Preparation method for compound modified emulsified asphalt material and application thereof in porous pavements

A technology of emulsified asphalt and compound modification, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of human harm, high cost, and energy consumption, and achieve no smoke emission, enhanced bending resistance, and improved viscosity. The effect of knot properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a method for preparing a composite modified emulsified asphalt material, which is characterized in that it comprises the following steps:

[0029] Mix 50-59 parts of emulsified asphalt, 5-45 parts of emulsified asphalt modification additive, 1-4.5 parts of styrene-butadiene latex, and 0.1-1 part of dispersant, and stir for 30 minutes at a speed of 300 r / min to obtain the composite modified Emulsified asphalt material; the emulsified asphalt modification additive contains the following components:

[0030] 5-10 parts of polyphosphoric acid, 15-30 parts of thermoplastic polyurethane elastomer, 10-20 parts of styrene-butadiene block copolymer, 10-15 parts of non-ionic asphalt emulsifier, 45-80 parts of deionized water.

[0031] As a preferred solution, the hard segment of the thermoplastic polyurethane elastomer is one of aromatic isocyanate and aliphatic isocyanate, and the soft segment of the thermoplastic polyurethane elastomer is polyester polyo...

Embodiment 1

[0049] Step 1, heating 10 parts of polyphosphoric acid to 100-110°C and keeping it warm;

[0050] Step 2. Heat 30 parts of thermoplastic polyether-isophorone diisocyanate elastomer to 55-65°C and keep it warm, while heating 15 parts of styrene-butadiene block copolymer to 55-65°C and insulation;

[0051] Step 3, adding the thermoplastic polyether-isophorone diisocyanate elastomer and styrene-butadiene block copolymer obtained in step 2 to the polyphosphoric acid kept warm in step 1, raising the temperature to 105-115°C and keeping it warm 2.5h obtains the mixture of thermoplastic polyether-isophorone diisocyanate elastomer and styrene-butadiene block copolymer and polyphosphoric acid;

[0052] Step 4. After the mixture in step 3 drops to room temperature, add 12 parts of non-ionic asphalt emulsifier, and then stir at 800r / min for 20 minutes. Under the condition of continuous stirring, add 70 parts of deionized water, and continue to stir until a uniform emulsion The emulsifi...

Embodiment 2

[0057] Step 1, heating 10 polyphosphoric acid to 100-110°C and keeping it warm;

[0058] Step 2. Heat 30 parts of thermoplastic polyester-diphenylmethane diisocyanate elastomer to 55-65°C and keep it warm; heat 10 parts of styrene-butadiene block copolymer to 55-65°C and insulation;

[0059] The thermoplastic polyester-diphenylmethane diisocyanate elastomer and the styrene-butadiene block copolymer of step 3 and step 2 are simultaneously added to the polyphosphoric acid kept warm in step 1, and the temperature is raised to 105-115°C and kept warm 2.5h, obtain the mixture of thermoplastic polyester-diphenylmethane diisocyanate type elastomer and styrene-butadiene block copolymer and polyphosphoric acid;

[0060] Step 4. After the mixture in step 3 has dropped to room temperature, add 12 parts of non-ionic asphalt emulsifier, then stir at 800r / min for 20 minutes, add 65 parts of deionized water under continuous stirring, and continue stirring until a uniform emulsion is formed....

PUM

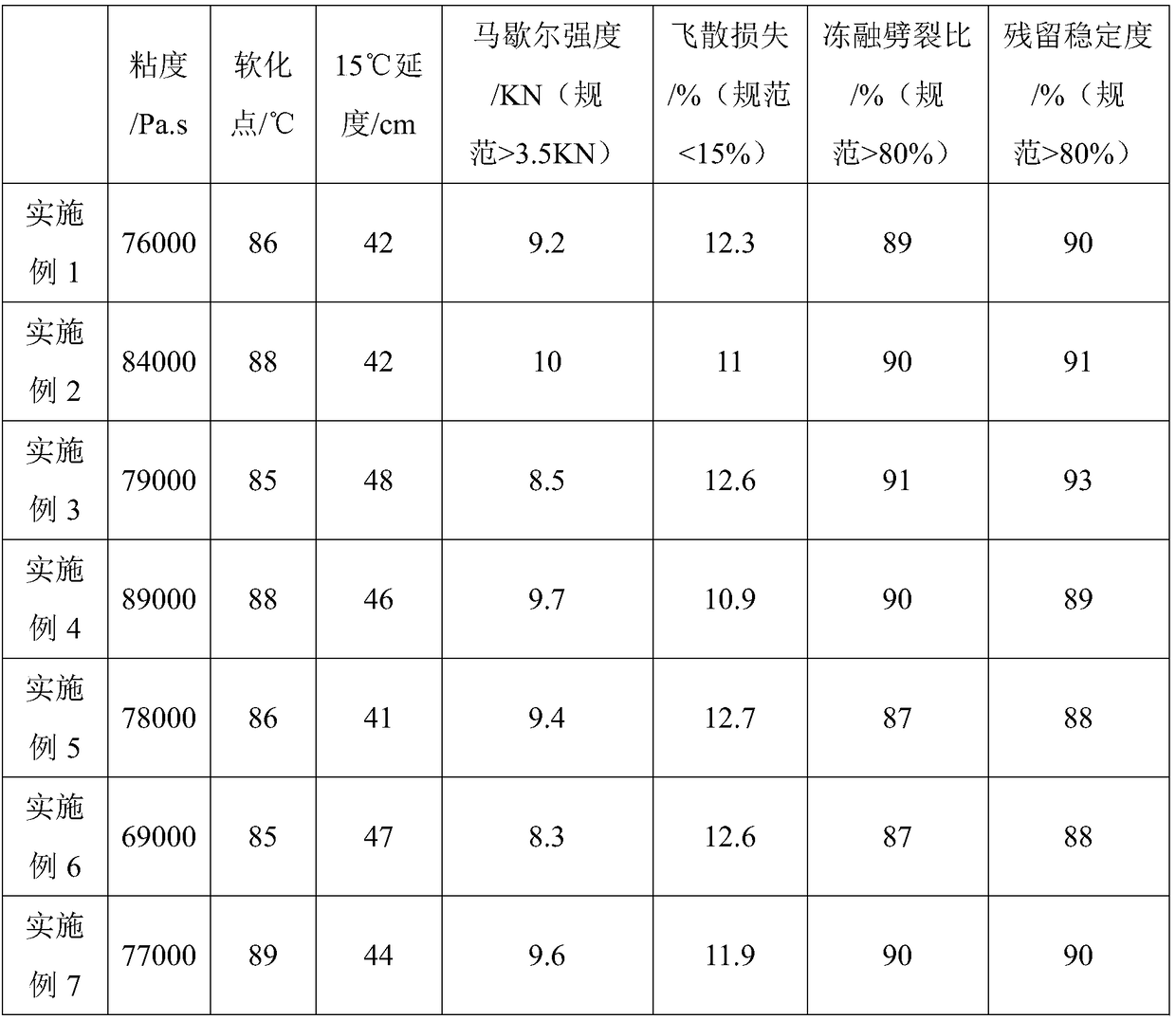

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com