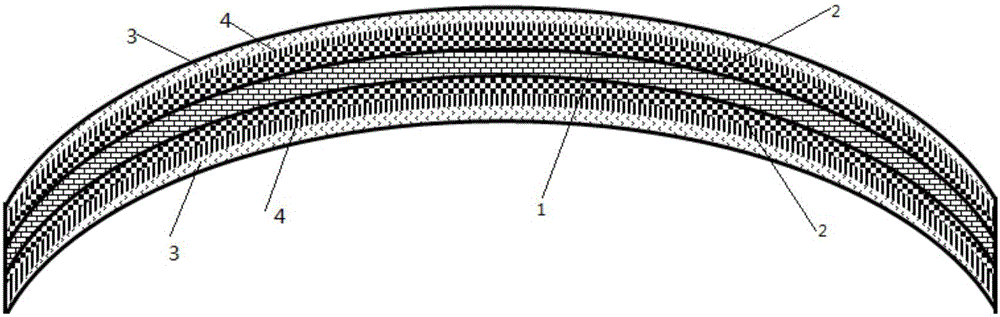

Plate spring of interlayer reinforced two-dimensional/three-dimensional braided composite material and preparation method thereof

A three-dimensional weaving, composite material technology, applied in leaf springs, springs, mechanical equipment, etc., can solve the problems of weak interlayer bonding strength, impact on vehicle safety, weak interlayer bonding, etc., to achieve long service life and improve product quality. and service life, the effect of increasing the loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) According to the loading requirements of heavy-duty trucks, high-strength carbon fibers, high-strength glass fibers, and high-performance aramid fibers are selected for hybrid preparation of yarns. The combined yarns prepared from tows of different materials are surface-treated after matching. The treatment is usually completed by vacuum high-temperature burning, and the sizing agent on the surface of the tow is fully removed, and then wound up for later use.

[0026] (2) The above-prepared mixed yarn is subjected to three-dimensional weaving treatment, wherein the middle layer of the leaf spring thickness uses carbon fiber and glass fiber mixed yarn for three-dimensional fabric preparation, and the weight ratio of carbon fiber to glass fiber is 2:1. A three-dimensional four-way structure is selected, and the thickness of the single layer is 40mm. The upper and lower surface layers of the thickness of the leaf spring are made of mixed yarns of carbon fiber and arami...

Embodiment 2

[0033] (1) According to the loading requirements of heavy-duty trucks, high-strength carbon fibers, high-strength glass fibers, and high-performance aramid fibers are selected for hybrid preparation of yarns. The combined yarns prepared from tows of different materials are surface-treated after matching. The treatment is usually completed by burning at high temperature in a nitrogen atmosphere to fully remove the sizing agent on the surface of the tow, and then wind it up for later use.

[0034] (2) The above-prepared mixed yarns are subjected to three-dimensional weaving processing, wherein the middle layer position of the leaf spring thickness is made of carbon fiber and glass fiber hybrid yarns for three-dimensional fabric preparation, and the weight ratio of carbon fiber to glass fiber is 4:1. A three-dimensional five-directional structure is selected, and the thickness of the single layer is 30mm. The upper and lower surface layers of the thickness of the leaf spring are ...

Embodiment 3

[0041] (1) According to the loading requirements of light-duty trucks, high-strength carbon fibers and high-strength glass fibers are selected for hybrid preparation of yarns. The combined yarns prepared from tows of different materials are matched and then surface-treated. Surface treatment is usually vacuum high-temperature firing Complete, fully remove the sizing agent on the surface of the tow, and then wind it up for later use.

[0042] (2) The above-prepared mixed yarns are subjected to three-dimensional weaving processing, wherein the middle layer position of the leaf spring thickness is made of carbon fiber and glass fiber hybrid yarns for three-dimensional fabric preparation, and the weight ratio of carbon fiber to glass fiber is 4:1. A three-dimensional six-directional structure is selected, and the thickness of the single layer is 20mm. The upper and lower surface layers of the thickness of the leaf spring are made of mixed yarns of carbon fiber and glass fiber to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com