Graphene composite rubber asphalt modifier as well as preparation method and application thereof

A graphene composite, rubber asphalt technology, applied in the field of asphalt modifier, can solve problems such as unfavorable popularization and use, increase the cost of graphene modified asphalt, etc. Avoid insufficiently dispersed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

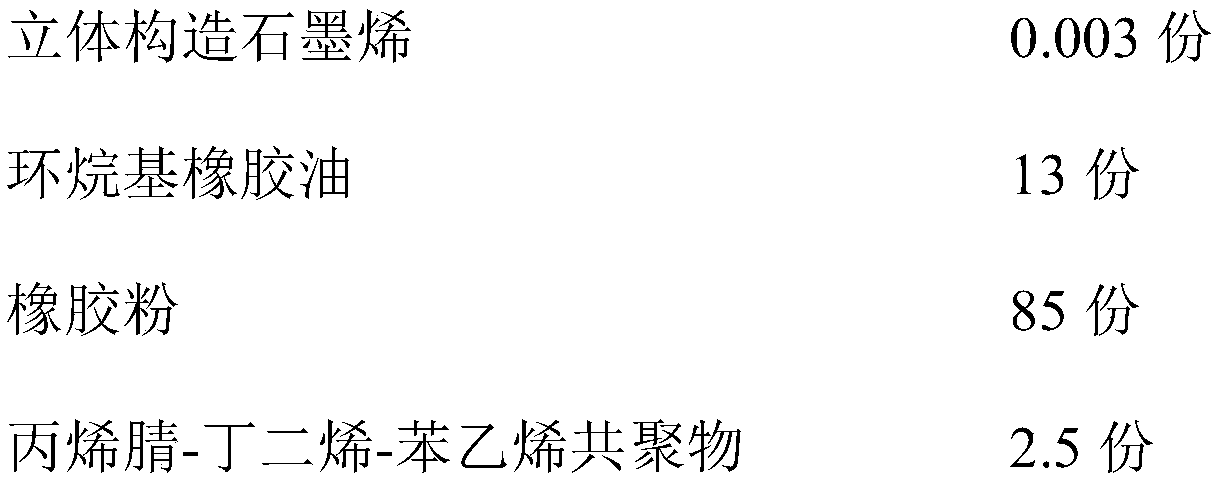

[0028] Component and preparation method of embodiment 1 graphene composite rubber asphalt modifier

[0029] Graphene composite rubber asphalt modifier component is as follows (by weight)

[0030]

[0031] The specific surface area of the above three-dimensional structure graphene is 500m 2 / g, the powder particle size of the rubber powder is 60 mesh.

[0032] The preparation method of above-mentioned graphene composite rubber asphalt modifier is as follows:

[0033] (1) Mix three-dimensional structure graphene and naphthenic rubber oil in a mass ratio of 0.003:13, mechanically stir, and disperse for 35 minutes with a high-speed shearing machine at 90° C., and obtain a graphene dispersion after cooling;

[0034] (2) Add the above prepared graphene dispersion, rubber powder and acrylonitrile-butadiene-styrene copolymer into the internal mixer at a mass ratio of 13:85:2.5, and carry out high-temperature internal mixing at 230°C for 35 minutes , after cooling, a graphene c...

Embodiment 2

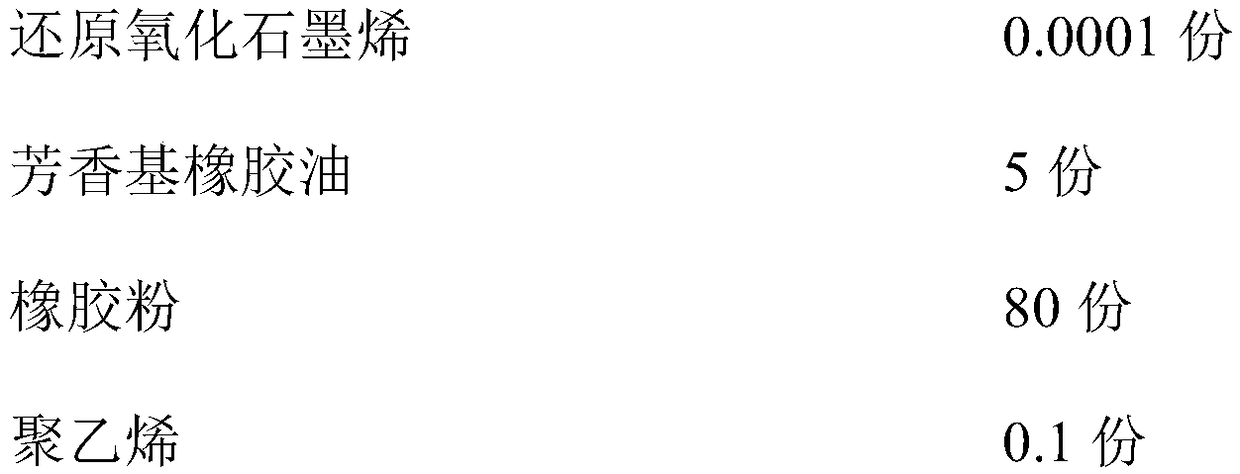

[0035] Component and preparation method of embodiment 2 graphene composite rubber asphalt modifier

[0036] Graphene composite rubber asphalt modifier component is as follows (by weight)

[0037]

[0038] The specific surface area of the above-mentioned reduced graphene oxide is 400m 2 / g, the powder particle size of the rubber powder is 40 mesh.

[0039] The preparation method of above-mentioned graphene composite rubber asphalt modifier is as follows:

[0040] (1) Mix the reduced graphene oxide and aromatic rubber oil at a mass ratio of 0.0001:5, stir mechanically, and disperse for 20 minutes with a high-speed shearing machine at 60°C, and obtain a graphene dispersion after cooling;

[0041] (2) Add the above prepared graphene dispersion, rubber powder and polyethylene into the internal mixer at a mass ratio of 5:80:0.1, carry out high-temperature internal mixing and kneading at 220°C for 20 minutes, and after cooling, make a graphene composite Rubber asphalt modifie...

Embodiment 3

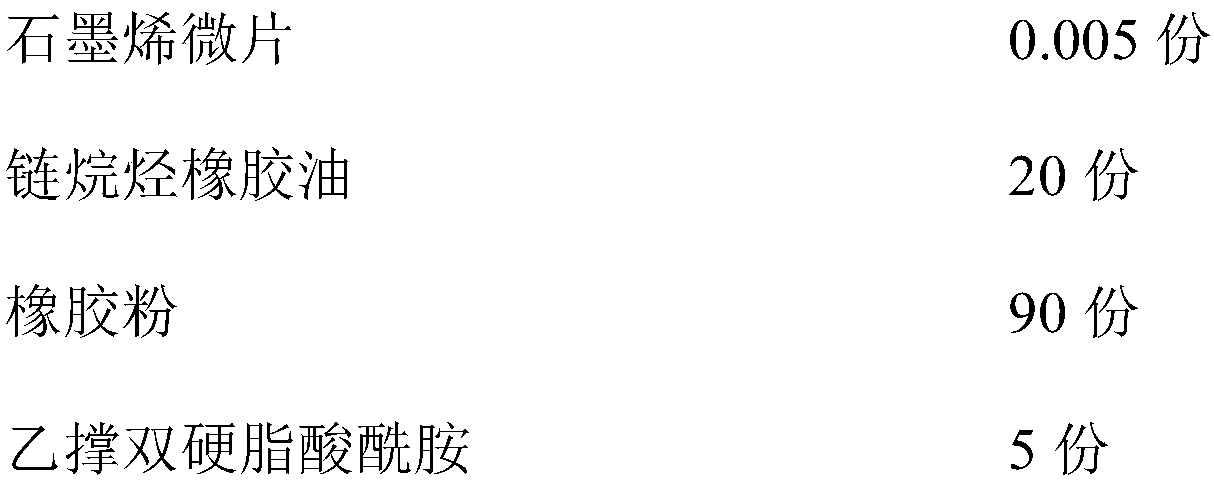

[0042] Component and preparation method of embodiment 3 graphene composite rubber asphalt modifier

[0043] Graphene composite rubber asphalt modifier component is as follows (by weight)

[0044]

[0045] The specific surface area of the above-mentioned graphene microsheets is 600m 2 / g, the powder particle size of the rubber powder is 80 mesh.

[0046] The preparation method of above-mentioned graphene composite rubber asphalt modifier is as follows:

[0047] (1) Mix graphene microflakes and paraffin rubber oil at a mass ratio of 0.005:20, stir mechanically, and disperse using a high-speed shearing machine at 120°C for 50 minutes, and obtain a graphene dispersion after cooling.

[0048] (2) Add the above prepared graphene dispersion, rubber powder and ethylene bis stearic acid amide in the internal mixer at a mass ratio of 20:90:5, carry out high-temperature internal mixing at 240° C. and knead for 50 minutes. After cooling, Made graphene composite rubber asphalt modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com