Waterproof heat-insulation exterior wall coating and preparation method thereof

An exterior wall paint, pigment and filler technology, applied in the field of paint, can solve the problems of poor waterproof and moisture-proof performance, poor flame retardant performance, etc., and achieve the effects of high waterproofness, easy industrial production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

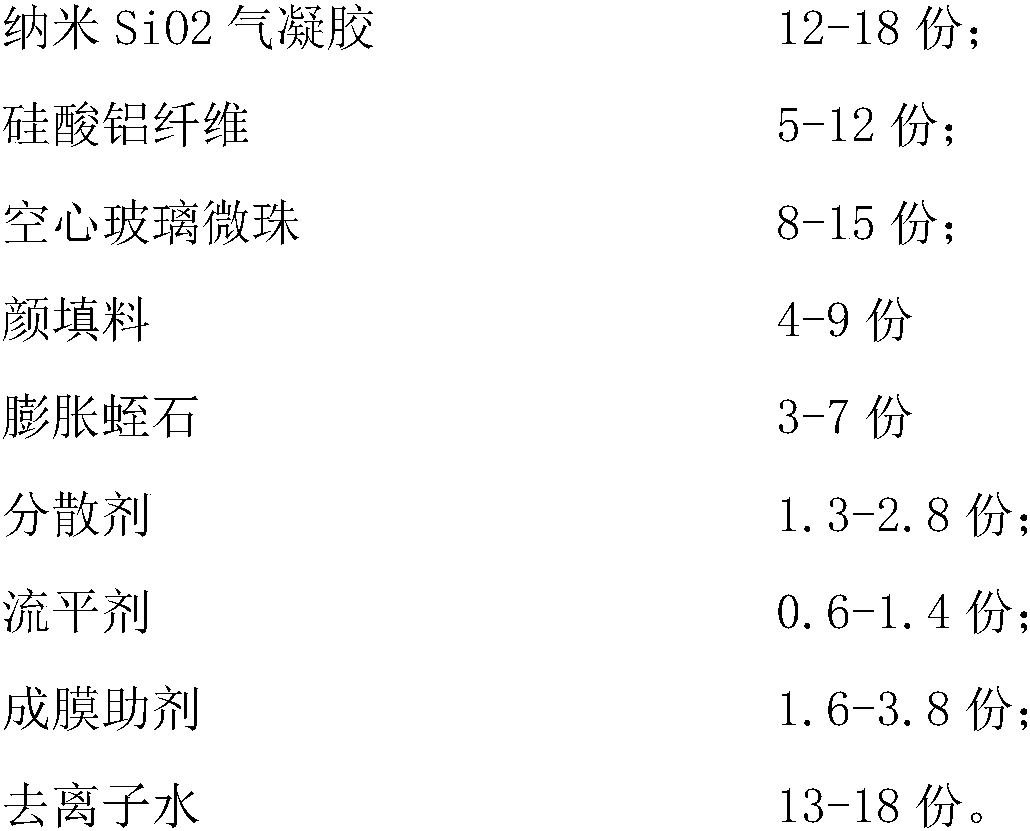

[0032] The waterproof and heat-insulating exterior wall paint of the present embodiment, in parts by weight, said material mainly includes the following components:

[0033]

[0034]

[0035] The nano-SiO2 airgel porosity of present embodiment is 85%-95%, and average aperture is 20nm, and specific surface area is 800-1100m 2 / g, the aluminum silicate fiber has a length of 0.25-2.2 μm and a diameter of 3-6 μm.

[0036] The pigments and fillers in this embodiment are selected from one or more of titanium dioxide, barium sulfate, and mica powder.

[0037] The dispersant in this embodiment is selected from any one of BYK-190, BYK-155, BYK-187 and BYK-184.

[0038] The leveling agent in this embodiment is selected from polyurethane leveling agents.

[0039] The film-forming aid of this embodiment is selected from Alcohol Twelve.

[0040] The present invention also provides a preparation method of waterproof and heat-insulating exterior wall coating, comprising the followin...

Embodiment 2

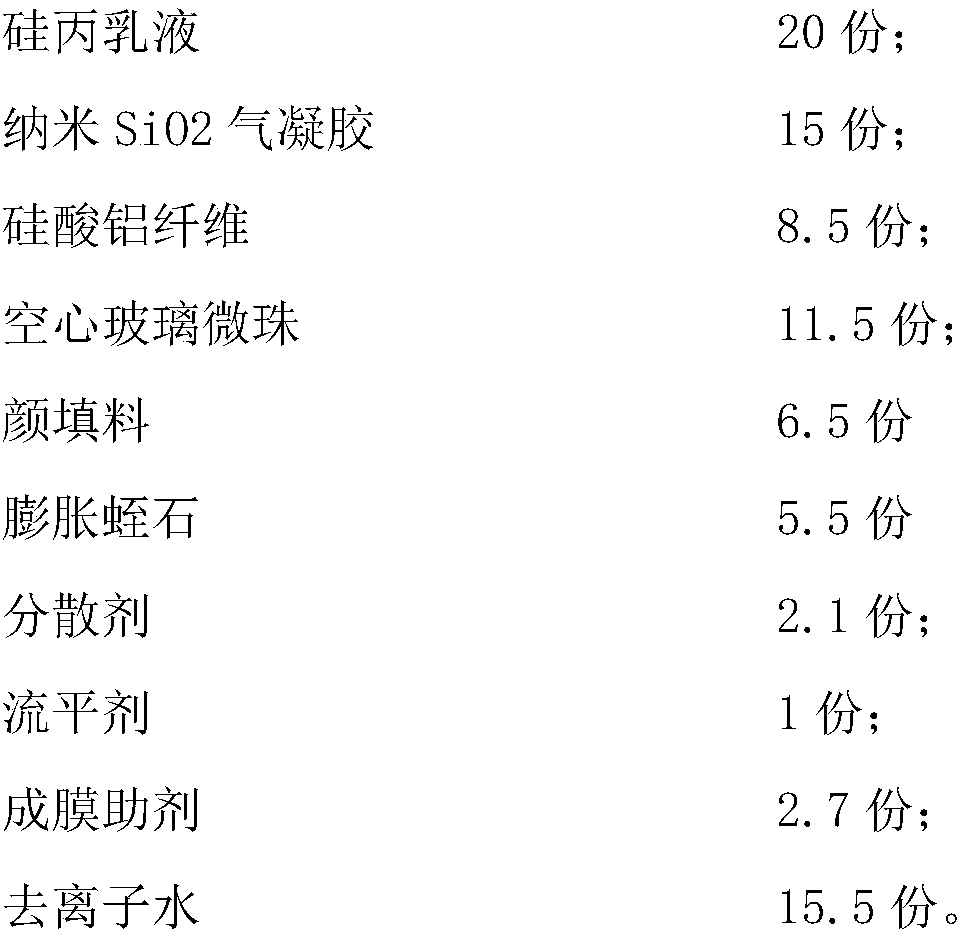

[0047] The waterproof and heat-insulating exterior wall paint of the present embodiment, in parts by weight, said material mainly includes the following components:

[0048]

[0049] The nano-SiO2 airgel porosity of present embodiment is 85%-95%, and average aperture is 20nm, and specific surface area is 800-1100m 2 / g, the aluminum silicate fiber has a length of 0.25-2.2 μm and a diameter of 3-6 μm.

[0050] The pigments and fillers in this embodiment are selected from one or more of titanium dioxide, barium sulfate, and mica powder.

[0051] The dispersant in this embodiment is selected from any one of BYK-190, BYK-155, BYK-187 and BYK-184.

[0052] The leveling agent in this embodiment is selected from polyurethane leveling agents.

[0053] The film-forming aid of this embodiment is selected from Alcohol Twelve.

[0054] The present invention also provides a preparation method of waterproof and heat-insulating exterior wall coating, comprising the following steps:

...

Embodiment 3

[0061] The waterproof and heat-insulating exterior wall paint of the present embodiment, in parts by weight, said material mainly includes the following components:

[0062]

[0063]The nano-SiO2 airgel porosity of present embodiment is 85%-95%, and average aperture is 20nm, and specific surface area is 800-1100m 2 / g, the aluminum silicate fiber has a length of 0.25-2.2 μm and a diameter of 3-6 μm.

[0064] The pigments and fillers in this embodiment are selected from one or more of titanium dioxide, barium sulfate, and mica powder.

[0065] The dispersant in this embodiment is selected from any one of BYK-190, BYK-155, BYK-187 and BYK-184.

[0066] The leveling agent in this embodiment is selected from polyurethane leveling agents.

[0067] The film-forming aid in this embodiment is selected from Alcohol Twelve.

[0068] The present invention also provides a preparation method of waterproof and heat-insulating exterior wall coating, comprising the following steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com