High-speed railway door system rubber sealing strip protection grease composition and preparation method thereof

A technology of rubber sealing strip and composition, applied in the field of rubber sealing, can solve the problems of high oil separation rate, poor high and low temperature stability, etc., and achieve excellent high and low temperature stability, good high and low temperature stability, and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

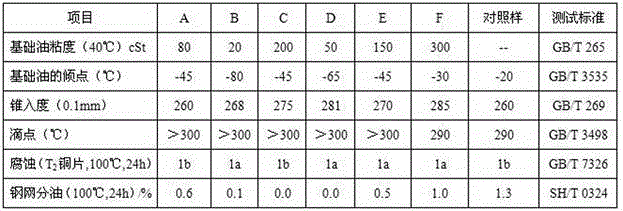

Examples

preparation example Construction

[0029] The preparation method of a protective grease composition for rubber sealing strips of high-speed iron door system of the present invention comprises the following steps: (1) Take base oil, heat up to 130-150°C, add thickener, stir evenly, heat-preserve and activate for 1-3 hours , continue to heat up to 155~165°C, refining for 0.3~0.5h; (2) Cool the refined product obtained in step (1) to no more than 90°C, add fillers, metal corrosion inhibitors and antioxidants, Stir well and grind into fat.

[0030] Specifically, in the step (2), the refined product is cooled to 80-90° C. and ground in a three-roll mill.

Embodiment 1

[0032]Add 60% by weight of perfluoropolyether base oil with a pour point of -45°C and a viscosity of 80cSt at 40°C to a 250mL beaker with mechanical stirring, raise the temperature to 135°C, and add 30% by weight of polyether base oil Stir the tetrafluoroethylene micro-powder thickener evenly, heat and activate it for 1 hour, heat up to 160°C for 0.5 hour refining; then, cool down to below 90°C, add 9% by weight of nano-calcium carbonate filler, 0.5% of anti-rust agent sulfonic acid Calcium, 0.5% by weight antioxidant pentaerythritol ester, after stirring evenly, grind into fat A through three-roll mill.

Embodiment 2

[0034] Add 50% by weight of perfluoropolyether base oil with a pour point of -80°C and a viscosity of 20cSt at 40°C to a 250mL beaker with mechanical stirring, raise the temperature to 130°C, and add 40% by weight of polyether base oil Stir the tetrafluoroethylene micro-powder thickener evenly. After 2 hours of heat preservation and activation, heat up to 165°C for refining for 0.3h; then, cool down to 90°C, add 8% by weight of MCA filler, 1% by weight of fumed silica filler, 0.3% calcium sulfonate antirust agent, 0.2% by weight antirust agent benzotriazole, 0.5% by weight antioxidant pentaerythritol ester, stirred evenly, and ground into fat B by three-roll mill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com