strong weather fastness; the compound modified emulsified asphalt material has an industry value.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

Low-temperature efficient liquid detergent composition and preparation process thereof

ActiveCN102533462AGood low temperature cleaning performanceImprove hard water resistanceAnionic-cationic-non-ionic surface-active compoundsWater savingHard water

A low-temperature efficient liquid detergent composition consists of, by weight, anionic surface agent 8-15%, non-ionic surface active agent 2-5%, anionic surface agent containing branched chains 5-14%, 4A zeolite 15-25%, sodium carbonate 2-6%, sodium silicate 2-6%, sodium citrate 0-5%, de-flocculating agent 0.005-0.5%, fluorescent brightener 0-0.1%, enzyme for washing 0-1%, preservative 0-0.1%, essence 0-0.2% and the balance water. The low-temperature efficient liquid detergent composition has the advantages of being good in low-temperature cleaning performance, hard water resisting performance and water-saving performance.

Owner:CHINA RES INST OF DAILY CHEM IND

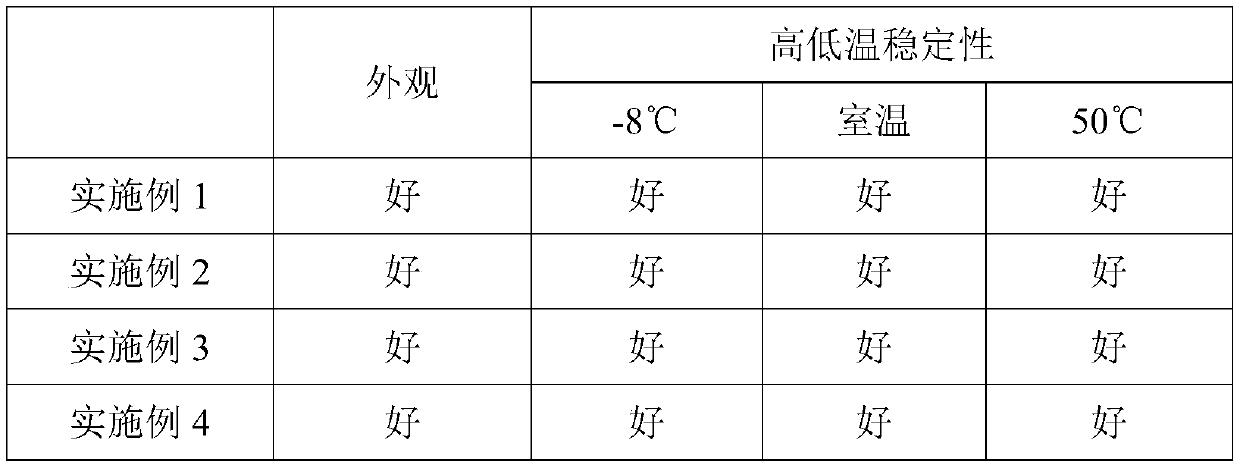

No-clean disinfection mousse composition

InactiveCN111249169AGood dispersionImprove wettabilityCosmetic preparationsToilet preparationsGlycineAlcohol ethyl

The invention relates to the technical fields of disinfection and sterilization, and more specifically relates to a no-clean disinfection mousse composition. The composition uses a novel material N-alkylpropylaminoglycine, the content and ratio of ethanol and the N-alkylpropylaminoglycine are adjusted, the foaming speed and foam tightness are adjusted, so that the dispersibility, wettability and drying speed of the no-clean mousse based on N-alkylpropylaminoglycine on hands are greatly improved, and the use sense and acceptance of the product are improved; the formula is simple, the productionprocess is convenient, a large amount of ethanol does not need to be added, and the safety factor in the production process is high; and in addition, the appearance is clear without turbidity or precipitation, has excellent high and low temperature stability, and does not show delamination, discoloration, precipitation and other phenomena when stored for 3 months at the environments of -8 DEG C,room temperature and 50 DEG C.

Owner:上海绿瑞生物科技有限公司

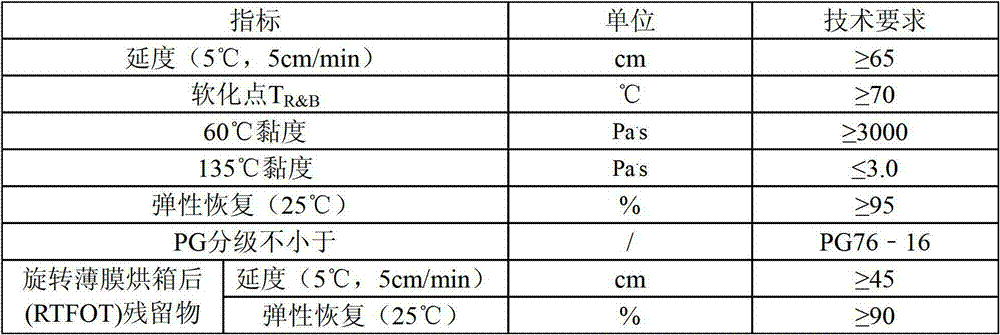

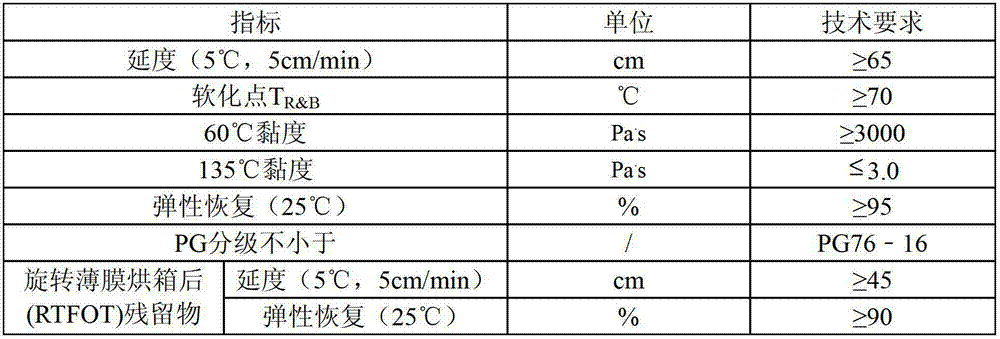

Composite modified asphalt material applicable to anti-crack layer with pavement structure and preparation method thereof

ActiveCN102876058AImprove fatigue lifeReduce singularityBuilding insulationsRoad surfaceReflective crack

The invention discloses a composite modified asphalt material applicable to an anti-crack layer with a pavement structure and a preparation method of the composite modified asphalt material. The composite modified asphalt comprises the following components by weight: 83.2-87.6 parts of substrate asphalt, 3.1-4.2 parts of thermoplastic styrene butadiene rubber (SBS), 1.3-1.7 parts of powder butadiene styrene rubber (PSBR), 5.3-6.7 parts of desulfuration rubber powder, 1.8-2.5 parts of acetyl tributyl citrate (ATBC), and 0.9-1.7 parts of accelerant, the sum of the parts in weight is 100, the accelerant is rubber filling oil. The composite modified asphalt is applicable to the anti-crack layer with the pavement structure; the anti-crack layer is usually used for a rigid-flexible composite pavement layer for additionally paving asphalt surface layer on a concrete rigid base layer with seams (old concrete pavement), also can be used for semi-rigid base asphalt pavement, so that delay the forming and expanding of reflection cracks can be delayed, the capability of the pavement structure is improved to resist fatigue cracks, the service quality of the pavement structure is improved, and the service life of the pavement structure is prolonged.

Owner:清远市金运再生资源有限公司

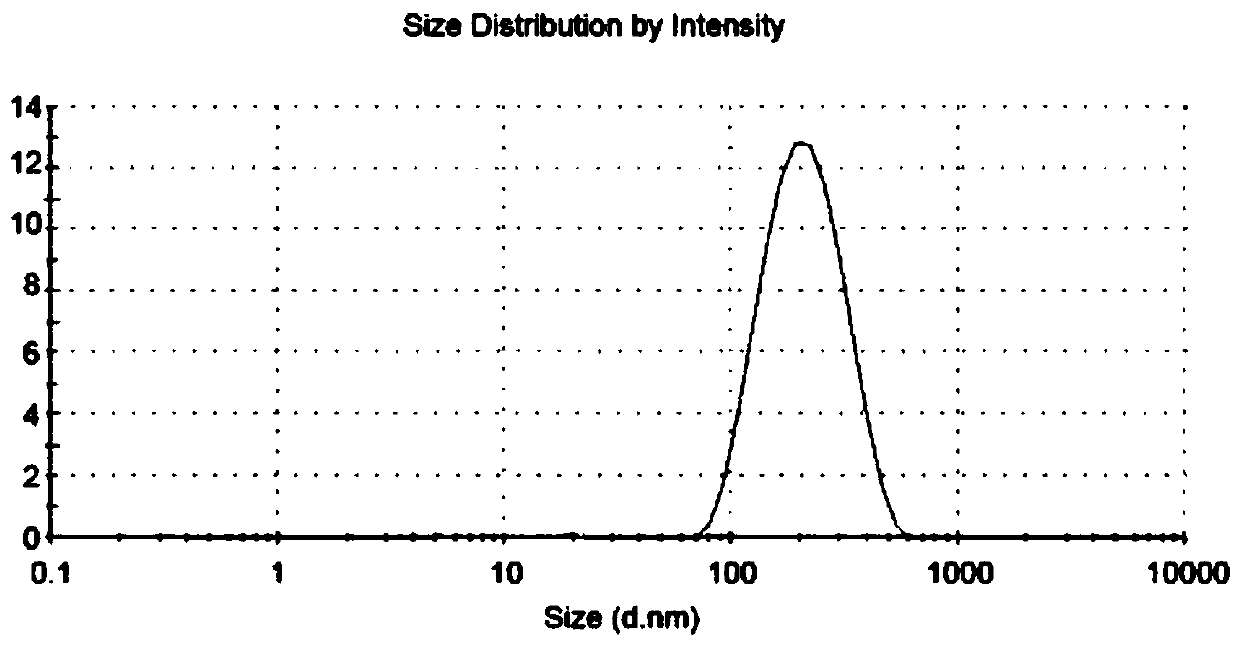

Skin-caring nano snake oil skin-care preparation

ActiveCN1762329APromote absorptionGood dispersionCosmetic preparationsToilet preparationsEmulsionGlycerol

Disclosed is a skin-caring nano snake oil skin-care preparation comprising at least the following components (by weight ratio): 0.001-25% of nanometer snake oil emulsion including medium and particles dispersed therein, the particles have a diameter of 1-200nm, and are snake oil coated by phosphatide, the medium being mixture of water and glycerol. The nano snake oil emulsion comprises 5-20 wt% of snake oil, 0.1-70 wt% of emulsifying agent. And 5-98 wt% of water.

Owner:克劳丽化妆品股份有限公司

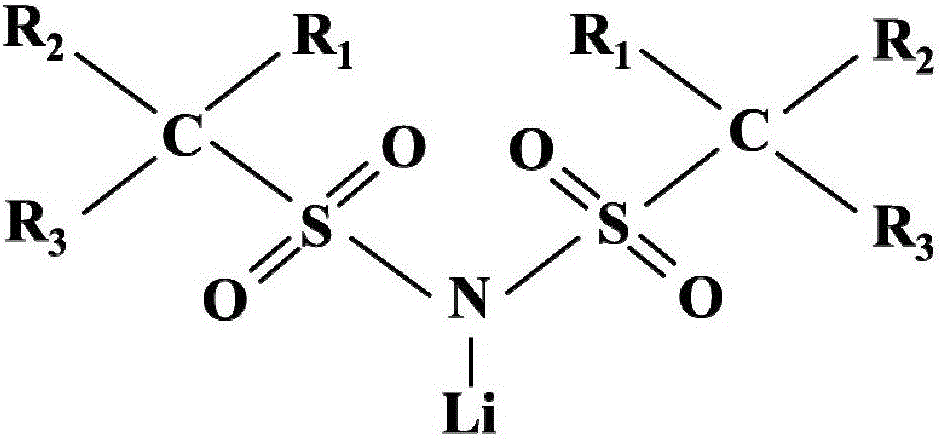

Electrolyte improving high temperature performance of battery, and lithium ion battery

InactiveCN106169609AImprove high temperature performanceIncrease energy densitySecondary cellsOrganic electrolytesHigh temperature storageElectrical battery

The present invention discloses an electrolyte improving high temperature performance of a battery, and a lithium ion battery. The electrolyte comprises a lithium salt, a non-aqueous solvent, a film formation additive, and a dehydrator. The chemical formula of the lithium salt is as shown in the specification, wherein R1, R2 and R3 are any one of alkyl, alkoxy carbonyl, alkyl sulfonyl, alkenyl, and a halogen atom with 1-12 carbon atoms. According to the electrolyte, the novel lithium salt, the film formation additive and the dehydrator play a synergetic role, so that lithium manganese iron phosphate is inhibited from absorbing water so as not to lead to the fact that the electrolyte is decomposed and generates air and metal ions of a ternary material precipitate , which affects the high temperature performance of the battery. The ternary mixed manganese iron phosphate lithium battery using the electrolyte has good high temperature cycle performance and high temperature storage performance. The high temperature performance is improved, so that the high and low temperature stability performance is improved, the high and low temperature security is ensured, the application range of the lithium ion battery is enlarged, and the product competitiveness is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

High-speed railway door system rubber sealing strip protection grease composition and preparation method thereof

InactiveCN106479610AGood compatibilityImprove stabilityLubricant compositionPerfluoropolyetherThermal insulation

The invention discloses a high-speed railway door system rubber sealing strip protection grease composition and a preparation method thereof, and belongs to the technical field of sealing greases, wherein the raw materials comprise, by weight, 40-80% of base oil, 10-50% of a thickener, 0-20% of a filler, 0.5-5% of a metal corrosion inhibitor, and 0-5% of an antioxidant, The invention further provides a preparation method of the protection grease composition, wherein the raw materials are subjected to thermal insulation activation, heating smelting and stirring grinding to prepare the high-speed railway door system rubber sealing strip protection grease composition. According to the present invention, the inert substance is used to form the perfluoropolyether lubricating grease type high-speed railway door system sealing grease, such that the obtained grease composition has characteristics of extremely low oil separation rate, white color, no pollution, and excellent high-low temperature stability; the good sealing property is ensured while the good protection performance is provided for the sealing glue strip and the metal member, such that the grease composition is the ideal high-speed railway door system sealing grease; and the preparation method is simple, is easy to control, and is suitable for industrialization.

Owner:青岛市资源化学与新材料研究中心

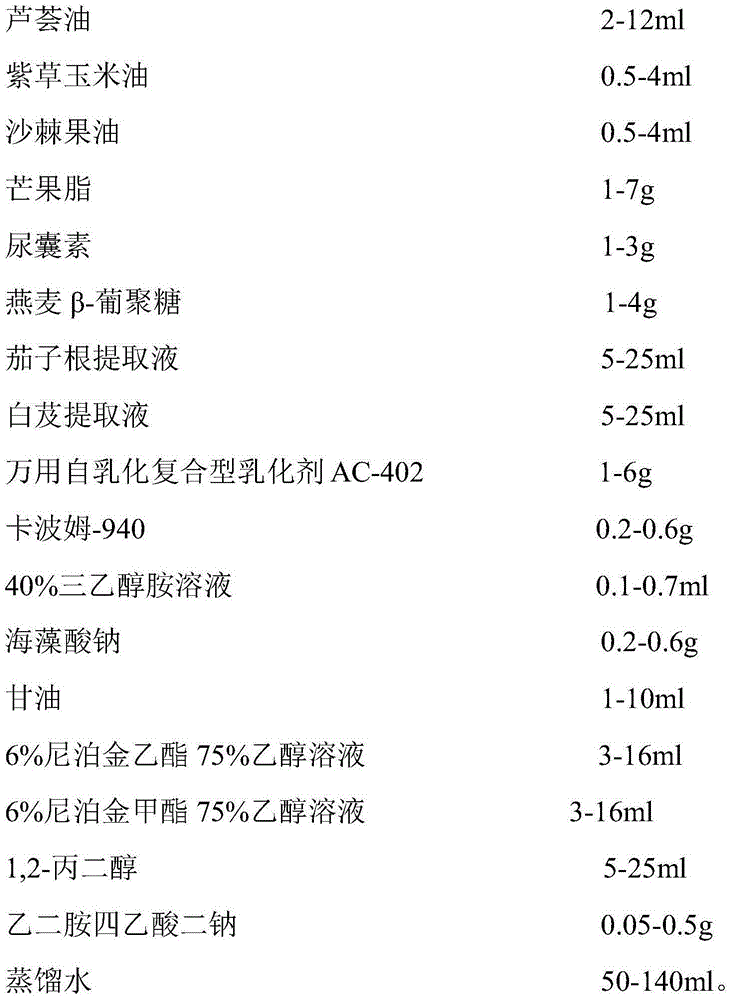

Chilblain ointment capable of protecting skin and smoothening scars as well as preparation method of ointment

ActiveCN105106660AMild in natureGood skin feelOrganic active ingredientsAerosol deliverySelf emulsifyingEthyl paraben

The invention discloses a chilblain ointment capable of protecting skin and smoothening scars as well as a preparation method of the ointment. The chilblain ointment comprises substances as follows: argan oil, horse fat, snake oil, aloe oil, mango grease, arnebia and corn oil, sea buckthorn fruit oil, oat beta-glucan, an eggplant root extract liquid, a bletilla extract liquid, allantoin, a universal self-emulsifying compound emulsifier AC-402, carbomer-940, a 40% triethanolamine solution, sodium alginate, ethylene diamine tetraacetic acid disodium salt, glycerin, a 75% ethyl alcohol solution of 6% ethylparaben, a 75% ethyl alcohol solution of 6% methylparaben, 1,2-propylene glycol and distilled water. Compared with the prior art, the chilblain ointment is mild and non-irritating in property and high in safety and can nourish problem skin deeply, significantly reduce the recurrence rate of chilblains, promote body surface blood circulation and metabolism, stimulate pore detoxification, promote wound healing, diminish inflammations, relieve pain, soften and whiten the skin and reducing speckles.

Owner:上海麦坤特医药科技有限公司

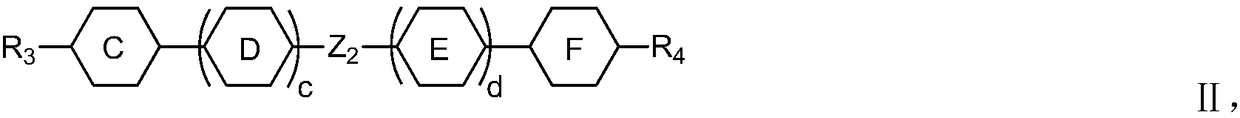

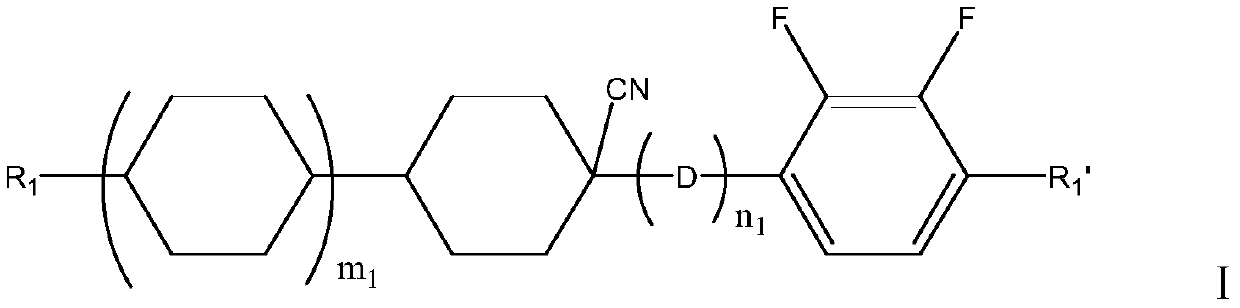

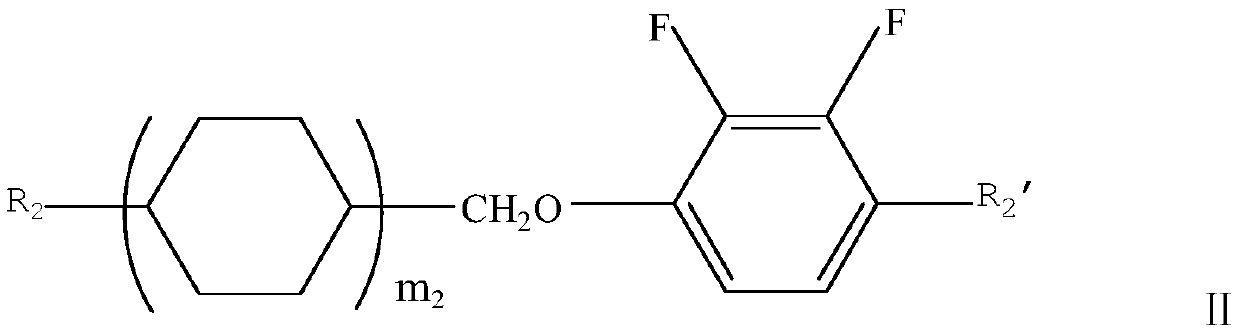

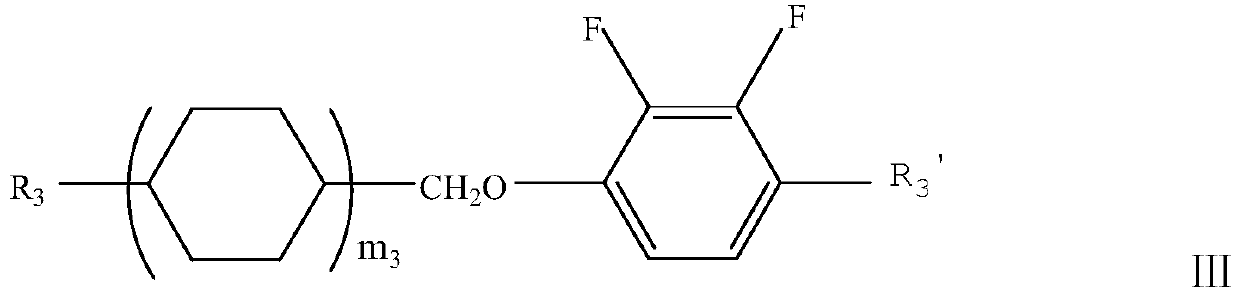

Liquid crystal composition with low threshold, low power consumption and wide working temperature range for VA-LCD

PendingCN110396413ALarge negative dielectric anisotropyModerate miscibilityLiquid crystal compositionsPhysical chemistryWorking temperature

The present invention relates to a low-threshold liquid crystal composition with low threshold, low power consumption and a wide working temperature range for VA-LCD. The composition contains 3-90% ofa compound selected from a formula (I) as a first component; 1-75% of a compound selected from a formula (II) as a second component; 1-75% of a compound selected from a formula (III) as a third component; 1-65% of a compound selected from a formula (IV) as a fourth component; 0-30% of a compound selected from a formula (V) as a fifth component; 0-30% of a compound selected from a formula (VI) asa sixth component; 0-20% by weight of a compound selected from a formula (VII) as a seventh component; 0-20% of a compound selected from formulas (VIII a) and (VIII b) as an eighth component; 0-10% ofa compound selected from formulas (IX a) and (IX b) as a ninth component; 0-20% of a compound selected from formulas (X a) and (X b) as a tenth component; and 0-30% of a compound selected from formulas (XI a), (XI b) and (XI c) as an eleventh component. The composition can still ensure a wide working temperature range under conditions of low threshold and low power consumption.

Owner:HEBEI MAIERSTON ELECTRONICS MATERIAL

Wear, heat and aging-resistant lubricating oil for precision instrument and preparation method of wear, heat and aging-resistant lubricating oil

InactiveCN107903993ASimple processing methodImprove the lubrication effectLubricant compositionMethacrylateRust

The invention discloses wear, heat and aging-resistant lubricating oil for a precision instrument. The wear, heat and aging-resistant lubricating oil consists of the following raw materials in part byweight: 100 parts of composite base oil, 10-20 parts of pentaerythritol ester, 0.5-1.5 parts of dodecafluoroheptyl methacrylate, 1-3 parts of triethanolamine borate, 3-6 parts of sulfurized fatty acid ester, 1-4 parts of alkaryl calcium sulfonate, 0.3-0.8 part of a diethylbenzene coupling agent, 3-6 parts of an anti-friction lubricating additive and 2-7 parts of a modified additive. The wear, heat and aging-resistant lubricating oil disclosed by the invention has the beneficial effects that the high-quality and high-performance composite base oil is adopted to be compounded with the other modified raw materials, and the lubricating oil with high lubricating performance, high corrosion, rust and wear resistance, high high and low-temperature resistance stability, excellent heat and aging resistance and high sustainability is prepared through a simple and effective preparation method; and the lubricating oil disclosed by the invention is thick and fine liquid and is simple in processingmethod, convenient to use and suitable for the high-precision instrument.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

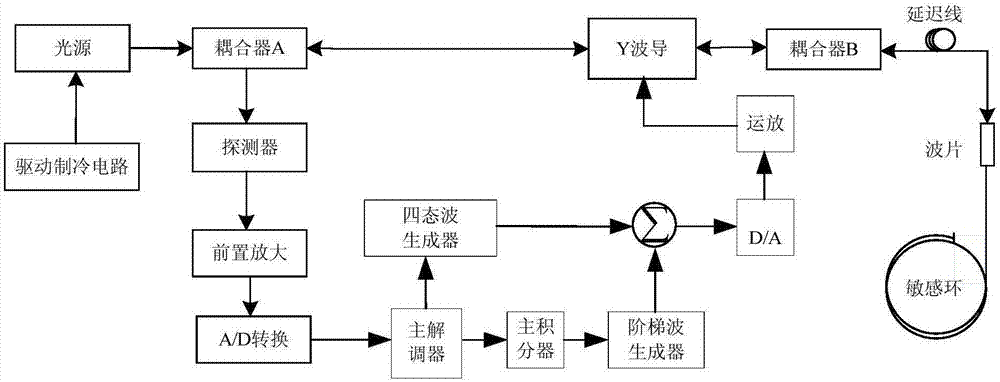

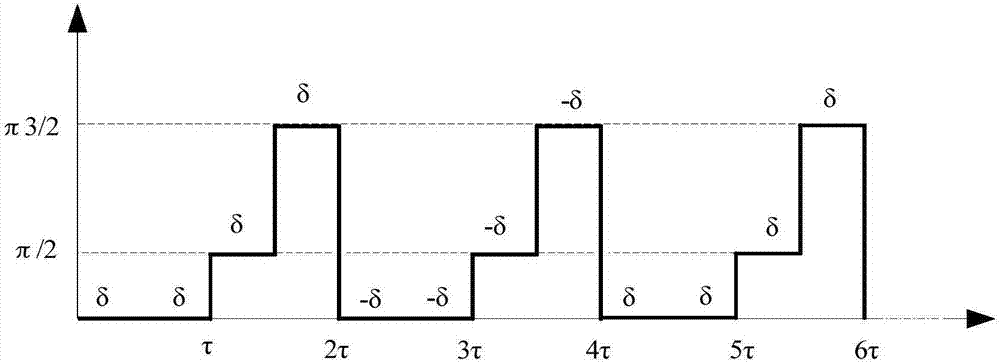

Modem method for suppressing luminous power fluctuation used for optical fiber current transducer

ActiveCN107422166AMinimize impact on test accuracyImprove test stabilityVoltage/current isolationCurrent transducerModem device

The invention discloses a modem method for suppressing luminous power fluctuation used for an optical fiber current transducer. The method comprises the following steps: switching on an optical fiber current transducer, a data demodulating module generating a modulation waveform, the modulation waveform being a four-state waveform; applying offset of a fixed amplitude on each modulation sequence in the modulation waveform, wherein a waveform corresponding to each four-state modulation cycle is a four-state waveform unit, symbols of offsets applied on the modulation sequences of adjacent four-state waveform units being opposite; after data demodulation on each two adjacent four-state waveform units, a luminous power value and a current value are obtained. The method can effectively reduce influence of luminous power fluctuation on accuracy of tests, stabilizes output, and is beneficial for improving small current measurement precision of an optical fiber current transducer, and has very important effect on improving high and low temperature stability of an optical fiber current transducer.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH +1

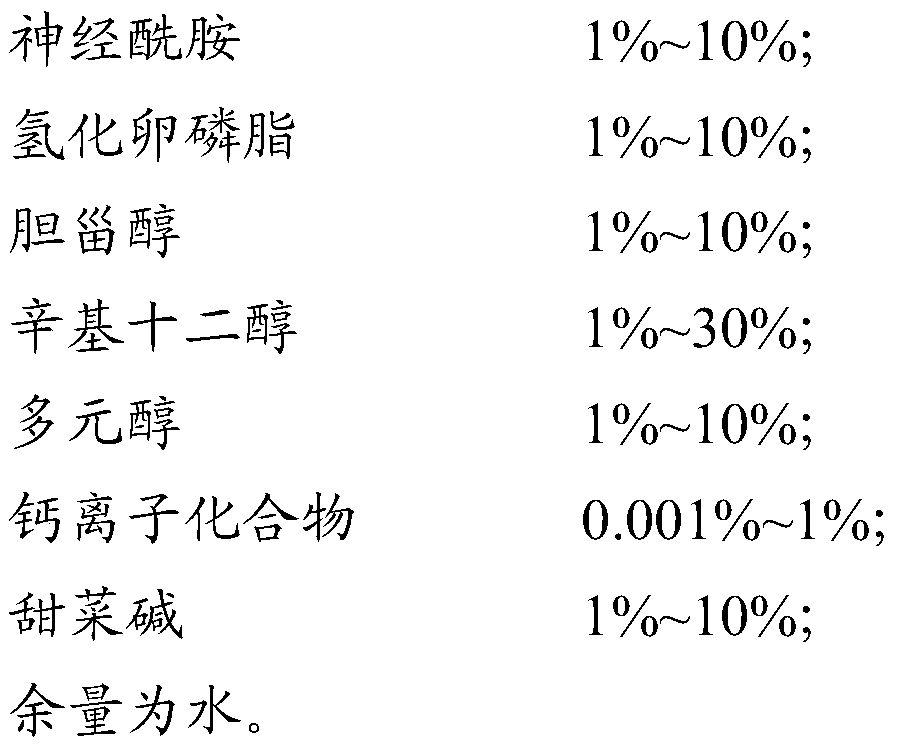

Composition capable of repairing skin barriers and preparation method and application of composition

PendingCN110638696AGood synergyObvious reliefCosmetic preparationsToilet preparationsBetaineCholesterol

The invention relates to the technical field of biological pharmaceuticals and personal nursing, in particular to a composition capable of repairing skin barriers and a preparation method and application of the composition. The composition provided by the invention consists of a calcium ion compound, ceramide, cholesterol, hydrogenated lecithin and betaine. The composition disclosed by the invention is used for repairing the skin barriers, and all the components achieve significant synergistic reactions, so that the synthesis of intercellular lipid of skin can be effectively supplemented and promoted, damaged skin and muscle can also be repaired, and skin and muscle barriers can be reconstructed. Besides, the invention provides an effective preparation method of the composition capable ofrepairing skin barriers. The composition has clear relieving and treating effects on sub-health skin of sensitive skin, atopic dermatitis and the like.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com