Polystyrene foam particle heat insulation mortar

A polystyrene foam, thermal insulation mortar technology, applied in the field of construction mortar, can solve the problems of high price of composite thermal insulation mortar, inability to meet performance requirements, difficult cracks, hollowing and other problems, and achieves light bulk density, long service life, and reduced The effect of cement dosage

Inactive Publication Date: 2005-03-02

SHANGHAI JIAO TONG UNIV

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the price of the composite thermal insulation mortar proposed in this paper is relatively high, the construction is complicated, and it is difficult to solve the problems of cracks and hollowing after construction.

The function is relatively single, and it cannot meet the requirements of modern buildings for other building properties of thermal insulation mortar, such as sound insulation, environmental protection and light weight, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] Example 1 82.0 100 450 0.103 7.5 1.2

Embodiment 2

[0026] Example 2 80.0 105 350 0.095 5.0 1.4

Embodiment 3

[0027] Example 3 82.0 110 480 0.115 7.0 1.1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

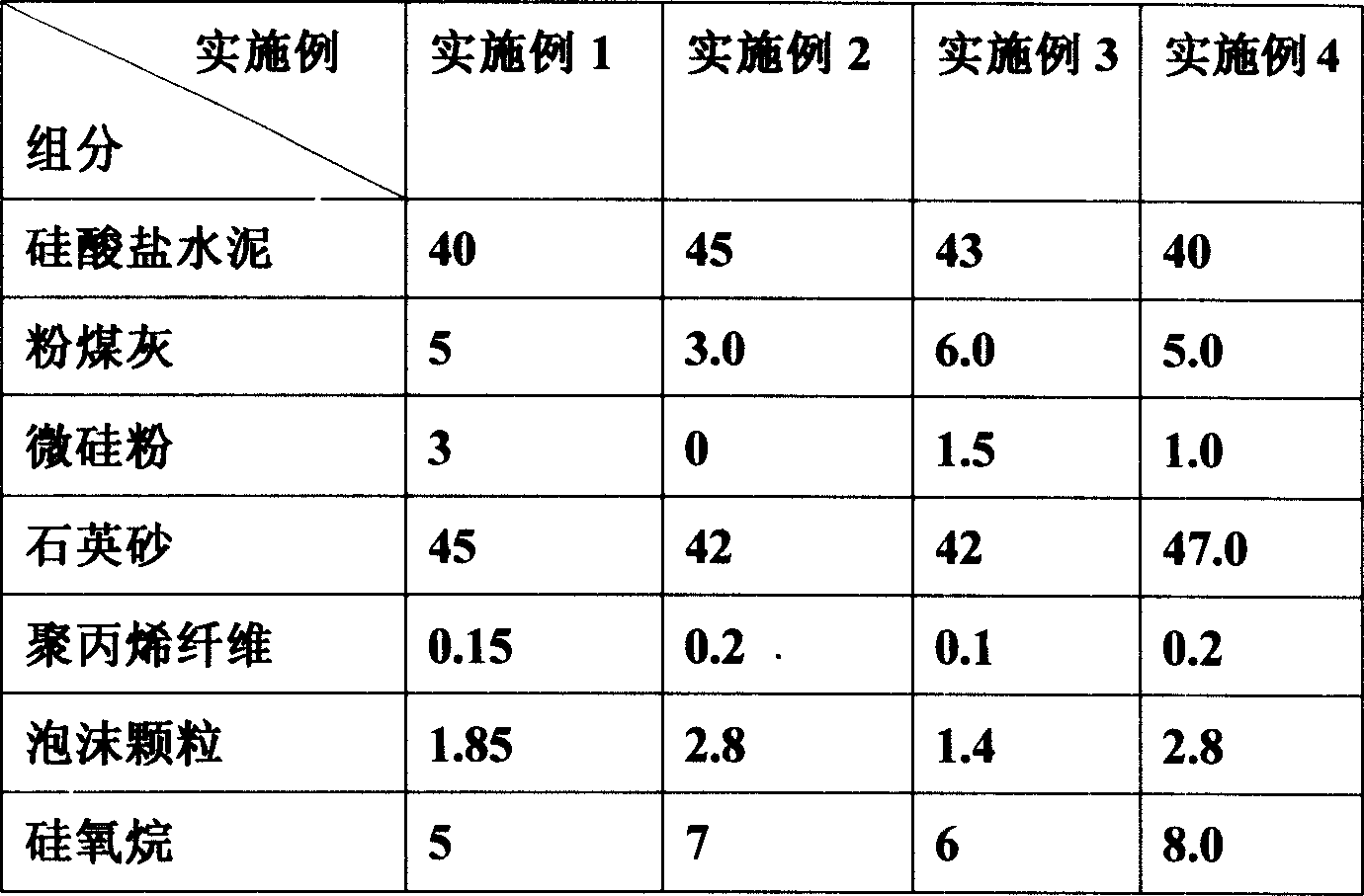

The heat insulating foamed polystyrene particle mortar used in building engineering consists of portland cement 40-45 wt%, flyash 3-6 wt%, fine silica powder 0-3 wt%, foamed polystyrene particle 1.3-2.8 wt%, polypropylene fiber 0.1-0.2 wt%, quartzite 42-47 wt% and water-thinned silane / siloxane emulsion 5-8 wt%. The present invention has light bulk weight, dry density 300-480 kg / cu m; good heat insulating and sound isolating performance, and heat conducting coefficient 0.07-0.13 W / m.k. The present invention utilizes partial flyash to replace cement and the product has no environment pollution.

Description

technical field [0001] The invention relates to a building mortar, in particular to a polystyrene foam particle thermal insulation mortar. It is used in the technical field of building materials engineering. Background technique [0002] At present, the country is vigorously developing and promoting environmental protection and energy-saving building structures. To implement building energy conservation, it is necessary to greatly improve the thermal performance of the outer envelope structure, especially the outer wall. However, it is unrealistic to generally adopt composite energy-saving wall materials in the Yangtze River Basin and southern regions of my country in the short term. Moreover, the materials used to build these insulating lightweight walls mostly use ordinary cement or mixed masonry mortar, and the apparent density of this type of mortar is generally 1600-1800kg / m 3 , the thermal conductivity is 0.8-1.0W / (m K), and the apparent density of lightweight insul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B14/06C04B16/06C04B16/08C04B18/08C04B28/04

CPCY02W30/91

Inventor 陈兵陈龙珠

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com