Nanometer luminescent core-shell zinc oxide-polymer particle and its prepn

A nanoparticle and polymer technology, applied in the field of nanomaterials, can solve the problems of poor composite stability, material properties decline, weak binding force, etc., and achieve the effect of stable physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

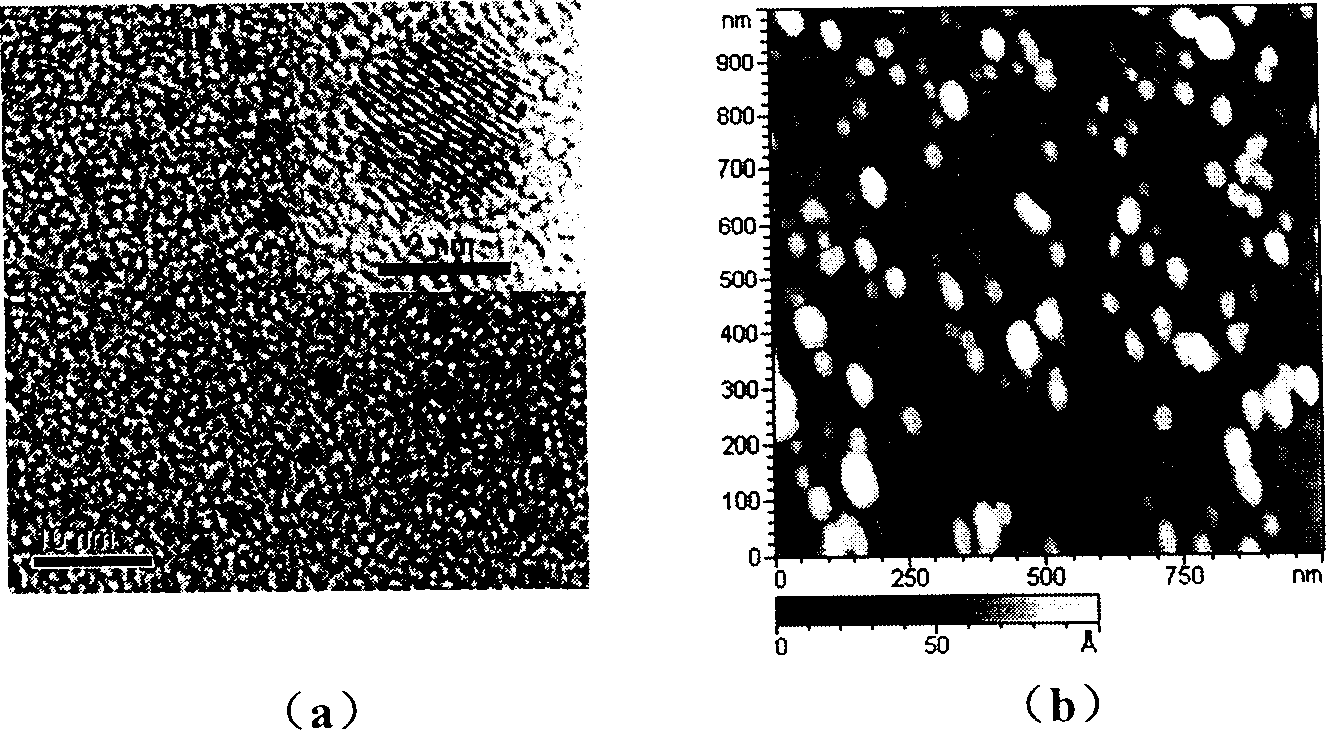

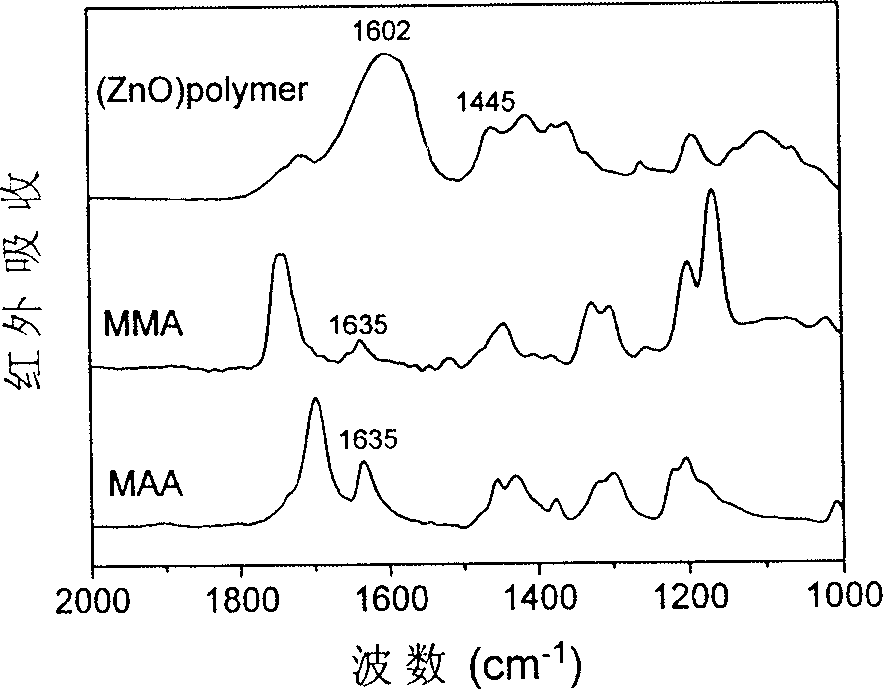

[0025] Dissolve 4.66g of zinc methacrylate in 200mL of ethanol, and reflux at 80°C for 3 hours to obtain a colorless and transparent solution, in which the concentration of zinc salt is about 0.1mol / L; dissolve 5g of lithium hydroxide in 500mL of ethanol, and stir vigorously at high speed To help dissolve, filter out the insolubles to obtain a colorless and transparent LiOH solution with a concentration of about 0.2mol / L. Use EDTA and oxalic acid standard solutions to titrate the exact concentrations of zinc methacrylate and lithium hydroxide respectively. Then the resulting zinc methacrylate and lithium hydroxide ethanol solution were prepared according to the molar ratio [Zn 2+] / [LiOH]=3.5 mixed. After the mixed solution was reacted at room temperature for 8 hours, most of the solvent was evaporated in a rotary evaporator, and the evaporation was stopped when white turbidity appeared. The above cloudy solution was cooled at 4° C. for 1 hour and then centrifuged. After the s...

Embodiment 2

[0028] The preparation method is the same as in Example 1, but the reaction time of zinc methacrylate and lithium hydroxide ethanol solution is extended to 100 hours at room temperature, and other conditions are unchanged, and finally the ZnO average diameter is 4.6 nanometers, and the thickness of the polymer shell is 2 nanometers. product. The emission wavelength is shifted to 500 nanometers, and the quantum efficiency is 30%.

Embodiment 3

[0030] The preparation method is the same as in Example 1, but the reaction time of zinc methacrylate and lithium hydroxide ethanol solution is extended to 48 hours at room temperature, dispersed in methyl methacrylate and circulated in a water bath at 60 ° C for 20 minutes, and finally the ZnO average A product with a diameter of 2.8 nm and a polymer shell thickness of 7 nm. The emission wavelength is shifted to 480 nm, and the quantum efficiency is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com