Washing powder and soap powder viscosity reduction synergist

A technology of washing powder and synergist, applied in the direction of organic washing compositions, etc., can solve the problems of application limitation, unknown influence of the viscosity of washing powder slurry, reducing the viscosity of washing powder slurry, etc., to achieve good resistance to hard water and biological Degradability, good wash synergy, effect of good wash synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

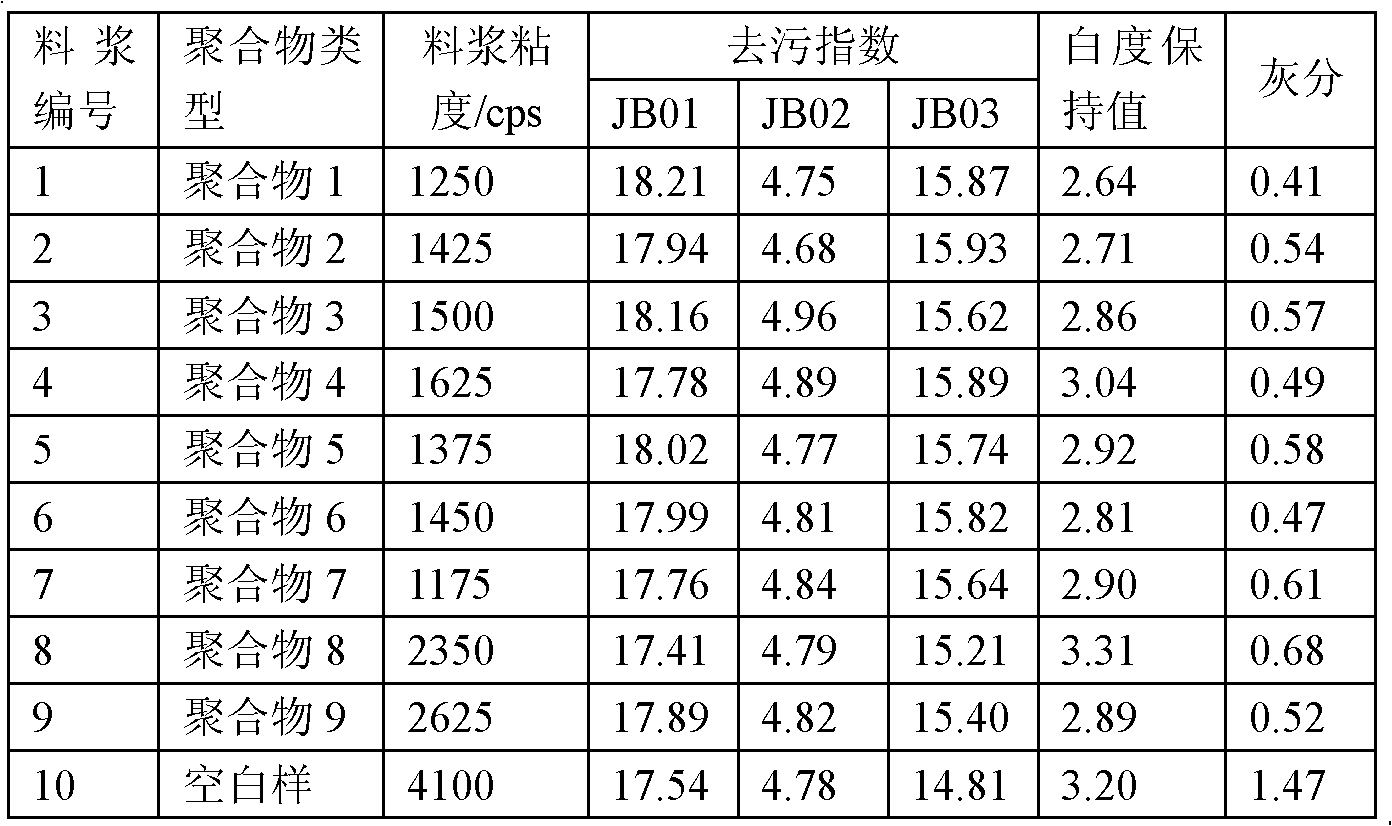

Examples

Embodiment 1

[0040] Add 50g water and 100g acetone into a 500g reactor, stir, heat to reflux, and drop the following materials respectively: A1: 50g acrylic acid, 10g allyl polyoxyethylene ether (20EO), 10g lauryl acrylate, 2g allyl alcohol and 0.05g mixture of methylenebisacrylamide, dropwise time 180min; B1: 10g10% sodium persulfate aqueous solution, dropwise time 200min; C1: 20g10% sodium sulfite aqueous solution, dropwise time 170min. After the dropwise addition of material B1, continue to keep warm for 30 minutes, then add water while vacuuming to remove isopropanol, keep the vacuum degree higher than -0.09MPa, and add water to keep the system from being too viscous. When the quality of the distillate reaches 200g, stop vacuuming, add an appropriate amount of sodium hydroxide solution to adjust the pH value to 7.0, and add a certain amount of water to make the solid content of the material 40%, to obtain polymer 1.

Embodiment 2

[0042] Add 50g water and 100g isopropanol to a 500g reactor, stir, heat to reflux, and drop the following materials respectively: A2: 55g methacrylic acid, 10g methoxypolyethylene glycol methacrylate (30EO), 5g1 - a mixture of tetradecene, 3g of acrylamide and 1g of mercaptoethanol, the dropwise addition time is 180min; B2: 10g of 10% sodium persulfate aqueous solution, the dropwise addition time is 200min. After the addition of material B2, continue to keep warm for 30 minutes, then add water while vacuuming to remove isopropanol, keep the vacuum degree higher than -0.09MPa, and add water to keep the system from being too viscous. When the quality of the distillate reached 200g, the vacuum was stopped, an appropriate amount of sodium hydroxide solution was added to adjust the pH to 7.0, and a certain amount of water was added to make the solid content of the material 40%, and polymer 2 was obtained.

Embodiment 3

[0044] Add 100g of isopropanol to a 500g reactor, stir, heat to reflux, and drop the following materials respectively: A3: 50g methacrylic acid, 10g allyl polyoxyethylene ether (20EO), 20g styrene and 3g methylene The mixture of propylsulfonic acid, the dropping time is 180min; B3: 20g 3% benzoyl peroxide solution in isopropanol, the dropping time is 200min. After the addition of material B3, continue to keep warm for 30 minutes, then add water while vacuuming to remove isopropanol, keep the vacuum degree higher than -0.09MPa, and add water to keep the system from being too viscous. When the quality of the distillate reaches 200g, stop vacuuming, add an appropriate amount of sodium hydroxide solution to adjust the pH value to 7.0, and add a certain amount of water to make the solid content of the material 40%, to obtain polymer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com