Pre-metering roll type coating device

A coating device, roll coating technology, applied to the surface coating liquid device, coating, etc., can solve problems such as improper installation of the scraper, environmental pollution of the coating station, and unguaranteed coating thickness. To achieve precise control, beneficial to physical properties, and beneficial to the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

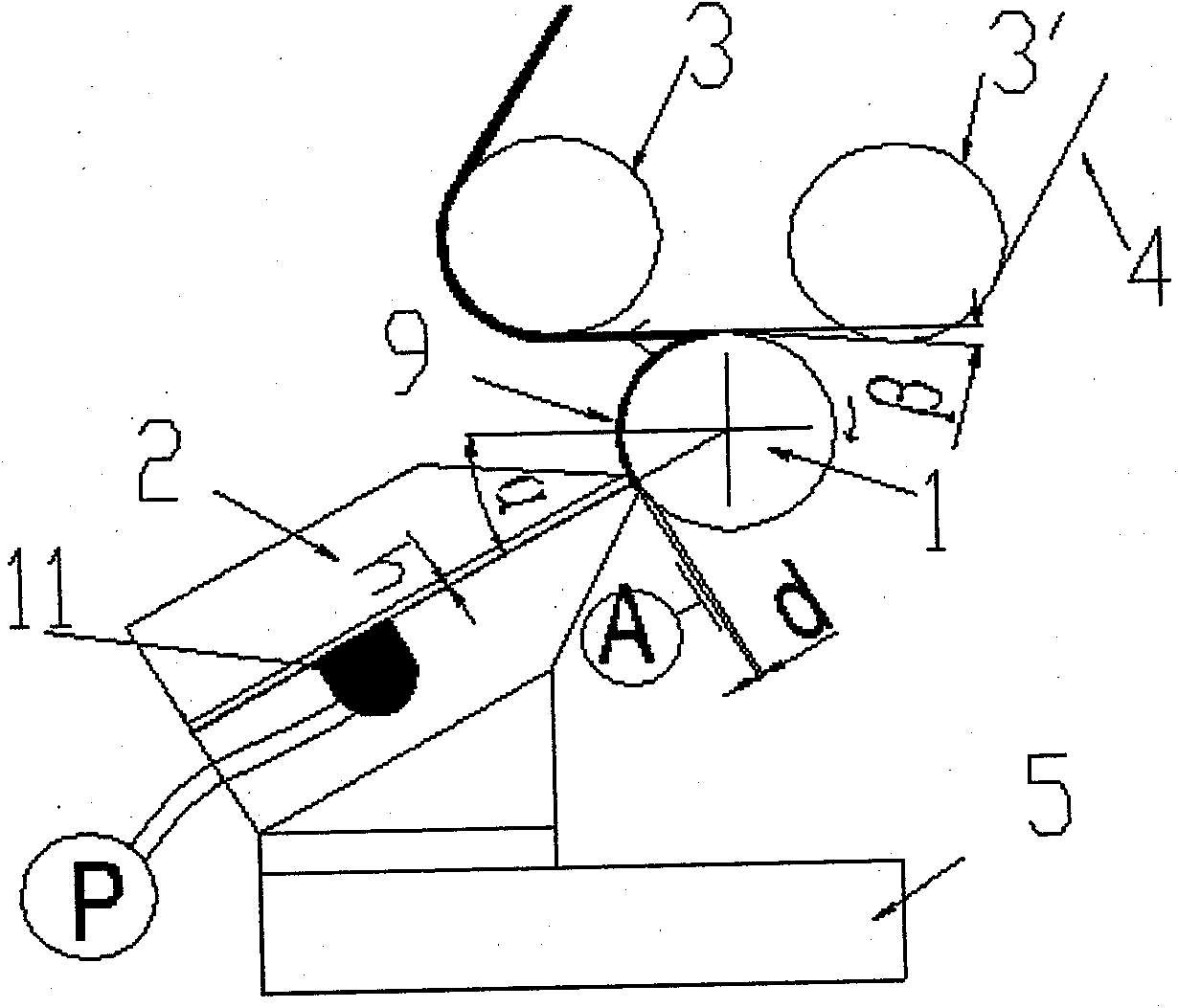

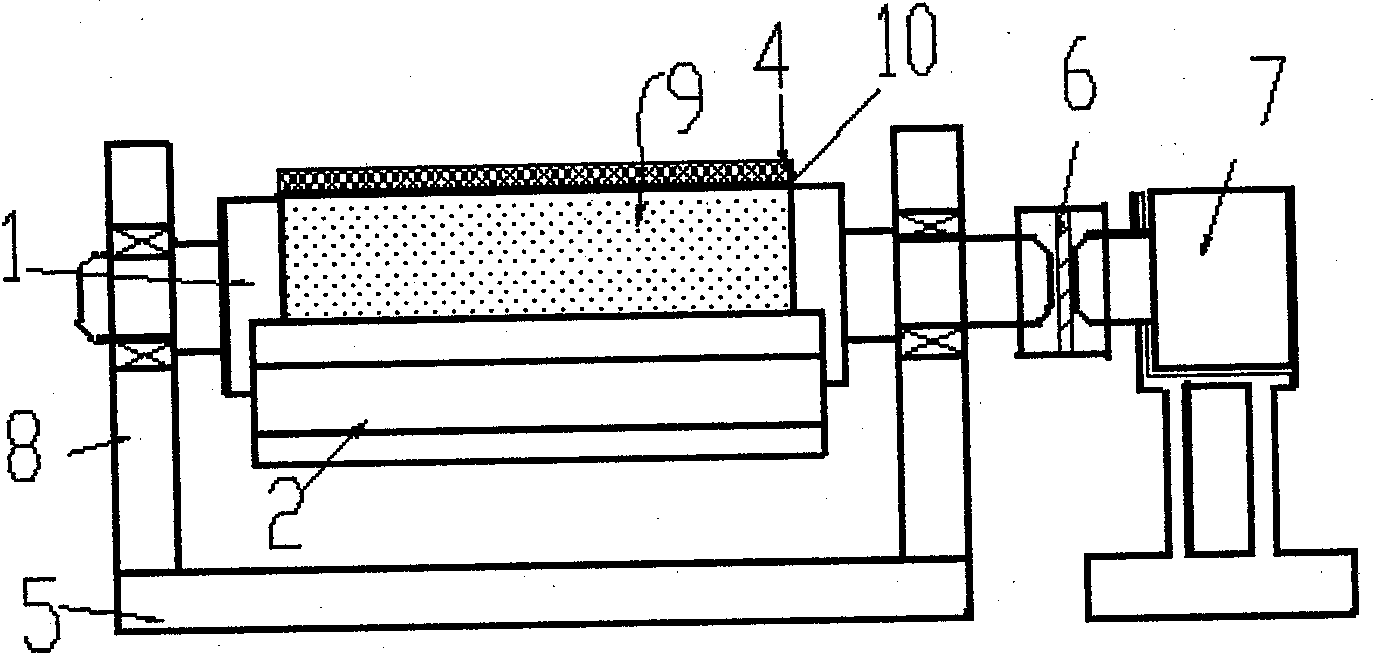

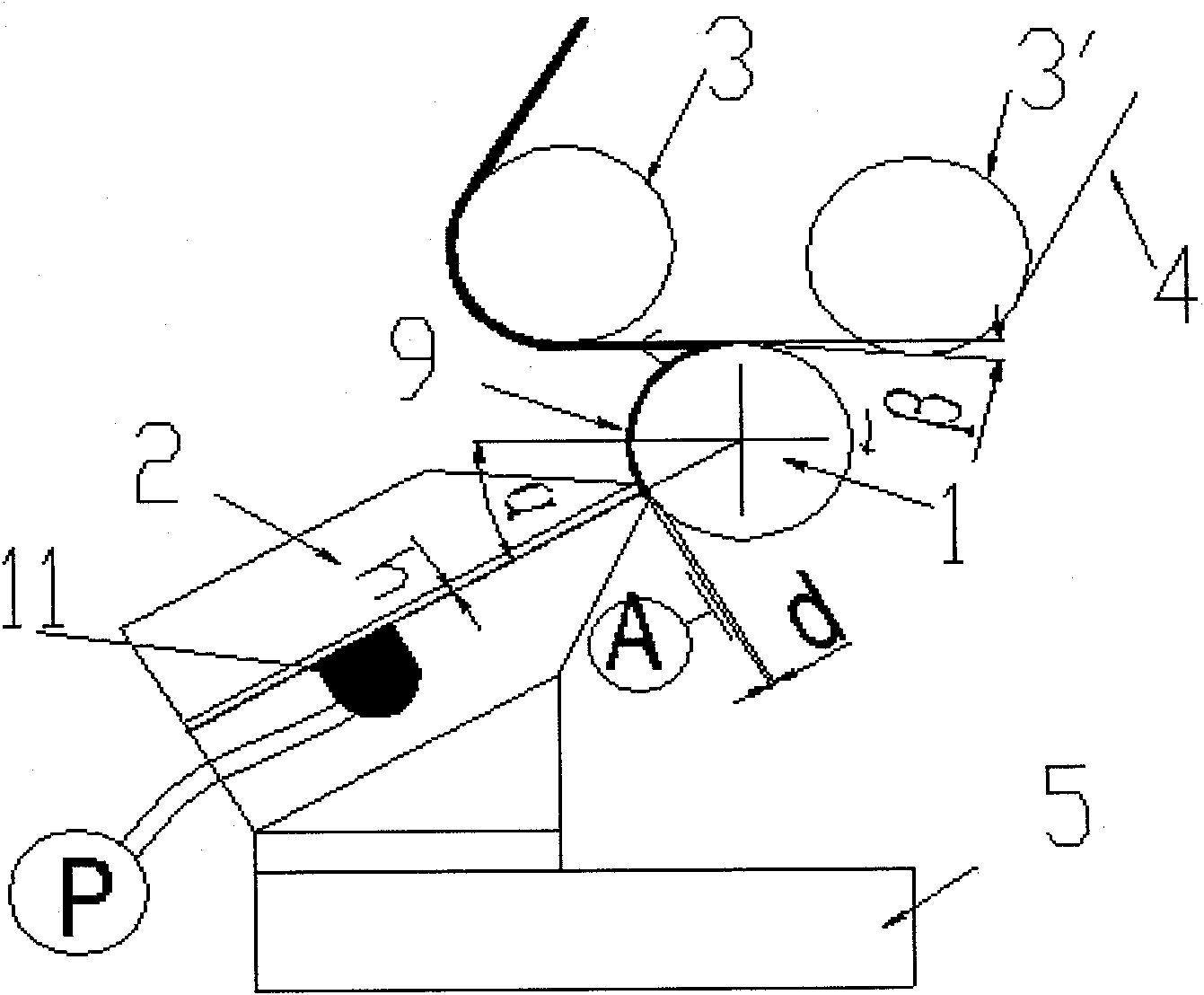

[0036] The present invention is described with reference to the accompanying drawings.

[0037] Coating roller 1 is 600mm long, 30mm in diameter, bearing housing 8 is equipped with at both ends, wherein one end is connected with drive motor 7 by coupling 6, rotates under the drive of drive motor 7.

[0038] The slit die head 2 is installed on the coating base 5 that can advance and retreat, and the inclination angle of the die head is 30°. Liquid supply gap d is controlled at 0.03mm.

[0039] The coating solution 9 is supplied to the filtering and defoaming device by a precision metering pump, and enters the slot die 2 after filtering and defoaming, and is extruded from the outlet gap h after passing through the flow equalization chamber 11, and the outlet gap h is set to 0.05mm .

[0040] When coating starts, the guide rollers 3, 3' press the base material 4 to the position where it contacts the coating roller 1, and the wrap angle β is controlled at 5° by adjusting the ver...

Embodiment 2

[0042] The coating process is the same as in Example 1, wherein: α is 90°, β is 10°, d is 0.05mm, h is 0.1mm, and the rate ratio is 1:1. The coating test results are shown in Table 1.

Embodiment 3

[0044] The coating process is the same as in Example 1, wherein: α is 20°, β is 0°, d is 0.01 mm, h is 0.02 mm, and the rate ratio is 1:1.5. The coating test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com