Low-temperature efficient liquid detergent composition and preparation process thereof

A liquid detergent and composition technology, applied in the field of low-temperature high-efficiency liquid detergent composition and its preparation technology, can solve the problem of not considering the low-temperature washing performance of the product, and achieve good low-temperature cleaning performance, good hard water resistance, and stable storage. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

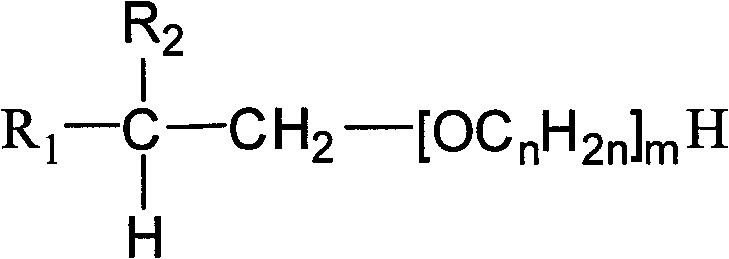

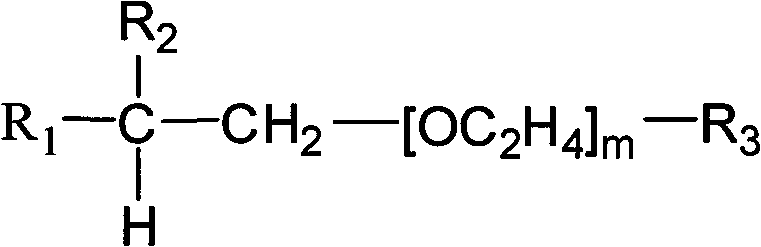

Method used

Image

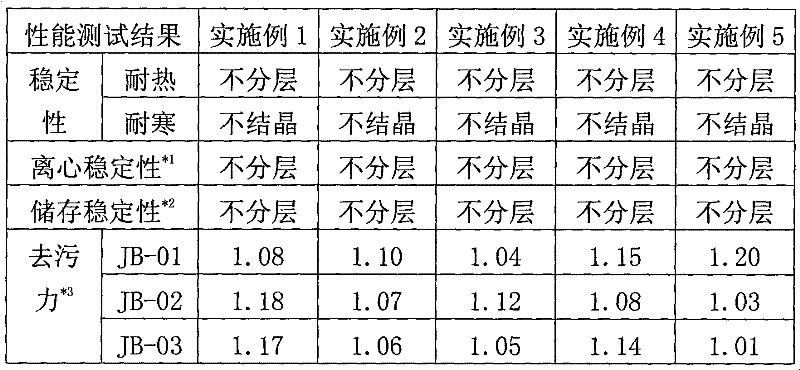

Examples

Embodiment 1

[0027] Anionic surfactant LAS accounts for 9.0wt%, MES accounts for 4.0wt%; Nonionic surfactant branched chain fatty alcohol polyoxyethylene ether (7) accounts for 3.0wt%; Branched chain alkyl sodium sulfate accounts for 10.0wt%; Agent: wherein 4A zeolite accounts for 20.0wt%, sodium carbonate accounts for 3.0wt%, sodium silicate accounts for 4.0wt%; deflocculant accounts for 0.1wt%; essence accounts for 0.2wt%; the rest is water.

[0028] At 50°C, add anionic surfactant LAS, MES, branched chain alkyl sodium sulfate and nonionic surfactant branched chain fatty alcohol polyoxyethylene ether (7) into water, stir well until all dissolve, cool to room temperature, and stir Continue to stir for 50 minutes after uniformity; then add 4A zeolite, sodium carbonate, sodium silicate, and anti-flocculant in sequence at a stirring speed of 80 rpm, and control the feeding speed so that all solid materials are added within 3 hours. Continue to stir for 100 minutes until the product is in a u...

Embodiment 2

[0030] Anionic surfactant MES accounts for 10.0wt%, AES accounts for 5.0wt%; nonionic surfactant branched chain fatty alcohol polyoxyethylene ether (9) accounts for 5.0wt%; branched chain alkylbenzene sulfonate sodium accounts for 4.5wt%; Inorganic additives: 18.0wt% of 4A zeolite, 4.0wt% of sodium carbonate, 3.0wt% of sodium citrate; 5.0wt% of sodium silicate; 0.08% of deflocculant; 0.2% of fluorescent whitening agent; The rest is water.

[0031] At 43°C, add anionic surfactant MES, AES, sodium branched alkylbenzene sulfonate and nonionic surfactant branched fatty alcohol polyoxyethylene ether (9) into water, stir well until completely dissolved, and cool to room temperature After stirring evenly, continue to stir for 40 minutes; then at a stirring speed of 100 rpm, add 4A zeolite, sodium carbonate, sodium citrate, sodium silicate, deflocculant, and fluorescent whitening agent in sequence, and control the feeding speed so that all solids Add the materials within 2 hours, and...

Embodiment 3

[0033] Anionic surfactant MES accounts for 11.0wt%, and AOS accounts for 3.0wt%; Nonionic surfactant branched chain alkyl glycoside APG (C 12-14 ) accounts for 3.0wt%; branched chain alkyl sulfonate accounts for 8.0wt%; inorganic additives: wherein 4A zeolite accounts for 20.0wt%, sodium carbonate accounts for 3.0wt%; sodium silicate accounts for 5.0wt%; wt%; preservatives account for 0.05wt%; optical brighteners account for 0.2wt%; the rest is water.

[0034] At 65°C, the anionic surfactant MES, AOS, sodium branched alkyl sulfonate and the nonionic surfactant branched chain alkyl glycoside APG (C 12-14 ) into water, fully stirred until completely dissolved, cooled to room temperature, stirred evenly and continued to stir for 60 minutes; then at a stirring speed of 70 rpm, sequentially added 4A zeolite, sodium carbonate, sodium silicate, anti-flocculating agent, fluorescence enhancer For whitening agents and preservatives, control the feeding speed so that all solid materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com