Electrolyte improving high temperature performance of battery, and lithium ion battery

A high-temperature performance, electrolyte technology, used in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of poor battery durability, and the high and low temperature cycle performance and stability of batteries have not been greatly improved. The effect of improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

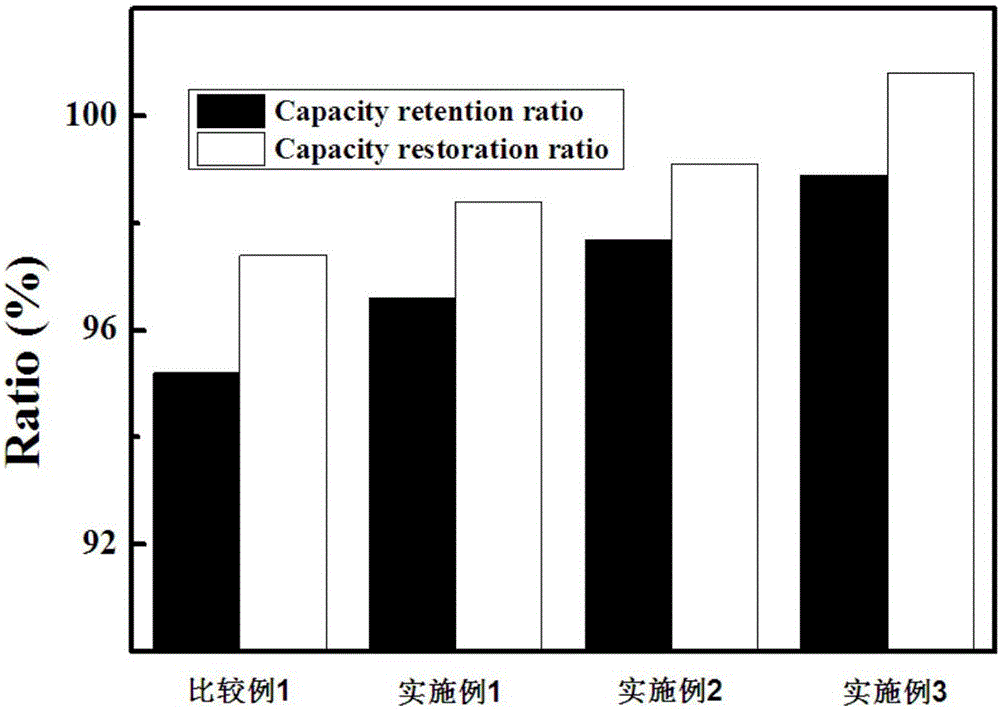

Examples

Embodiment 1

[0024] (1) Electrolyte preparation: 1 mol / LLiTFSI electrolyte was prepared according to the volume ratio of FEC:PC:DEC:EMC=35:5:35:25.

[0025] (2) Preparation of positive electrode material: NCM523 (nickel-cobalt-manganese ternary material) + LFMP (lithium iron manganese phosphate) (7:3, positive electrode active material) with a weight percentage of 91% mixed with 4% by weight SP (superconducting carbon black) and PVDF (bonding agent) of 5% by weight, and add N-methylpyrrolidone to it to make slurry, slurry is coated on the aluminum foil, rolls after drying, Obtain the positive electrode material.

[0026] (3) Preparation of negative electrode material: mixing artificial graphite of 75% by weight, mesophase carbon microspheres of 20% by weight, sodium carboxymethyl cellulose of 5% by weight, and adding deionized water, and then coating the slurry on a copper foil, drying and rolling to obtain the negative electrode material.

[0027] (4) The above-mentioned positive and ne...

Embodiment 2

[0030] (1) Electrolyte preparation: add 2% of total weight of VC, 1% of total weight of water remover, prepare 1mol / L LiTFSI electrolysis according to FEC:PC:DEC:EMC=35:5:35:25 (volume ratio) liquid.

[0031] (2) Preparation of positive electrode material: NCM523+LFMP (7:3, positive electrode active material) of mixed weight percentage 91%, SP (superconducting carbon black) of weight percentage 4% and weight percentage 5% PVDF (binder), and N-methylpyrrolidone was added to it to make a slurry, the slurry was coated on an aluminum foil, dried and rolled to obtain the positive electrode material.

[0032] (3) Preparation of negative electrode material: mixing artificial graphite of 75% by weight, mesophase carbon microspheres of 20% by weight, sodium carboxymethyl cellulose of 5% by weight, and adding deionized water, and then coating the slurry on a copper foil, drying and rolling to obtain the negative electrode material.

[0033] (4) The above-mentioned positive and negativ...

Embodiment 3

[0036] (1) Electrolyte preparation: add VC of 2% of total weight, MMDS of 1% of total weight, and water remover of 1% of total weight, according to FEC:PC:DEC:EMC=35:5:35:25 (volume ratio ) to prepare 1mol / L LiTFSI electrolyte.

[0037] (2) Preparation of positive electrode material: NCM523+LFMP (8:2, positive electrode active material) of mixed weight percentage 91%, SP (superconducting carbon black) of weight percentage 4% and weight percentage 5% PVDF (binder), and N-methylpyrrolidone was added to it to make a slurry, the slurry was coated on an aluminum foil, dried and rolled to obtain the positive electrode material.

[0038](3) Preparation of negative electrode material: mixing artificial graphite of 75% by weight, mesophase carbon microspheres of 20% by weight, sodium carboxymethyl cellulose of 5% by weight, and adding deionized water, and then coating the slurry on a copper foil, drying and rolling to obtain the negative electrode material.

[0039] (4) The above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com