Composite modified asphalt material applicable to anti-crack layer with pavement structure and preparation method thereof

A composite modified asphalt and pavement structure technology, which is applied in building insulation materials, building components, building structures, etc., can solve the limited ability to prevent reflection cracks, the difficulty of modified asphalt materials to meet the requirements, and the performance requirements of asphalt materials High-level problems, to achieve excellent shear cracking resistance and high and low temperature performance, a wide range of applicable regions, and the effect of promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

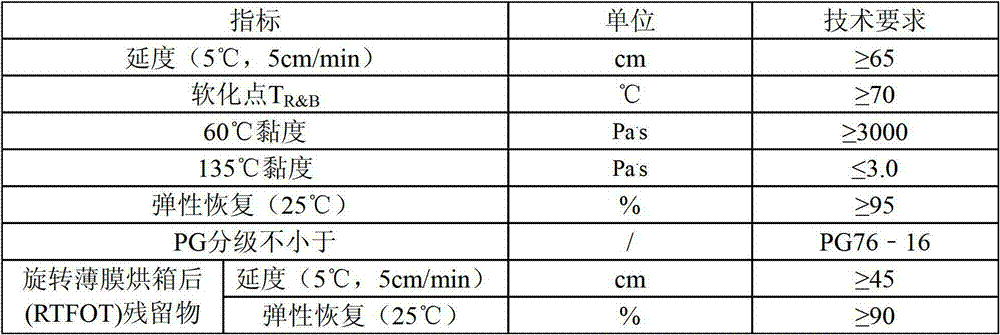

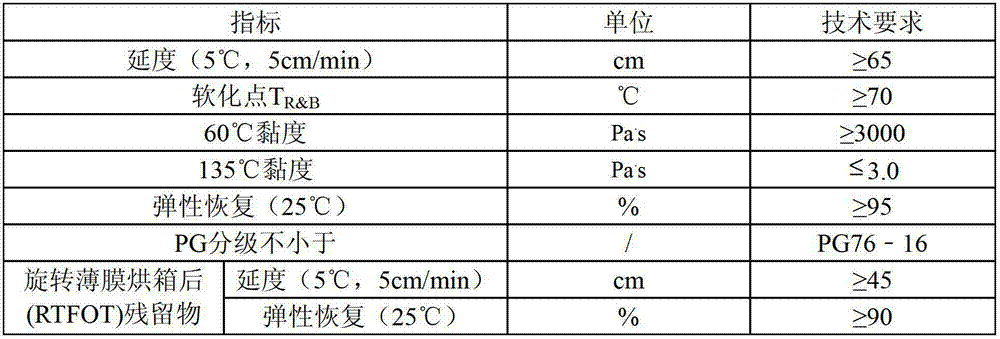

Examples

Embodiment 1

[0031] Put 83.2 parts by mass of base asphalt (produced by China National Offshore Oil Corporation) with a penetration value of 71 at 25°C in an oven at 175°C for 1 hour; at a temperature of 175°C, add 4.2 Parts by mass of thermoplastic styrene-butadiene rubber (YH791 produced by Hunan Yueyang Baling Petrochemical Co., Ltd., with a relative molecular weight of 100,000) and 6.7 parts by mass of 40-mesh desulfurized rubber powder (produced by Sichuan Zhengzhong Road Technology Co., Ltd.), and uniformly mixed with a glass rod Stir for 15 minutes; lower the temperature to 170°C, add 1.7 parts by mass of 20-mesh powdered styrene-butadiene rubber (produced by Zibo Qiaolong Industry and Trade Co., Ltd.), 2.5 parts by mass of acetyl tributyl citrate (produced by Shanghai Jinjinle Industrial Co., Ltd. ) and 1.7 parts by mass of accelerator rubber filler oil (produced by Hubei Daoweisi Technology Development Co., Ltd.) and the mixture was sheared at a high speed for 30 minutes in a high-...

Embodiment 2

[0033]Put 85.3 parts by mass of base asphalt (produced by China National Offshore Oil Corporation) with a penetration value of 71 at 25°C in an oven at 175°C for 1 hour; at a temperature of 175°C, add 3.8 mass Parts of thermoplastic styrene-butadiene rubber (YH791 produced by Hunan Yueyang Baling Petrochemical Co., Ltd., with a relative molecular weight of 100,000) and 6.0 parts by mass of 60-mesh desulfurized rubber powder (produced by Hebei Hongyun Reclaimed Rubber Factory), and stirred evenly with a glass rod for 15 Minutes; lower the temperature to 170°C, add 1.5 parts by mass of 30-mesh powdered styrene-butadiene rubber (produced by Shandong Gaoshi Technology Industry and Trade Co., Ltd.), 2.1 parts by mass of acetyl tributyl citrate (Hubei Chushengwei Chemical Co., Ltd. production) and 1.3 parts by mass of accelerator rubber filler oil (produced by Shandong Jiangshan Polymer Material Co., Ltd.), and the mixture was sheared at high speed in a high-speed shearer for 30 minu...

Embodiment 3

[0035] Put 87.6 parts by mass of base asphalt (produced by China National Offshore Oil Corporation) with a penetration value of 71 at 25°C in an oven at 175°C for 1 hour; at a temperature of 175°C, add 3.1 mass Parts of thermoplastic styrene-butadiene rubber (YH791 produced by Hunan Yueyang Baling Petrochemical Co., Ltd., with a relative molecular weight of 100,000) and 5.3 parts by mass of 80-mesh desulfurized rubber powder (produced by Wuhan Lvhuanyu Technology Co., Ltd.), and stirred evenly with a glass rod 15 minutes; lower the temperature to 170°C, add 1.3 parts by mass of 40-mesh powdered styrene-butadiene rubber (produced by Gansu Ningda Petrochemical Engineering Co., Ltd.), 1.8 parts by mass of acetyl tributyl citrate (Wuhan Xin Triangle Technology Development Co., Ltd. production) and 0.9 parts by mass of accelerator rubber filler oil (produced by Shandong Jiangshan Polymer Material Co., Ltd.), and the mixture was sheared at high speed in a high-speed shearing instrume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com