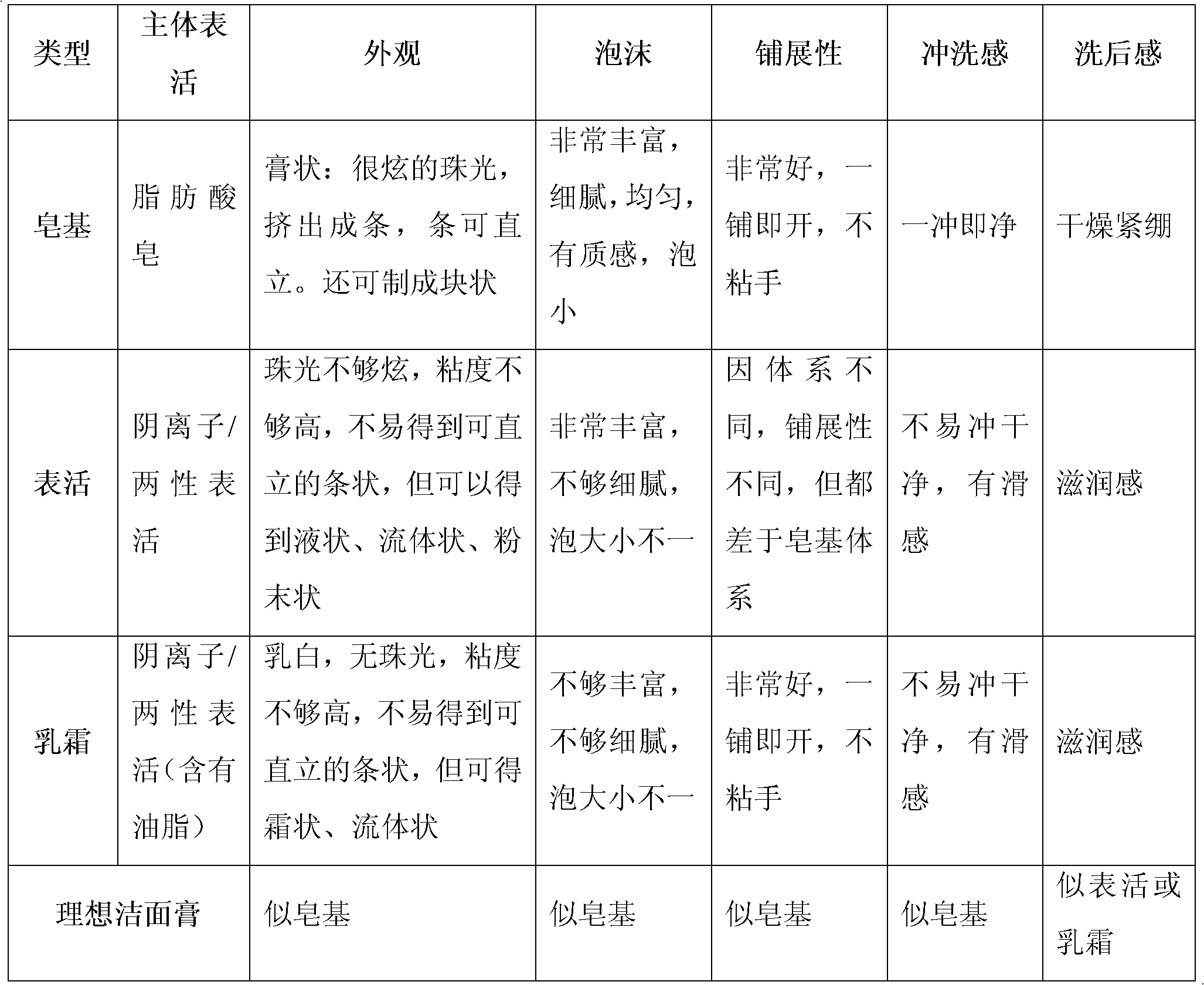

Mild soap base cleansing cream composition and production process thereof

A technology of cleansing cream and composition, applied in the field of daily chemicals, can solve the problems of undetectable cause, inconsistent heat preservation and stirring time, affecting the crystal form of soap base, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment I-X

[0135] A suitable method for preparing the mild soap-based cleansing cream described in Examples I-X is the production process described in the present invention, that is: adding phase A substances into the main reaction kettle in sequence, stirring slowly and heating to 78°C-82°C, stirring until the substance Completely dissolve and disperse evenly, and the fatty acid is in the shape of fine oil droplets; add the phase B substances into the premixing kettle one by one, heat to 73°C-77°C while stirring, and continue stirring until the alkali dissolves evenly; at a speed of 0.15-0.30m / s Under the condition of stirring, add the phase B substance dissolved in the premixing pot, control the temperature to 83°C-87°C, keep stirring at 0.15-0.30m / s for 10 minutes, and then 83°C at a speed of 0.05-0.10m / s Stir at -87°C for about 30 minutes, until the soap block is evenly dispersed and all the materials are mixed evenly; when the temperature drops to 45°C-50°C, add phase C substances in...

Embodiment I-V

[0137] Embodiment I-V formula

[0138]

[0139]

Embodiment VI

[0140] Embodiment VI-X formula

[0141]

[0142]

[0143] The above-mentioned mild cleansing cream has a good skin feel effect after mild moisturizing and washing without dryness or tightness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com