Glass insulator

A glass insulator and terminal technology, applied in insulators, lead-in/through-type insulators, electrical components, etc., can solve the problems of increasing the probability of air leakage, high thermal expansion coefficient, reducing sealing performance, etc., to improve sealing performance, high resistance Voltage and current performance, the effect of reducing the chance of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

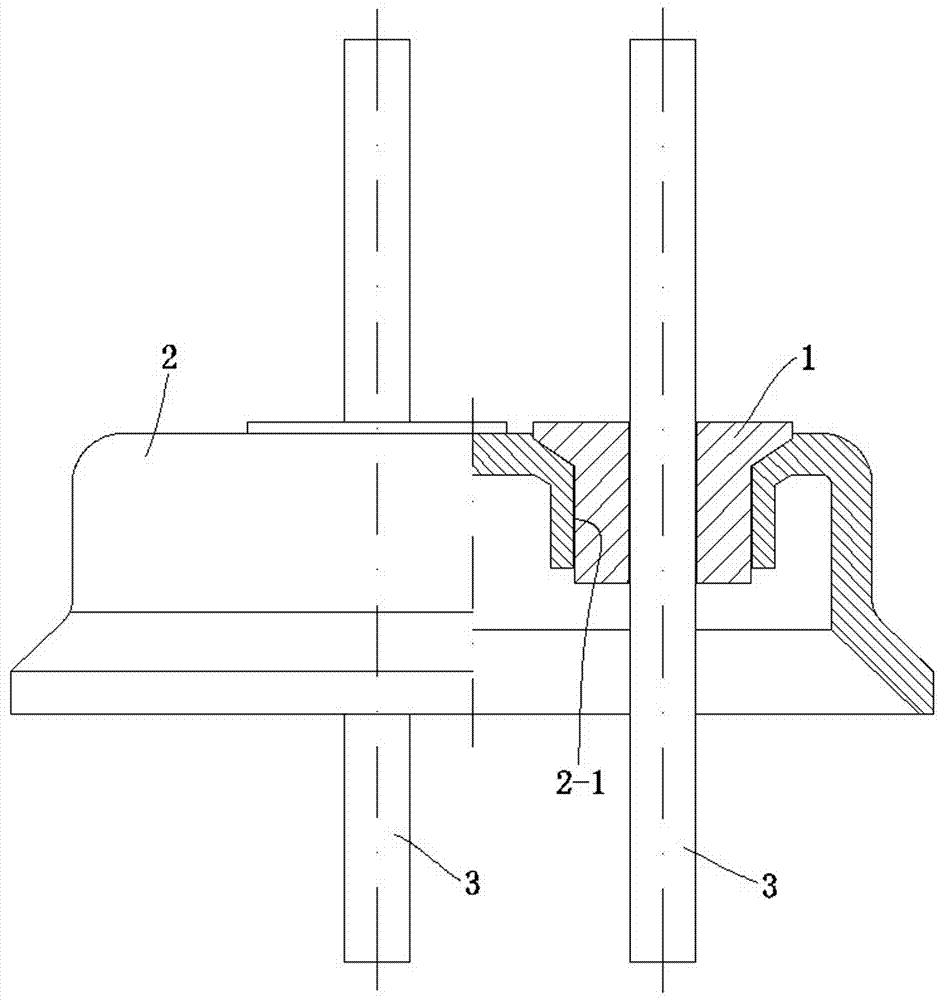

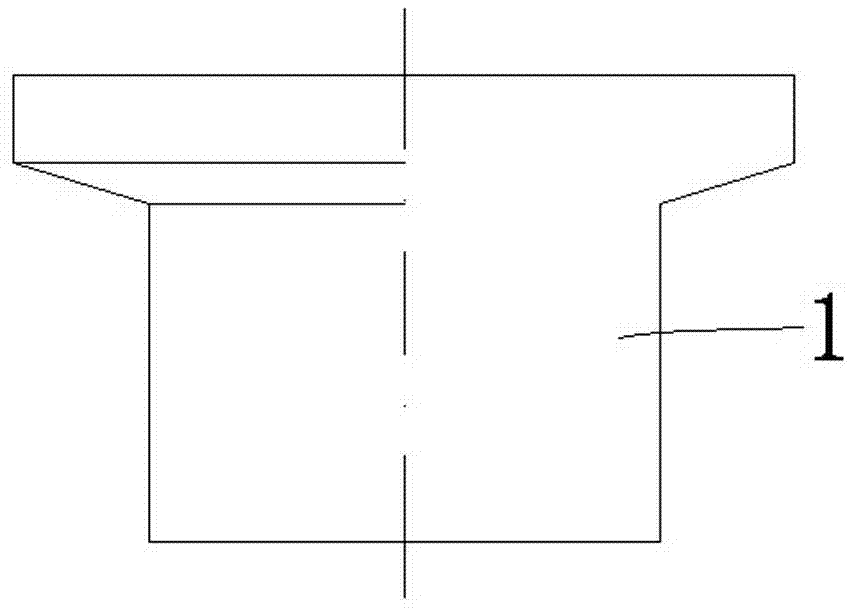

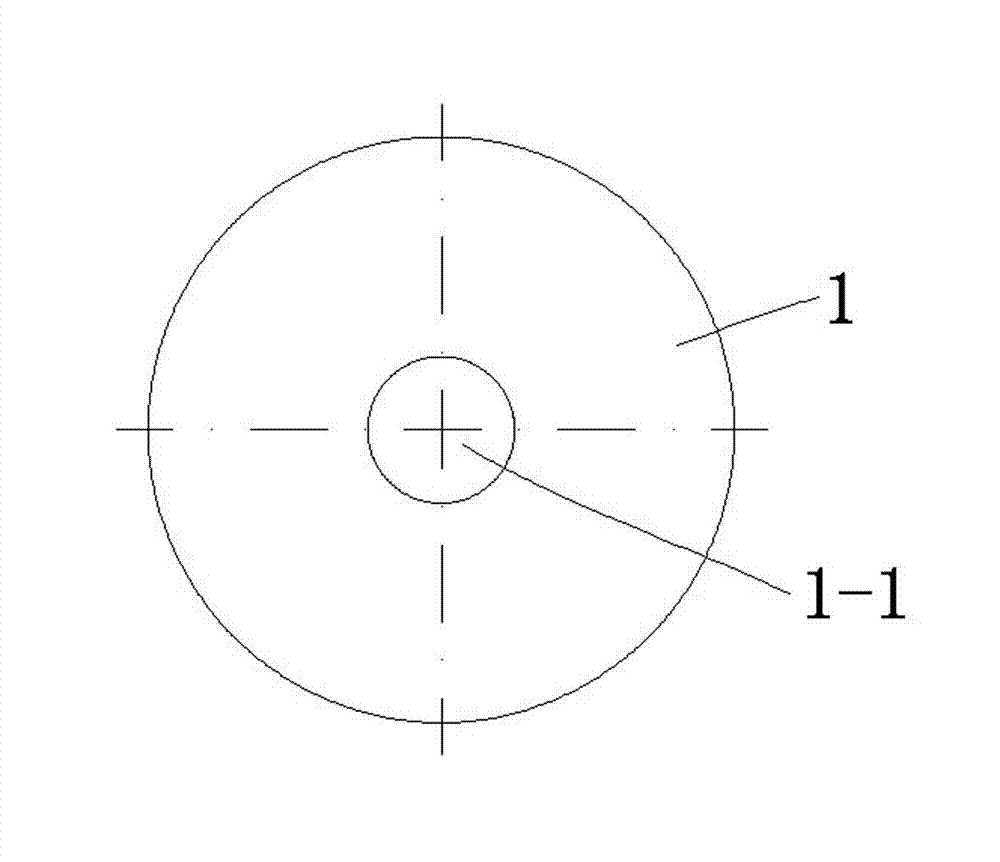

[0023] see figure 1 , 2 A compressor connection terminal shown in and 3, the compressor connection terminal is mainly composed of three parts: a metal end cover 2, a metal conductive column 3 and a glass insulator 1, and the metal end cover 2 is provided with a hole 2-1 , the metal conductive post 3 passes through the hole 2 - 1 of the metal end cap 2 and is packaged and connected with the metal end cap 2 through the glass insulator 1 , and the glass insulator 1 plays the role of sealing and insulation. The glass insulator is made of SiO 2 、Al 2 o 3 、 Bi 2 o 3 、TiO 2 Composed of SrO and SrO, the weight percentage of each component in the glass insulator is: SiO 2 92~94%, Al 2 o 3 3~4%, Bi 2 o 3 0.5~1%,TiO 2 0.5-1%, SrO 1.5-2.5%. By adjusting the weight percentages of each component, the sum of all component weight percentages should equal one hundred percent.

[0024] In the present invention, the SiO 2 、Al 2 o 3 、 Bi 2 o 3 、TiO 2 And the weight percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com