Quick-dry type dry film lubricating agent and preparation method thereof

A dry-film lubricant and lubricant technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of slow film-forming speed of dry-film lubricants, affecting production efficiency, and long production process cycle, achieving low friction coefficient, The effect of keeping clean and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

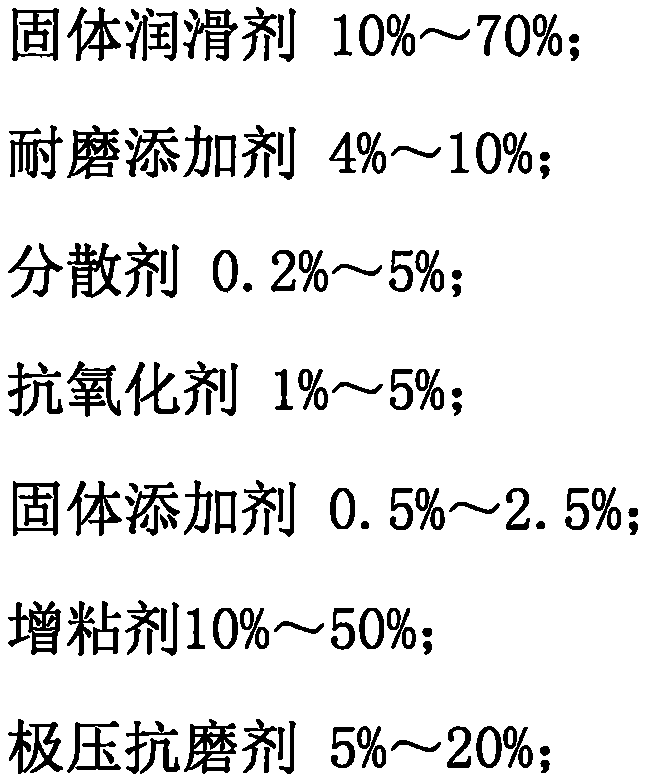

[0071] Embodiment 1: a kind of quick-drying type dry film lubricant, it is characterized in that, by weight percentage, its raw material is composed of:

[0072] Solid lubricant 10% ~ 70%;

[0073] Wear-resistant additives 4% to 10%;

[0074] Dispersant 0.2%~5%;

[0075] Antioxidant 1%~5%;

[0076] Solid additives 0.5% to 2.5%;

[0077] Tackifier 10%~50%;

[0078] Extreme pressure antiwear agent 5% to 20%;

[0079] The above-mentioned solid lubricant is selected from colloidal graphite; the described wear-resistant additive is selected from talcum powder, light calcium carbonate, precipitated barium sulfate, magnesium carbonate, silicon dioxide, magnesium oxide, high alumina cement, montmorillonite, kaolin, In zirconia; described dispersant is selected OP-10, span-80; described antioxidant is selected antimony trioxide, lead oxide; described solid additive is selected ferric oxide, nickel zinc copper ferrite for use; Described tackifier selects sodium silicate, potassium...

Embodiment 2

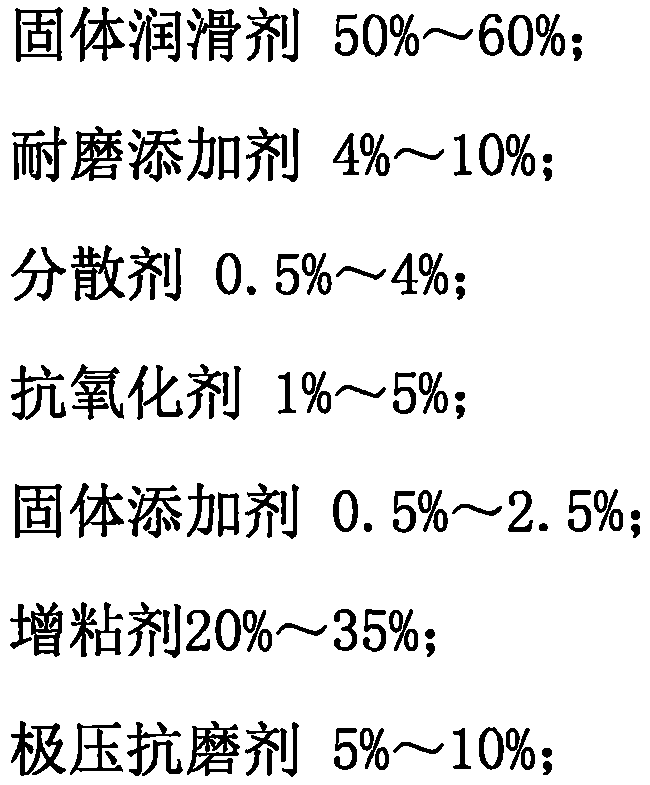

[0081] Embodiment two: a kind of quick-drying type dry film lubricant is characterized in that, by weight percentage, its raw material is composed of:

[0082] Solid lubricant 50% ~ 60%;

[0083] Wear-resistant additives 4% to 10%;

[0084] Dispersant 0.5%~4%;

[0085] Antioxidant 1%~5%;

[0086] Solid additives 0.5% to 2.5%;

[0087] Tackifier 20%~35%;

[0088] Extreme pressure antiwear agent 5% to 10%;

[0089] The above-mentioned solid lubricant selects polytetrafluoroethylene and light calcium carbonate; the described wear-resistant additive selects magnesium carbonate, silicon dioxide, magnesium hydroxide, aluminum hydroxide, magnesium oxide, high alumina cement, kaolin, oxide Zirconium; described dispersant selects tween-20, polyethylene glycol, polyvinyl butyral for use; described antioxidant selects alkylated phenyl-alpha-naphthylamine, octyl-butyl diphenylamine, containing Ester-based phenol; the solid additive is manganese-zinc ferrite and magnesium-zinc ferrit...

Embodiment 3

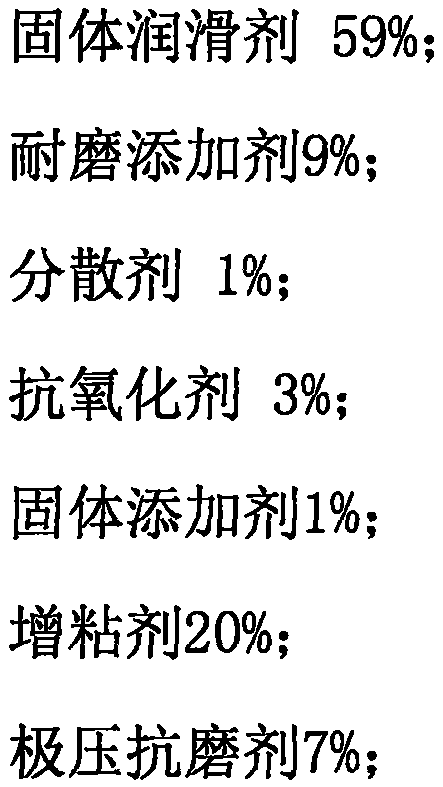

[0091] Embodiment three: a kind of quick-drying type dry film lubricant, it is characterized in that, by weight percentage, its raw material is composed of:

[0092] Solid lubricant 59%;

[0093] Anti-wear additive 9%;

[0094] Dispersant 1%;

[0095] Antioxidant 3%;

[0096] Solid additive 1%;

[0097] Tackifier 20%;

[0098] Extreme pressure antiwear agent 7%;

[0099] The above-mentioned solid lubricant is selected from polytetrafluoroethylene and nano-diamond; the described wear-resistant additive is selected from precipitated barium sulfate, magnesium carbonate, silicon dioxide, magnesium hydroxide, high alumina cement, montmorillonite, kaolin, zirconia Described dispersant selects polyvinyl formal, polyvinyl butyral for use; Described antioxidant selects octyl-butyl diphenylamine, containing ester group phenol, containing ester group hindered phenol; Described solid additive Nickel-zinc-copper ferrite and manganese-zinc ferrite are selected; the tackifier is select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com